Abstract

High alignment of graphene in mesophase pitch-based carbon fibers endows them with excellent properties such as high thermal conductivity and ultrahigh modulus. However, the weak interlayer interaction between large planar molecules leads to unwanted open crack in circular carbon fiber, leading to low strain-to-failure and low utilization rate in composite manufacturing. It remains a challenge to produce split-free circular carbon fiber while keeping a high degree of alignment of graphite layers. Herein, a die swell manipulating strategy is employed to address the problem through elaborating spinneret design. By applying an exit angle of 30° at the spinneret, the stored stress and shear-induced orientation of crystallites during the capillary flow were relaxed at the exit to enhance the die swell. The disoriented texture of fibers prevents the carbon fibers from splitting while still maintaining high degree of molecular alignment. The obtained carbon fibers present 20% higher of tensile strength, and more than twice of the compressive strength than the split ones, without sacrificing their superior thermal properties, which is up to 512 W·m−1·K−1. The work provides valuable insights into the design of carbon fiber for structural and functional integration materials in aerospace and beyond.

Graphical abstract

Similar content being viewed by others

References

Zuo P, Leistenschneider D, Kim Y, Ivey DG, Chen W (2021) The effect of thermal pretreatment temperature on the diameters and mechanical properties of asphaltene-derived carbon fibers. J Mater Sci. https://doi.org/10.1007/s10853-021-06249-7

Fan B, Liu Y, He D, Bai J (2017) Enhanced thermal conductivity for mesophase pitch-based carbon fiber/modified boron nitride/epoxy composites. Polymer 122:71–76. https://doi.org/10.1016/j.polymer.2017.06.060

Shimanoe H, Mashio T, Nakabayashi K, Inoue T, Hamaguchi M, Miyawaki J, Mochida I, Yoon S-H (2020) Manufacturing spinnable mesophase pitch using direct coal extracted fraction and its derived mesophase pitch based carbon fiber. Carbon 158:922–929. https://doi.org/10.1016/j.carbon.2019.11.082

Ji T, Feng Y, Qin M, Li S, Zhang F, Lv F, Feng W (2018) Thermal conductive and flexible silastic composite based on a hierarchical framework of aligned carbon fibers-carbon nanotubes. Carbon 131:149–159. https://doi.org/10.1016/j.carbon.2018.02.002

Zhai X, Liu J, Zhang Y, Fan Q, Li Z, Zhou Y (2019) Microcrystal structure evolution of mesophase pitch-based carbon fibers with enhanced oxidation resistance and tensile strength induced by boron doping. Ceram Int 45:11734–11738. https://doi.org/10.1016/j.ceramint.2019.03.049

Huang D, Tan RX, Liu L, Ye C, Zhu SP, Fan Z, Zhang P, Wu H, Han F, Liu HB, Liu JS (2021) Preparation and properties of the three-dimensional highly thermal conductive carbon/carbon-silicon carbide composite using the mesophase-pitch-based carbon fibers and pyrocarbon as thermal diffusion channels. J Eur Ceram Soc 41:4438–4446. https://doi.org/10.1016/j.jeurceramsoc.2021.03.011

Zhang XW, Meng YC, Fan BL, Ma ZK, Song HH (2019) Preparation of mesophase pitch from refined coal tar pitch using naphthalene-based mesophase pitch as nucleating agent. Fuel 243:390–397. https://doi.org/10.1016/j.fuel.2019.01.114

Wang L, Liu Z, Guo Q, Yang J, Dong X, Li D, Liu J, Shi J, Lu C, Liu L (2015) Structure of silicon-modified mesophase pitch-based graphite fibers. Carbon 94:335–341. https://doi.org/10.1016/j.carbon.2015.06.068

Li WW, Kang HL, Xu J, Liu RG (2017) Effects of ultra-high temperature treatment on the microstructure of carbon fibers. Chin J Polym Sci 35:764–772. https://doi.org/10.1007/s10118-017-1922-9

Wang J, Xiao Y, Inoue K, Kawai M, Xue Y (2019) Modeling of nonlinear response in loading-unloading tests for fibrous composites under tension and compression. Compos Struct 207:894–908. https://doi.org/10.1016/j.compstruct.2018.09.054

Yang Z, Yan H (2020) Multiscale modeling and failure analysis of an 8-harness satin woven composite. Compos Struct 242:112186. https://doi.org/10.1016/j.compstruct.2020.112186

Pinho S, Darvizeh R, Robinson P, Schuecker C, Camanho P (2012) Material and structural response of polymer-matrix fibre-reinforced composites. J Compos Mater 46:2313–2341. https://doi.org/10.1177/0021998312454478

Ko S, Choi JE, Lee CW, Jeon YP (2020) Preparation of petroleum-based mesophase pitch toward cost-competitive high-performance carbon fibers. Carbon Lett 30:35–44. https://doi.org/10.1007/s42823-019-00067-3

Bermudez V, Ogale AA (2020) Adverse effect of mesophase pitch draw-down ratio on carbon fiber strength. Carbon. https://doi.org/10.1016/j.carbon.2020.06.062

Kundu S, Ogale AA (2006) Rheostructural studies on a synthetic mesophase pitch during transient shear flow. Carbon 44:2224–2235

Zhao J, Ouyang T, Yao X, Fei Y (2016) The effect of the spinning conditions on the structure of mesophase pitch-based carbon fibers by Taguchi method. Carbon letters 19:89–98. https://doi.org/10.5714/CL.2016.19.089

Alway-Cooper RM, Anderson DP, Ogale AA (2013) Carbon black modification of mesophase pitch-based carbon fibers. Carbon 59:40–48. https://doi.org/10.1016/j.carbon.2013.02.048

Zhang X, Ning S, Ma Z, Song H, Wang D, Zhang M, Fan B, Zhang S, Yan X (2020) The structural properties of chemically derived graphene nanosheets/mesophase pitch-based composite carbon fibers with high conductivities. Carbon 156:499–505. https://doi.org/10.1016/j.carbon.2019.09.085

Ogale AA, Edie DD, Rao AM (2004) Mesophase pitch-based carbon fibers with carbon nanotube reinforcements. US

Mochida I, Yoon SH, Korai Y (1993) Control of transversal texture in circular mesophase pitch-based carbon fibre using non-circular spinning nozzles. J Mater Sci 28:2331–2336. https://doi.org/10.1007/BF01151662

Yoon SH, Takano N, Korai Y, Mochida I (1997) Crack formation in mesophase pitch-based carbon fibres: Part I Some influential factors for crack formation. J Mater Sci 32:2753–2758. https://doi.org/10.1023/A:1018699711846

Cho T, Lee YS, Rao R, Rao AM, Edie DD, Ogale AA (2003) Structure of carbon fiber obtained from nanotube-reinforced mesophase pitch. Carbon 41:1419–1424. https://doi.org/10.1016/s0008-6223(03)00086-1

Yao Y, Chen J, Liu L, Dong Y, Liu A (2014) Mesophase pitch-based carbon fiber spinning through a filter assembly and the microstructure evolution mechanism. J Mater Sci 49:191–198. https://doi.org/10.1007/s10853-013-7692-z

Yuan G, Li X, Dong Z, Xiong X, Rand B, Cui Z, Ye C, Jiang Z, Li Y, Zhang Z (2014) Pitch-based ribbon-shaped carbon-fiber-reinforced one-dimensional carbon/carbon composites with ultrahigh thermal conductivity. Carbon 68:413–425. https://doi.org/10.1016/j.carbon.2013.11.018

Hayes GJ, Edie DD, Kennedy JM (1993) The recoil compressive strength of pitch-based carbon fibres. J Mater Sci 28:3247–3257. https://doi.org/10.1007/BF00354243

Lavin JG, Boyington DR, Lahijani J, Nystem B, Issi JP (1993) The correlation of thermal conductivity with electrical resistivity in mesophase pitch-based carbon fiber. Carbon 31:1001–1002. https://doi.org/10.1016/0008-6223(93)90207-Q

Yao Y, Chen J, Ling L, Dong Y, Liu A (2012) Tailoring structures and properties of mesophase pitch-based carbon fibers based on isotropic/mesophase incompatible blends. J Mater Sci 47:5509–5516. https://doi.org/10.1007/s10853-012-6442-y

Liua Amp Y, Kumara S (2012) Recent progress in fabrication, structure, and properties of carbon fibers. Polym Rev. 52(234):258. https://doi.org/10.1080/15583724.2012.705410

Naito K, Tanaka Y, Yang JM, Kagawa Y (2008) Tensile properties of ultrahigh strength PAN-based, ultrahigh modulus pitch-based and high ductility pitch-based carbon fibers. Carbon 46:189–195. https://doi.org/10.1016/j.carbon.2007.11.001

Qin X, Lu Y, Xiao H, Wen Y, Yu T (2012) A comparison of the effect of graphitization on microstructures and properties of polyacrylonitrile and mesophase pitch-based carbon fibers. Carbon 50:4459–4469. https://doi.org/10.1016/j.carbon.2012.05.024

Lim TH, Yeo SY (2017) Investigation of the degradation of pitch-based carbon fibers properties upon insufficient or excess thermal treatment. Sci Rep 7:1–12. https://doi.org/10.1038/s41598-017-05192-5

Ogale AA, Lin C, Anderson DP, Kearns KM (2002) Orientation and dimensional changes in mesophase pitch-based carbon fibers. Carbon 40:1309–1319. https://doi.org/10.1016/S0008-6223(01)00300-1

Matsumoto M, Iwashita T, Arai Y, Tomioka T (1993) Effect of spinning conditions on structures of pitch-based carbon fiber. Carbon 31:715–720. https://doi.org/10.1016/0008-6223(93)90008-X

Emmerich FG (2014) Young’s modulus, thermal conductivity, electrical resistivity and coefficient of thermal expansion of mesophase pitch-based carbon fibers. Carbon 79:274–293. https://doi.org/10.1016/j.carbon.2014.07.068

Aldosari SM, Khan M, Rahatekar S (2020) Manufacturing carbon fibres from pitch and polyethylene blend precursors: a review. J Mark Res 9:7786–7806. https://doi.org/10.1016/j.jmrt.2020.05.037

Ahn YR, Lee YS, Ogale AA, Yun CH, Park CR (2006) Compressional behavior of carbon nanotube reinforced mesophase pitch-based carbon fibers. Fibers and Polym 7:85–87. https://doi.org/10.1007/BF02933609

Lu S, Blanco C, Rand B (2002) Large diameter carbon fibres from mesophase pitch. Carbon 40:2109–2116. https://doi.org/10.1016/S0008-6223(02)00060-X

Newcomb BA (2016) Processing, structure, and properties of carbon fibers. Compos Part A: Applied Manufactur 91:262–282. https://doi.org/10.1016/j.compositesa.2016.10.018

Kundu S, Ogale AA (2010) Rheostructural studies of a discotic mesophase pitch at processing flow conditions. Rheol Acta 49:845–854. https://doi.org/10.1007/s00397-010-0448-7

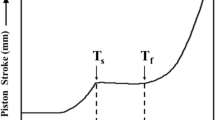

Zhao J, Ouyang T, Yao X, Fei Y (2016) Die swell behavior of liquid crystalline mesophase pitch. J Mater Sci 51:7361–7369. https://doi.org/10.1007/s10853-016-0025-2

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (Grant No.: 531118010508), Special Fund for Innovative Construction Province of Hunan (Grant No.: 2019RS2058, 2020RC3075, 2020GK4029), China Postdoctoral Science Foundation (Grant No.: 2020M672480), the National Natural Science Foundation of China (Grant No.: 52002104), the independent research projects for State Key Laboratory of Advanced Design and Manufacturing for vehicle body (Grant No.: 62065001), and the Science and Technology Planning Project of Changsha (Grant No.: kh2003018).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Chris Cornelius.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, H., Huang, D., Ye, C. et al. Engineering microstructure toward split-free mesophase pitch-based carbon fibers. J Mater Sci 57, 2411–2423 (2022). https://doi.org/10.1007/s10853-021-06770-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06770-9