Abstract

Recently, thermoelectric (TE) devices have attracted much attention because they have no moving parts, simple structures, high reliability, and environmental friendly, when compared to other green energy techniques. In this paper, we report a novel thermoelectric composite constructed one with a self-assembled highly oriented Sb doped Bi2Te3 and one without doping nanoflake layer deposited on regular vertically aligned checkerboard-patterned multi-walled carbon nanotube (MWCNT) arrays (500 nm squares and 1 µm pitch) on insulated SiO2/Si substrates. The height of Bi2Te3/Bi0.4Sb1.6Te3, MWCNTs and volumetric ratio of MWCNT to Bi2Te3/ Bi0.4Sb1.6Te3 are about 3 μm, 1.5 μm, and 25%, respectively. The blending of regular vertically aligned MWCNT patterns into Bi0.4Sb1.6Te3 results in a dramatically enhancement of Seebeck coefficient and electrical conductivity. The Seebeck coefficient and power factor of Bi0.4Sb1.6Te3-MWCNTs show a maximum value of 600 μV/K and 60 μW/cm-K2 at 160 K and gradually decrease to 409 μV/K, and about 14.1 μW/cm-K2 at 300 K, respectively. The significant records of the low temperature Seebeck coefficients and relative electrical properties are extremely important for the fundamental understanding of vertically aligned MWCNT embedded thermoelectric composites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the last decade, thermoelectric (TE) devices have attracted much attention because they have no moving parts, simple structures, high reliability, and long life times are environmental friendly, and have quiet operation when compared to other green energy techniques [1,2,3]. However, TE materials exhibit a relatively low conversion efficiency, which is one of the most fundamental scientific issues that seriously limits further applications of TE materials; the low conversion efficiency is caused by a dimensionless figure-of-merit, which is represented by ZT = S2σT/κ, where S is the Seebeck coefficient, σ is the electrical conductivity, T is the absolute temperature, and κ is the summation of the electron and phonon thermal conductivity, respectively. The power factor is most often used for the properties of the thermoelectric, which is given by S2σ term in the numerator of ZT [4]. Among various categories of thermoelectric bulk materials including metals [5], oxides [6], and polymers [7] for any working temperatures. In addition, Bi2Te3-based alloys doped with Sb, Sn, Zn, and Pb have been widely considered to make thermoelectric devices, because of the high atomic weights which affect the phonon transport in the material and hence decreasing the thermal conductivity [8]. Furthermore, bismuth telluride (Bi2Te3) based devices exhibit a relative high performance (ZT ~ 1) that are used commercially at near room temperature (200–400 K). Therefore, BiTe (p-type semiconductor) binary compounds as well as bismuth antimony telluride (BiSbTe) ternary compound has attracted many attention on the thermoelectric applications including thermoelectric cooling/generators and thermal sensors.

Some theoretical predictions and large numbers of experimental observations have clearly addressed that a decrease in dimensions or the partial introduction of nanostructures for any thermoelectric materials would greatly enhance the ZT values, compared to their bulk counterparts [9, 10]. The major breakthrough of Bi2Te3 (ZT ~ 2) was made by preparing Bi2Te3/Sb2Te3 superlattices which are considered to effectively resist phonon transport in solid state materials due to quantum confinement in quantum wells [11]. In contrast to the highly controlled superlattices, Ma et al. showed the importance of the appearance of nanostructures in conventional bulk materials [12]. However, these improvements in ZT should not just simply increase the nanograin boundaries at the phonon scattering centers, which significantly reduce thermal conductivity, because the electrical conductivity would also be simultaneously reduced [13]. To overcome this problem, another potential approach for obtaining high ZT is the concept of using composites to further optimize the ZT relative parameters independently [14]. Tritt et al. demonstrated that the electrical properties of Bi2Te3 nanostructures could be greatly improved by applying alkali metal nanoparticle coatings on Bi2Te3 nanograins [15].

Carbons nanotubes (CNTs) are considered as a candidate to integrate with other thermoelectric materials due to the extraordinary thermal and electrical properties of their one-dimensional structures [1]. For instance, the Seebeck coefficient of semiconducting SWNTs (50 ~ 300 μV/K) [16, 17] is greater than metallic MWNTs (− 50 to + 65 μV/K) [18] around room temperature. Although the thermal conductivity is as high as 3000 W/mK along the one-dimensional direction of an isolated CNT [19], for random-packed three-dimensional networks of CNTs, the extremely low value of 0.13 W/mK is attributed to the intertube contact resistance [20]. Yu et al. clearly demonstrated an increase in ZT when a segregated-network of CNTs was added, as it enhances the electric conductivity, but inhibits the thermal conductivity of the 20 wt% CNT-polymer composites [21]. These characteristics suggest that either pure CNTs or CNT integrated composites can be candidates for thermoelectric applications due to quantum confinement effects, which enhances the Seebeck coefficient and the electrical conductivity. In addition, the increased grain boundaries will simultaneously reduce the thermal conductivity.

In this paper, we report a novel thermoelectric composite constructed with a self-assembled highly oriented Sb doped Bi2Te3 nanoflake layer deposited on regular vertically aligned checkerboard-patterned MWCNT arrays (500 nm squares and 1 µm pitch) on insulated SiO2/Si substrates. This unique highly oriented composite is newly designed and is expected to have excellent thermoelectric properties due to the following possible physical principles. First, the checkerboard-patterned CNT arrays would play the important role of improving electron transport in the self-assembled Bi2Te3 nanoflake films. Secondly, the Schottky barrier between Bi2Te3 nanoflakes and CNTs would accompany the electronic filtering effect to improve the Seebeck coefficient [22]. Finally, the nanograin boundaries and the intertube contact resistances are expected to dramatically reduce the thermal conductivity. This study provides valuable temperature dependent data for the fundamental understanding of the vertically aligned CNT embedded thermoelectric composites which have not been reported elsewhere.

Experimental methods

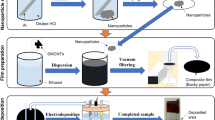

Regular vertically aligned MWCNT integrated Bi2Te3 and Bi0.4Sb1.6Te3 nanostructures were fabricated by combining electron beam lithography (EBL), thermal chemical vapor deposition (CVD), and pulsed laser deposition (PLD). Figure 1 shows schematically the process flow. EBL has been shown to be a straightforward approach defining an array of a metal catalyst with a designated size and separation. EBL was employed to prepare 1 cm squares of Al/Fe checkerboard patterns and were used as catalyst for the growth of MWCNTs. Photoresist ZEP 520A was coated to a thickness of 250 nm on a 4 inch SiO2 (600 nm)/Si wafer substrate, followed by EBL exposure and development. The Al (10 nm)/Fe (1 nm) (buffer layer/catalyst) were then deposited either by E-gun evaporation or radio frequency sputtering, followed by lift-off. The Al/Fe checkerboard patterns were designed to have an area and pitch of 500 nm square and 1 µm, respectively, since V. D. Das and N. Soundararajan [10] have pointed out that the mean free path of phonons in Bi2Te3 thin films is about 620 nm at 300 K. Regular vertically aligned MWCNT patterns were synthesized by thermal CVD, the feed gas mixture used in the thermal CVD process was C2H2/H2 with flow rates of 60/10 sccm, and the system pressure was 20 mTorr.

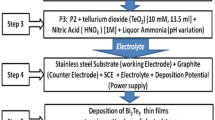

On the side, the raw materials of Bi2Te3 and Bi0.4Sb1.6Te3 powders whose purity is greater than 99.99%. Both of the powders were dry pressed into discs of 10 mm diameter and 2 mm thickness and then annealed under hydrogen ambient of 20 torr at 300 °C for 10 h. The crystal structure and composition of the prepared targets were confirmed as the starting materials by X-ray diffraction (XRD) and energy dispersive spectroscopy (EDS), respectively. A Q-switched Nd:YAG pulsed laser with a focused laser fluence of about 8.3 J/cm2 (355 nm wavelength, 10 ns pulse duration, 8 mm beam diameter and 5 Hz repetition rate) was used for the film deposition. The deposition chamber was evacuated to a base pressure of 10−6 torr and 99.999% purity Ar was introduced at a constant flow rate, maintaining a pressure of 0.1 torr. The deposition rate was estimated to be 0.1 nm/s and the substrate temperature was 500 °C. Bi2Te3 and Bi0.4Sb1.6Te3 were then, respectively, deposited on the prepared vertically aligned MWCNTs/SiO2/Si substrates for the fabrication of composites by PLD process. The results herein demonstrate that vertically aligned MWCNT with encapsulating by Bi2Te3 and Bi0.4Sb1.6Te3 materials, respectively, were fabricated, and the height of Bi2Te3/Bi0.4Sb1.6Te3, MWCNTs and volumetric ratio of MWCNT to Bi2Te3/ Bi0.4Sb1.6Te3 are about 3 μm, 1.5 μm, and 25%, respectively. The schematic of measurement framework is shown in Fig. 2. The four lines (copper, diameter is about 100 μm) were mounted by silver glue paste in sample, followed by put into the sample stage in the vacuum chamber. The line A and B are temperature analysis by thermocouple, and line C and D are voltage analysis by Keithley meter. The position of line B is heating part. Based on the above measurement framework, it showed that both of Seebeck coefficient and electrical resistivity measurement are “in-plane” direction.

Results and discussion

Images of vertically aligned MWCNTs were taken using a JEOL 7000 field emission scanning electron microscope (FE-SEM) and high-resolution transmission electron microscopy (HRTEM) (JEOL JEN-2100F) as can be seen in Fig. 3a, b. For SEM analysis, sample was mechanically broken and mounted on the specimen holder using carbon tape. The SEM cross section was taken at 45 degrees tilt. To further confirm the MWCNTs microstructure, HRTEM was performed to reveal the graphite layer. The HRTEM sample preparation process began with immersing the MWCNTs and Bi0.4Sb1.6Te3/ MWCNTs into organic solvent (ethanol), respectively. Then, the solution was sonicated in a bath sonicator for 15 min to create MWCNT and Bi0.4Sb1.6Te3/ MWCNTs suspension, respectively, followed dropping about 1 cc of the MWCNT and Bi0.4Sb1.6Te3/ MWCNTs suspension on a carbon-coated copper grid, respectively. Finally, dry the Cu-grid under reduced pressure at room temperature and used it for TEM analysis. The images in (a) and (b) are not taken from the same sample. The prepared MWCNTs consisting of ~ 20 concentric shells were straight and hollow with an average outer diameter and length of about 1.5 μm and 20 nm as shown in Fig. 3b, c, respectively. In addition, a low amount of graphite was observed in the outermost layer of the current MWCNTs. Tip growth mode was employed with a cone shaped iron catalyst encapsulated on the tip of CNT as can be found in the inset of Fig. 3c. The lesser graphite phases of MWCNTs can reduce the influence on electrical and thermal properties [23, 24].

Bi2Te3 and Bi0.4Sb1.6Te3 are the most representative TE materials; hence, these materials were selected for blending with MWCNTs by PLD. The PLD deposition conditions were optimized for the formation of nanoparticles and nanoflakes which is considered to form the Schottky barrier between MWCNTs and Bi2Te3/Bi0.4Sb1.6Te3 nanostructures. The FE-SEM images represented in Fig. 4 clearly show that MWCNTs were encapsulated by dense Bi0.4Sb1.6Te3 nanostructures to form MWCNTs/Bi0.4Sb1.6Te3 core/shell composites. As presented in the inset of Fig. 4, the Bi0.4Sb1.6Te3 “flakes” had attached upon the side of CNTs. The presence of Bi0.4Sb1.6Te3/ MWCNTs is observed by the TEM cross-sectional depicted in Fig. 5. The inset (a) and (b) show images of higher magnification of MWCNTs and composition of Bi0.4Sb1.6Te3, respectively. Inset (a) revealed that the concentric shells and diameter are consistent with that of pure MWCNTs (Fig. 3c). It is believed that that the structure of MWCNTs will not be affected by growing Bi0.4Sb1.6Te3. In addition, the composition of the Bi0.4Sb1.6Te3 by using energy dispersive X-ray spectroscopy (EDS) we observed Bi, Sb and Te elements in inset (b).

SEM image of the Bi0.4Sb1.6Te3/MWCNTs, which the black points are denote MWCNTs positions. The Bi0.4Sb1.6Te3 was attached upon side of MWCNTs as shown in inset of Fig. 4

The XRD patterns illustrated in Fig. 6a, b confirm the crystal structure and high crystallinity of the Bi2Te3, and Bi0.4Sb1.6Te3 nanostructures, respectively.

In order to elucidate the influence of regular vertically CNTs patterns, a series of composites including Bi2Te3, Bi2Te3-MWCNTs, Bi0.4Sb1.6Te3 and Bi0.4Sb1.6Te3-MWCNTs were designed and prepared for the thermoelectric property analyses. Figure 7 shows the Seebeck coefficient, electrical resistivity and power factor of Bi2Te3(Bi0.4Sb1.6Te3) and Bi2Te3-MWCNTs (Bi0.4Sb1.6Te3-MWCNTs) specimens measured at various temperatures from 150 to 288 K and 150 to 300 K, respectively.

The absolute value of the Seebeck coefficient measured from 150 to 288 K for Bi2Te3 and Bi0.4Sb1.6Te3 shown in Fig. 7a was significantly less than those of Bi2Te3-MWCNTs and Bi0.4Sb1.6Te3-MWCNTs, clearly indicating the effect of the periodic appearance of the vertically aligned MWCNTs. Under the Seebeck coefficient measurement, a temperature difference of about 10 °C was created between two rectangular electrodes with an interval of 1 cm. The electrons can pass through the vertically aligned MWCNTs barrier height to lower energies because of the high kinetic energies at the higher temperature end. On the other hand, the electrons in the lower temperature area cannot pass through vertically aligned MWCNTs barriers. Thus, a voltage difference was reinforced between higher and lower temperature areas. Hence, the Seebeck coefficients of Bi2Te3-MWCNTs and Bi0.4Sb1.6Te3-MWCNTs were greater than those of Bi2Te3 and Bi0.4Sb1.6Te3. This result may be attributed to tube–tube interactions within a forest, which have been proposed as a method for prompting the density of states at EF, which should impact transport properties, and as well as the “barrier” between the Bi2Te3/Bi0.4Sb1.6Te3 and MWCNTs [25]. Meanwhile, the absolute value of the Seebeck coefficient decreased above 160 K due to electron–hole generation by thermal excitation. In addition, the inset of Fig. 3c indicates that the Fe magnetic catalyst particles were encapsulated by the CNTs, which might act as one of the key factors on the enhancement of the Seebeck coefficient as shown in Fig. 7a. It is might be that the magnetic impurities coming from the catalyst particles during the synthesis of MWCNTs could led to a Seebeck peak via the Kondo effect [26]. In addition, the trend variation of Seebeck coefficient from low temperature to room temperature was similar to that presented by Kong et al.[27]. The Seebeck coefficient of thermoelectric materials can be simplified to Eq. (1) [28] where C is a constant (\({\text{C}}\, = \,2\, + \,\ln \,\frac{{2\left( {2\pi m^{ * } k_{B} T} \right)^{{{\raise0.7ex\hbox{$3$} \!\mathord{\left/ {\vphantom {3 2}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$2$}}}} }}{{h^{3} }}\), which is independent on the scattering factor, and concentration), KB is the Boltzmann constant, e is the charge of electron, γ is the scattering factor (γ = 0 for lattice scattering, γ = 2 is the impurity scattering), and nc is the carrier concentration at a constant temperature.

According to Eq. (1), the Seebeck coefficient is mainly ruled by the variables of γ and nc. A decrease of carrier concentration can effectively increase the Seebeck coefficient when the scattering factor is assumed to be a constant. To clear this point, the carrier concentration and mobility of the present Bi2Te3, Bi2Te3-MWCNTs, Bi0.4Sb1.6Te3, and Bi0.4Sb1.6Te3-MWCNTs were analyzed using the Hall method. It was found that the measured carrier concentration indeed decreased from 8.7 × 1018 to 5.3 × 1018 cm−3 and the mobility slightly increased from 53.2 to 60.4 cm2V−1 s−1 for Bi0.4Sb1.6Te3 and Bi0.4Sb1.6Te3-MWCNTs, respectively, at room temperature. Similar tendency was also found in the Bi2Te3 and Bi2Te3-MWCNT systems. Generally speaking, the direction and velocity of the electrons motion will be changed and affected by the magnetic field. It means that magnetic field acts as a sort of scattering agent. In general, the effect of a magnetic field is to increase the electrical resistance [29].

The temperature dependent electrical conductivity of the Bi0.4Sb1.6Te3-MWCNTs (Bi2Te3-MWCNTs) shown in Fig. 7b was greater than that of Bi0.4Sb1.6Te3 (Bi2Te3) from 150 to 300 K even though the carrier concentration of Bi0.4Sb1.6Te3-MWCNTs was slightly less than that of Bi0.4Sb1.6Te3 as mentioned above. However, the results showed that the strength of the resistivity uncorrelated well with the strength of the thermopower, suggesting that Kondo scattering may make a fewer contribution to the low-T resistivity. It is important to note that the Bi2Te3/Bi0.4Sb1.6Te3 in CNTs mats exhibit a significantly reduced low-T upturn. It might be due to the Bi2Te3/Bi0.4Sb1.6Te3 putting a cover over the MWCNTs and diminishing the interaction between free electron and magnetic impurity “Fe” (catalyst for growing CNTs). The strong low-T upturn in the resistivity was evident, and this anomaly has been considerably discussed for an as-SWNT system [30], but not complicated composite system. In addition, Kaiser et al. showed only a very small increase in resistivity at low temperatures as characteristics of most of CNTs are belonging to metallic term [30]. As can be seen in Fig. 7, the thermopower data for only Bi2Te3/Bi0.4Sb1.6Te3 very near suppresses the Kondo peak, keeping an almost flat thermopower trend. This may be evidence that Bi2Te3/Bi0.4Sb1.6Te3 are not active Kondo scattering. From the SEM image shown in Fig. 4, the MWCNTs embedded Bi0.4Sb1.6Te3 films is not fully dense and include some defects. In general, these defects, e.g., grain boundaries, surface, holes and voids, will greatly reduce the electrical conductivities of the polycrystalline thin film [31]. Thus, it is reasonable to consider that these porous structures with a number of boundaries, caused by the introduction of MWCNTs, should also exhibit a lower electrical conductivity than that of structures without MWCNTs. However, since CNTs have remarkable electronic properties due to their unique band structure and other excellent characteristics, the overall electrical conductivity of the MWCNT-embedded Bi–Te films is greater than that of intrinsic ones. Unfortunately, these unique features are highly direction dependent because the electrons transport direction in CNTs is along the so-called chiral vector (C axis), i.e., perpendicular to the sample surface in the present case. Thus, the vertically aligned CNTs could not provide fully contributions to the in-plane electrical conductivity as shown in Fig. 7b. The complicated characteristics between thermopower and resistivity may be influenced by many factors such as the contact tunneling behavior between CNTs in the mat [30], magnetic impurities [26], contribution from semiconducting and metallic term of CNTs [18], CNTs and polymer separated to form “barrier” [32], and so on, which are proposed to explain the anomalous behavior between thermopower and resistivity. We do not yet know exact reason for the Kondo effect difference in thermopower and resistivity, but it might be related to the blending Bi2Te3/Bi0.4Sb1.6Te3 on vertically aligned MWCNTs, and characteristics of MWCNTs.

Using the measured electrical resistivity and Seebeck coefficient, the power factor was obtained as displayed in Fig. 7c. The power factor may be influenced by many factors, such as the Fermi level [33], density of states [34], mobility (electrons and holes) [21], and phonon scattering. In this study, the highest power factor for Bi2Te3, Bi0.4Sb1.6Te3, Bi2Te3-MWCNTs, and Bi0.4Sb1.6Te3-MWCNTs at room temperature is 0.08, 1.3, 3.6, and 14.1 μW/cm-K2, respectively. The results were consistent with the electrical conductivity equation. It is believed that this might be due to changes in carrier mobility after blending with vertically aligned MWCNTs.

Conclusions

In conclusion, blending with vertically aligned MWCNTs in both Bi2Te3 and Bi0.4Sb1.6Te3 system by thermal CVD and PLD has been demonstrated to enhance thermoelectric properties. The Seebeck coefficient of Bi0.4Sb1.6Te3-MWCNTs reaches a maximum value of ~ 600 μV/K at 160 K and decreases to 409 μV/K at 300 K. The Seebeck coefficient of Bi0.4Sb1.6Te3 is significantly lower than Bi0.4Sb1.6Te3-MWCNTs in all the measured temperature range. These enhanced properties might directly result from the MWCNTs barrier heights effect between the Bi0.4Sb1.6Te3 areas, which increased the voltage difference. Additionally, the Fe catalyst particles could lead to a Seebeck peak via the Kondo effect. The electrical conductivity of the Bi0.4Sb1.6Te3-MWCNTs (Bi2Te3-MWCNTs) is higher than that of Bi0.4Sb1.6Te3 (Bi2Te3), even though the carrier concentration of Bi0.4Sb1.6Te3-MWCNTs slightly smaller than Bi0.4Sb1.6Te3. The vertically aligned MWCNTs play the role of supporting electrical conductivities in both of Bi0.4Sb1.6Te3 and Bi2Te3. Finally, the power factor of Bi0.4Sb1.6Te3-MWCNTs is about 14.1 μW/cm-K2. The present data clearly address that regular vertically aligned MWCNT patterns can greatly enhance thermoelectric properties in Bi2Te3/Bi0.4Sb1.6Te3 polycrystalline nanomaterials.

References

Zhang Y, Zhang Q, Chen G (2020) Carbon and carbon composites for thermoelectric applications. Carbon Energy 2:408–436. https://doi.org/10.1002/cey2.68

Wei J, Yang L, Ma Z, Song P, Zhang M, Ma J, Yang F, Wang X (2020) Review of current high-ZT thermoelectric materials. J Mater Sci 55:14242–12704. https://doi.org/10.1007/s10853-020-04949-0

Mansouri N, Timm E, Schock H, Sahoo D, Kotrba A (2016) Development of a circular thermoelectric skutterudite couple using compression technology. J Energy Resour Technol 138:052003–052015. https://doi.org/10.1115/1.4032619

Poudel B, Hao Q, Ma Y, Lan Y, Minnich A, Yu B, Yan X, Wang D, Muto A, Vashaee D, Chen X, Liu J, Dresslaus MS, Chen G, Ren Z (2008) High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320(5876):634–638. https://doi.org/10.1126/science.1156446

Chao H, Qiao S, Zhen L, Shi XD (2016) Thermoelectric enhacement of different kinds of metal chalcogenides. Adv Energy Mater 6:1600498-1–1600498-36. https://doi.org/10.1002/aenm.201600498

Assadi MHN, Moreno JJG, Fronzi M (2020) High perfromance thermoelectric oxides based on spinel structure. ACS Appl Energy Mater 3:5666–5674. https://doi.org/10.1021/acsaem.0c00640

Li Z, Deng L, Lv H, Liang L, Deng W, Zhang Y, Chen G (2021) Mechanically robust and flexible films of ionic liquid modulated polymer thermoelectric composites. Adv Funct Mater 31(42):2104836. https://doi.org/10.1002/adfm.202104836

Tseng SC, Chao WH, Yang PH, Chu HS, Hwang JD, Wu RJ (2014) Enhanced thermoelectric properties of (Bi0.5Sb1.5Te3)1–x-y (PbTe)x(Zn4Sb3)y by combinatorial screening. J Alloy compd 588:658–661. https://doi.org/10.1016/j.jallcom.2013.11.139

Du C, Cao M, Li G, Hu Y, Zhang Y, Liang L, Liu Z, Chen G (2022) Toward precision recognition of complex hand motions: wearable thermoelectrics by synergistic 2D nanostructure confinement and controlled reduction. Adv Funct Mater 32(36):2206083. https://doi.org/10.1002/adfm.202206083

Goncalves LM, Couto C, Alpuim P, Rowe DM, Correia JH (2006) Thermoelectric microstructures of Bi2Te3/Sb2Te3 for a self-calibrated micro-pyrometer. Sens Actuators A 130:346–351. https://doi.org/10.1016/j.sna.2005.10.014

Das VD, Soundararajan N (1988) Size and temperature effects on the thermoelectric power and electric resistvity of bismuth telluride thin film. Phy Rev B 37:4552–4559. https://doi.org/10.1103/PhysRevB.37.4552

Venkatasubramanian R, Siivola E, Colpitts T, Quinn BQ (2001) Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413(6856):597–602. https://doi.org/10.1038/35098012

Ma Y, Qing H, Bed P, Yucheng L, Bo Y, Dezhi W, Gang C, Zhifeng R (2008) Enhanced thermoelectric figure-of-merit in p-type nanostructured bismuth antimony tellurium alloys made from elemental chunks. Nano Lett 8(8):2580–2584. https://doi.org/10.1021/nl8009928

Nolas GS, Morelli DT, Tritt TM (1999) Skutterudites: a phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu Rev Mater Sci 29:89–116. https://doi.org/10.1146/annurev.matsci.29.1.89

Ji X, He J, Su Z, Gothard N, Tritt TM (2008) Improved thermoelectric performance in polycrystalline p-type Bi2Te3 via an alkali metal salt hydrothermal nanocoating treatment approach. J Appl Phys 104(3):034907-1–034907-6. https://doi.org/10.1063/1.2963706

Yanagi K, Kanda S, Oshima Y, Kitamura Y, Kawai H, Yamamoto T, Takenobu T, Nakai Y, Maniwa Y (2014) Tuning of the thermoelectric properties of one-dimensional material networks by electric double layer techniques using ionic liquids. Nano Lett 14:6437–6442. https://doi.org/10.1021/nl502982f

Fukuhara K, Ichinose Y, Nishidome H, Yomogida Y, Katsutani F, Komatsu N, Gao W, Kono J, Yanagi K (2018) Isotropic seebeck coefficient of aligned single-wall carbo nanotube films. App Phys Lett 113:243105-1–243105-4. https://doi.org/10.1063/1.5066021

Hone J, Ellwood I, Muno M, Mizel A, Marvin L, Zettl A, Rinzler AG, Smalley RE (1998) Thermoelectric power of single-walled carbon nanotubes. Phys Rev Lett 80(5):1042–1045. https://doi.org/10.1103/PhysRevLett.80.1042

Kim P, Shi L, Majumdar A, McEuen PL (2001) Thermal transport measurements of individual multiwalled nanotubes. Phys Rev Lett 87(21):2155021–2155024. https://doi.org/10.1103/PhysRevLett.87.215502

Prasher RS, Hu XJ, Chalopin Y, Mingo N, Lofgreen K, Volz S, Cleri F, Keblinski P (2009) Turning carbon nanotubes from exceptional heat conductors into insulators. Phys Rev Lett 102(10):105901–105904. https://doi.org/10.1103/PhysRevLett.102.105901

Yu C, Shi L, Yao Z, Li D, Majumdar A (2005) Thermal conductance and thermopower of an individual single-wall carbon nanotube. Nano Lett 5(9):1842–1846. https://doi.org/10.1021/nl051044e

Zide JMO, Vashaee D, Bian ZX, Zeng G, Bowers JE, Shakouri A, Gossard AC (2006) Demonstration of electron filtering to increase the Seebeck coefficient in In0.53 Ga0.47As/In0.53Ga0.28Al0.19 as superlattices. Phys Rev B 74(20):205335–205339. https://doi.org/10.1103/PhysRevB.74.205335

Zhang HL, Li JF, Zhang BP, Yao KF, Liu WS, Wang H (2006) Electrical and thermal properties of carbon nanotube bulk materials: experimental studies for the 328–958 K temperature range. Phys Rev B 74:2054071–2054079. https://doi.org/10.1103/PhysRevB.75.205407

Bourlon B, Miko C, Forro L, Glattli DC, Bachtold A (2004) Determination of the intershell conductance in multiwalled carbon nanotubes. Phys Rev Lett 93(17):1768061–1768064. https://doi.org/10.1103/PhysRevLett.93.176806

Delaney P, Choi HJ, Ihm J, Louie SG, Cohen ML (1998) Broken symmetry and pseudogaps in ropes of carbon nanotubes. Nature 391(6666):466–468. https://doi.org/10.1038/35099

Grigorian L, Sumanasekera GUG, Loper AL, Fang SL, Allen JL, Eklund PC (1999) Giant thermopower in carbon nanotubes: a one-dimensional Kondo system. Phys Rev B 60(16):R11309–R113012. https://doi.org/10.1103/PhysRevB.60.R11309

Kong WJ, Lu L, Wei BQ, Wu DH (2005) Thermoelectric power of a single-walled carbon nanotubes strand. J Phys: Condens Matter 17(12):1923–1928. https://doi.org/10.1088/0953-8984/17/12/015

Kim HC, Oh TS, Hyun DB (2000) Thermoelectric properties of the p-type Bi2Te3-Sb2Te3-Sb2Se3 alloys fabricated by mechanical alloying and hot pressing. J Phys Chem Solids 61:743–749. https://doi.org/10.1016/S0022-3697(99)00269-3

Bhandari CM (1995) Handbook of thermoelectrics-thermoelectric transport theory. CRC, Boca Raton, pp 27–42

Kaiser AB, Dusberg G, Toth S (1998) Heterogeneous model for conduction in carbon nanotube. Phys Rev B-Condens Matter Mater Phys 57(3):1418–1421. https://doi.org/10.1103/PhysRevB.57.1418

Kishimoto K, Tsukamoto M, Koyanagi T (2002) Temperature dependence of the Seebeck coefficient and the potential barrier scattering of n-type PbTe films prepared on heated glass substrates by rf sputtering. J Appl Phys 92(9):5331–5339. https://doi.org/10.1063/1.1512964

Park YW, Heeger AJ, Druy MA, MacDiarmid AG (1980) Electrical transport in doped polyacetylene. J Chem Phys 73(2):946–957. https://doi.org/10.1063/1.440214

Partoens B, Peeters FM (2006) From graphene to graphite: electronic structure around the K point. Phys Rev B 74(7):075404–075414. https://doi.org/10.1103/PhysRevB.74.075404

Hick LD, Dresselhaus MS (1993) Effect of quantum-well structures on the thermoelectric figure of merit. Phys Rev B 47(19):12727–12731. https://doi.org/10.1103/PhysRevB.47.12727

Acknowledgements

The authors would like to thank the National Science Council, Taiwan, R.O.C. for financially supporting this research under Contract No. 108-2221-E-007 -082 -MY3 and 110-2218-E-007 -029 -MY4.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tseng, S.C., Wang, CA., Chu, H.S. et al. Thermoelectric properties of a vertically aligned carbon nanotube array with embedded bismuth telluride. J Mater Sci 57, 19396–19404 (2022). https://doi.org/10.1007/s10853-022-07846-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07846-w