Abstract

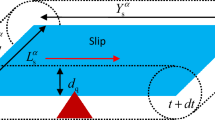

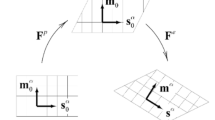

An innovative crystal plasticity model was developed by incorporating the dislocation density-based hardening law, in which the grain-level hardening behavior is dependent on the evolution of the dislocation density in the cell walls and cell interiors and the evolution of the volume fraction of the cell walls. The large plastic deformations of OFHC copper single crystals and polycrystals were simulated by the two crystal plasticity models in conjunction with the dislocation density-based hardening law and the classic saturation-type phenomenological hardening law, respectively. A comprehensive comparison study on the 2 hardening laws was accordingly carried out in terms of the stress–strain responses and texture evolutions. The simulation results of the two crystal plasticity models conjuncted with the different hardening laws have a good consistency, and both of them are generally in good agreement with the experimental data, which therefore validate the developed crystal plasticity model incorporated with the dislocation density-based hardening law. The Taylor-type mean-field model and Voronoi-type full-field model were, respectively, used as the homogenization schemes to calculate the macroscopic stress–strain responses of the polycrystalline aggregate, and the two kinds of calculated results were compared and analyzed in detail. By using the Taylor-type mean-field crystal plasticity finite element method (CPFEM), the processes of single shot impact along the different impact angles were numerically simulated; the macroscopic plastic deformations, microscopic texture evolutions and dislocation density evolutions were resultantly investigated, which would conduce to the further study on the microscopic strengthening mechanisms of shot peening or surface mechanical attrition treatment, and the rise of the new ideas for relevant modeling.

Similar content being viewed by others

References

Naghdi PM (1990) A critical review of the state of finite plasticity. Zeitschrift für angewandte Mathematik und Physik ZAMP 41(3):315–394. https://doi.org/10.1007/BF00959986

Sachs G (1929) Zur Ableitung einer Fließbedingung. Mitteilungen der deutschen Materialprüfungsanstalten. Springer, Berlin, Heidelberg, pp 94–97

Taylor GI (1938) Plastic strain in metals. J Inst Metals 62:307–324

Hill R (1966) Generalized constitutive relations for incremental deformation of metal crystals by multislip. J Mech Phys Solids 14(2):95–102. https://doi.org/10.1016/0022-5096(66)90040-8

Hill R (1967) The essential structure of constitutive laws for metal composites and polycrystals. J Mech Phys Solids 15(2):79–95. https://doi.org/10.1016/0022-5096(67)90018-X

Hill R, Rice JR (1972) Constitutive analysis of elastic-plastic crystals at arbitrary strain. J Mech Phys Solids 20(6):401–413. https://doi.org/10.1016/0022-5096(72)90017-8

Asaro RJ, Rice JR (1977) Strain localization in ductile single crystals. J Mech Phys Solids 25(5):309–338. https://doi.org/10.1016/0022-5096(77)90001-1

Asaro RJ (1983) Micromechanics of crystals and polycrystals. Adv Appl Mech 23(8):1–115. https://doi.org/10.1016/S0065-2156(08)70242-4

Peirce D, Shih CF, Needleman A (1984) A tangent modulus method for rate dependent solids. Comput Struct 18(5):875–887. https://doi.org/10.1016/0045-7949(84)90033-6

Anand L, Kalidindi SR (1994) The process of shear band formation in plane strain compression of fcc metals: effects of crystallographic texture. Mech Mater 17(2–3):223–243. https://doi.org/10.1016/0167-6636(94)90062-0

Delaire F, Raphanel JL, Rey C (2000) Plastic heterogeneities of a copper multicrystal deformed in uniaxial tension: experimental study and finite element simulations. Acta Mater 48(5):1075–1087. https://doi.org/10.1016/S1359-6454(99)00408-5

Raabe D, Sachtleber M, Zhao Z, Roters F, Zaefferer S (2001) Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater 49(17):3433–3441. https://doi.org/10.1016/S1359-6454(01)00242-7

Dawson PR, MacEwen SR, Wu PD (2003) Advances in sheet metal forming analyses: dealing with mechanical anisotropy from crystallographic texture. Int Mater Rev 48(2):86–122. https://doi.org/10.1179/095066003225002415

Huang SY, Zhang SR, Li DY, Peng YH (2011) Simulation of texture evolution during plastic deformation of FCC, BCC and HCP structured crystals with crystal plasticity based finite element method. Trans Nonferrous Metal Soc 21(8):1817–1825. https://doi.org/10.1016/S1003-6326(11)60936-9

Knezevic M, Savage DJ (2014) A high-performance computational framework for fast crystal plasticity simulations. Comput Mater Sci 83:101–106. https://doi.org/10.1016/j.commatsci.2013.11.012

Kweon S, Raja DS (2017) Comparison of anisotropy evolution in BCC and FCC metals using crystal plasticity and texture analysis. Eur J Mech A Solid 62:22–38. https://doi.org/10.1016/j.euromechsol.2016.11.002

Huang Y (1991) A user-material subroutine incroporating single crystal plasticity in the ABAQUS finite element program. Harvard University, Cambridge

Lebensohn RA, Tomé CN (1993) A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: application to zirconium alloys. Acta Metall Mater 41(9):2611–2624. https://doi.org/10.1016/0956-7151(93)90130-K

Marin EB, Dawson PR (1998) On modelling the elasto-viscoplastic response of metals using polycrystal plasticity. Comput Method Appl M 165(1–4):1–21. https://doi.org/10.1016/S0045-7825(98)00034-6

Roters F, Eisenlohr P, Kords C, Tjahjanto DD, Diehl M, Raabe D (2012) DAMASK: the Düsseldorf advanced material Simulation Kit for studying crystal plasticity using an FE based or a spectral numerical solver. Proc IUTAM 3:3–10. https://doi.org/10.1016/j.piutam.2012.03.001

Yaghoobi M, Ganesan S, Sundar S, Lakshmanan A, Rudraraju S, Allison JE, Sundararaghavan V (2019) PRISMS-plasticity: an open-source crystal plasticity finite element software. Comput Mater Sci 169:109078. https://doi.org/10.1016/j.commatsci.2019.109078

Schmid E (1924) Yield point of a crystals: critical shear stress law. Proc Internat Congr Appl Mech 342

Kohar CP, Bassani JL, Brahme A, Muhammad W, Mishra RK, Inal K (2019) A new multi-scale framework to incorporate microstructure evolution in phenomenological plasticity: theory, explicit finite element formulation, implementation and validation. Int J Plast 117:122–156. https://doi.org/10.1016/j.ijplas.2017.08.006

Khan AS, Liu J (2016) A deformation mechanism based crystal plasticity model of ultrafine-grained/nanocrystalline FCC polycrystals. Int J Plast 86:56–69. https://doi.org/10.1016/j.ijplas.2016.08.001

Peirce D, Asaro RJ, Needleman A (1982) An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall 30(6):1087–1119. https://doi.org/10.1016/0001-6160(82)90005-0

Kalidindi SR, Bronkhorst CA, Anand L (1992) Crystallographic texture evolution in bulk deformation processing of FCC metals. J Mech Phys Solids 40(3):537–569. https://doi.org/10.1016/0022-5096(92)80003-9

Kalidindi SR, Anand L (1994) Macroscopic shape change and evolution of crystallographic texture in pre-textured FCC metals. J Mech Phys Solids 42(3):459–490. https://doi.org/10.1016/0022-5096(94)90027-2

Agnew SR, Yoo MH, Tome CN (2001) Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater 49(20):4277–4289. https://doi.org/10.1016/S1359-6454(01)00297-X

Khadyko M, Dumoulin S, Cailletaud G, Hopperstad OS (2016) Latent hardening and plastic anisotropy evolution in AA6060 aluminium alloy. Int J Plast 76:51–74. https://doi.org/10.1016/j.ijplas.2015.07.010

Zecevic M, Knezevic M (2018) Latent hardening within the elasto-plastic self-consistent polycrystal homogenization to enable the prediction of anisotropy of AA6022-T4 sheets. Int J Plast 105:141–163. https://doi.org/10.1016/j.ijplas.2018.02.007

Wu PD, Neale KW, Van der Giessen E (1996) Simulation of the behaviour of FCC polycrystals during reversed torsion. Int J Plast 12(9):1199–1219. https://doi.org/10.1016/S0749-6419(96)00048-4

Guo XQ, Ma C, Wang H, Miao XB, Wu PD (2019) Numerical study of large strain behavior of OFHC copper: the role of latent hardening. Mater Sci Eng A Struct 744:386–395. https://doi.org/10.1016/j.msea.2018.12.028

Mecking H, Kocks UF (1981) Kinetics of flow and strain-hardening. Acta Metall 29(11):1865–1875. https://doi.org/10.1016/0001-6160(81)90112-7

Estrin Y, Mecking H (1984) A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall 32(1):57–70. https://doi.org/10.1016/0001-6160(84)90202-5

Ma A, Roters F, Raabe D (2006) A dislocation density based constitutive model for crystal plasticity FEM including geometrically necessary dislocations. Acta Mater 54(8):2169–2179. https://doi.org/10.1016/j.actamat.2006.01.005

Alankar A, Mastorakos IN, Field DP (2009) A dislocation-density-based 3D crystal plasticity model for pure aluminum. Acta Mater 57(19):5936–5946. https://doi.org/10.1016/j.actamat.2009.08.028

Lee MG, Lim H, Adams BL, Hirth JP, Wagoner RH (2010) A dislocation density-based single crystal constitutive equation. Int J Plast 26(7):925–938. https://doi.org/10.1016/j.ijplas.2009.11.004

Nix WD, Gibeling JC, Hughes DA (1985) Time-dependent deformation of metals. Metall Trans A 16(12):2215–2226. https://doi.org/10.1007/BF02670420

Ungar T, Mughrabi H, Rönnpagel D, Wilkens M (1984) X-ray line-broadening study of the dislocation cell structure in deformed [001]-orientated copper single crystals. Acta Metall 32(3):333–342. https://doi.org/10.1016/0001-6160(84)90106-8

Ungár T, Tóth LS, Illy J, Kovacs I (1986) Dislocation structure and work hardening in polycrystalline OFHC copper rods deformed by torsion and tension. Acta Metall 34(7):1257–1267. https://doi.org/10.1016/0001-6160(86)90012-X

Estrin Y (1998) Dislocation theory based constitutive modelling: foundations and applications. J Mater Process Technol 80:33–39. https://doi.org/10.1016/S0924-0136(98)00208-8

Estrin Y, Toth LS, Molinari A, Brechet Y (1998) A dislocation-based model for all hardening stages in large strain deformation. Acta Mater 46(15):5509–5522. https://doi.org/10.1016/S1359-6454(98)00196-7

Estrin Y, Kim HS (2007) Modelling microstructure evolution toward ultrafine crystallinity produced by severe plastic deformation. J Mater Sci 42(5):1512–1516. https://doi.org/10.1007/s10853-006-1282-2

Roters F, Raabe D, Gottstein G (2000) Work hardening in heterogeneous alloys: a microstructural approach based on three internal state variables. Acta Mater 48(17):4181–4189. https://doi.org/10.1016/S1359-6454(00)00289-5

Prasad G, Goerdeler M, Gottstein G (2005) Work hardening model based on multiple dislocation densities. Mater Sci Eng A Struct 400:231–233. https://doi.org/10.1016/j.msea.2005.03.061

Zhang HM, Dong XH, Du DP, Wang Q (2013) A unified physically based crystal plasticity model for FCC metals over a wide range of temperatures and strain rates. Mater Sci Eng A Struct 564:431–441. https://doi.org/10.1016/j.msea.2012.12.001

Lim H, Battaile CC, Bishop JE, Foulk JW (2019) Investigating mesh sensitivity and polycrystalline RVEs in crystal plasticity finite element simulations. Int J Plast 121:101–115. https://doi.org/10.1016/j.ijplas.2019.06.001

Han FB, Diehl M, Roters F, Raabe D (2020) Using spectral-based representative volume element crystal plasticity simulations to predict yield surface evolution during large scale forming simulations. J Mater Process Tech 277:116449. https://doi.org/10.1016/j.jmatprotec.2019.116449

Wang C, Wu HL, Wang XG, Wang CL, Wang L (2020) Numerical study of microscale laser bulging based on crystal plasticity. Int J Mech Sci 177:105553. https://doi.org/10.1016/j.ijmecsci.2020.105553

Guo XQ, Wu PD, Wang H, Mao XB, Neale KW (2016) Study of large strain behavior of OFHC copper: The role of polycrystal plasticity model. Int J Solids Struct 90:12–21. https://doi.org/10.1016/j.ijsolstr.2016.04.015

Lebensohn RA, Kanjarla AK, Eisenlohr P (2012) An elasto-viscoplastic formulation based on fast Fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int J Plast 32:59–69. https://doi.org/10.1016/j.ijplas.2011.12.005

Eisenlohr P, Diehl M, Lebensohn RA, Roters F (2013) A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int J Plast 46:37–53. https://doi.org/10.1016/j.ijplas.2012.09.012

Roters F, Eisenlohr P, Hantcherli L, Tjahjanto DD, Bieler TR, Raabe D (2010) Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: theory, experiments, applications. Acta Mater 58(4):1152–1211. https://doi.org/10.1016/j.actamat.2009.10.058

Knezevic M, Beyerlein IJ, Nizolek T, Mara NA, Pollock TM (2013) Anomalous basal slip activity in zirconium under high-strain deformation. Mater Res Lett 1(3):133–140. https://doi.org/10.1080/21663831.2013.794375

Lu XC, Zhang X, Shi MX, Roters F, Kang GZ, Raabe D (2019) Dislocation mechanism based size-dependent crystal plasticity modeling and simulation of gradient nano-grained copper. Int J Plast 113:52–73. https://doi.org/10.1016/j.ijplas.2018.09.007

Roters F, Diehl M, Shanthraj P, Eisenlohr P, Reuber C, Wong SL, Maiti T, Ebrahimi A, Hochrainer T, Fabritius HO, Nikolov S, Friak M, Fujita N, Grilli N, Janssens KGF, Jia N, Kok PJJ, Ma D, Meier F, Werner E, Stricker M, Weygand D, Raabe D (2019) DAMASK–the Düsseldorf advanced material simulation kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput Mater Sci 158:420–478. https://doi.org/10.1016/j.commatsci.2018.04.030

Zhang HM, Dong XH, Wang Q, Zeng Z (2012) An effective semi-implicit integration scheme for rate dependent crystal plasticity using explicit finite element codes. Comput Mater Sci 54:208–218. https://doi.org/10.1016/j.commatsci.2011.10.011

Bronkhorst CA, Kalidindi SR, Anand L (1992) Polycrystalline plasticity and the evolution of crystallographic texture in FCC metals. Philos Trans R Soc Lond Ser A Phys Eng Sci 341(1662):443–477. https://doi.org/10.1098/rsta.1992.0111

Ludwik P (1909) Elemente der technologischen Mechanik. Springer. https://doi.org/10.1007/978-3-662-40293-1

Ding H, Shen N, Shin YC (2011) Modeling of grain refinement in aluminum and copper subjected to cutting. Comput Mater Sci 50(10):3016–3025. https://doi.org/10.1016/j.commatsci.2011.05.020

Paik S, Kumar N, Dutta BK, Durgaprasad PV, Tewari R (2020) Deformation of copper single crystals: comparison of experimental results with crystal plasticity simulations. Mater Today Commun 24:100997. https://doi.org/10.1016/j.mtcomm.2020.100997

Zehetbauer M, Schafler E, Ungar T, Kopacz I, Bernstorff S (2002) Investigation of the microstructural evolution during large strain cold working of metals by means of synchrotron radiation—a comparative overview. J Eng Mater-T ASME 124(1):41–47. https://doi.org/10.1115/1.1421049

Toth LS, Molinari A, Estrin Y (2002) Strain hardening at large strains as predicted by dislocation based polycrystal plasticity model. J Eng Mater-T ASME 124(1):71–77. https://doi.org/10.1115/1.1421350

Patra A, Zhu T, McDowell DL (2014) Constitutive equations for modeling non-Schmid effects in single crystal bcc-Fe at low and ambient temperatures. Int J Plast 59:1–14. https://doi.org/10.1016/j.ijplas.2014.03.016

Zhao JF, Lu XC, Yuan FP, Kan QH, Qu SX, Kang GZ, Zhang X (2020) Multiple mechanism based constitutive modeling of gradient nanograined material. Int J Plasticity 125:314–330. https://doi.org/10.1016/j.ijplas.2019.09.018

Wang C, Wang L, Wang XG, Xu YJ (2018) Numerical study of grain refinement induced by severe shot peening. Int J Mech Sci 146:280–294. https://doi.org/10.1016/j.ijmecsci.2018.08.005

Wang C, Lai Y, Wang L, Wang CL (2020) Dislocation-based study on the influences of shot peening on fatigue resistance. Surf Coat Tech 383:125247. https://doi.org/10.1016/j.surfcoat.2019.125247

Wang C, Hu JC, Gu ZB, Xu XJ, Wang XG (2017) Simulation on residual stress of shot peening based on a symmetrical cell model. Chin J Mech Eng 30(2):344–351. https://doi.org/10.1007/s10033-017-0084-6

Kim T, Lee JH, Lee H, Cheong S (2010) An area-average approach to peening residual stress under multi-impacts using a three-dimensional symmetry-cell finite element model with plastic shots. Mater Des 31(1):50–59. https://doi.org/10.1016/j.matdes.2009.07.032

Acknowledgements

The authors are grateful for the supports provided by Anhui Provincial Natural Science Foundation (2008085QE228), Public Technology Research Program of Zhejiang Province (LGG21E050013), Natural Science Foundation of Anhui Higher Education Institutions of China (KJ2019A0126) and the Foundation of Anhui University of Science and Technology (QN2018106).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, C., Wang, X., Wang, C. et al. A comparative study of plastic deformation behaviors of OFHC copper based on crystal plasticity models in conjunction with phenomenological and dislocation density-based hardening laws. J Mater Sci 56, 8789–8814 (2021). https://doi.org/10.1007/s10853-021-05816-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05816-2