Abstract

Due to their polymorphism, TiO2 films are quintessential components of state-of-the-art functional materials and devices for various applications from dynamic random access memory to solar water splitting. However, contrary to other semiconductors/dielectric materials, the relationship between structural/morphological and electrical properties at the nano and microscales remains unclear. In this context, the morphological characteristics of TiO2 films obtained by metal–organic chemical vapor deposition (MOCVD) and plasma-enhanced chemical vapor deposition (PECVD), the latter including nitrogen doping, are investigated and they are linked to their in- and out-plane electrical properties. A transition from dense to tree-like columnar morphology is observed for the MOCVD films with increasing deposition temperature. It results in the decrease in grain size and the increase in porosity and disorder, and subsequently, it leads to the decrease in lateral carrier mobility. The increase in nitrogen amount in the PECVD films enhances the disorder in their pillar-like columnar morphology along with a slight increase in density. A similar behavior is observed for the out-plane current between the low temperature MOCVD films and the undoped PECVD ones. The pillar-like structure of the latter presents a lower in-plane resistivity than the low temperature MOCVD films, whereas the out-plane resistivity is lower. The tree-like columnar structure exhibits poor in- and out-plane conductivity properties, whereas pillar-like and dense TiO2 exhibits similar in- and out-plane conductivities even if their morphologies are noticeably different.

Graphical Abstract

Similar content being viewed by others

References

Kim SK, Choi GJ, Lee SY, Seo M, Lee SW, Han JH, Ahn HS, Han S, Hwang CS (2008) Al-doped TiO2 films with ultralow leakage currents for next generation DRAM capacitors. Adv Mat 20:1429–1435

Archa T, Arivanandhan M, Jayavel R (2019) TiO2 nanostructures with controlled morphology for improved electrical properties of photoanodes and quantum dot sensitized solar cell characteristics. Surf Interfaces 17:100350

Fujishima A, Honda K (1972) electrochemical photolysis of water at a semiconductor electrode. Nature 238:37–38

Singh R, Dutta S (2018) A review on H2 production through photocatalytic reactions using TiO2/TiO2-assisted catalysts. Fuel 220:607–620

Docampo P, Guldin S, Steiner U, Snaith HJ (2013) Charge transport limitations in self-assembled TiO2 photoanodes for Dye-sensitized solar cells. J Phys Chem Lett 4:698–703

Suhail MH, Mohan Rao G, Mohan S (1992) dc reactive magnetron sputtering of titanium-structural and optical characterization of TiO2 films. J Appl Phys 71:1421

Niemelä JP, Marin G, Karppinen M (2017) Titanium dioxide thin films by atomic layer deposition: a review. Semicond Sci Technol 32:093005

Baryshnikova M, Filatov L, Mishin M, Uvarov A, Kondrateva A, Alexandrov S (2015) Evolution of the microstructure in titanium dioxide films during chemical vapor deposition. Phys Status Solidi 212:1533–1538

Kim SJ, Dang VS, Xu K, Barreca D, Maccato C, Carraro G, Bhakta RK, Winter M, Becker HW, Rogalla D, Sada C, Fischer RA, Devi A (2015) MOCVD of TiO2 thin films from a modified titanium alkoxide precursor. Phys Status Solidi A 7:1563–1570

Amassian A, Desjardins P, Martinus L (2004) Study of TiO2 film growth mechanisms in low-pressure plasma by in situ real-time spectroscopic ellipsometry. Thin Solids Films 447:40–45

Li D, Goullet A, Carette M, Granier A, Ladesman JP (2016) Effect of growth interuptions on TiO2 films deposited by plasma enhanced chemical vapour deposition. Mater Chem Phys 182:409–417

Rafieian D, Ogieglo W, Savenije T, Lammertink RGH (2015) Controlled formation of anatase and rutile TiO2 thin films by reactive magnetron sputtering. AIP Adv 5:097168

Suciu RC, Indrea E, Silipas TD, Dreve S, Rosu MC, Popescu V, Popescu G, Nascu HI (2009) TiO2 thin films prepared by sol–gel method. J Phys Conf Ser 182:012080

Karuppuchamy S, Nonomura K, Yoshida T, Sugiura T, Minoura H (2002) Cathodic electrodeposition of oxide semiconductor thin films and their application to dye-sensitized solar cells. Solid State Ionics 151:19–27

Tang H, Prasad K, Sanjinès R, Schmid PE, Lévy F (1994) Electrical and optical properties of TiO2 anatase thin films. J Appl Phys 75:2042

Bakri AS, Sahdan MZ, Adriyanto F, Raship NA, Said NDM, Abdullah SA, Rahim MS (2017) Effect of annealling temperature of titanium dioxide thin films on structural and electrical properties. AIP Conf Proc 1788:030030

Lévy F, Berger H, Forro L, Zuppiroli L, Emin D, Chauvet O (2002) High mobility n-type charge carriers in large single crystals of anatase (TiO2). J Appl Phys 75:633–635

Dorow-Gerspach D, Wuttig M (2019) Metal-like conductivity in undoped TiO2-x: Understanding an unconventional transparent conducting oxide. Thin Solid Films 669:1–7

Hun OhS, Jin Kim D, Hong Hahn S, Jung Kim E (2003) Comparison of optical and photocatalytic properties of TiO2 thin films prepared by electron-beam evaporation and sol-gel dip-coating. Mater Lett 57:4151–4155

Chen J, Tao HB, Liu B (2017) Unraveling the intrinsic structures that influence the transport of charges in TiO2 electrodes. Adv Energy Mater 1700886:1–30

Song SH, Wang X, Xiao P (2002) Effect of microstructural features on the electrical properties of TiO2. Mater Sci Eng B 94:40–47

Bhachu DS, Egdell RG, Sankar G, Carmalt CJ, Parkin IP (2017) Electronic properties of antimony-doped anatase TiO2 thin films preparated by aerosol assisted chemical vapour deposition. J Mater Chem C 5:9694–9701

Hernadez S, Hidalgo D, Sacco A, Chiodoni A, Lamberti A, Cauda V, Tresco E, Saracco G (2015) Comparison of photocatalytic and transport properties of TiO2 and ZnO nanostructures for solar-driven water splitting. Phys Chem Chem Phys 17:7775–7786

de Souza A, Filho E, Pieretti EF, Teixeira Bento R, Marina Fuser Pillis M (2020) Effect of nitrogen-doping on the surface chemistry and corrosion stability of TiO2 films. J Mater Res and Technol 9(1):922–934

Slonopas A, Melia M, Xie K, Globus T, Fitz-Gerald JM, Norris P (2016) Factors limiting doping efficiency of Iridium in pulsed laser deposited TiO2 transparent conducting oxide. J Mat Sci 51:8995–9004

Miquelot A, Debieu O, Rouessac V, Villeneuve C, Prud’homme N, Cure J, Constantoudis V, Papavieros G, Roualdes S, Vahlas C (2019) TiO2 nanotree films for the production of green H2 by solar water splitting: from microstructural and optical characteristics to the photocathalytic properties. Appl Surf Sci 494:1127–1137

Youssef L, Kinfack Leoga-infack AJ, Roualdes S, Bassil J, Zakhour M, Rouessac V, Ayral A, Nakhl M (2017) Optimization of N-doped TiO2 multifunctional thin layers by low frequency PECVD process. Eur Ceram Soc 37:5289–5303

Chen J, Bin Yang H, Tao HB, Zhang L, Miao J, Wang HY, Chen J, Zhang H, Liu B (2016) Surface rutilization of anatase TiO2 nanorods for creation of synergistically bridging and fencing electron highways. Adv Funct Mater 26:456–465

Murakami K, Rommel M, Hudec B, Rosova A, Husekova K, Dobrocka E, Rammula R, Kasikov A, Han JH, Lee W, Song SJ, Paskaleva A, Bauer AJ, Frey L, Frohlich K, Aarik J, Hwang CS (2014) Nanoscale characterization of TiO2 films grown by atomic layer deposition on RuO2 electrodes. Appl Mat Interfaces 6:2486–2492

Duminica FD, Maury F, Senocq F (2004) Atmospheric pressure MOCVD of TiO2 thin films using various reactive gas mixtures. Surf Coat Techn 188(255):255–259

Yu YP, Liu W, Wu SX, Li SW (2012) Impact of nitrogen doping on electrical conduction in anatase TiO2 thin films. J Phys Chem C 116(37):19625–19629

Aviziotis IG, Cheimarios N, Duguet T, Vahlas C, Boudouvis AG (2016) Multiscale modeling and experimental analysis of chemical vapor deposited aluminum films: linking reactor operating conditions with roughness evolution. Chem Eng Sci 155:449–458

Hersee SD, Ballingall JM (1990) The operation of metalorganic bubblers at reduced pressure. J Vac Sci Technol A 8:800

Tauc J (1968) Optical properties and electronic structure of amorphous Ge and Si. Mater Res Bull 3:37–46

Gunes M, Sato H, Pinsard-Gaudart L, Berardan D, Dragoe N (2017) A versatile system for hall effect measurements at high temperature. Meas Sci Technol 28:105905

Lindemuth J and Mizuta S I (2011) Hall measurements on low-mobility materials and high resistivity materials, Proc. SPIE 8110, Thin Film Solar Technology III, 81100I https://doi.org/https://doi.org/10.1117/12.893100

Werner F (2017) Hall measurements on low-mobility thin films. J Appl Phys 122:135306

Pecunia V, Occhipinti LG, Chakraborty A, Pan Y, Peng Y (2020) Lead-free halide perovskite photovoltaics: challenges, open questions, and opportunities. APL Mater 8:100901

Youssef L, Roualdes S, Bassil J, Zakhour M, Rouessac V, Lamy C, Nakhl M (2019) Effect of plasma power on the semiconducting behavior of low-frequency PECVD TiO2 and nitrogen-doped TiO2 anodic thin coatings: photo-electrochemical studies in a single compartment cell for hydrogen generation by solar water splitting. J Appl Electrochem 49:135–150

Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y (2001) Visible-light photocatalysis in nitrogen-doped titanium dioxide. Science 293:269–271

Zhao Z, Liu Q (2008) Mechanism of higher photocatalytic activity of anatase TiO2 doped with nitrogen under visible-light irradiation from density functional theory calculation. J Phys D Appl Phys 41:025105

Bak T, Nowotny J, Nowotny MK (2006) Defect disorder of titanium dioxide. J Phys Chem B 110:21560–21567

Nowotny J, Alim MA, Bak T, Idris MA, Ionescu M, Prince K, Sahdan MZ, Sopian K, Mat Teridie MA, Sigmundf W (2015) Defect chemistry and defect engineering of TiO2-based semiconductors for solar energy conversion. Chem Soc Rev 44:8424–8442

Bernardi MIB, Lee EJH, Lisboa-Filho PN, Leite ER, Longo E, Varela JA (2001) TiO2 thin film growth using the MOCVD method. Mat Res 4(3):223–226. https://doi.org/10.1590/S1516-14392001000300014

Cheng X, Gotoh K, Nakagawa Y, Usami N (2018) Effect of substrate type on the electrical and structural properties of TiO2 thin films deposited by reactive DC sputtering. J Cryst Growth 491:120–125

Michalas L, Khiat A, Stathopoulos S, Prodromakis T (2018) Electrical characteristics of interfacial barriers at metal—TiO2 contacts. J Phys D Appl Phys 51:425101

Yildiz A, Lisesivdin SB, Kasap M, Mardare D (2007) High temperature variable-range hopping conductivity in undoped TiO2 thin film. Optoelectron Adv Mater 1:531

Wang W, Feng X, Ma X, He L, Cao Q, Ma J (2017) Epitaxial growth and properties of Nb-doped anatase TiO2 films on LSAT by MOCVD. J Alloy Compd 729:38–42

Krasienapibal TS, Fukumura T, Hirose Y, Hasegawa T (2014) Improved room temperature electron mobility in self-buffered anatase TiO2 epitaxial thin film grown at low temperature. Jpn J Appl Phys 53:090305

Youssef L (2018) Développement par procédé plasma de couches minces de type TiO2 dopé à l’azote pour la production d’hydrogène par photo-électrolyse de l’eau sous lumière solaire, PhD thesis, 19 novembre 2018 (Univ. Montpellier, France)

Warren SC, Voitchovsky K, Dotan H, Leroy CM, Cornuz M, Stellaci F, Hebert C, Rothschild A, Grätzel M (2013) Indentifying champion nanostructures for solar water-splitting. Nat Mater 12:842–849

Sorensen PR (1982) Conductivity, charge transfer and transport number: an AC-investigation of the polymer electrolyte LiSCN-poly (ethylenoxide). Electrochim Acta 27:1671–1675

Nara H, Mukoyama D, Shimizu R, Momma T, Osaka T (2019) Systematic analysis of interfacial resistance between cathode layer and the current collector in lithium-ion batteries by electrochemical impedance spectroscopy. J Power Sources 409:139–147

Nizard H, Kosinova ML, Fainer NI, Rumyantsev YM, Ayupov BM, Shubin YV (2008) Deposition of titanium dioxide from TTIP by plasma enhanced and remote plasma enhanced chemical vapor deposition. Surf Coat Technol 202:4076–4985

Acknowledgements

This work was supported by funding from Toulouse Tech'Interlab and Association Instituts Carnot.

Funding

This project has been funded with support from Lebanese University (UL) in collaboration with AZM&SAADÉ foundation.

Author information

Authors and Affiliations

Contributions

We are indebted to Olivier Debieu, Claire Tendero, Diane Samelor, Daniel Sadowski, Cédric Charvillat, Olivier Marsan, Jérôme Esvan, Benoît Malard, Bertrand Viguier, Alessandro Pugliara (Cirimat), Stéphane Leblond du Plouy, Arnaud Proietti, Claudie Josse (UMS Castaing) and Emmanouil Soulos (IEM) for their contributions to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Till Froemling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

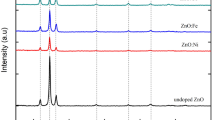

Appendix 1: TiO2 thin films crystallographic orientation

Figure

10 compares XRD patterns obtained in a theta-theta mode on TiO2 films deposited by MOCVD on silicon and SiO2 substrates, respectively at the different Td. For both substrates, peaks measured at 25.4, 38.5, 48.1, 55.1, 62.7, 70.3, 75 and 76° correspond to the (101), (112), (020), (121), (024), (220), (125) and (031) crystallographic planes of anatase, respectively. Concerning films deposited at temperature ranging from 325 °C to 400 °C on Si substrate (Fig. 10a), similar diffractograms are obtained with two major peaks (101) and (020). At higher temperature (450 °C–500 °C), we assist to the vanishing of (101) and (020) peaks, whereas the (112) and the (220) peaks increase. The same behavior is observed for films deposited on SiO2 substrate. These results emphasize that for our TiO2 films the substrate has only a slight influence on films morphology.

Appendix 2: TiO2 absorption spectrum

Figure 11a represents the transmission spectra for various deposition temperatures. At high temperature, interference fringes are clearly visible. Interferences and increasing of transmission signal compared to low temperature are due to high surface roughness related to large structures. Figures from A2b to A2e depict the Tauc plot of the absorption coefficient α for indirect semiconductors related to transmission spectrum (Fig. 11a). The tangent plot permits to determine energy gap. However, some issues appear at low and high temperatures. For low temperature (325 °C and 350 °C), the gap determination is impossible as the linear part is not reached. For high temperature (450 °C and 500 °C), the gap determination is possible but interference fringes impact determination reliability.

a Transmission spectrum for TiO2 layers processed by MOCVD at different temperatures. The following color coding is used: 325 °C (dark blue), 350 °C (light blue), 375 °C (green), 400 °C (yellow), 450 °C (orange) and 500 °C (red). Tauc plot of the absorption coefficient determined by UV–Vis–Nir transmission spectroscopy for samples deposited at b 375 °C, c 400 °C, d 450 °C and e 500 °C

Rights and permissions

About this article

Cite this article

Miquelot, A., Youssef, L., Villeneuve-Faure, C. et al. In- and out-plane transport properties of chemical vapor deposited TiO2 anatase films. J Mater Sci 56, 10458–10476 (2021). https://doi.org/10.1007/s10853-021-05955-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05955-6