Abstract

The high Sc-alloyed Al–Sc sputtering target is applied to produce Sc-doped AlN (Al1−xScxN) thin films through reactive magnetron sputtering. The sputtering process demands Al–Sc sputtering targets with fine and stable grain sizes featuring random orientations. In this work, laser treatment with varying scanning speeds is applied to the Al-(10 at.%, 20 at.%) Sc alloys, and the microstructure is characterized using the electron backscatter diffraction (EBSD) method and transmission electron microscopy (TEM). The results indicate that the laser treatment enhances the solubility of Sc in the matrix; however, the nucleation crystallography during solidification differs among these alloys. Epitaxial growth is observed in Al–20Sc, remaining a large grain size with different scanning speeds. In contrast, Al–10Sc exhibits refined grain sizes, reduced to about 2 μm compared to 200 μm in the as-casted alloy. Laser treatment generates more than 40% twin boundaries, leading to the randomization of the texture and refinement of the grain size through twin variants. This study demonstrates the feasibility of grain boundary engineering for Al–10Sc sputtering targets through laser scanning.

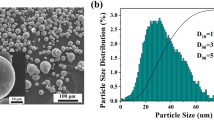

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Akiyama M, Kamohara T, Kano K, Teshigahara A, Takeuchi Y, Kawahara N (2009) Enhancement of piezoelectric response in scandium aluminum nitride alloy thin films prepared by dual reactive cosputtering. Adv Mater 21:593. https://doi.org/10.1002/adma.200802611

Tasnadi F, Alling B, Höglund C et al (2010) Origin of the anomalous piezoelectric response in wurtzite ScxAl1−xN alloys. Phy Rev Lett 104:137601. https://doi.org/10.1103/PhysRevLett.104.137601

Akiyama M, Kano K, Teshigahara A (2009) Influence of growth temperature and scandium concentration on piezoelectric response of scandium aluminum nitride alloy thin films. Appl Phys Lett 95:162107. https://doi.org/10.1063/1.3251072

Piazza G, Felmetsger V, Muralt P, Olsson RH III, Ruby R (2012) Piezoelectric aluminum nitride thin films for microelectromechanical systems. MRS Bull 37:1051. https://doi.org/10.1557/mrs.2012.268

Akiyama M, Tabaru T, Nishikubo K, Teshigahara A, Kano K (2010) Preparation of scandium aluminum nitride thin films by using scandium aluminum alloy sputtering target and design of experiments. J Ceram Soc Jpn 118:1166. https://doi.org/10.2109/jcersj2.118.1166

Yasuoka S, Shimizu T, Tateyama A et al (2020) Effects of deposition conditions on the ferroelectric properties of (Al1−xScx) N thin films. J Appl Phys 128:114103. https://doi.org/10.1063/5.0015281

Wall J, Yan F (2023) Sputtering process of ScxAl1-xN thin films for ferroelectric applications. Coatings 13:54. https://doi.org/10.3390/coatings13010054

Gschneidner K, Calderwood F (1989) The Al–Sc (aluminum-scandium) system. Bulletin of Alloy Phase Diagrams 10:34. https://doi.org/10.1007/BF02881486

Wang X, Wang Y, Jia Q, Ding Z, He J, Hui S (2023) Novel twinned Al3Sc dendrites in as-casted Al–Sc alloy. Rare Met 42:838–843. https://doi.org/10.1007/s12598-023-02276-2

Trdan U, Skarba M, Grum J (2014) Laser shock peening effect on the dislocation transitions and grain refinement of Al–Mg–Si alloy. Mater Charact 97:57. https://doi.org/10.1016/j.matchar.2014.08.020

Lou S, Li Y, Zhou L, Nie X, He G, He W (2016) Surface nanocrystallization of metallic alloys with different stacking fault energy induced by laser shock processing. Mater Des 104:320. https://doi.org/10.1016/j.matdes.2016.05.028

Zhang J, Song B, Wei Q, Bourell D, Shi Y (2019) A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends. J Mater Sci Technol 35:270. https://doi.org/10.1016/j.jmst.2018.09.004

Pinto M, Cheung N, Ierardi M, Garcia A (2003) Microstructural and hardness investigation of an aluminum–copper alloy processed by laser surface melting. Mater Charact 50:249. https://doi.org/10.1016/S1044-5803(03)00091-3

You M, Li S, Shi Z (2022) Significant hardness improvement of a low-density Al-Si-Mg-Li-Fe alloy through laser-aging surface treatment. Mater Today Commun 32:104000. https://doi.org/10.1016/j.mtcomm.2022.104000

Aboulkhair N, Everitt N, Maskery I, Ashcroft I, Tuck C (2017) Selective laser melting of aluminum alloys. MRS Bull 42:311. https://doi.org/10.1557/mrs.2017.63

Koutny D, Skulina D, Pantělejev L et al (2018) Processing of Al–Sc aluminum alloy using SLM technology. Procedia Cirp 74:44. https://doi.org/10.1016/j.procir.2018.08.027

Jia Q, Zhang F, Rometsch P et al (2020) Precipitation kinetics, microstructure evolution and mechanical behavior of a developed Al-Mn-Sc alloy fabricated by selective laser melting. Acta Mater 193:239. https://doi.org/10.1016/j.actamat.2020.04.015

Schliephake D, Lopes C, Eggeler Y et al (2022) Improved work hardening capability and ductility of an additively manufactured and deformed Al-Mn-Mg-Sc-Zr alloy. J Alloy Compd 924:166499. https://doi.org/10.1016/j.jallcom.2022.166499

Yang X, Cai R, Chen C et al (2022) High-performance aluminum alloy with fully equiaxed grain microstructure fabricated by laser metal deposition. J Mater Res 37:3658. https://doi.org/10.1557/s43578-022-00738-4

Kuo C, Peng P (2023) The strengthening mechanism synergy of heat-treated 3D printed Al–Sc alloy. Virtual and Physical Prototyping 18:e2166539. https://doi.org/10.1080/17452759.2023.2166539

Gu X, Furuhara T, Zhang W (2016) PTCLab: free and open-source software for calculating phase transformation crystallography. J Appl Crystallogr 49:1099. https://doi.org/10.1107/S1600576716006075

Zhao Y, Zhang W, Koe B, et al. (2019) 3D characterization of the primary Al3Sc phases in an Al–Sc alloy using Synchrotron X-ray tomography and electron microscopy. arXiv preprint arXiv:1909.09388. Doi: https://doi.org/10.48550/arXiv.1909.09388

Marquis E, Seidman D (2001) Nanoscale structural evolution of Al3Sc precipitates in Al (Sc) alloys. Acta Mater 49:1909. https://doi.org/10.1016/S1359-6454(01)00116-1

Brandon D (1966) The structure of high-angle grain boundaries. Acta Metall 14:1479. https://doi.org/10.1016/0001-6160(66)90168-4

Watanabe T (2011) Grain boundary engineering: historical perspective and future prospects. J Mater Sci 46:4095. https://doi.org/10.1007/s10853-011-5393-z

Du A, Wang W, Gu X et al (2021) The dependence of precipitate morphology on the grain boundary types in an aged Al–Cu binary alloy. J Mater Sci 56:781. https://doi.org/10.1007/s10853-020-05239-5

Porter D, Easterling K (2009) Phase transformations in metals and alloys (revised reprint). CRC Press

Hyde K, Norman A, Prangnell P (2001) The effect of cooling rate on the morphology of primary Al3Sc intermetallic particles in Al–Sc alloys. Acta Mater 49:1327. https://doi.org/10.1016/S1359-6454(01)00050-7

Fukunaga K, Shouji T, Miura Y (1997) Temperature dependence of dislocation structure of L12–Al3Sc. Mater Sci Eng A 239–240:202. https://doi.org/10.1016/S0921-5093(97)00582-0

Turchin A, Zuijderwijk M, Pool J, Eskin D, Katgerman L (2007) Feathery grain growth during solidification under forced flow conditions. Acta Mater 55:3795. https://doi.org/10.1016/j.actamat.2007.02.030

Henry S, Rappaz M, Jarry P (1998) <110> dendrite growth in aluminum feathery grains. Metall Mater Trans A 29:2807. https://doi.org/10.1007/s11661-998-0321-9

Henry S, Gruen G, Rappaz M (2004) Influence of convection on feathery grain formation in aluminum alloys. Metall Mater Trans A 35:2495. https://doi.org/10.1007/s11661-006-0229-1

Perdew J, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phy Rev Lett 77:3865. https://doi.org/10.1103/PhysRevLett.77.3865

Tschopp M, McDowell D (2007) Asymmetric tilt grain boundary structure and energy in copper and aluminium. Philos Mag 87:3871. https://doi.org/10.1080/14786430701455321

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2022YFB3504403).

Author information

Authors and Affiliations

Contributions

He Jinjiang contributed to conceptualization, investigation, and draft preparation. Jia Qian contributed to experiment on laser treatment and data analysis. Wang Xingquan, Cao Xiaomeng, and Cao Ziqi contributed to data curation and visualization. Ding Zhaochong contributed to the casted alloy preparation. Xinfu Gu contributed to conceptualization, supervision, and data analysis. All authors were involved in writing and reviewing the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The authors declare that no experiments were involved with human tissue.

Additional information

Handling Editor: Zhao Shen.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jinjiang, H., Qian, J., Xingquan, W. et al. Transformation microstructure and nucleation crystallography in high Sc-contained Al–Sc alloys after laser treatment. J Mater Sci 59, 7075–7088 (2024). https://doi.org/10.1007/s10853-024-09576-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09576-7