Abstract

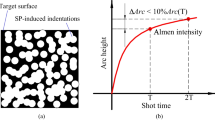

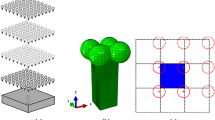

The symmetrical cell model is widely used to study the residual stress induced by shot peening. However, the correlation between the predicted residual stresses and the shot peening coverage, which is a big challenge for the researchers of the symmetrical cell model, is still not established. Based on the dynamic stresses and the residual stresses outputted from the symmetrical cell model, the residual stresses corresponding to full coverage are evaluated by normal distribution analysis. The predicted nodal dynamic stresses with respect to four corner points indicate that the equi-biaxial stress state exists only for the first shot impact. Along with the increase of shot number, the interactions of multiple shot impacts make the fluctuation of the nodal dynamic stresses about an almost identical value more and more obvious. The mean values and standard deviations of the residual stresses gradually tend to be stable with the increase of the number of shot peening series. The mean values at each corner point are almost the same after the third peening series, which means that an equi-biaxial stress state corresponding to the full coverage of shot peening is achieved. Therefore, the mean values of the nodal residual stresses with respect to a specific transverse cross-section below the peened surface can be used to correlate the measured data by X-ray. The predicted residual stress profile agrees with the experimental results very well under 200% peening coverage. An effective correlation method is proposed for the nodal residual stresses predicted by the symmetrical cell model and the shot peening coverage.

Similar content being viewed by others

References

WANG R Z, RU J L. Overall evaluation of the effect of residual stress induced by shot peening in the improvement of fatigue fracture resistance for metallic materials[J]. Chinese Journal of Mechanical Engineering, 2015, 28(2): 416–421.

MIAO H, ZUO D W, WANG M, et al. Numerical calculation and experimental research on residual stress in precipitation-hardening layer of NAK80 steel for shot peening[J]. Chinese Journal of Mechanical Engineering, 2011, 24(3): 439–445.

FU P, JIANG C, ZHANG Z, et al. Residual stress and micro-structure of GCr15 steel after multistep shot peening[J]. Surface Engineering, 2014, 30(11): 847–851.

ZHAO C M, GAO Y K, GUO J, et al. Investigation on residual stress induced by shot peening[J]. Journal of Materials Engineering and Performance, 2015, 24: 1340–1346.

SONG W T, XU C G, PAN Q X, et al. Nondestructive testing and characterization of residual stress field using an ultrasonic method[J]. Chinese Journal of Mechanical Engineering, 2016, 29(2): 365–371.

LV Y, LEI L Q, SUN L N. Effect of shot peening on the fatigue resistance of laser surface melted 20CrMnTi steel gear[J]. Materials Science & Engineering A, 2015, 629: 8–15.

HE B Y, SOADY K A, MELLOR B G, et al. Fatigue crack growth behavior in the LCF regime in a shot peened steam turbine blade material[J]. International Journal of Fatigue, 2016, 82: 280–291.

XING Y M, LU J. An experimental study of residual stress induced by ultrasonic shot peening[J]. Journal of Materials Processing Technology, 2004, 152: 56–61.

MIAO H Y, DEMERS D, LAROSE S, et al. Experimental study of shot peeening and stress peen forming[J]. Journal of Materials Processing Technology, 2010, 210(15): 2089–2102.

LING X, PENG W W, NI H F. Simulation of 3D residual stress field of shot peening by dynamic finite element analysis[J]. Chinese Journal of Mechanical Engineering, 2006, 42(8): 182–189. (in Chinese).

LI Y, LEI L P, ZENG P. Shot stream finite element model for shot peening numerical simulation and its experiment study[J]. Chinese Journal of Mechanical Engineering, 2011, 47(22): 43–48. (in Chinese).

WANG B, WU L Z, MA L, et al. Low-velocity impact characteristics and residual tensile strength of carbon fiber composite lattice core sandwich structures [J]. Composites Part B: Engineering, 2011, 42(4): 891–897.

AL-OBAID Y F. A rudimentary analysis of improving fatigue life of metals by shot-peening[J]. Journal of Applied Mechanics, 1990, 57(2): 307–312.

Al-Obaid Y F. Three-dimensional dynamic finite element analysis for shot-peening mechanics[J]. Computers & Structures, 1990, 36(4): 681–689.

Al-Obaid Y F. Shot peening mechanics: experimental and theoretical analysis[J]. Mecahnics of Materials, 1995, 19(2): 251–260.

HONG T, OOI J Y, SHAW B. A numerical simulation to relate the shot peening parameters to the induced residual stresses[J]. Engineering Failure Analysis, 2008, 15: 1097–1110.

MEGUID S A, SHAGAL G, STRANART J C. 3D FE analysis of peening of strain-rate sensitive materials using multiple impingement model[J]. International Journal of Impact Engineering, 2002, 27: 119–134.

MEGUID S A, SHAGAL G, STRANART J C. Development and validation of novel FE models for 3D analysis of peening of strain-rate sensitive materials[J]. Journal of Engineering Materials and Technology, 2007, 129: 271–283.

KIM T, LEE H, JUNG S, et al. A 3D FE model with plastic shot for evaluation of equi-biaxial peening residual stress due to multi-impacts[J]. Surface & Coatings Technology, 2012, 206: 3125–3136.

MAJZOOBI G H, AZIZI R, ALAVI NIA A. A three-dimensional simulation of shot peening process using multiple shot impacts[J]. Journal of Materials Processing Technology, 2005, 164–165: 1226–1234.

KIM T, LEE J H, LEE H, et al. An area-average approach to peening residual stress under multi-impacts using a three-dimensional symmetry-cell finite element model with plastic shots[J]. Materials and Design, 2010, 31: 50–59.

BHUVARAGHAN B, SRINIVASAN S M, MAFFEO B. Optimization of the fatigue strength of materials due to shot peening: a survey[J]. International Journal of Structural Changes in Solids, 2010, 2(2): 33–63.

ZHAN K, JIANG C H, JI V. Uniformity of residual stress distribution on the surface of S30432 austenitic stainless steel by different shot peening processes[J]. Materials Letters, 2013, 99: 61–64.

HASSANI-GANGARAJ S M, GUAGLIANO M, FARRAHI G H. Finite element simulation of shot peening coverage with the special attention on surface nanocrystallization[J]. Procedia Engineering, 2011, 10: 2464–2471.

MEGUID S A, SHAGAL G, STRANART J C. Three-dimensional dynamic finite element analysis of shot peening induced residual stresses[J]. Finite Element in Analysis and Design, 1999, 31(3): 179–191..

MEGUID S A, SHAGAL G, STRANART J C. Finite element modelling of shot-peening residual stresses[J]. Journal of Materials Processing Technology, 1999, 92–93: 401–404.

BAGHERIFARD S, GHELICHI R, GUAGLIANO M. Mesh sensitivity assessment of shot peening finite element simulation aimed at surface grain refinement[J]. Surface & Coating Technology, 2014, 243: 58–64.

TORRES M A S, VOORWALD H J C. An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel[J]. International Journal of Fatigue, 2002, 24: 877–886.

XIE L C, ZHANG J, XIONG C B, et al. Investigation on experiments and numerical modelling of the residual stress distribution in deformed surface layer of Ti-6Al-4V after shot peening[J]. Materials and Design, 2012, 41: 314–318.

Cowper G R, Symonds P S. Strain-hardening and strain-rate effects in the impact loading of cantilever beams[R]. Brown Univ Providence Ri, 1957.

KLEMENZ M, SCHULZE V, ROHR I, et al. Application of the FEM for the prediction of the surface layer characteristics after shot peening[J]. Journal of Materials Processing Technology, 2009, 209: 4093–4102.

SANJURJO P, RODRÍGUEZ C, PEÑUELAS I, et al. Influence of the target material constitutive model on the numerical simulation of a shot peening process[J]. Surface & Coatings Technology, 2014, 258: 822–831.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China (Grant Nos. 51175469, 51375448).

Rights and permissions

About this article

Cite this article

WANG, C., HU, J., GU, Z. et al. Simulation on Residual Stress of Shot Peening Based on a Symmetrical Cell Model. Chin. J. Mech. Eng. 30, 344–351 (2017). https://doi.org/10.1007/s10033-017-0084-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10033-017-0084-6