Abstract

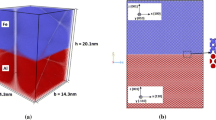

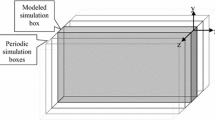

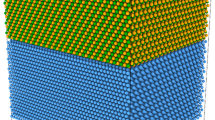

Molecular dynamics simulations are utilized to study the shear deformation behavior of aluminum interfaces formed through jump-to-contact (JC) mechanism. In the presence of misorientation between substrates, when shear is applied, (111)-oriented systems exhibit resistance-free sliding, whereas in the (001)- and (110)-oriented systems, dislocation multiplication (DM), which originates from the network of interfacial dislocations, is found to be the controlling mechanism. It is observed that by a decrease in the misorientation angle or an increase in the strain normal to the interface (a consequence of JC), more DM occurs. (110)-oriented systems are found to be the most prone system to DM due to the existence of dislocations with Burgers vector of a < 100 > in their interface. Ultimately, using the profile of average atomic volume along the direction perpendicular to the interface, two characterizing parameters are defined: interface volume expansion (IVE) and interface thickness (IT). IVE describes the excess free atomic volume at the interface relative to that in the bulk, and IT is an estimate of the portion of the system that is considered as the interface region (where defects are concentrated). IVE and IT are shown to have a reverse and direct relationship with the shear strength of the system, respectively, and therefore are introduced as new tools for prediction of shear deformation behavior. Calculation of the IVE and IT parameters enables linking the microscopic characteristics of the interface to shear deformation behavior, which is a controlling phenomenon in various applications. Particularly, the IT parameter is found to be very promising as the direct relationship between IT and shear strength is shown to be independent of the orientation of the interface plane.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Shah A, Gaul H, Schneider-Ramelow M, Reichl H, Mayer M, Zhou Y (2009) Ultrasonic friction power during Al wire wedge-wedge bonding. J Appl Phys 106:013503. https://doi.org/10.1063/1.3158065

Seppänen H, Kurppa R, Meriläinen A, Hæggström E (2013) Real time contact resistance measurement to determine when microwelds start to form during ultrasonic wire bonding. Microelectron Eng 104:114–119. https://doi.org/10.1016/J.MEE.2012.12.003

Kumar Rajak D, Pagar DD, Menezes PL, Eyvazian A (2020) Friction-based welding processes: friction welding and friction stir welding. J Adhes Sci Technol 34(24):2613–2637

Heidarzadeh A, Mironov S, Kaibyshev R, Çam G, Simar A, Gerlich A, Khodabakhshi F, Mostafaei A, Field DP, Robson JD, Deschamps A, Withers PJ (2021) Friction stir welding/processing of metals and alloys: a comprehensive review on microstructural evolution. Prog Mater Sci 117:100752. https://doi.org/10.1016/J.PMATSCI.2020.100752

Bakavos D, Prangnell PB (2010) Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet. Mater Sci Eng A 527:6320–6334. https://doi.org/10.1016/J.MSEA.2010.06.038

Geissler U, Funck J, Schneider-Ramelow M, Engelmann HJ, Rooch I, Müller WH, Reichl H (2010) Interface formation in the US-Wedge/Wedge-bond process of AlSi1/CuNiAu contacts. J Electron Mater 40(2):239–246

Smith J, Bozzolo G, Banerjea A, Ferrante J (1989) Avalanche in adhesion. Phys Rev Lett 63:1269–1272

Mo Y, Turner KT, Szlufarska I (2009) Friction laws at the nanoscale. Nature 457(7233):1116–1119

Luan B, Robbins MO (2005) The breakdown of continuum models for mechanical contacts. Nature 435(7044):929–932

Gimzewski JK, Möller R (1987) Transition from the tunneling regime to point contact studied using scanning tunneling microscopy. Phys Rev B 36:1284–1287. https://doi.org/10.1103/PhysRevB.36.1284

Agraït N, Rodrigo JG, Vieira S (1993) Conductance steps and quantization in atomic-size contacts. Phys Rev B 47:12345–12348. https://doi.org/10.1103/PhysRevB.47.12345

Voets J, Keijsers RJP, Shklyarevskii OI, van Kempen H (1996) Effects of electrode interactions observed in a mechanically controllable break junction. Phys Rev B 53:1072–1075. https://doi.org/10.1103/PhysRevB.53.1072

Krans JM, Muller CJ, Yanson IK, Govaert TCM, Hesper R, van Ruitenbeek JM (1993) One-atom point contacts. Phys Rev B 48:14721–14724. https://doi.org/10.1103/PhysRevB.48.14721

Landman U, Luedtke WD, Burnham NA, Colton RJ (1990) Atomistic mechanisms and dynamics of adhesion, nanoindentation, and fracture. Science 248:454–461. https://doi.org/10.1126/science.248.4954.454

Khajehvand M, Sepehrband P (2018) The effect of crystallographic misorientation and interfacial separation on jump-to-contact behavior and defect generation in aluminum. Model Simul Mater Sci Eng 26(5):055007. https://doi.org/10.1088/1361-651X/aac427

Khajehvand M, Seppänen H, Sepehrband P (2019) Nanoscale contact behavior of (1 1 1) fcc metallic surfaces. Comput Mater Sci 170:109149. https://doi.org/10.1016/j.commatsci.2019.109149

Jiang H, Szlufarska I (2018) Small-angle twist grain boundaries as sinks for point defects. Sci Rep 8(1):1–3

Shao S, Wang J, Misra A, Hoagland RG (2013) 2013 Spiral patterns of dislocations at nodes in (111) semi-coherent FCC interfaces. Sci. Reports 31(3):1–7. https://doi.org/10.1038/srep02448

Guleryuz E, Mesarovic SD (2016) Dislocation nucleation on grain boundaries: low angle twist and asymmetric tilt boundaries. Crystals 6(7):77

Wang J, Zhang RF, Zhou CZ, Beyerlein IJ, Misra A (2014) Interface dislocation patterns and dislocation nucleation in face-centered-cubic and body-centered-cubic bicrystal interfaces. Int J Plast 53:40–55. https://doi.org/10.1016/J.IJPLAS.2013.07.002

Farkas D (2013) Atomistic simulations of metallic microstructures. Curr Opin Solid State Mater Sci 17:284–297. https://doi.org/10.1016/J.COSSMS.2013.11.002

Bomarito GF, Lin Y, Warner DH (2015) An atomistic modeling survey of the shear strength of twist grain boundaries in aluminum. Scr Mater 101:72–75. https://doi.org/10.1016/J.SCRIPTAMAT.2015.01.022

Tucker GJ, Tschopp MA, McDowell DL (2010) Evolution of structure and free volume in symmetric tilt grain boundaries during dislocation nucleation. Acta Mater 58:6464–6473. https://doi.org/10.1016/J.ACTAMAT.2010.08.008

Tucker GJ, McDowell DL (2011) Non-equilibrium grain boundary structure and inelastic deformation using atomistic simulations. Int J Plast 27:841–857. https://doi.org/10.1016/J.IJPLAS.2010.09.011

Sansoz F, Molinari JF (2005) Mechanical behavior of Σ tilt grain boundaries in nanoscale Cu and Al: A quasicontinuum study. Acta Mater 53:1931–1944. https://doi.org/10.1016/J.ACTAMAT.2005.01.007

Lu Y, Huang JY, Wang C, Sun S, Lou J (2010) Cold welding of ultrathin gold nanowires. Nat Nanotechnol 5:218–224. https://doi.org/10.1038/nnano.2010.4

Wan L, Wang S (2009) Shear response of the Σ11, 〈1 1 0〉 {1 3 1} symmetric tilt grain boundary studied by molecular dynamics. Model Simul Mater Sci Eng 17:045008. https://doi.org/10.1088/0965-0393/17/4/045008

Yuasa M, Nakazawa T, Mabuchi M (2010) Atomic simulation of grain boundary sliding in Co/Cu two-phase bicrystals. Mater Sci Eng A 527:2629–2636. https://doi.org/10.1016/J.MSEA.2009.12.025

Wang J, Misra A, Hirth JP (2011) Shear response of Σ 3 112 twin boundaries in face-centered-cubic metals. Phys Rev B 83(6):064106

Raj R, Ashby MF (1971) On grain boundary sliding and diffusional creep. Metall Trans 4:1113–1127

Van Swygenhoven H, Derlet PM (2001) Grain-boundary sliding in nanocrystalline fcc metals. Phys Rev B 64:224105. https://doi.org/10.1103/PhysRevB.64.224105

Schönfelder B, Gottstein G, Shvindlerman LS (2005) Comparative study of grain-boundary migration and grain-boundary self-diffusion of [0 0 1] twist-grain boundaries in copper by atomistic simulations. Acta Mater 53:1597–1609. https://doi.org/10.1016/J.ACTAMAT.2004.12.010

Daphalapurkar NP, Ramesh KT (2012) Orientation dependence of the nucleation and growth of partial dislocations and possible twinning mechanisms in aluminum. J Mech Phys Solids 60:277–294. https://doi.org/10.1016/J.JMPS.2011.10.009

Plimpton S (1995) Fast Parallel Algorithms for Short-Range Molecular Dynamics. J Comput Phys 117:1–19. https://doi.org/10.1006/JCPH.1995.1039

Sheng HW, Kramer MJ, Cadien A, Fujita T, Chen MW (2011) Highly optimized embedded-atom-method potentials for fourteen fcc metals. Phys Rev B 83:134118. https://doi.org/10.1103/PhysRevB.83.134118

Nosé S (1984) A molecular dynamics method for simulations in the canonical ensemble. Mol Phys 52:255–268. https://doi.org/10.1080/00268978400101201

Hoover WG (1985) Canonical dynamics: Equilibrium phase-space distributions. Phys Rev A 31:1695–1697. https://doi.org/10.1103/PhysRevA.31.1695

Hoover WG (1986) Constant-pressure equations of motion. Phys Rev A 34:2499–2500. https://doi.org/10.1103/PhysRevA.34.2499

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Model Simul Mater Sci Eng 20:085007. https://doi.org/10.1088/0965-0393/20/8/085007

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model Simul Mater Sci Eng 18:015012. https://doi.org/10.1088/0965-0393/18/1/015012

Dodaran M, Wang J, Chen Y, Meng WJ, Shao S (2019) Energetic, structural and mechanical properties of terraced interfaces. Acta Mater 171:92–107. https://doi.org/10.1016/J.ACTAMAT.2019.04.016

Ogata S, Li J, Yip S (2002) Ideal pure shear strength of aluminum and copper. Sci 298(5594):807–811

Yang L, Lai C, Li S (2019) Atomistic simulations of energies for arbitrary grain boundaries. Part II: Statistical analysis of energies for tilt and twist grain boundaries. Comput Mater Sci 162:268–276. https://doi.org/10.1016/J.COMMATSCI.2019.03.010

Yin Q, Wang Z, Mishra R, Xia Z (2017) Atomic simulations of twist grain boundary structures and deformation behaviors in aluminum. AIP Adv 7:015040. https://doi.org/10.1063/1.4975042

Wolf D (1989) Correlation between energy and volume expansion for grain boundaries in FCC metals. Scr Metall 23:1913–1918. https://doi.org/10.1016/0036-9748(89)90482-1

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain Bound Energy Acta Mater 57:3694–3703. https://doi.org/10.1016/J.ACTAMAT.2009.04.007

Poletaev GM, Zorya IV, Starostenkov MD (2018) Role of point defects in self-diffusion along low-angle twist boundaries in fcc metals: a molecular dynamics study. J Micromech Mol Phys 3:1850001

Poletaev GM, Martynov AN, Starostenkov MD (2010) The structure and energy of twist grain boundaries in fcc metals. Fundam Probl Sovrem Materialoved Basic Probl Mater Sci 7(4):27–34

Dai S, Xiang Y, Srolovitz DJ (2014) Atomistic, generalized Peierls-Nabarro and analytical models for (1 1 1) twist boundaries in Al, Cu and Ni for all twist angles. Acta Mater 69:162–174. https://doi.org/10.1016/J.ACTAMAT.2014.01.022

Spearot DE (2008) Evolution of the E structural unit during uniaxial and constrained tensile deformation. Mech Res Commun 35:81–88. https://doi.org/10.1016/J.MECHRESCOM.2007.09.002

Acknowledgements

This work was supported by the National Science Foundation (CMMI-1728652) and the School of Engineering at Santa Clara University. Computing resources for running the LAMMPS simulations were provided by the Wiegand Advanced Visualization Environment (WAVE) at Santa Clara University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors state that they have no known competing financial interests or personal relationships that could have appeared to influence the work presented in this article.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khajehvand, M., Seppänen, H. & Sepehrband, P. Interface-mediated shear behavior of bonded aluminum substrates. J Mater Sci 57, 20957–20973 (2022). https://doi.org/10.1007/s10853-022-07926-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07926-x