Abstract

Purpose. High-fidelity mannequins are increasingly used to train the medical staff on many medical procedures. Lately, a new challenge regarding echogenic materials to build ultrasound-responding phantoms has emerged. The challenge is to find materials with a suitable combination of ultrasound velocity and consistency to the touch. Methods. Bibliographic research was performed to identify materials with promising stiffness, shape retention, and ultrasound velocity combinations. As-standardized-as-possible specimens were realized and tested using an A-mode ultrasound machine to evaluate the US velocity through them. Four differently doped silicones, five gelatin-based materials, five synthetic gelatins, and a 3D printable resin were included in the study. After being tested, the materials were monitored for 12 days to assess their durability and shape retention and tested again to evaluate the ultrasound velocity’s stability. In the paper, the results of the characterization and follow-up of the materials are presented. Results. Outcomes show that gelatins are exceptional soft tissue-mimicking materials in terms of ultrasound velocity and consistency to the touch, but are poor in terms of overtime stability and therefore suitable for disposable short-term phantoms only. Doped silicones present lower ultrasound velocity compared to the reference value of 1540 m/s found in the literature, but excellent overtime stability, and shape retention properties. Values close to biological ones were also given by the Elastic 50A and by polyvinyl chloride plastisol. Conclusion. The paper gives a quantitative overview of the fidelity of both already-in-use and non-conventional materials, focusing on the ultrasound velocity value through them and their longevity in terms of macroscopically observed dehydration, shape retention, and bacterial onset.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ultrasound-based techniques are widely used in everyday clinical practice for diagnostic purposes, especially for the identification of superficial masses or foreign bodies (e.g., in the thyroid, udders, testicles, limbs, and some lymph nodes). Echography is portable, widely available, relatively inexpensive, and most importantly, it is risk-free as it does not use radiation. Echography is also commonly used to guide a biopsy and to position intravenous catheters. An example is the endobronchial ultrasound-guided transbronchial needle aspiration (EBUS-TBNA), a low-risk procedure that utilizes ultrasound imaging to visualize structures around the airway wall, whose success highly depends on the medical staff’s skills, who therefore requires appropriate training. Among the major disadvantages of the ultrasound (US) techniques is the high operator dependence on the image quality.

In this context, clinical simulations based on high-fidelity phantoms have a crucial role in training both residents and attendings to clinical procedures without placing patients at risk [1]. When performing internal echo-guided procedures such as EBUS-TBNA or catheter insertion, thorough training to develop fine eye–hand coordination is crucial, and a fair amount of dexterity is required. On the other hand, when performing a diagnostic test, obtaining a clear image is the most important skill. In both cases, in-depth training of the medical staff on those procedures on high-fidelity (HF) phantoms to better train the staff and therefore ensure the patient the best possible service. To achieve this, medical training and clinical simulations have become part of the medical staff training path. In this context, the use of the so-called tissue-mimicking materials (TMM) is widespread since they simulate the real biological tissues’ properties.

Tissue-mimicking phantoms are also used in the field of characterization and calibration of ultrasound imaging systems [2]. Given the relevance of having US-responding phantoms for the training on new methods, technologies, and applications, the identification of materials with optical properties ranging between the reference values for human soft tissue that at the same time present characteristics of durability, mechanical adequacy, and shape retention is crucial.

In a relevant study by Jafary et al. [3], many TMMs have been tested under several aspects, including mechanical properties and B-mode visualization, but ultrasound velocity has not been quantitatively assessed.

The latter plays a crucial role in medical imaging as it determines the speed at which sound waves propagate through tissues. Aiming for a target velocity of ~1540 m/s, optimized for clinical transducers, ensures optimal image resolution and clarity. This specific velocity aids in minimizing artifacts caused by variations in tissue density and composition. Additionally, it enhances echogenicity, allowing for clearer delineation of structures and abnormalities. Moreover, maintaining this velocity helps mitigate excessive attenuation and backscatter, optimizing diagnostic accuracy in various imaging modalities like ultrasound [4].

In the article, the results of a study aiming to identify easy-to-manufacture materials with promising echogenicity to characterize in terms of US velocity to evaluate their suitability to be used to realize ultrasound phantoms are reported.

This study is part of a larger project whose aim is the development of a mediastinal echogenic phantom. For this reason, at this early stage of the project, the authors also intend to assess the stability of the materials when stored in air by just evaluating the occurrence of dehydration and/or mold.

Thorough bibliographic research was carried out and it has emerged that the most used materials to build in-house US-responding phantoms can be divided into the following categories, which will be discussed in dedicated subparagraphs:

-

Doped silicones. Silicone rubbers are commonly used for their durability and stability over time, but their pure forms do not match soft tissues’ acoustic velocity [5]. With the addition of doping agents, their US velocity can indeed be modified [6].

-

Hydrogels. Water-based gelatins, despite being commonly used to manufacture phantoms for ultrasound and optical imaging techniques, present disadvantages such as easy degradation, bacterial susceptibility, and low temporal stability [7, 8].

-

Synthetic gels. Some commercially available materials with a gel-like consistency are synthetic and should not encounter dehydration and bacteria invasion typical of organic water-based gelatins.

The choice of materials to be included in the study was limited to those that could be fabricated with the instrumentation present at the Department of Industrial Engineering of the University of Florence (DIEF).

Materials and methods

Doped silicones

Silicones are overtime stable rubbers and have mechanical properties that can be adjusted by means of additives to match the ones of biological soft tissues [6, 9, 10] and are therefore widely used to manufacture phantoms that simulate human tissue. According to the literature, pure silicone is almost anechoic [11], but its acoustical properties can be modulated by means of additives [6]. Many studies aiming to find the right recipe to reach tissue-mimicking values of acoustic properties have already been published. According to Maggi [6] who carried out a material characterization study, the materials that obtained the best results in terms of acoustic properties mixed with silicone were silicone oil, Vaseline, and glycerin. Carbone et al. [12] studied innovative formulations of silicone mixtures with echogenic properties. They tested three types of room-temperature vulcanizing (RTV) silicones combined with different percentages of Slacker® (a commercial additive commonly used to achieve flesh-like consistency in silicone phantoms) and PAAG (Polyacrylamide Gel). The addition of the latter seemed to provide a marked increase in echogenicity, but no quantitative data referring to the US velocity were reported. Also, Piazza et al. [9] qualitatively assessed the echogenicity of some silicon-based mixtures by means of US examination. The tested RTV silicones were Dragon Skin® and Ecoflex® by SmoothOn Inc (Pennsylvania, USA). Among the most remarkable studies, there is one by Pacioni et al. [11], who developed a doping formula to make the silicone respond to the US similarly to biological soft tissues, later reused by Furferi et al. [5] to build an echogenic simulator for the ultrasound-guided peripheral venous access. Cafarelli et al. [10] too evaluated the combination of different combinations of silicones added with liquid (glycerol, commercial detergent, and N-Propanol) and solid inclusions (aluminum oxide, graphene, steel, and silicon powder), but the obtained results regarding the speed of sound are quite distant from the mean reference value of US velocity in the soft tissue of 1540 m/s.

The authors decided to include in the study the EcoFlex 00-10 and the EcoFlex 00-30, two soft and elastic platinum silicones that differ in Shore 00 hardness, doped according to Pacioni’s formula [11] with Vaseline oil, Slacker (SmoothOn Inc, Pennsylvania, USA), which is a single-component tactile mutator to reproduce the consistency of human skin, Thinner (SmoothOn Inc, Pennsylvania, USA), which is a fluidizing agent for silicones, and substituting the graphite powder with the same percentage of talc to avoid the darkening of the material. As a novel solution, the use of glycerol instead of paraffin oil as an additive to the EcoFlex 00-30 was planned to be evaluated in two different percentages, for an overall total of four differently doped silicones.

Organic gelatins

Gelatin is a homogeneous colloid gel primarily derived from collagen in animal tissues [2] that can be usually purchased in the form of dry sheets or powder. It is extremely inexpensive, can be easily retrieved, and can be safely stored [13]. Evidence regarding its use for US-responding soft tissue mimicking was found in the literature [6, 11, 14,15,16,17,18,19,20,21]. Gelatin gels are in fact simple to manufacture, are of low cost, and have easily controllable US properties and stiffness [22]. Among the main drawbacks of gelatin gels, there is susceptibility to bacteria, which can be overcome with antimicrobial additives [8, 14, 16, 20, 23]. As reported by Armstrong et al. [18], hydrated materials tend to experience dehydration and this leads to an overall low overtime stability [6, 15, 19]. To resolve this problem, many solutions have been proposed over time. For instance, Brewin et al. [24] stored their agar-based specimens in a solution of water and benzalkonium chloride to prevent both dehydration and bacterial and fungal invasion, Baba et al. [25] stored the gelatinous phantom wrapped in cling film and refrigerated at −4 °C to prevent degradation, Chen et al. [20] used vacuum-sealed bags, while Madsen et al. used safflower oil as a vapor barrier to prevent desiccation of the gelatin-based phantom materials [26].

Given the high correspondence about the use of gelatin to realize soft tissue-mimicking phantoms found in the literature, gelatin-based hydrogels were included in the study. Despite being susceptible to dehydration and bacteria invasion, their low cost and echogenic velocity make them particularly suitable in the case of disposable simulators. Six different gelatin-based hydrogels were selected, to test both different percentages and the effectiveness of the addition of chlorhexidine as an antimold agent. The selected percentages corresponded to gelatin mass and in-house ballistic gel. The first is commonly used in pastry and is made of 17% by-weight gelatin in an aqueous solution. The authors wanted to test both gelatin sheets and gelatin powder as base materials as well as the addition of chlorhexidine in a 0.04% solution as an antibacterial agent. To realize in-house ballistic gel, 10% by-weight gelatin in an aqueous solution is needed. A variant with 0.04% chlorhexidine was realized for this combination, too.

Synthetic gels

PVA-C. Preparation of PVA-C (polyvinyl alcohol cryogel) requires freeze–thaw cycles to enhance cross-linking between polymer chains. Preparation time is usually long and precise temperature control is required [2]. Despite that, feedback about its use has been found in the literature given its characteristics of indefinite longevity and low cost [16]. PVA-C manufactured with different process parameters (polymer concentration, number of freeze–thaw cycles, and the duration of each cycle) has been proved to be an effective tissue-mimicking material for ultrasound and MR (magnetic resonance) imaging [11, 18, 27,28,29,30,31,32,33,34,35]. PVA-Cs are quite different from PVA hydrogels that are chemically cross-linked by the addition of compounds such as aldehydes or borates to a PVA solution—in PVA-C, the cross-linking through hydrogen bonding is obtained with the freeze–thaw process [35]. The most used PVA percentages to form cryogel via a freeze–thaw process are 10% [28, 30,31,32,33, 36] and 15% [29, 35, 37] by-weight PVA in aqueous solution.

PVA cryogel was excluded from the study since to obtain it a controlled process is needed, and the authors’ laboratory did not have a programmable cooling/heating plate.

PVC-P. Evidence regarding the use of PVC-P (polyvinyl chloride plastisol) as a tissue-mimicking material was also found in the literature [11, 15, 18, 38,39,40,41,42]. PVC-plastisol is a suspension of PVC in a plasticizer that can be purchased in the form of a ready-to-use homogeneous liquid mixture from companies that specialize in fishing lure construction [39]. According to Lenov et al. [15], plastisol is usually available in different stiffnesses obtained by premixing different ratios of polymer and softener. Those combinations are proprietary and could not be obtained.

PVC-P is a material used in the fabrication of fishing lures and it is available from different retailers. Previous studies have been conducted by Hungr et al. [39] and by Li et al. [38] who found a US velocity that is lower if compared to the mean reference value of 1540 m/s of the biological soft tissue reported in the literature [44]. Nevertheless, the authors decided to include it in the study given its characteristics of moderate cost, easy management, and overtime stability.

Paraffin gel. Paraffin gel waxes as tissue-mimicking material have been investigated by Veira et al. [43] for their characteristics of immunity to dehydration and bacterial attack as well as non-toxicity, chemical stability, and durability over time in a wide range of temperatures. Paraffin gel waxes are reported to not suffer from dehydration, are non-toxic, immune to bacterial attack, have good chemical stability, and can maintain their form for a long time in a broad range of temperatures. For those reasons, Chmarra et al. [16] investigated the use of candle gel to obtain homogeneous and echogenicity-adequate simulated parenchyma.

Paraffin gel, which is a readily available material that is commonly used in a wide range of daily applications, especially in the candle industry, was included in the study and therefore purchased from a company selling hobby equipment. Since the speed of sound reported in the literature ranges from 1425 to 1433 m/s depending on the density of the material [43], the authors also decided to realize a second set of specimens, to test the effect of the addition of glycerol, whose US velocity was reported by Ferousson et al. [45] to correspond to 1964 \(\pm\) 10 m/s. The use of glycerol to raise propagation speeds in ultrasound phantom materials has been previously encountered in the literature [23] and the authors decided to include it in the study, too. The chosen glycerol–paraffin ratio was 1:4.

Raytech® Magic Gel. As another novel material, the authors also included a bicomponent polymer gel commonly used as an insulating agent for electrical installations, which is characterized by gel-like consistency and indefinite overtime stability and whose commercial name is Magic Gel (Raytech S.r.l., Settimo Milanese (MI), Italy). Being it a gel and therefore similar to the touch to gelatins and other synthetic gels, it was evaluated that it could reproduce the consistency of the biological soft tissue, and therefore, investigating the US velocity in this novel material could be valuable.

Elastic 50A. Finally, Elastic 50A (Formlabs Inc., Somerville, USA) resin was also included in the characterization study. Elastic 50 A is a clear resin with a 50 Shore A hardness suitable for the realization of parts that can withstand deformations without damage and without compromising their capability of returning to their original shapes. Authors found no evidence in the literature about its use to realize soft tissue-mimicking US-responding phantoms and decided to evaluate its US velocity for the importance that the usability of this material could play in realizing echogenic small components. The possibility of realizing directly 3D printed objects instead of having to proceed with a multistage process could in fact represent a significant advantage.

Composition details and percentages of the materials included in the characterization are reported in Table 1.

Specimens’ realization

For each of the materials that the authors decided to include in the study, three independent specimens were realized to also evaluate the robustness of the US velocity’s repeatability in relation to the manual production of the specimens. All the selected materials but the Elastic 50A (which is directly 3D printed) must be poured into containers to be manufactured. The different manufacturing processes related to the different materials are discussed in detail in the dedicated subparagraphs. The authors decided to standardize the process by realizing 3D printed PLA cups with a diameter of 25 mm and a height of 15 mm. All the materials, except plastisol, must be poured at a temperature below 60 °C, at which the PLA begins to lose mechanical strength [46]. Since the PVC-P needs to be brought to higher temperatures, six 9-centiliter tempered glass containers were used.

All the specimens were realized on the same day to reduce any bias due to material aging. Details on the various specimens’ realization are reported thereafter.

Silicones. Silicon-based specimens were all realized independently, by mixing the selected percentages of liquid silicone compounds, additives, and pigments, degassing the mixture using a vacuum pump to remove trapped air, and pouring it into the PLA cup. All the rubbers used as a base had a curing time of 16 h after which the specimens were ready to be tested. Three specimens were realized for each formula that the authors wanted to test. Altogether, twelve specimens with silicon-based materials were realized (visible in Fig. 1).

Silicon-based specimens realized in triplicate for each formula. ID numbers according to Table 1 are reported.

Gelatins. To produce the gelatin-based specimens, different amounts of gelatin were separately mixed in distilled water or distilled water and chlorhexidine for 20 min in a beaker using a magnetic stirrer with a plate temperature of 130 °C. Once the gelatin had completely dissolved and the mixture became clear, the warm liquid was gently poured into the PLA cup and placed at a temperature of 4 °C to allow solidification. The specimens are shown in Fig. 2.

Gelatin-based specimens realized in triplicate for each formula. ID numbers according to Table 1 are reported. The differences in color between different sets are due to different compositions.

Paraffin Gel. Pure paraffin gel was melted in a tempered glass container using the microwave, let cool, and gently poured into three PLA cups once the temperature went under 60 °C. Unfortunately, when realizing the mixture of paraffin gel and glycerol, it was discovered that the latter is not miscible with the melted wax and the two phases tend to separate. The liquid was, however, poured into the cups and let cool. The specimens are shown in Fig. 3.

Paraffin gel-based specimens realized in triplicate for each formula. ID numbers according to Table 1 are reported.

Raytech® Magic Gel. Raytech® Magic Gel is a bicomponent self-sealing polymer that once mixed with a 1:1 ratio tends to rapidly cross-link (the process takes about 10 min at a room temperature of 25 °C, but is susceptible to the temperature). To avoid air bubbles that could compromise the US response of the material, once mixed, it was degassed using a vacuum pump and then gently poured into the PLA cup. Given the material’s high viscosity, air bubbles tended to get stuck on the surface. For this reason, three non-degassed specimens were realized, too, to test the presence of any changes in the US speed (Fig. 4).

Magic Gel specimens realized in triplicate for each formula. ID number according to Table 1 is reported.

PVC-P. Plastisol is a ready-to-use liquid mixture. Three specimens for both the purchased variants (soft and very soft) were realized following the instructions of the manufacturer. The one-component mixture was brought to a temperature of 160 °C, and once it became transparent, it was poured into tempered glass containers and let it cure at room temperature. Once cured, the specimens could be easily removed from the glass (see Fig. 5).

PVA-plastisol specimens of different heights realized in triplicate for each formula. ID number according to Table 1 is shown. Differences in color among the same set of specimens are due to human error.

No additives or dyes were used. The difference in the color of the independently realized specimens is due to the difficulties in monitoring the process parameters. The material has in fact to be heated until transparent (to avoid bubble formation as in the under-heated discarded specimens shown in Fig. 6), but it is very easy to overheat it and cause its yellowing. However, a slight overheating should not cause significant changes in the US velocity [39].

Elastic 50A. The specimens were directly 3D printed using Formlabs Form 3B + (Formlabs: https://Dental.Formlabs.Com/It/Products/Form-3b/, n.d.) 3D printer, based on the SLA (StereoLitogrAphy) technique. As widely known, once printed, all the parts realized by SLA need a wash and curing post-processing. The three specimens after post-processing are shown in Fig. 7.

Elastic 50A specimens realized in triplicate. ID number according to Table 1 is reported.

Characterization setup

Each specimen was US tested using the TDS 520B (Tektronix, Beaverton, Oregon, USA) two-channel digitizing oscilloscope and a computer-controlled pulser/receiver, namely Model 5800 by Panametrics (Houston, Texas, USA). Eco-supergel® (Ceracarta, Forlì, Italy) water-soluble ultrasound gel was used to avoid the presence of air between the probe and the material surface and therefore have a good echographic interface. The measuring system is shown in Fig. 8.

Using A-mode ultrasound, the acquisition of the echoes as a function of depth was acquired. Return echoes are represented as peaks whose amplitude corresponds to the intensity [44]. A 5 MHz probe was used for gelatins and synthetic gels. To enhance the peaks’ amplitude, a 1 MHz probe was used for the other materials (silicones and Elastic 50A). Frequency directly influences the spatial resolution, but its increase reduces the ultrasound beam intensity, decreasing the penetration capacity. For this reason, when the attenuation, which is due to reflection and acoustic absorption phenomena, is high, low-frequency probes must be used. For both probes, the zero offsets were calculated using data derived from the US characterization of an aluminum bar as a reference.

Silicones and Elastic 50A were tested using the 1 MHz probe, and the operative settings are reported in Table 2.

Gelatins and synthetic gels were tested using the 5 MHz probe, and the operative settings are reported in Table 3.

Materials’ US velocity can be calculated using Eq. 1:

\(h\) = specimen’s height; \({\text{ToF}}\) = time of flight; \(v\) = material US velocity.

A LabVIEW (National Instruments, Austin, Texas, USA) script was used to acquire the US velocity data. Specimens’ thickness (acquired using a digital caliper) and zero offsets had to be entered via keyboard and the echoes had to be flagged manually using the cursor. Once all the correct parameters were inserted, the script returned the US velocity values calculated using both the first echo and the zero offset and the second and the first echoes. The user interface is shown in Fig. 9.

Analysis and results

Mean US velocity

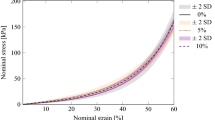

Three measurements were acquired for each of the three specimens realized for each material. To give a complete overview of the materials’ properties, the presence of significant changes in their US velocity was assessed by repeating the measure after 12 days, when the gelatins’ dehydration process was already at an advanced stage. A p-value of 0.05 was selected as a threshold to distinguish between statistically significant and casual differences. A comparison between mean US velocity (M_US_V) value and standard deviation (SD) values on day 0 and day 12 is reported in Table 4 and Fig. 10, while more details about the acquired data are presented in Appendix I (Table A1 and Table A2). Since after 12 days the gelatins have been disposed due to marked dehydration, a third acquisition has not been made.

Materials’ consistency to the touch

Despite secondary importance compared to the speed of sound propagation, the tactile consistency of the material, namely the tactile sensation or perception of how a material appears or feels when touched, has also been assessed, albeit in a purely qualitative manner, thanks to the collaboration of a medical expert who offered to give an evaluation on this aspect based on his experience. Tactile consistency is fundamental for making reproductions of anatomical tissues realistic. If a material fails to accurately simulate the tactile sensation of real tissue, the user experience could be unconvincing for healthcare practitioners, medical students, or patients using simulations for training or understanding medical procedures.

For these reasons, qualitative evaluations were carried out by applying a 60 g weight to the upper surface of the specimens and assessing the displacement.

Material durability

The specimens containing silicones, the synthetic gels, and the Elastic 50A were stored at room temperature in a carton box, away from the light, according to the manufacturer’s user manual. Gelatins were stored in a carton box at a temperature of 4 °C and checked every two days to monitor dehydration and the eventual onset of bacterial invasion. The monitoring period lasted 12 days, at the end of which the observations summarized in Table 5 were made. It is important to specify that the onset of the dehydration process does not depend on the gelatin’s dimensions, but its effect does. It was observed that specimens with bigger dimensions experienced a lower shrinkage in the same period. This of course influences the approximate life. Detailed photographic evidence about the materials monitoring is presented in Appendix II.

A side effect of dehydration is the change in the consistency to the touch of the material, which tends to harden as qualitatively evaluated on day 12.

Discussion

US-responding phantoms find application in many fields such as the simulation of echo-guided procedures for training and learning purposes and for the characterization and periodical calibration of ultrasound imaging systems to evaluate and adjust their precision and accuracy to ensure they are performing as designed. It is, therefore, crucial to find materials that have an appropriate tissue-mimicking behavior when stimulated with ultrasounds to produce high-fidelity mannequins.

With this study, the authors wanted to quantitatively investigate the US velocity through a wide range of materials, both novel and identified with thorough bibliographic research.

From previous studies on this topic, it has been assessed that pure silicone does not present a good US response, but this limit can be partially overcome by means of additives. The four formulas allow obtaining a US velocity between 1083 and 1138 m/s, which are 26–29% lower than the mean reference value for soft tissues of 1540 m/s. Nevertheless, among the doped silicones that have been tested in this study, silicone #3 is the only one that combines adequate consistency and US speed. The other three are excessively sticky to the touch, thus making it impossible to remove the casted item from a mold without damage. Consequently, these have been considered as unusable despite their excellent tissue-mimicking US velocity. For what concerns the stability over time, no statistically significant differences emerged. However, the following points can be made. Firstly, silicones showed the most significant percentage variation in US velocity, particularly marked in silicones #1 and #2, which are the worst in terms of cohesion maintenance. Contextually, a decrease in the SD values was registered. That may be due to an internal settling of the additives used, but further studies are required to assess its causes.

Moving on to gelatins, the results shown in Table 2 demonstrate that they are exceptional tissue-mimicking materials in terms of US velocity, corroborating all the evidence found in the previous literature. Unfortunately, gelatins tend to quickly dehydrate, and their geometrical properties tend to unpredictably degrade over time, sometimes having a negative impact on the SD. Due to dehydration, the specimens experienced a shrinkage, but according to the results shown in Table 4, it did not significantly affect the value of the US velocity through the means. Observing the data, it can in fact be observed that the percentage change is not statistically significant. However, according to the values shown in Table 2, there is an increase in SD. This can be attributed to the casual shrinkage process that compromises the repeatability of the measure among different specimens as the dehydration process progresses. Since the degradation of the geometry happens before the onset of the bacteria or mold invasion, the use of chlorhexidine is unnecessary. Referring therefore to pure gelatin, the extremely low cost, its ease of use, and its consistency similar to that of biological soft tissues and US velocity make it particularly suitable for disposable simulators. However, its perishability makes it unsuitable for durable simulators, especially with small dimensions.

Paraffin gel has a US velocity mean value matching that of biological tissue (1528 m/s versus 1540 m/s), which is also over time stable, but when planning its usage, two aspects must be considered: (1) melted gel has a temperature between 70 and 90 °C, so compatibility with other materials, if any, has to be assessed, and (2) bubble formation during the casting is commonly experienced. (This problem could be resolved by heating the vessel again at a temperature of 90 °C, after checking the eventual susceptibility of other materials to the high temperature.)

The value of US velocity through paraffin gel added with 20% glycerol is even more remarkable. With this material combination, some problems have emerged. In particular, the selected percentage of glycerol has proved to be excessive and therefore not completely miscible. A separation between the two phases occurred during casting, confirmed also by the US analysis. Two peaks were in fact produced by the material: the first corresponding to a velocity of around 1964 m/s (which is the reference value adopted for pure glycerol [45]) and the second to a mean value of 1527 m/s (see Table 2), which is higher than that of pure paraffin gel. Moreover, glycerol sedimentation was found by destroying the specimens after tests, as shown in Fig. 11. It can therefore be concluded that the addition of glycerol causes an increase in the US velocity, but further studies on the adequate percentage to avoid the mixture’s saturation and glycerol excess should be eventually carried out.

Despite being an extremely easy-to-use material that does not require heating, Raytech® Magic Gel does not have adequate US velocity, since its value is markedly lower than that through the other synthetic gels tested (see Table 2). There is almost no difference between the US velocity through the degassed and the non-degassed one, which means that apparently, the small bubbles that remain trapped in the gel do not affect the US propagation. The degassed version of the gel shows a higher percentage reduction compared to the non-degassed version, but since the same effect was not observed in the non-degassed specimens and considering that the value is still under the p-value threshold, this result is likely due to human bias in the measurements.

PVC-plastisol features a satisfactory and stable US response that does not vary between the soft and the very soft versions, but presents some limits. A microwave was used to heat the material to start the curing process, which was reported to be highly time and temperature dependent by Bakaric et al. [48], but there was no way to control the material temperature. This had a negative impact on the realization of the specimens which turned out of different colors. (The authors suspect that the yellowing of the materials may be caused by overheating the mixture.) Special equipment is therefore required to try to control and standardize the curing process. Lastly, it has an optimum curing temperature between 160 and 180 °C [48], which means that other present parts must be heat-resistant to be compatible with the casting process.

Elastic 50A resulted in a globally stable US response. The value of 1646 m/s is near the soft tissue reference value of 1540 m/s. The possibility of direct 3D printing may be an advantage, but there are side aspects that must be considered. Firstly, Elastic 50A is used in SLA, a technique that requires post-processing to get to the finished part, secondly in the case of reduced thickness, before polymerization, it is an easy-to-break material, and finally, it is pricey (see Table 5).

Table 5 reports a detailed summary of the results presented in this paper, including materials’ costs, since when choosing a material, this aspect must be considered too, as well as its properties and stability over time. Both for completion’s sake and to give a complete overview of the tested materials, costs per kilo were added to the table.

The obtained results are coherent with the literature, and being the SD small, the measurement procedure of the ultrasound velocity can be considered robust. The variability between the specimens’ composition due to human error and the measurement errors has in fact to be considered affecting the quality of repeatability of the measure. Regarding the seconds, they can be attributed to the variable pressure applied to the specimen with the probe, or to a non-total perpendicularity of it despite the adoption of a support system.

The study does have potential limitations. The number of duplicates produced for each specimen could be increased to further improve the robustness of the measurement. Moreover, the productive process of some of the specimens would benefit from better and more advanced equipment. Indeed, while to produce gelatins a scale and a magnetic stirrer are more than sufficient as well as for producing the silicones just a scale and a vacuum pump are needed, for the management of PVC-P as well as the paraffin gel, a system that better allows controlling the temperature is needed. Another limit can be identified in the storage conditions for gelatins since a common fridge was used with no system for detecting any power cuts outside of business hours.

Conclusions

In the simulation field, the possibility of disposing of high-fidelity mannequins made of materials that mimic the biological tissue’s properties is crucial to building a realistic scenario and making the simulation effective. US-responding phantoms, made of tissue-mimicking echogenic materials, are increasingly being used both for training the medical staff on US-guided procedures and characterizing and calibrating ultrasound imaging systems. With his study, the authors aimed to quantitatively assess the US velocity of novel and already-in-use tissue-mimicking materials, namely measuring the US velocity through standardized specimens.

Among the tested materials, gelatins are the best ones in terms of ultrasound velocity value, but because of their perishability and despite the many techniques that can be used to slow down the dehydration process, they are not suitable for the realization of durable ultrasound training phantoms. Given their low cost and their reusability, if mold has not occurred, by simply re-melting the mass, they are particularly suitable for disposable solutions. When long-term stability is required, other materials must be used. Silicone is an exceptional material with characteristics of durability and geometry maintenance over time. The drawback of this material lies in the not properly soft tissue-mimicking US velocity since velocity values are still significantly lower than the literature reference value of 1540 m/s despite the additives used. The biological US response is in fact not precisely reproduced not even with the addition of additives. Moreover, when using additives, it must be taken into account that the possible deterioration of consistency and cohesion may make it impossible its remove from a mold. Among the synthetic materials, the most promising seems to be the PVC-plastisol that, once the problems related to its high temperature are overcome, allows to obtain a clear stable structure with bubbles that also has remarkable US velocity. Paraffin gel has even better US velocity values, especially if added with glycerol, but further studies on its use have to be carried out both to resolve the problem of bubble formation and that of the immiscibility of high percentages of glycerol. Finally, Elastic 50A may be considered when small and precise components are needed, given its adequate US response but extremely high cost. Moreover, a laboratory with professional equipment (e.g., an extractor hood) is needed. In conclusion, the presented study gives a quantitative overview of the acoustic velocity and therefore potential echogenicity of different materials, both assessing the suitability of already-in-use materials and providing new insights regarding the use of non-conventional ones. The ultimate material selection will hinge upon its application, considering factors such as cost-effectiveness, storage requirements, and the accuracy of acoustic velocity.

Data and code availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Bootsma K, Dimbath E, Berberich J, Sparks JL (2016) Materials used as tissue phantoms in medical simulation. In: Studies in Mechanobiology, Tissue Engineering and Biomaterials.Springer Science and Business Media Deutschland GmbH, Berlin/Heidelberg, pp 1–48. https://doi.org/10.1007/8415_2016_1

Culjat MO, Goldenberg D, Tewari P, Singh RS (2010) A review of tissue substitutes for ultrasound imaging. Ultrasound Med Biol 36(6):861–873. https://doi.org/10.1016/j.ultrasmedbio.2010.02.012. (Elsevier USA)

Jafary R, Armstrong S, Byrne T, Stephens A, Pellegrino V, Gregory SD (2022) Fabrication and characterization of tissue-mimicking phantoms for ultrasound-guided cannulation training. ASAIO J (American Society for Artificial Internal Organs: 1992) 68(7):940–948. https://doi.org/10.1097/MAT.0000000000001593

Cho MH, Kang LH, Kim JS, Lee SY (2009) An efficient sound speed estimation method to enhance image resolution in ultrasound imaging. Ultrasonics 49(8):774–778. https://doi.org/10.1016/j.ultras.2009.06.005. (Elsevier USA)

Furferi R, Guariento L, McGreevy KS, Mussi E, Parri N, Uccheddu F, Volpe Y (2020) 3d printing-based pediatric trainer for ultrasound-guided peripheral venous access. In: IFMBE proceedings, Springer, Cham, pp 735–745. https://doi.org/10.1007/978-3-030-31635-8_87

Maggi LE. Development of Silicon-Based materials for Ultrasound Biological Phantoms

Cabrelli LC, Pelissari PIBGB, Deana AM, Carneiro AAO, Pavan TZ (2017) Stable phantom materials for ultrasound and optical imaging. Phys Med Biol 62(2):432–447. https://doi.org/10.1088/1361-6560/62/2/432

Kondo T, Fujimoto H (2002) Ultrasound tissue-mimicking materials using oil gel and measurement of their characteristics. Jpn J Appl Phys 41(5B):3598–3599. https://doi.org/10.1143/jjap.41.3598

Piazza R, Condino S, Carbone M, Mattei L, Ferrari V, Di Puccio F, Caramella D, Forte P (2012) Material characterization for elastosonographic phanthoms. Int J Comput Assist Radiol Surg 7:51–52. https://doi.org/10.1007/s11548-012-0729-y

Cafarelli A, Miloro P, Verbeni A, Carbone M, Menciassi A (2016) Speed of sound in rubber-based materials for ultrasonic phantoms. J Ultrasound 19(4):251–256. https://doi.org/10.1007/s40477-016-0204-7

Pacioni A, Carbone M, Freschi C, Viglialoro R, Ferrari V, Ferrari M (2015) Patient-specific ultrasound liver phantom: materials and fabrication method. Int J Comput Assist Radiol Surg 10(7):1065–1075. https://doi.org/10.1007/s11548-014-1120-y

Carbone M, Condino S, Mattei L, Forte P, Ferrari V, Mosca F (2012) Anthropomorphic ultrasound elastography phantoms characterization of silicone materials to build breast elastography phantoms. In Proceedings of the annual international conference of the IEEE engineering in medicine and biology society, EMBS, pp 492–494. https://doi.org/10.1109/EMBC.2012.6345975

Sultan SF, Shorten G, Iohom G (2013) Simulators for training in ultrasound guided procedures. Med Ultrason 15(2):125–131. https://doi.org/10.11152/mu.2013.2066.152.sfs1gs2

Li JW, Karmakar MK, Li X, Kwok WH, Kee WDN (2011) Gelatin-agar lumbosacral spine phantom: a simple model for learning the basic skills required to perform real-time sonographically guided central neuraxial blocks. J Ultrasound Med 30(2):263–272. https://doi.org/10.7863/jum.2011.30.2.263

Leonov D, Kodenko M, Leichenco D, Nasibullina A, Kulberg N (2022) Design and validation of a phantom for transcranial ultrasonography. Int J Comput Assist Radiol Surg 17(9):1579–1588. https://doi.org/10.1007/s11548-022-02614-2

Chmarra MK, Hansen R, Mårvik R, Langø T (2013) Multimodal phantom of liver tissue. PLoS One 8(5):e64180. https://doi.org/10.1371/journal.pone.0064180

Sorger H, Hofstad EF, Amundsen T, Langø T, Leira HO (2016) A novel platform for electromagnetic navigated ultrasound bronchoscopy (EBUS). Int J Comput Assist Radiol Surg 11(8):1431–1443. https://doi.org/10.1007/s11548-015-1326-7

Armstrong SA, Jafary R, Forsythe JS, Gregory SD (2023) Tissue-mimicking materials for ultrasound-guided needle intervention phantoms: a comprehensive review. Ultrasound Med Biol 49(1):18–30. https://doi.org/10.1016/j.ultrasmedbio.2022.07.016. (Elsevier Inc.)

Leong SS, Wong JHD, Shah MNM, Vijayananthan A, Jalalonmuhali M, Sharif NHM, Abas NK, Ng KH (2020) Stiffness and anisotropy effect on shear wave elastography: a phantom and in vivo renal study. Ultrasound Med Biol 46(1):34–45. https://doi.org/10.1016/j.ultrasmedbio.2019.08.011

Chen AI, Balter ML, Chen MI, Gross D, Alam SK, Maguire TJ, Yarmush ML (2016) Multilayered tissue mimicking skin and vessel phantoms with tunable mechanical, optical, and acoustic properties. Med Phys 43(6):3117–3131. https://doi.org/10.1118/1.4951729

Nicholson RA, Crofton M (1997) Training phantom for ultrasound guided biopsy. Br J Radiol 70(830):192–194

Hunt A, Ristolainen A, Ross P, Öpik R, Krumme A, Kruusmaa M (2013) Low cost anatomically realistic renal biopsy phantoms for interventional radiology trainees. Eur J Radiol 82(4):594–600. https://doi.org/10.1016/j.ejrad.2012.12.020

Madsen EL, Hobson MA, Shi H, Varghese T, Frank GR (2005) Tissue-mimicking agar/gelatin materials for use in heterogeneous elastography phantoms. Phys Med Biol 50(23):5597–5618. https://doi.org/10.1088/0031-9155/50/23/013

Brewin MP, Pike LC, Rowland DE, Birch MJ (2008) The acoustic properties, centered on 20 MHZ, of an IEC agar-based tissue-mimicking material and its temperature, frequency and age dependence. Ultrasound Med Biol 34(8):1292–1306. https://doi.org/10.1016/j.ultrasmedbio.2007.12.017

Baba M, Matsumoto K, Yamasaki N, Shindo H, Yano H, Matsumoto M, Otsubo R, Lawn MJ, Matsuo N, Yamamoto I, Hidaka S, Nagayasu T (2017) Development of a tailored thyroid gland phantom for fine-needle aspiration cytology by three-dimensional printing. J Surg Educ 74(6):1039–1046. https://doi.org/10.1016/j.jsurg.2017.05.012

Madsen EL, Hobson MA, Frank GR, Shi H, Jiang J, Hall TJ, Varghese T, Doyley MM, Weaver JB (2006) Anthropomorphic breast phantoms for testing elastography systems. Ultrasound Med Biol 32(6):857–874. https://doi.org/10.1016/j.ultrasmedbio.2006.02.1428

Tsai A, Barnewolt CE, Prabhu SP, Yonekura R, Hosme A, Schulz E, Weinstock PH (2017) Creation and validation of a simulator for neonatal brain ultrasonography: a pilot study. Acad Radiol 24(1):76–83. https://doi.org/10.1016/j.acra.2016.09.007

Duboeuf F, Basarab A, Liebgott H, Brusseau E, Delachartre P, Vray D (2009) Investigation of PVA cryogel Young’s modulus stability with time, controlled by a simple reliable technique. Med Phys 36(2):656–661. https://doi.org/10.1118/1.3065031

Funamoto K, Yamashita O, Hayase T (2015) Poly(vinyl alcohol) gel ultrasound phantom with durability and visibility of internal flow. J Med Ultrason 42(1):17–23. https://doi.org/10.1007/s10396-014-0560-x

King DM, Moran CM, McNamara JD, Fagan AJ, Browne JE (2011) Development of a vessel-mimicking material for use in anatomically realistic doppler flow phantoms. Ultrasound Med Biol 37(5):813–826. https://doi.org/10.1016/j.ultrasmedbio.2011.02.012

Song R (2011) Multi-component hemodynamic measurement in flexible vascular phantom using echo particle image velocimetry. IEEE

Surry KJM, Austin HJB, Fenster A, Peters TM (2004) Poly(vinyl alcohol) cryogel phantoms for use in ultrasound and MR imaging. Phys Med Biol 49(24):5529–5546. https://doi.org/10.1088/0031-9155/49/24/009

Pazos V, Mongrain R, Tardif JC (2009) Polyvinyl alcohol cryogel: Optimizing the parameters of cryogenic treatment using hyperelastic models. J Mech Behav Biomed Mater 2(5):542–549. https://doi.org/10.1016/j.jmbbm.2009.01.003

Jy-Shyang Chen S, Hellier P, Gauvrit J-Y, Marchal M, Morandi X, Louis Collins D (2010) An anthropomorphic polyvinyl alcohol triple-modality brain phantom based on Colin27. [Online]. Available: https://hal.inria.fr/inria-00535810

Chu KC, Rutt BK (1997) Polyvinyl alcohol cryogel: an ideal phantom material for MR studies of arterial flow and elasticity. Magn Reson Med 37(2):314–319. https://doi.org/10.1002/mrm.1910370230

Loyd AM, Amador C, An K-N (2014) The effects of time and moisture on elasticity imaging phantom physical and mechanical properties: a pilot study. Rev Ing Bioméd 8:27–35. https://doi.org/10.14508/rbme.2014.8.15.27-35

Dineley J, Meagher S, Poepping TL, McDicken WN, Hoskins PR (2006) Design and characterisation of a wall motion phantom. Ultrasound Med Biol 32(9):1349–1357. https://doi.org/10.1016/j.ultrasmedbio.2006.05.033

Li W, Belmon B, Greve JM, Manders AB, Downey BC, Zhang X, Xu Z, Guo D, Shih A (2016) Polyvinyl chloride as a multimodal tissue-mimicking material with tuned mechanical and medical imaging properties. Med Phys 43(10):5577–5592. https://doi.org/10.1118/1.4962649

Hungr N, Long JA, Beix V, Troccaz J (2012) A realistic deformable prostate phantom for multimodal imaging and needle-insertion procedures. Med Phys 39(4):2031–2041. https://doi.org/10.1118/1.3692179

De Matheo LL, Geremia J, Calas MJG, Costa-Júnior JFS, da Silva FFF, von Krüger MA, Pereira WCA (2018) PVCP-based anthropomorphic breast phantoms containing structures similar to lactiferous ducts for ultrasound imaging: A comparison with human breasts. Ultrasonics 90:144–152. https://doi.org/10.1016/j.ultras.2018.06.013

Spirou GM, Oraevsky AA, Alex Vitkin I, Whelan WM (2005) Optical and acoustic properties at 1064 nm of polyvinyl chloride-plastisol for use as a tissue phantom in biomedical optoacoustics. Phys Med Biol 50(14):N141–N153. https://doi.org/10.1088/0031-9155/50/14/N01

Misra S, Reed KB, Schafer BW, Ramesh KT, Okamura AM (2010) Mechanics of flexible needles robotically steered through soft tissue. Int J Robot Res 29(13):1640–1660. https://doi.org/10.1177/0278364910369714

Vieira SL, Pavan TZ, Junior JE, Carneiro AAO (2013) Paraffin-gel tissue-mimicking material for ultrasound-guided needle biopsy phantom. Ultrasound Med Biol 39(12):2477–2484. https://doi.org/10.1016/j.ultrasmedbio.2013.06.008

Carovac A, Smajlovic F, Junuzovic D (2011) Application of ultrasound in medicine. Acta Inform Med 19(3):168. https://doi.org/10.5455/aim.2011.19.168-171

Ferousson FAA, Guptill EW, Macdonald AD (1954) Velocity of sound in glycerol. [Online]. Available: http://acousticalsociety.org/content/terms

Prusa Research a.s.: https://www.prusa3d.com

Bakaric M, Miloro P, Zeqiri B, Cox BT, Treeby BE (2020) The effect of curing temperature and time on the acoustic and optical properties of PVCP. IEEE Trans Ultrason Ferroelectr Freq Control 67(3):505–512. https://doi.org/10.1109/TUFFC.2019.2947341

Acknowledgements

The authors wish to acknowledge the Tuscany Region (Italy) for co-funding the PRECISE project (BANDO RICERCA SALUTE 2018), which originated and made possible this research.

Funding

Open access funding provided by Università degli Studi di Firenze within the CRUI-CARE Agreement. This work was supported by Regione Toscana (No. B14I20001160005).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflicts of interest

Not applicable: The authors declare that they have no conflict of interest.

Ethical approval

Not applicable: This article does not contain any studies with human participants or animals performed by any of the authors and contains no patient data.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mencarelli, M., Puggelli, L., Virga, A. et al. Acoustic velocity and stability of tissue-mimicking echogenic materials for ultrasound training phantoms. J Mater Sci 59, 6509–6524 (2024). https://doi.org/10.1007/s10853-024-09610-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09610-8