Abstract

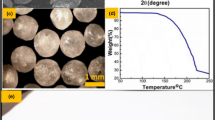

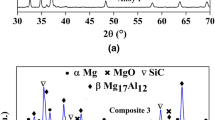

In recent years, metal foams have gained a lot of attention due to their distinctive physical, mechanical properties, and unique applications. Here, we fabricate magnesium base foam using viscose rayon fibers (VRFs) as a source of hydrogen by casting process at atmospheric pressure via the Gasar method. The chemical composition, pyrolysis of VRFs, and structure of magnesium foams are investigated in this study. By changing the amount of foaming agent from 0.4 to 2.2 wt%, the porosity rate changes from 10 to 52%. As the amount of foaming agent rises, the percentage of porosity first increases to a maximum and then remains almost constant, which can be due to the solubility of hydrogen in the magnesium melt. The highest obtained porosity is about 52% using 1.41 wt% of the foaming agent. The average diameter of the pores (in the range of 1.01–1.06 mm) shows no considerable change when the foaming agent amount is increased. As a result of this study, VRFs may serve as an effective foaming agent in fabricating magnesium foams to be used in load-bearing, weight-saving, and impact-absorbing structures.

Similar content being viewed by others

Data availability

The authors have presented all the data required for evaluating the conclusions in the paper, and they may provide additional data to support their arguments.

References

Liu X, Li Y, Wang J, He Y (2018) The pore growth process and pore coalescence process in Gasar copper. Mater Charact 137:231–243

Zou N, Li Q (2020) Microstructure and hardness of porous magnesium processed by powder metallurgy using polystyrene as the space holder. In: Jordon JB, Miller V, Joshi VV, Neelameggham NR (eds) Magnesium technology 2020. Springer International Publishing, Cham, pp 387–391

Esfahani AK, Babaei M, Sarrami-Foroushani S (2021) A numerical model coupling phase transformation to predict microstructure evolution and residual stress during quenching of 1045 steel. Math Comput Simul 179:1–22

Gupta M, Meenashisundaram GK (2015) Processing, mechanical and corrosion characteristics, insight into designing biocompatible magnesium alloys and composites. Springer, Singapore

Shapovalov VI (1999) Metal-hydrogen phase diagrams in the vicinity of melting temperatures. In: Conference: AVS International Liquid Metal Processing and Casting Symposium, Santa Fe, NM (US), 02/21/1999–02/24/1999; Other Information: PBD: 6 Jan 1999United States, 1999, pp. Medium: P; Size: 16 pages

Cheng M-Q, Wahafu T, Jiang G-F, Liu W, Qiao Y-Q, Peng X-C, Cheng T, Zhang X-L, He G, Liu X-Y (2016) A novel open-porous magnesium scaffold with controllable microstructures and properties for bone regeneration. Sci Rep 6:24134

Esfahani AK (2021) Numerical simulation of heat treatment process by incorporating stress state on martensitic transformation to investigate microstructure and stress state of 1045 steel gear parts. Metall Mater Trans B 52:4109–4129

Yazdimamaghani M, Razavi M, Vashaee D, Moharamzadeh K, Boccaccini AR, Tayebi L (2017) Porous magnesium-based scaffolds for tissue engineering. Mater Sci Eng C 71:1253–1266

Kovačič A, Borovinšek M, Vesenjak M, Ren Z (2018) Indirect reconstruction of pore morphology for parametric computational characterization of unidirectional porous iron. Materials (Basel, Switzerland) 11:193

Ghali S, Eissa M (2018) Influence of different parameters on compression strength of foam steel produced by slip reaction foam sintering. Ironmaking Steelmaking 45:90–97

Boczkal G, Janoska M, Setman D, Schafler E, Dlugosz P, Darlak P (2021) Magnesium gasar as a potential monolithic hydrogen absorbent. Int J Hydrogen Energy 46:13106–13115

Patel P, Bhingole PP, Makwana D (2018) Manufacturing, characterization and applications of lightweight metallic foams for structural applications: review. Mater Today Proc 5:20391–20402

Shahin K, Barazandeh M, Zhang L, Hedayatkhah A, He T, Bao H, Mansoorianfar M, Pang M, Wang H, Wei R, Wang R (2021) Biodiversity of new lytic bacteriophages infecting Shigella spp. in freshwater environment. Front Microbiol 12:619323

Shahin K, Zhang L, Bao H, Hedayatkhah A, Komijani M (2020) An in-vitro study on a novel six-phage cocktail against multi-drug resistant-ESBL Shigella in aquatic environment. Lett Appl Microbiol 72:231–237

Shapovalov V (2007) Prospective applications of gas-eutectic porous materials (Gasars) in USA. Mater Sci Forum 539–543:1183–1187

Shapovalov V, Boyko L (2004) Gasar—a new class of porous materials. Adv Eng Mater 6:407–410

Kucharczyk A, Naplocha K, Kaczmar JW, Dieringa H, Kainer KU (2018) Current status and recent developments in porous magnesium fabrication. Adv Eng Mater 20:1700562

Nakajima H (2013) Porous metals with directional pores. Springer, Tokyo

(2000) Chapter 2 - Making metal foams. In: Ashby MF, Evans AG, Fleck NA, Gibson LJ, Hutchinson JW, Wadley HNG (eds.) Metal Foams. Butterworth-Heinemann, Burlington, pp 6–23

Ide T, Tane M, Nakajima H (2013) Effect of solidification condition and alloy composition on formation and shape of pores in directionally solidified Ni–Al alloys. Metall Mater Trans A 44:4257–4265

Yuan L, Yanxiang L, Jiang W, Huawei Z (2005) Evaluation of porosity in lotus-type porous magnesium fabricated by metal/gas eutectic unidirectional solidification. Mater Sci Eng A 402:47–54

Rajak DK, Gupta M (2020) Manufacturing methods of metal foams. In: Rajak DK, Gupta M (eds) An insight into metal based foams: processing properties and applications. Springer, Singapore, pp 39–52

Liu PS, Chen GF (2014) Chapter five—fabricating porous ceramics. In: Liu PS, Chen GF (eds) Porous materials. Butterworth-Heinemann, Boston, pp 221–302

Banhart J (2013) Light-metal foams—history of innovation and technological challenges. Adv Eng Mater 15:82–111

Liu Y, Li Y, Wan J (2007) Directional solidification of metal-gas eutectic and fabrication of regular porous metals. Front Mech Eng China 2:180–183

Chen Z, Kirlikovali KO, Idrees KB, Wasson MC, Farha OK (2022) Porous materials for hydrogen storage. Chem 8:693–716

Nakajima H (2007) Fabrication, properties and application of porous metals with directional pores. Prog Mater Sci 52:1091–1173

Onishi H, Ueno S, Hyun SK, Nakajima H (2009) Fabrication of lotus-type porous cobalt and silicon through decomposition of moisture. Metall Mater Trans A 40:438–443

Nakajima H, Kim SY, Park JS (2009) Fabrication of porous aluminium with directional pores through thermal decomposition method. J Phys Conf Ser 165:012063

Kim TB, Suzuki S, Nakajima H (2009) Fabrication of a lotus-type porous Al–Si alloy by continuous casting with a thermal decomposition method. J Phys Conf Ser 165:012067

Mohammadi Zahrani M, Meratian M, Kabiri Y (2012) Innovative processing of lotus-type porous magnesium through thermal decomposition of wood. Mater Lett 85:14–17

Li S, Lyons-Hart J, Banyasz J, Shafer K (2001) Real-time evolved gas analysis by FTIR method: an experimental study of cellulose pyrolysis. Fuel 80:1809–1817

Zhang C, Chao L, Zhang Z, Zhang L, Li Q, Fan H, Zhang S, Liu Q, Qiao Y, Tian Y, Wang Y, Hu X (2021) Pyrolysis of cellulose: evolution of functionalities and structure of bio-char versus temperature. Renew Sustain Energy Rev 135:110416

Pavia DL, Lampman GM, Kriz GS, Vyvyan JR (2015) Introduction to spectroscopy. In: 4th ed., BROOKS/COLE, Department of Chemistry Western Washington University Bellingham, Washington

Banyasz JL, Li S, Lyons-Hart J, Shafer KH (2001) Gas evolution and the mechanism of cellulose pyrolysis. Fuel 80:1757–1763

Ebrahimi M, Mobasherpour I, Barzegar H, Shirani F (2019) Taguchi design for optimization of structural and mechanical properties of hydroxyapatite–alumina–titanium nanocomposite. Ceram Int 45:10097–10105

Mansoorianfar M, Mansourianfar M, Fathi M, Bonakdar S, Ebrahimi M, Zahrani EM, Hojjati-Najafabadi A, Li D (2020) Surface modification of orthopedic implants by optimized fluorine-substituted hydroxyapatite coating: enhancing corrosion behavior and cell function. Ceram Int 46:2139–2146

Mansoorianfar M, Rahighi R, Hojjati-Najafabadi A, Mei C, Li D (2021) Amorphous/crystalline phase control of nanotubular TiO2 membranes via pressure-engineered anodizing. Mater Des 198:109314

Mansoorianfar M, Shahin K, Marlen M, Li D (2021) Cellulose-reinforced bioglass composite as flexible bioactive bandage to enhance bone healing. Ceram Int 47:416–423

Rahighi R, Panahi M, Akhavan O, Mansoorianfar M (2021) Pressure-engineered electrophoretic deposition for gentamicin loading within osteoblast-specific cellulose nanofiber scaffolds. Mater Chem Phys 272:125018

Mansoorianfar M, Tavoosi M, Mozafarinia R, Ghasemi A, Doostmohammadi A (2017) Preparation and characterization of TiO2 nanotube arrays on Ti6Al4V surface for enhancement of cell treatment. Surf Coat Technol 321:409–415

Hussain Z, Ullah I, Liu X, Shen W, Ding P, Zhang Y, Gao T, Mansoorianfar M, Gao T, Pei R (2022) Tannin-reinforced iron substituted hydroxyapatite nanorods functionalized collagen-based composite nanofibrous coating as a cell-instructive bone-implant interface scaffold. Chem Eng J 438:135611

Teng Y, Wei J, Du H, Mojtaba M, Li D (2020) A solar and thermal multi-sensing microfiber supercapacitor with intelligent self-conditioned capacitance and body temperature monitoring. J Mater Chem A 8:11695–11711

Shahin K, Bao H, Zhu S, Soleimani-Delfan A, He T, Mansoorianfar M, Wang R (2022) Bio-control of O157:H7, and colistin-resistant MCR-1-positive Escherichia coli using a new designed broad host range phage cocktail. LWT 154:112836

Yang K, Peng H, Wen Y, Li N (2010) Re-examination of characteristic FTIR spectrum of secondary layer in bilayer oleic acid-coated Fe3O4 nanoparticles. Appl Surf Sci 256:3093–3097

Wan Z, Chen C, Meng T, Mojtaba M, Teng Y, Feng Q, Li D (2019) Multifunctional wet-spun filaments through robust nanocellulose networks wrapping to single-walled carbon nanotubes. ACS Appl Mater Interfaces 11:42808–42817

Panda RN, Hsieh MF, Chung RJ, Chin TS (2003) FTIR, XRD, SEM and solid state NMR investigations of carbonate-containing hydroxyapatite nano-particles synthesized by hydroxide-gel technique. J Phys Chem Solids 64:193–199

Chen JH, Liu PS, Song S (2022) Preparation and compression performance of porous magnesium alloy composite with ceramic hollow spheres. J Alloy Compd 894:162397

Hussain Z, Ullah S, Yan J, Wang Z, Ullah I, Ahmad Z, Zhang Y, Cao Y, Wang L, Mansoorianfar M, Pei R (2022) Electrospun tannin-rich nanofibrous solid-state membrane for wastewater environmental monitoring and remediation. Chemosphere 307:135810

Liu Y, Zhang Y, An Z, Zhao H, Zhang L, Cao Y, Mansoorianfar M, Liu X, Pei R (2021) Slide-ring structure-based double-network hydrogel with enhanced stretchability and toughness for 3D-bio-printing and its potential application as artificial small-diameter blood vessels. ACS Appl Bio Mater 4:8597–8606

Acknowledgements

Thanks to the Isfahan University of Technology for its financial support, laboratory facilities, and legal assistance.

Funding

We have no pecuniary or other personal interest, direct or indirect, in any matter that raises or may raise a conflict with our duties. In order for our article to proceed to publication, all authors gratefully acknowledge the financial support provided by the Jiangsu Postdoctoral Research Funding Program (Grant no. 2021K306C) for financial support.

Author information

Authors and Affiliations

Contributions

ZS helped in experiment, analyzing, and writing; MM helped in writing, polishing, and revising; MM and MP cotributed to supervision and financial support.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interests.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sadeghi, Z., Mansoorianfar, M., Panjepour, M. et al. Lotus-type porous magnesium production via in situ pyrolysis of viscose rayon fiber in a melting process. J Mater Sci 58, 9297–9307 (2023). https://doi.org/10.1007/s10853-023-08563-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08563-8