Abstract

The current global death rate has threatened humans due to increase in deadly unknown infections caused by pathogenic microorganisms. On the contrary, the emergence of multidrug-resistant bacteria is also increasing which is leading to elevated lethality rate worldwide. Development of drug-resistant bacteria has become one of the daunting global challenges due to failure in approaching to combat against them. Methicillin-resistant Staphylococcus aureus (MRSA) is one of those drug-resistant bacteria which has led to increase in global mortality rate causing various lethal infections. Polymer synthesis can be one of the significant approaches to combat MRSA by fabricating polymeric coatings to prevent the spread of infections. This review provides last decade information in the development of various polymers against MRSA.

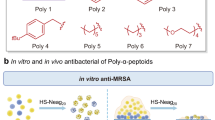

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Throughout recent years, biofilm formation and the advent of drug resistance microbes to modern antibiotics have been a significant problem in the area of biomedical science [1,2,3,4,5,6]. One-quarter of deaths occur worldwide due to microbial infections, particularly in developing countries [7,8,9,10]. As per the data reported by US Centers for Disease Control and Prevention, millions of people are infected with antibiotic-resistant bacteria [11, 12]. Since 1980, the number of hospital-acquired infections (HAIs) has increased steadily worldwide, due to rise and spread of multidrug-resistant (MDR) bacteria [13]. MDR is defined as the resistance or insensitivity of microorganisms to the antimicrobial drugs enforced [14]. MDR is recognized as the major cause for the emergence of public health problems [15]. The microorganisms which are resistant to drugs are termed as ESKAPE pathogens [16]. These ESKAPE pathogens comprise both gram-positive and gram-negative species (Enterococcus faecium, Staphylococcus aureus, Klebsiella pneumoniae, Acinetobacter baumannii, Pseudomonas aeruginosa and Enterobacter species), and these species are responsible for the spread of nosocomial infections and HAIs worldwide [17, 18]. Few most important pathogens which cause HAIs are vancomycin-resistant Enterococcus spp. (VRE), Clostridium difficile, A. baumannii, methicillin-resistant S. aureus (MRSA), P. aeruginosa and Enterobacteriaceae strains [13, 19,20,21,22]. Pathogens such as Candida species, viruses [influenza, hepatitis B viruses, adenoviruses, parainfluenza, noroviruses, rotaviruses and severe acute respiratory syndrome (SARS)-associated coronaviruses] also survive on medical equipments and surfaces, to a lesser extent [23, 24].

Many studies have found that > 60% of HAI's around the world is due to the attachment of different pathogens on fracture fixation devices, medical devices and implants and urinary catheters [13, 25,26,27,28,29,30]. Therefore, there is a necessity to fight against the spreading of MDR.

Among these pathogens, numerous infectious diseases, namely purulent meningitis, pleuritis, pneumonia, tympanitis and bloodstream infections, are caused by gram-positive methicillin-resistant S. aureus (MRSA) [31, 32]. Methicillin-resistant S. aureus (MRSA) pathogen is a major cause for nosocomial and community infections throughout the world [33]. It causes severe infections which exhibit notable antibiotic resistance [34, 35]. Infections of the skin caused by invasive pathogens begin when the outer skin is affected due to skin diseases, like atopic dermatitis and injury, such as a burn, and these invasive skin infections are majorly caused by S. aureus which includes MRSA [36,37,38,39]. Overall mortality rate is leading to 10–30% due to the treatment failure of MRSA-induced bacteraemia [31, 40]. Due to the increased virulence of epidemic strains the restraint of S. aureus, particularly MRSA is very difficult [36]. Transmission control is concentrated on the prevention of spread of these pathogens by environment (contaminated equipments and surfaces) and health-care workers (contaminated hands) [41]. A relevant amount of microbes is disrupted by disinfection process, using chemical agents like aldehydes, quaternary ammonium compounds, halogens and alcohols, or heat and radiation [13, 22, 42,43,44,45,46]. Sterilization and disinfection processes and at times aerosols need to be used to clean air to constraint hospital infections [22, 42]. Developing novel antibacterial methods to counter MRSA infections is an urgent need.

In recent years, several polymer-coated antimicrobial surfaces, antimicrobial surfaces and polymer-based antimicrobial hydrogels with several properties are developed to deal with clinical threats [1, 47,48,49,50,51,52]. Antimicrobial polymers are strong candidates among such antimicrobial materials, because they can successfully kill microbes and help to eliminate such pathogens [31, 53]. Such antimicrobial polymers target primarily the microbial membrane and show less tendency to cause the development of resistance [1]. They are used in environments at high risk of contamination, with uses such as self-sterilizing catheter tubes, medical drug coatings, surgical devices and wound dressings [54, 55]. Thus, synthetic polymers are commonly used as a new molecular framework for the development of antimicrobials that are active against drug-resistant bacteria [56,57,58,59,60]. This article focuses on various synthesized polymers and polymeric coatings used against methicillin-resistant S. aureus (MRSA) and their study on mechanism, minimum inhibitory concentration (MIC) or zone of inhibition (ZOI).

Polymers containing quaternary ammonium compounds

Hydroxypropyltrimethyl ammonium chloride chitosan (HACC) with various degree of substitution (6%, 18% and 44%) of quaternary ammonium was prepared by the reaction of chitosan with glycidyl trimethylammonium chloride by Peng et al. in 2010. Three bacteria responsible for orthopedic implant-related infections, Staphylococcus epidermidis, methicillin-resistant S. aureus and S. aureus, were used to evaluate the antibacterial activity of these synthesized polymers. The cationic group of the synthesized polymers targets the bacterial cell surface which is negatively charged. HACC (18% substitution) showed excellent potential to inhibit bacterial growth and biocompatibility with osteogenic cells. Biocompatibility and cytotoxicity were also tested for these polymers [61,62,63].

A series of amphiphilic and biodegradable, broad-spectrum antimicrobial polycarbonates were synthesized by Chin et al. in 2013 by metal-free organocatalytic ring-opening polymerization using (MTC-OCH2 BnCl) as monomer. The synthesized polycarbonates were further quaternized by post-polymerization quaternization reaction with quaternary ammonium groups of various pendant structure to obtain cationic polymers. The antimicrobial activity of synthesized polycarbonates was tested against P. aeruginosa, Escherichia coli and S. aureus and clinically isolated nosocomial microbes such as VRE, C. neoformans, A. baumannii and MRSA. Among the synthesized polycarbonates, polymer pbutyl_20 showed excellent antimicrobial activity and selectivity against clinically isolated drug-resistant microbes (VRE, MRSA and carbapenem resistant A. baumannii). Increase in alkyl chain length and hydrophobicity of the polymer raises its tendency to attach to the lipid membrane which leads to membrane disruption and results in cell death. The mechanism of action was studied by field emission scanning electron microscopy [64,65,66,67].

Biodegradable antimicrobial polycarbonates, pButyl-20 and pButyl0.5Benzyl0.5–20, containing cationic groups were synthesized by Cheng et al. in 2015. The polycarbonates were synthesized via organocatalytic ring-opening polymerization of benzyl chloride-functionalized cyclic carbonate monomer. The polymers were further quaternized by N,N-dimethylbutylamine and N,N-dimethylbutylamine/N,N-dimethylbenzylamine (1:1 molar ratio) as the cationic groups. These polymers form pores on the plasma membrane which eventually destroys the bacterial cell which was studied by transmission electron microscopy. The authors concluded that the synthesized polymers had a wide range of antimicrobial activity and were used for treating multidrug resistance MRSA infection [40, 64, 68, 69].

Uppu et al. in 2016 synthesized cationic amphiphilic polymers by polymerization of poly-(isobutylene-alt-maleic anhydride) with 3-aminopropyldimethylamine followed by quaternization of the tertiary nitrogen of polymerization product, poly(isobutylene-alt-N-(N′,N′-dimethylaminopropylmaleimide). The cyclized hydrophobic side chains attached to the cationic part far from the macromolecule are responsible for the death of bacteria. The obtained polymers showed good antimicrobial activity against S. aureus, MRSA, E. coli and vancomycin resistant E. faecium [70,71,72,73].

Li et al. in 2016 synthesized a novel antimicrobial polymer, poly(N,N-dimethylaminoethylmethacrylate)-block-poly(l-lacticacid)-block-poly(N,N-dimethylaminoethylmethacrylate) conjugated with poly(ethylene glycol) (D-PLLA-D@PEG) triblock copolymers by the combination of atom transfer radical polymerization. These polymers were further quaternized with two different chemical compositions (D-PLLA-D@Q 1: 12.3%; D-PLLA-D@Q 2: 26.2%). The amphiphilic and cationic groups are present in the polymer targets and rupture the bacterial membrane through electrostatic interaction and infuse into the membrane lipid domains and decrease the resistance of bacteria. All these polymers exhibited good antimicrobial activity against methicillin-resistant S. aureus. The authors concluded this could be used for coating hospital surfaces, gowns and prevents MDR bacteria [74,75,76,77].

Based on cationic polyaspartamide derivatives, four kinds of novel biodegradable antibacterial polymer with various lengths of side chains were synthesized by using β-benzyl-l-aspartate N-carboxy anhydride through ring-opening polymerization by Yan et al. in 2019. The synthesized Q-PAsp (BDA) catiomers showed a wide range of antibacterial activity against gram-negative and gram-positive bacteria. To enhance the biocompatibility of polycations, carboxylatopillar[5]arene (CP[5]A) was introduced to polymeric catiomers. The synthesized polymers attach to the surface of bacteria through electrostatic interaction (between polymer and negatively charged cell membrane) and disturb the normal functioning of bacteria leading to structural destabilization resulting in bacterial cell death. The mechanism was studied by scanning electron microscopy and confocal laser scanning microscopy. The authors concluded Q@CP[5]A exhibited excellent activity against in vivo MRSA and hence could be used for wound healing and inhibit antibiotic-resistant pathogenic bacterium [78,79,80,81] (Table 1).

Surface-coated polymers containing quaternary ammonium compounds

The importance of coating organo-Si quaternary ammonium chloride (QAC) polymer, a JUC spray on surfaces of medical devices to reduce MRSA contamination in hospital environments, was studied by Yuen et al. in 2015. The bactericidal property is exhibited due to the electrostatic force between the positively charged coated surface and negatively charged cell membrane. The authors demonstrate the antimicrobial coating of QAC polymer in addition to hypochlorite wiping on bed units and high-touch surfaces could significantly reduce the contamination rate in hospital wards [82,83,84,85] (Table 2).

Polymers without quaternary ammonium compounds

For hospital infection control, permanent sterile-surface materials were developed by Zhou et al. in 2011. Four guanidine hydrochloride polymers (polyoctamethylene guanidine hydrochloride (POMG) (polymer C8), polyhexamethylene guanidine hydrochloride (PHMG) (polymer C6), polybutamethylene guanidine hydrochloride (polymer C4) and poly(m-xylylene methylene guanidine hydrochloride) (polymer C8(benzene))) were synthesized, and their antimicrobial activity was evaluated against meticillin-resistant S. aureus, multidrug-resistant P. aeruginosa, coagulase-negative staphylococci, ceftazidime-resistant Citrobacter spp. and Enterobacter spp., vancomycin-resistant E. faecium. PHMG and POMG showed immense and tremendous antimicrobial activity against antibiotic-resistant bacteria which causes nosocomial infections. The probable mechanism is that the antimicrobial activity is due to the physicochemical interaction between the bacterial envelop and polymer molecule. The positively charged hydrophobic polymer interacts with the negatively charged phospholipids which damages the cytoplasmic membrane resulting in cell lysis [86,87,88].

Thoma et al. in 2014 synthesized ammonium ethyl methacrylate homopolymers (AEMPs) with primary ammonium groups in the side chain with various molecular weights (P7.7, P10, P12) by RAFT polymerization. E. coli, P. aeruginosa, S. saprohyticus, A. baumannii, S. aureus, Bacillus subtilis, Enterococcus faecalis and MRSA were used to study the antimicrobial activity of the synthesized polymers. These polymers showed a wide range of activity against gram-positive bacteria including MRSA, than gram-negative bacteria. Probably, the primary ammonium groups present in the side chains of the polymer were the cause for disruption of bacterial cell membrane. This article demonstrates that the synthesized polymers could be used for treatment of topical S. aureus infections [56, 89, 90].

For the control of hospital-acquired infections, surface-active, photodynamic antimicrobial polymers incorporated with photosensitizers were prepared by McCoy et al. in 2014 and their antimicrobial activity was tested against MRSA and E. coli. High-density poly(ethylene) (HDPE) were incorporated with various photosensitizers (TMPyP, TPP, TBO and MB) using hot-melt extrusion process, which exhibits antimicrobial activity in the presence of light. HDPE films and HDPE films incorporated with sentisizers were placed on one another and made into a twin layer by platen press. The reactive oxygen species (ROS) generated due to the irradiation of photosensitizers incorporated in the polymer films reacts with the bacterial cell components (lipids, proteins and nucleic acids) and causes cell death. HDPE films incorporated with TMPyP exhibited excellent antimicrobial activity against MRSA in the presence of light [91,92,93].

Labena et al. in 2016 synthesized hyperbranched poly(amidoamine) (h-PAMAM) with various terminal groups (h-PAMAM-ester, h-PAMAM-amine, h-PAMAM-amine plus) by repeated Michael addition and amidation to enhance reliability of the synthesis. The antimicrobial activity was tested against B. subtilis, Candia albicans, S. aureus, Aspergillus niger, P. aeruginosa, E. coli and MRSA. The electrostatic interactions between the cell membrane and h-PAMAM molecules cause denaturation of membrane’s protein and enter into phospholipid layer, which with raise in permeability causes membrane destabilization followed by intracellular structure leakage which leads to bacterial cell death. The authors demonstrated that h-PAMAM with amine terminations (amine and amine plus) showed broad-spectrum antimicrobial activity against MRSA [94,95,96,97].

A series of amphiphilic, cationic polycarbonate polymers containing primary amino groups (single, diblock and random) was synthesized by Nimmagadda et al. in 2016, and their antimicrobial activity was tested against three gram-positive bacterial strains vancomycin-resistant E. faecalis (VREF), methicillin-resistant S. aureus (MRSA) and methicillin-resistant S. epidermidis (MRSE). The random polymers exhibited a wide range of antimicrobial activity than single or diblock polymers. The random polymer with 20 hydrophobic and 20 hydrophilic units showed excellent activity against multidrug-resistant bacteria (MRSA). The polymer micelle on contact with bacterial surface breaks into small entities due to change in electrostatic interactions. Due to the amphipathic nature of the free polymer chain, it enters through the surface of bacteria which disrupts the bacterial membrane and leads to cell death; the mechanism was studied by TEM [65, 66, 98, 99].

A series of six cationic chitosan derivatives, N-(2-hydroxypropyl)-3-trimethylammonium chitosan chlorides (HTCC), by changing the mole ratio of glycidyltrimethylammonium chloride (GTMAC) were synthesized by Hoque et al. in 2016. The synthesized cationic polymers on interaction with anionic bacterial membrane disrupt the cell membrane leading to cell death. The mechanism of action was confirmed by several microscopic and spectroscopic methods. The antifungal and antibacterial property of the prepared HTCC polymers was evaluated against drug-sensitive bacteria (A. baumannii, S. aureus and E. coli) and MDR bacteria (VRE, MRSA and β-lactam-resistant K. pneumonia). Among the synthesized series of derivatives, two active polymers (HTCC3 and HTCC6) showed significant activity against MRSA in a murine model of superficial skin infection [100,101,102,103].

In another study, Kamaruzzaman et al. in 2016 found that a cationic polymer, polyhexamethylene biguanide (PHMB), had excellent antimicrobial properties and could be treated against intracellular MRSA (EMRSA-15 and USA 300). PHMB co-localizes with intracellular MRSA in keratinocytes, indicating that killing occurs by direct interactions inside host cells. The authors conclude that PHMB has potential to treat skin infections caused by intracellular MRSA and other intracellular bacteria [36, 104,105,106].

Hong et al. in 2017 synthesized cationic amphiphilic random methacrylate copolymer (PE31) with pH-responsive activity by RAFT polymerization. The mechanism explained is electrostatic interaction occurs between the positively charged polymer and negatively charged cell wall. On interaction, the hydrophobic side chains of a polymer enter into hydrophobic portion of bacterial lipid membrane, which causes disruption of membrane leading to bacterial cell death. The authors concluded that the polymer showed high antimicrobial activity against vancomycin-intermediate S. aureus and methicillin-resistant S. aureus at neutral pH [107,108,109,110].

Biocompatible, inexpensive, water-soluble macromolecular antimicrobial polyionenes were developed by Liu et al. in 2017 for the treatment of hospital-acquired and MDR infections. Catalytic-free, polyaddition polymerization process was used for the synthesis of series of antimicrobial polyionenes. Hydrophilic and hydrophobic groups were distributed alternatively in the polymer chain, among which hydrophobic components were in contact with negatively charged cell wall. The hydrophobic components target the lipid bilayer causing cytoplasmic membrane disruption and resulting in cell lysis. The antimicrobial activity of synthesized polymers was examined against MRSA, S. aureus, K. pneumonia, A. bacumanii, C. neoformans, E. coli and C. albicans [59, 111, 112].

An antimicrobial polymer which showed activity against S. aureus, MRSA, MSSA and other HAIs was synthesized by Mercer et al. in 2017. The authors prepared NP 108, a cationic, poly-lysine polymer made up of amino acid building blocks which was water-soluble and had a wide range of antimicrobial activity. The macromolecule shows membrane-acting bactericidal activity due to net positive charge present on the polylysine, which causes disruption of cell membrane resulting in cell death. These polymers were used for nasal delcolonization of S. aureus and prevention of HAI [53, 113, 114].

To eradicate multidrug-resistant (MDR) bacterial infections, Chin et al. in 2018 synthesized a biodegradable macromolecule, guanidinium-functionalized polycarbonates. The synthesized polymers (pEt_10 and pEt_20) showed broad-spectrum antimicrobial activity against MDR P. aeruginosa, E. coli, A. baumannii, MRSA and K. pneumonia. This polymer also exhibits electrostatic interaction between the polymer and cell wall, and targets cytoplasmic membrane resulting in releasing of cell constituents which leads to cell death. These polymers were less toxic and had great potential for the treatment and prevention of MDR systemic infections [115,116,117,118].

Poly(para-phenylene ethynylene) (PPE)-and poly(para-phenylene vinylene) (PPV)-poly[(2-(methacryloyloxy)ethyl)trimethylammonium chloride] (PMETAC) graft copolymers of low and high molecular weights were synthesized by Damavandi et al. in 2018. The cationic side chains present in the conjugated polymers interact with the negatively charged surface of bacterial cell and exhibit antimicrobial activity. The antimicrobial activities of synthesized polymers were tested against MRSA, E. coli, E. faecium and A. baumannii. The authors found that the low molecular weight PPE-g-PMETAC copolymer showed significant antimicrobial activity [119,120,121].

In 2019, Hong et al., studied about novel antimicrobial polyionene, poly(N,N′-(ethane-1,2-diyl)bis(4-(chloromethyl)benzamide)-co-tetramethyl-1,3-diaminopropane), synthesized by Lou et al. in 2018 for the treatment of MRSA-induced bloodstream infection. Antimicrobial polymers form pores on plasma which leads to leakage of cytoplasmic components resulting in cell death. The authors demonstrated that the polymer possessed strong antimicrobial activity against MRSA. Due to negligible toxicity and potential therapeutic effect, the polymer could be used to treat MRSA caused, especially blood stream infections [31, 122, 123].

Electrospun fiber mats were synthesized by Boncu et al. in 2019 for the treatment methicillin-resistant S. aureus (MRSA) associated with bone infections and soft tissues. Biodegradable polymers, poly(lactic-co-glycolic) acid (PLGA) and polycaprolactone (PCL) loaded with linezolid, were used for preparing electrospun fiber mats. The antibacterial activity of synthesized fiber mats was examined against isolated bacteria (MRSA) which causes prosthetic infections. The fibers were non-toxic, biocompatible, biodegradable and had long-term activity [124,125,126].

Kuroki et al. in 2019 synthesized series of ammonium and guanidinium polymers of various sequences (statistical, diblock and tetrablock) by RAFT polymerization. The synthesized polymers were tested for antimicrobial activity against MDR methicillin-sensitive strains (MSSA) and methicillin-resistant S. aureus (MRSA). The authors concluded that diblock guanidinium (GD30) polymer had major impact for the treatment of intracellular, MDR bacteria (MSSA and MRSA). Here bacterial DNA binding and pore formation both would have occurred, leading to death of bacteria [127,128,129,130].

For the treatment of MRSA a new method, Antibacterial Photodynamic Therapy (APDT) was used by Guo et al. in 2020, to deliver photosensitizers. In this article self-assembled, lipase sensitive micelle was developed to deliver hydrophobic hypocrellin A (HA). Polymeric micelle made up of methoxy poly(ethylene glycol)-block-poly(ε-caprolactone) (mPEG-PCL/HA), an amphiphilic copolymer, was used to encapsulate HA. The polymeric micelles could release HA in the presence of lipase, on irradiation of light or in appropriate wavelength range and this improved the APDT activity. These mPEG-PCL/HA micelles showed high activity against MRSA and could be used to combat MRSA infections [131,132,133,134].

Christofferson et al. in 2020 synthesized diblock and triblock oligomers by photo-induced atom transfer radical polymerization and studied their antimicrobial activity against gram-positive bacteria namely S. aureus and MRSA. In this article, it has been reported that the triblock oligomers showed excellent antibacterial activity ~ 99% and 98% against S. aureus and MRSA compared to the diblock oligomers, because the oligomer systems had conformational differences. The interaction between peptidoglycan functional group leads to the disruption of peptidoglycan layers [135, 136] (Table 3).

Surface-coated polymers without quaternary ammonium compounds

Antifouling surface coatings were developed with antimicrobial properties on silicon rubber to fight against intravascular catheter-associated infections (CAIs) using diblock copolymers which was synthesized by Ding et al. in 2012. (PEG-b-cationic polycarbonates) were synthesized by metal-free organocatalytic ring-opening copolymerization of poly(ethylene glycol) (PEG) and cationic polycarbonate. Polymers coatings were developed using reactive polydopamine (PDA) to increase antimicrobial properties of substrate surface. These properties of the polymeric coatings were systematically investigated against methicillin-resistant S. aureus and methicillin-susceptible S. aureus, which are the major causes of intravascular catheter-associated infections. The tests were carried out for various polymers compositions. The hydrophobic monomer unit present in the polymer may interact with the bacterial cell membrane by incorporating into the lipid domain and resulting in cell death [137,138,139,140].

The efficacy of biodegradable poly-d,l-(lactide) (PDLLA) polymer solution loaded with linezolid antibiotic and coated on orthopedic Kirschner wires (K-wires) by dip coating technique to prevent the adhesion of MRSA was studied by Kaur et al. in 2014. The adherence of MRSA was evaluated on naked wires, PDLLA wires, K1, K2 and K3 wires (PDLLA impregnated with three different concentrations of linezolid (2.5%, 5% and 10%)). The authors concluded that K2 and K3 wires decreased bacterial adhesion by 60% when compared to K1 (which decreased by 40%), PDLLA and naked wires. The reduction in the bacterial attachment on wires was correlated with the amount of drug released from the wires [141,142,143,144].

Dinjaski et al. in 2014 studied the antimicrobial properties of poly-3-hydroxy-acetyllthioalkanoate-co-3-hydroxyalkanoate (PHACOS) containing thioester groups in the side chains by comparing it with non-reactive poly(3-hydroxyoctanoate-co-hydroxyhexanoate) (PHO) and poly(ethylene terephthalate) (PET). PET disks were coated with PHACOS and PHO by solvent casting, and uncoated PET disks were used as control for examining the antimicrobial activity and bacterial adhesion of S. aureus subsp. aureus, Streptococcus pyogenes, Mycobacterium smegmatis, B. subtilis subsp. subtilis, E. coli, S. epidermidis, MRSA, P. aeruginosa and Streptococcus dysgalactiae subsp. equisimilis. The bacterial activity of S. aureus on PHO was more compared to that of PHACOS, which demonstrates that PHACOS possesses anti-staphylococcal activity. In addition to this, PHACOS effectively inhibits the growth of MRSA. This activity is exhibited by functionalized side chains which possess thioester groups. This article concludes that PHACOS acts as contact active surface which decreases the adhesion of S. aureus and MRSA, and hence can be used in biomedical implants as an infection-resistant material [110, 145,146,147].

Polyastaxanthin (p (ATX)) coatings were developed by Weintraub et al. in 2018, and their antimicrobial activity was examined against S. aureus (MRSA and MSSA) and S. epedermidis by coating them on polyurethane catheters. Since the polymeric coating material was biodegradable and had excellent antimicrobial properties, authors concluded that the coatings could be used as antimicrobial coating for medical devices [148,149,150] (Table 4).

The antimicrobial activity exhibited by the polymers depends on the molecular weight [56, 64, 100, 119, 135], alkyl chain length [64, 70, 86, 115] and terminal functional group [94] of the polymers. The synthesized polymers had various advantages such as biocompatibility and low toxicity and thus were used for several applications such as in biomedical implants, disinfectants for hospital infection control, in orthopedic operations, treatment of nasal colonization infections, skin infections and bloodstream infections. Few polymers were used for coating kirschner wires, polyurethane tubes, etc., to prevent the spread of bacteria. Certain polymers had resistant ability only toward few pathogens, and they had MIC values slightly higher compared to their corresponding standards due to which the application was limited in biomedical field.

Conclusion

Drug-resistant MRSA which causes numerous deadly infectious diseases, namely tympanitis, pneumonia, purulent meningitis pleuritis and bloodstream infection, can be reduced by the approach toward polymeric synthesis. This article reports the polymers synthesized by various research groups to treat MRSA since last decade. Polymers with various beneficial properties like biocompatibility, stability (thermal and mechanical) and antimicrobial activity were synthesized, and their ability to prevent MRSA has been described. This article also discusses the authors who showed interest in loading antibiotics to polymeric backbones to fight against MRSA. On the whole, the mechanisms explained for various polymers are in two ways (i) electrostatic interaction between polymers and cell wall and (ii) polymers targeting cytoplasmic membrane. Future research in the field of combating MRSA can be focused on polymer surface coatings to restrain the spread of MRSA and other multidrug-resistant bacteria.

References

Konai MM, Bhattacharjee B, Ghosh S, Haldar J (2018) Recent progress in polymer research to tackle infections and antimicrobial resistance. Biomacromol 19:1888–1917. https://doi.org/10.1021/acs.biomac.8b00458

Torgerson CM, Mapp B (2017) Drug-resistant bacteria ranked. Nature. https://doi.org/10.1038/nature.2017.21550

Brown ED, Wright GD (2016) Antibacterial drug discovery in the resistance era. Nature 529:336–343. https://doi.org/10.1038/nature17042

Bush K, Courvalin P, Dantas G et al (2011) Tackling antibiotic resistance. Nat Rev Microbiol 9:894–896. https://doi.org/10.1038/nrmicro2693

Butler MS, Blaskovich MA, Cooper MA (2017) Antibiotics in the clinical pipeline at the end of 2015. J Antibiot (Tokyo) 70:3–24. https://doi.org/10.1038/ja.2016.72

Boucher HW, Talbot GH, Bradley JS et al (2009) Bad bugs, no drugs: no ESKAPE! An update from the Infectious Diseases Society of America. Clin Infect Dis 48:1–12. https://doi.org/10.1086/595011

Nagaraja A, Jalageri MD, Puttaiahgowda YM et al (2019) A review on various maleic anhydride antimicrobial polymers. J Microbiol Methods 163:105650. https://doi.org/10.1016/j.mimet.2019.105650

Nagaraja A, Puttaiahgowda YM, Kulal A et al (2019) Synthesis, characterization, and fabrication of hydrophilic antimicrobial polymer thin film coatings. Macromol Res 27:301–309. https://doi.org/10.1007/s13233-019-7040-5

Jalageri MD (2019) Synthesis and fabrication of highly functionalized Jeffamine antimicrobial polymeric coating. Polym Adv Technol 30:1616–1627. https://doi.org/10.1002/pat.4592

Jalageri MD, Malgar Puttaiahgowda Y, Parambil AM, Kulal A (2019) Design of multifunctionalized piperazine polymer and its activity toward pathogenic microorganisms. J Appl Polym Sci. https://doi.org/10.1002/app.47521

Nagaraja A, Puttaiahgowda YM, Devadiga D (2019) Synthesis and fabrication of high-potent antimicrobial polymeric ultrathin coatings. J Appl Polym Sci 136:1–10. https://doi.org/10.1002/app.47893

Nagaraja A, Manohara Dhulappa Jalageri YMP (2020) A thirst for polymeric antimicrobial surfaces/coatings for diverse applications. In: Engineered antimicrobial surfaces, pp 13–32

Abreu AC, Tavares RR, Borges A et al (2013) Current and emergent strategies for disinfection of hospital environments. J Antimicrob Chemother 68:2718–2732. https://doi.org/10.1093/jac/dkt281

Tanwar J, Das S, Fatima Z, Hameed S (2014) Multidrug resistance: an emerging crisis. Interdiscip Perspect Infect Dis. https://doi.org/10.1155/2014/541340

van Duin D, Paterson DL (2016) Multidrug-resistant bacteria in the community: trends and lessons learned. Infect Dis Clin North Am 30:377–390. https://doi.org/10.1016/j.idc.2016.02.004

Khan SN, Khan AU (2016) Breaking the spell: combating multidrug resistant “superbugs.” Front Microbiol 7:1–11. https://doi.org/10.3389/fmicb.2016.00174

Santajit S, Indrawattana N (2016) Mechanisms of antimicrobial resistance in Pasteurellaceae. PBioMed Res Int 2016:1–8

Rice LB (2010) Progress and challenges in implementing the research on ESKAPE pathogens. Infect Control Hosp Epidemiol 31:S7–S10. https://doi.org/10.1086/655995

Talon D (1999) The role of the hospital environment in the epidemiology of multi-resistant bacteria. J Hosp Infect 43:13–17. https://doi.org/10.1053/jhin.1999.0613

Madigan MT, Martinko JM, Parker J (2003) Brock biology of microorganisms, 10th edn. Southern Illinois University, Carbondale

Kramer A, Schwebke I, Kampf G (2006) How long do nosocomial pathogens persist on inanimate surfaces? A systematic review. BMC Infect Dis 6:1–8. https://doi.org/10.1186/1471-2334-6-130

Weinstein RA, Hota B (2004) Contamination, disinfection, and cross-colonization: are hospital surfaces reservoirs for nosocomial infection? Clin Infect Dis 39:1182–1189. https://doi.org/10.1086/424667

Zsuzsanna Schelz JH (2010) Recent advances in research of antimicrobial effects of essential oils and plant derived compounds on bacteria. Ethnomedicine A Source Complement Ther 661:179–201

Dancer SJ (2004) How do we assess hospital cleaning? A proposal for microbiological standards for surface hygiene in hospitals. J Hosp Infect 56:10–15. https://doi.org/10.1016/j.jhin.2003.09.017

Pinto MS, Mcgahan ME, Steiner WW, Priefer R (2011) The use of the pseudo-polyelectrolyte, poly(4-vinylphenol ), in multilayered films as an antimicrobial surface coating. Colloids Surfaces A Physicochem Eng Asp 377:182–186. https://doi.org/10.1016/j.colsurfa.2010.12.038

Griffith CJ, Cooper RA, Gilmore J et al (2000) An evaluation of hospital cleaning regimes and standards. J Hosp Infect 45:19–28. https://doi.org/10.1053/jhin.1999.0717

Weber DJ, Rutala WA, Miller MB, Huslage K (2010) Role of hospital surfaces in the transmission of emerging health care- associated pathogens: norovirus, Clostridium difficile, and Acinetobacter species. Am J Infect Control 38:S25–S33. https://doi.org/10.1016/j.ajic.2010.04.196

Cozad A, Jones RD, Aam RM (2003) Disinfection and the prevention of infectious disease. Environ Cause Infect. https://doi.org/10.1067/mic.2003.49

Otter JA, Yezli S, French GL (2011) The role played by contaminated surfaces in the transmission of nosocomial pathogens. Infect Control Hosp Epidemiol 32:687–699. https://doi.org/10.1086/660363

J.W. C, L. M, C.R. A, (2005) Biofilm in implant infections: its production and regulation. Int J Artif Organs 28:1062–1068

Chen X, Lou W, Liu J et al (2019) A novel antimicrobial polymer efficiently treats multidrug-resistant MRSA-induced bloodstream infection. Biosci Rep. https://doi.org/10.1042/BSR20192354

Arias-Ortiz PM, del Calderón L, Castillo JS et al (2016) Risk factors for methicillin-resistant Staphylococcus aureus bacteremia: a multicenter matched case–control study. Biomedica 36:612–619. https://doi.org/10.7705/biomedica.v36i4.3193

Bukharie HA (2010) Review article: A review of community-acquired methicillin-resistant Staphylococcus aureus for primary care physicians. J Family Community Med. https://doi.org/10.4103/1319-1683.74320

Foxley MA, Friedline AW, Jensen JM et al (2016) Efficacy of ampicillin against methicillin-resistant Staphylococcus aureus restored through synergy with branched poly(ethylenimine). J Antibiotics. https://doi.org/10.1038/ja.2016.44

Dhanalakshmi TA (2012) Prevalence of inducible clindamycin resistance in Staphylococcus aureus. J Acad Med Sci 2:73–76. https://doi.org/10.4103/2249-4855.118664

Kamaruzzaman NF, Firdessa R, Good L (2016) Bactericidal effects of polyhexamethylene biguanide against intracellular Staphylococcus aureus EMRSA-15 and USA 300. J Antimicrob Chemother 71:1252–1259. https://doi.org/10.1093/jac/dkv474

Dryden MS (2010) Complicated skin and soft tissue infection. J Antimicrob Chemother 65:35–44. https://doi.org/10.1093/jac/dkq302

Grice EA, Segre JA (2011) The skin microbiome. Nat Rev Microbiol 9:244–253. https://doi.org/10.1038/nrmicro2537

Singer AJ, Talan DA (2014) Management of skin abscesses in the era of methicillin-resistant Staphylococcus aureus. N Engl J Med 370:1039–1047. https://doi.org/10.1056/NEJMra1212788

Cheng J, Chin W, Dong H et al (2015) Biodegradable antimicrobial polycarbonates with in vivo efficacy against multidrug-resistant MRSA systemic infection. Adv Healthc Mater. https://doi.org/10.1002/adhm.201500471

Hebert C, Weber SG (2011) Common Approaches to the control of multidrug-resistant organisms other than methicillin-resistant Staphylococcus aureus (MRSA). Infect Dis Clin NA 25:181–200. https://doi.org/10.1016/j.idc.2010.11.006

Rutala WA, Weber DJ (2001) Surface disinfection: should we do it? J Hosp Infect 48:64–68

Simo M (2010) A review of current and emergent biofilm control strategies. LWT Food Sci Technol 43:573–583. https://doi.org/10.1016/j.lwt.2009.12.008

Russell AD (1999) Bacterial resistance present knowledge to disinfectants: and future problems. J Hosp Infect 43:57–68

Peng R, Luo Y, Cui Q et al (2020) Near-infrared conjugated oligomer for effective killing of bacterial through combination of photodynamic and photothermal treatment. ACS Appl Bio Mater 3:1305–1311. https://doi.org/10.1021/acsabm.9b01242

Zeng M, Xu J, Luo Q et al (2020) Constructing antibacterial polymer nanocapsules based on pyridine quaternary ammonium salt. Mater Sci Eng C 108:110383. https://doi.org/10.1016/j.msec.2019.110383

Han J, Chen Q, Shen Y et al (2020) Click-chemistry approach toward antibacterial and degradable hybrid hydrogels based on octa-betaine ester polyhedral oligomeric silsesquioxane. Biomacromol 21:3512–3522. https://doi.org/10.1021/acs.biomac.0c00530

Mansouri J, Truong VK, MacLaughlin S et al (2019) Polymerization-induced phase segregation and self-assembly of siloxane additives to provide thermoset coatings with a defined surface topology and biocidal and self-cleaning properties. Nanomaterials 9:1–19. https://doi.org/10.3390/nano9111610

He J, Shi M, Liang Y, Guo B (2020) Conductive adhesive self-healing nanocomposite hydrogel wound dressing for photothermal therapy of infected full-thickness skin wounds. Chem Eng J 394:124888. https://doi.org/10.1016/j.cej.2020.124888

Liang Y, Chen B, Li M et al (2020) Injectable antimicrobial conductive hydrogels for wound disinfection and infectious wound healing. Biomacromol 21:1841–1852. https://doi.org/10.1021/acs.biomac.9b01732

Zhang B, He J, Shi M et al (2020) Injectable self-healing supramolecular hydrogels with conductivity and photo-thermal antibacterial activity to enhance complete skin regeneration. Chem Eng J 400:125994. https://doi.org/10.1016/j.cej.2020.125994

Zhao X, Liang Y, Huang Y et al (2020) Physical double-network hydrogel adhesives with rapid shape adaptability, fast self-healing, antioxidant and NIR/pH stimulus-responsiveness for multidrug-resistant bacterial infection and removable wound dressing. Adv Funct Mater 30:1–18. https://doi.org/10.1002/adfm.201910748

Mercer DK, Katvars LK, Hewitt F et al (2017) NP108, an antimicrobial polymer with activity against methicillin and mupirocin resistant Staphylococcus aureus. Antimicrob Agent. https://doi.org/10.1128/AAC.00502-17

Lienkamp K, Madkour AE, Kumar KN et al (2009) Antimicrobial polymers prepared by ring-opening metathesis polymerization: manipulating antimicrobial properties by organic counterion and charge density variation. Chem - A Eur J 15:11715–11722. https://doi.org/10.1002/chem.200900606

Madkour AE, Tew GN (2008) Towards self-sterilizing medical devices: controlling infection 10:6–10. https://doi.org/10.1002/pi.2399

Thoma LM, Boles BR, Kuroda K (2014) Cationic methacrylate polymers as topical antimicrobial agents against Staphylococcus aureus nasal colonization. Biomacromol 15:2933–2943. https://doi.org/10.1021/bm500557d

Engler AC, Wiradharma N, Ong ZY et al (2012) Emerging trends in macromolecular antimicrobials to fight multi-drug-resistant infections. Nano Today 7:201–222. https://doi.org/10.1016/j.nantod.2012.04.003

Kuroda K, Caputo GA (2013) Antimicrobial polymers as synthetic mimics of host-defense peptides. Wiley Interdiscip Rev Nanomed Nanobiotechnol 5:49–66. https://doi.org/10.1002/wnan.1199

Li P, Li X, Saravanan R et al (2012) Antimicrobial macromolecules: synthesis methods and future applications. RSC Adv. https://doi.org/10.1039/c2ra01297a

Muñoz-Bonilla A, Fernández-García M (2012) Polymeric materials with antimicrobial activity. Prog Polym Sci 37:281–339. https://doi.org/10.1016/j.progpolymsci.2011.08.005

Peng ZX, Wang L, Du L et al (2010) Adjustment of the antibacterial activity and biocompatibility of hydroxypropyltrimethyl ammonium chloride chitosan by varying the degree of substitution of quaternary ammonium. Carbohydr Polym 81:275–283. https://doi.org/10.1016/j.carbpol.2010.02.008

Qin C, Xiao Q, Li H et al (2004) Calorimetric studies of the action of chitosan-N-2-hydroxypropyl trimethyl ammonium chloride on the growth of microorganisms. Int J Biol Macromol 34:121–126. https://doi.org/10.1016/j.ijbiomac.2004.03.009

Chung YC, Chen CY (2008) Antibacterial characteristics and activity of acid-soluble chitosan. Bioresour Technol 99:2806–2814. https://doi.org/10.1016/j.biortech.2007.06.044

Chin W, Yang C, Ng VWL et al (2013) Biodegradable broad-spectrum antimicrobial polycarbonates: Investigating the role of chemical structure on activity and selectivity. Macromolecules 46:8797–8807. https://doi.org/10.1021/ma4019685

Nederberg F, Zhang Y, Tan JPK et al (2011) Biodegradable nanostructures with selective lysis of microbial membranes. Nat Chem 3:409–414. https://doi.org/10.1038/nchem.1012

Qiao Y, Yang C, Coady DJ et al (2012) Highly dynamic biodegradable micelles capable of lysing gram-positive and gram-negative bacterial membrane. Biomaterials 33:1146–1153. https://doi.org/10.1016/j.biomaterials.2011.10.020

Coles MP (2009) Bicyclic-guanidines, -guanidinates and -guanidinium salts: wide ranging applications from a simple family of molecules. Chem Commun. https://doi.org/10.1039/b901940e

Sambhy V, Peterson BR, Sen A (2008) Antibacterial and hemolytic activities of pyridinium polymers as a function of the spatial relationship between the positive charge and the pendant alkyl tail. Angew Chemie Int Ed 47:1250–1254. https://doi.org/10.1002/anie.200702287

Testing S (2013) M100-S23 Performance Standards for Antimicrobial

Uppu DS, Bhowmik M, Samaddar S, Haldar J (2016) Cyclization and unsaturation rather than isomerisation of side chains govern the selective antibacterial activity of cationic-amphiphilic polymers. Chemical Commun. 52(25):4644–4647. https://doi.org/10.1039/C5CC09930G

Gabriel GJ, Madkour AE, Dabkowski JM et al (2008) Synthetic mimic of antimicrobial peptide with nonmembrane-disrupting antibacterial properties. Biomacromol 9:2980–2983. https://doi.org/10.1021/bm800855t

Uppu DS, Akkapeddi P, Manjunath GB, Yarlagadda V, Hoque J, Haldar J (2013) Polymers with tunable side-chain amphiphilicity as non-hemolytic antibacterial agents. Chem Commun 49(82):9389–9391. https://doi.org/10.1039/c3cc43751e

Choi H, Chakraborty S, Liu R et al (2014) Medium effects on minimum inhibitory concentrations of nylon-3 polymers against E. coli. PLoS ONE. https://doi.org/10.1371/journal.pone.0104500

Li Z, a Pei Lin Cheea, Cally Owha RL and XJL, (2016) Safe and efficient membrane permeabilizing polymers based on PLLA for antibacterial applications. R Soc Chem. https://doi.org/10.1039/C6RA04531F

Liu F, Hu J, Liu G et al (2014) Emulsion and nanocapsules of ternary graft copolymers. Polym Chem 5:1381–1392. https://doi.org/10.1039/c3py01316b

Zhang X, Tan BH, He C (2013) Tailoring the LCST of PNIPAAM-b-PLA-b-PNIPAAM triblock copolymers via stereocomplexation. Macromol Rapid Commun 34(22):1761–1766

Wu X, He X, Zhong L et al (2011) Water-soluble dendritic-linear triblock copolymer-modified magnetic nanoparticles: preparation, characterization and drug release properties. J Mater Chem 21:13611–13620. https://doi.org/10.1039/c1jm11613d

Yan S, Chen S, Gou X, Yang J, An J, Jin X, Yang YW, Chen L, Gao H (2019) Biodegradable supramolecular materials based on cationic polyaspartamides and Pillar [5] arene for targeting gram-positive bacteria and mitigating antimicrobial resistance. Adv Funct Mater. 29(38):1904683. https://doi.org/10.1002/adfm.201904683

Ogoshi T, Kanai S, Fujinami S, Yamagishi TA, Nakamoto Y (2008) para-Bridged symmetrical pillar [5] arenes: their Lewis acid catalyzed synthesis and host–guest property. J Am Chem Soc. 130(15):5022–5023

Yang Y, He P, Wang Y et al (2017) Supramolecular radical anions triggered by bacteria in situ for selective photothermal therapy. Angew Chemie 129:16457–16460. https://doi.org/10.1002/ange.201708971

Itaka K, Ishii T, Hasegawa Y, Kataoka K (2010) Biodegradable polyamino acid-based polycations as safe and effective gene carrier minimizing cumulative toxicity. Biomaterials 31:3707–3714. https://doi.org/10.1016/j.biomaterials.2009.11.072

Yuen JWM, Chung TWK, Loke AY (2015) Methicillin-resistant Staphylococcus aureus (MRSA) contamination in bedside surfaces of a hospital ward and the potential effectiveness of enhanced disinfection with an antimicrobial polymer surfactant. Int J Environ Res Public Health 12:3026–3041. https://doi.org/10.3390/ijerph120303026

Yuen YWM, Yung J (2013) Medical implications of antimicrobial coating polymers-organosilicon quaternary ammonium chloride. Mod Chem Appl 1:1–4. https://doi.org/10.4172/2329-6798.1000107

Wan KA, Ng MY, Wong YT (2011) New horizon on community-acquired methicillin resistant Staphylococcus aureus (CA-MRSA) skin and soft tissue infection: nanotechnology antimicrobial spray. Hong Kong J Emerg Med. 18(6):432–436. https://doi.org/10.1177/102490791101800611

Boyce JM (2007) Environmental contamination makes an important contribution to hospital infection. J Hosp Infect 65:50–54. https://doi.org/10.1016/S0195-6701(07)60015-2

Zhou Z, Wei D, Guan Y et al (2011) Extensive in vitro activity of guanidine hydrochloride polymer analogs against antibiotics-resistant clinically isolated strains. Mater Sci Eng C 31:1836–1843. https://doi.org/10.1016/j.msec.2011.08.015

Sun S, An Q, Li X et al (2010) Synergistic effects of chitosan-guanidine complexes on enhancing antimicrobial activity and wet-strength of paper. Bioresour Technol 101:5693–5700. https://doi.org/10.1016/j.biortech.2010.02.046

Guan Y, Qian L, Xiao H, Zheng A (2008) Preparation of novel antimicrobial-modified starch and its adsorption on cellulose fibers: Part I. Optimization of synthetic conditions and antimicrobial activities. Cellulose 15:609–618. https://doi.org/10.1007/s10570-008-9208-6

Palermo EF, Vemparala S, Kuroda K (2012) Cationic spacer arm design strategy for control of antimicrobial activity and conformation of amphiphilic methacrylate random copolymers. Biomacromol 13:1632–1641. https://doi.org/10.1021/bm300342u

Ishitake K, Satoh K, Kamigaito M, Okamoto Y (2009) Stereogradient polymers formed by controlled/living radical polymerization of bulky methacrylate monomers. Angew Chemie Int Ed 48:1991–1994. https://doi.org/10.1002/anie.200805168

McCoy CP, O’Neil EJ, Cowley JF et al (2014) Photodynamic antimicrobial polymers for infection control. PLoS ONE 9:1–11. https://doi.org/10.1371/journal.pone.0108500

Wilson BC, Patterson MS (2008) The physics, biophysics and technology of photodynamic therapy. Phys Med Biol. https://doi.org/10.1088/0031-9155/53/9/R01

Hamblin MR, O’Donnell DA, Murthy N et al (2002) Polycationic photosensitizer conjugates: Effects of chain length and Gram classification on the photodynamic inactivation of bacteria. J Antimicrob Chemother 49:941–951. https://doi.org/10.1093/jac/dkf053

Labena A, Kabel KI, Farag RK (2016) One-pot synthesize of dendritic hyperbranched PAMAM and assessment as a broad spectrum antimicrobial agent and anti-biofilm. Mater Sci Eng C 58:1150–1159. https://doi.org/10.1016/j.msec.2015.09.042

Hoovers J, Comanita B (1999) Dendrimers and dendrimer-polymer hybrids. Adv Polym Sci 142:179–228. https://doi.org/10.1007/3-540-68310-0_4

Slany M, Bardaji M, Casanove MJ, Caminade AM, Majoral JP, Chaudret B (1995) Dendrimer surface chemistry. Facile route to polyphosphines and their gold complexes. J Am Chem Soc 117(38):9764–9765. https://doi.org/10.1021/ja00143a023

Cao L, Yang W, Wang C, Fu S (2007) Synthesis and striking fluorescence properties of hyperbranched poly(amido amine). J Macromol Sci Part A Pure Appl Chem 44(4):417–424. https://doi.org/10.1080/10601320601188299

Nimmagadda A, Liu X, Teng P et al (2016) Polycarbonates with potent and selective antimicrobial activity toward gram-positive bacteria polycarbonates with potent and selective antimicrobial activity toward gram-positive. Biomacromol. https://doi.org/10.1021/acs.biomac.6b01385

Li Y, Smith C, Wu H, Padhee S, Manoj N, Cardiello J, Qiao Q, Cao C, Yin HCJ (2014) Lipidated cyclic γ-AApeptides display both antimicrobial and anti-inflammatory activity. ACS Chem Biol. https://doi.org/10.1021/cb4006613

Hoque J, Adhikary U, Yadav V et al (2016) Chitosan derivatives active against multidrug-resistant bacteria and pathogenic fungi. In vivo evaluation as topical antimicrobials. Mol Pharm 13:3578–3589. https://doi.org/10.1021/acs.molpharmaceut.6b00764

Kaminski K, Szczubialka K, Zazakowny K, Lach R, Nowakowska M (2010) Chitosan derivatives as novel potential heparin reversal agents. J Med Chem 53(10):4141–4147. https://doi.org/10.1021/jm1001666

Cui D, Szarpak A, Pignot-Paintrand I et al (2010) Contact-killing polyelectrolyte microcapsules based on chitosan derivatives. Adv Funct Mater 20:3303–3312. https://doi.org/10.1002/adfm.201000601

Wiegand I, Hilpert K, Hancock REW (2008) Agar and broth dilution methods to determine the minimal inhibitory concentration (MIC) of antimicrobial substances. Nat Protoc 3:163–175. https://doi.org/10.1038/nprot.2007.521

Moore K, Gray D (2007) Using PHMB antimicrobial to prevent wound infection. Wounds 3:96–102

Firdessa R, Good L, Amstalden MC, Chindera K, Kamaruzzaman NF, Schultheis M, Röger B, Hecht N, Oelschlaeger TA, Meinel L, Lühmann T (2015) Pathogen-and host-directed antileishmanial effects mediated by polyhexanide (PHMB). PLoS Negl Trop Dis 9(10):e0004041. https://doi.org/10.1371/journal.pntd.0004041

Cockerill F, Wikler M, Bush K, et al (2007) Performance standards for antimicrobial susceptibility testing; seventeenth informational supplement

Hong S, Takahashi H, Nadres ET et al (2017) A cationic amphiphilic random copolymer with ph-responsive activity against methicillin-resistant Staphylococcus aureus. PLoS ONE 12:1–17. https://doi.org/10.1371/journal.pone.0169262

Takahashi H, Palermo EF, Yasuhara K et al (2013) Molecular design, structures, and activity of antimicrobial peptide-mimetic polymers. Macromol Biosci 13:1285–1299. https://doi.org/10.1002/mabi.201300126

Schmid-Wendtner MH, Korting HC (2006) The pH of the skin surface and its impact on the barrier function. Skin Pharmacol Physiol 19:296–302. https://doi.org/10.1159/000094670

Clinical and Laboratory Standards Institute (CLSI) (2015) M07–A10 Methods for dilution antimicrobial susceptibility tests for bacteria that grow aerobically; approved standard—tenth edition. Clin Infect Dis. https://doi.org/10.1093/cid/ciw353

Liu S, Ono RJ, Wu H et al (2017) Highly potent antimicrobial polyionenes with rapid killing kinetics, skin biocompatibility and in vivo bactericidal activity. Biomaterials 127:36–48. https://doi.org/10.1016/j.biomaterials.2017.02.027

Wee V, Ng L, Pang J et al (2014) Antimicrobial polycarbonates: investigating the impact of nitrogen- containing heterocycles as quaternizing agents. Macromolecules 47:1285–1291

Hyldgaard M, Mygind T, Vad BS, Stenvang M, Otzen DE, Meyer RL (2014) The Antimicrobial mechanism of action of epsilon-poly-L-lysine. Appl Environ Microbiol 80(24):7758–7770. https://doi.org/10.1128/AEM.02204-14

Hamano Y (2011) Occurrence, biosynthesis, biodegradation, and industrial and medical applications of a naturally occurring ε-poly-l-lysine. Biosci Biotechnol Biochem 75:1226–1233. https://doi.org/10.1271/bbb.110201

Chin W, Zhong G, Pu Q et al (2018) A macromolecular approach to eradicate multidrug resistant bacterial infections while mitigating drug resistance onset. Nat Commun 9:1–14. https://doi.org/10.1038/s41467-018-03325-6

Engler AC, Tan JPK, Ong ZY et al (2013) Antimicrobial polycarbonates: Investigating the impact of balancing charge and hydrophobicity using a same-centered polymer approach. Biomacromol 14:4331–4339. https://doi.org/10.1021/bm401248t

Pratt RC, Nederberg F, Waymouth M, Hedrick JL (2008) Tagging alcohols with cyclic carbonate: a versatile equivalent of (meth) acrylate for ring-opening polymerization. Chem Commun 2:114–116. https://doi.org/10.1039/b713925j

Pratt RC, Lohmeijer BG, Long DA, Lundberg PP, Dove AP, Li H, Wade CG, Waymouth RM, Hedrick JL (2006) Exploration, optimization, and application of supramolecular thiourea−amine catalysts for the synthesis of lactide (co) polymers. Macromolecules 39(23):7863–7871

Damavandi M, Pilkington LI, Whitehead KA et al (2018) Poly(para-phenylene ethynylene) (PPE)- and poly(para-phenylene vinylene) (PPV)-poly[(2-(methacryloyloxy)ethyl) trimethylammonium chloride] (PMETAC) graft copolymers exhibit selective antimicrobial activity. Eur Polym J 98:368–374. https://doi.org/10.1016/j.eurpolymj.2017.11.044

Matyjaszewski K, Tsarevsky NV (2014) Macromolecular engineering by atom transfer radical polymerization. J Am Chem Soc 136:6513–6533. https://doi.org/10.1021/ja408069v

Pintauer T, Matyjaszewski K (2008) Atom transfer radical addition and polymerization reactions catalyzed by ppm amounts of copper complexes. Chem Soc Rev 37:1087–1097. https://doi.org/10.1039/b714578k

Lou W, Venkataraman S, Zhong G, Ding B, Tan JP, Xu L, Fan W, Yang YY (2018) Antimicrobial polymers as therapeutics for treatment of multidrug-resistant Klebsiella pneumoniae lung infection. Acta Biomater 78:78–88. https://doi.org/10.1016/j.actbio.2018.07.038

Zhong G, Cheng J, Liang ZC, Xu L, Lou W, Bao C, Ong ZY, Dong H, Yang YY, Fan W (2017) Short synthetic β-sheet antimicrobial peptides for the treatment of multidrug-resistant Pseudomonas aeruginosa burn wound infections. Adv Healthc Mater 6(7):1601134

Eren Boncu T, Uskudar Guclu A, Catma MF et al (2020) In vitro and in vivo evaluation of linezolid loaded electrospun PLGA and PLGA/PCL fiber mats for prophylaxis and treatment of MRSA induced prosthetic infections. Int J Pharm 573:118758. https://doi.org/10.1016/j.ijpharm.2019.118758

Pelipenko J, Kocbek P, Kristl J (2015) Critical attributes of nanofibers: preparation, drug loading, and tissue regeneration. Int J Pharm 484:57–74. https://doi.org/10.1016/j.ijpharm.2015.02.043

Li WJ, Laurencin CT, Caterson EJ, Tuan RS, Ko FK (2002) Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res 60(4):613–621

Kuroki A, Kengmo Tchoupa A, Hartlieb M et al (2019) Targeting intracellular, multi-drug resistant Staphylococcus aureus with guanidinium polymers by elucidating the structure-activity relationship. Biomaterials 217:119249. https://doi.org/10.1016/j.biomaterials.2019.119249

Perrier S (2017) 50th anniversary perspective: RAFT polymerization: a user guide. Macromolecules 50(19):7433–7447. https://doi.org/10.1021/acs.macromol.7b00767

Moad G, Rizzardo E, Thang SH (2012) Living radical polymerization by the RAFT process a third update. Aust J Chem 65:985–1076. https://doi.org/10.1071/CH12295

Kuroki A, Martinez-Botella I, Hornung CH, Martin L, Williams EG, Locock KE, Hartlieb M, Perrier S (2017) Looped flow RAFT polymerization for multiblock copolymer synthesis. Polym Chem 8(21):3249–3254. https://doi.org/10.1039/C7PY00630F

Guo L, Yan S, Tao X et al (2020) Evaluation of hypocrellin A-loaded lipase sensitive polymer micelles for intervening methicillin-resistant Staphylococcus aureus antibiotic-resistant bacterial infection. Mater Sci Eng C 106:110230. https://doi.org/10.1016/j.msec.2019.110230

Hu Y, Zhang L, Cao Y, Ge H, Jiang X, Yang C (2004) Degradation behavior of poly(ε-caprolactone)-b-poly(ethylene glycol)-b-poly(ε-caprolactone) micelles in aqueous solution. Biomacromol 5(5):1756–1762

Huynh DP, Nguyen MK, Lee DS (2010) Controlling the degradation of pH/temperature-sensitive injectable hydrogels based on poly(β-amino ester). Mol Res 18:192–199. https://doi.org/10.1007/s13233-009-0182-0

Hyun H, Kim YH, Song IB et al (2007) In vitro and in vivo release of albumin using a biodegradable MPEG-PCL diblock copolymer as an in situ gel-forming carrier. Biomacromol 8:1093–1100. https://doi.org/10.1021/bm060991u

Christofferson AJ, Elbourne A, Cheeseman S et al (2020) Conformationally tuned antibacterial oligomers target the peptidoglycan of gram-positive bacteria. J Colloid Interface Sci 580:850–862. https://doi.org/10.1016/j.jcis.2020.07.090

Barbon SM, Truong NP, Elliott AG et al (2019) Elucidating the effect of sequence and degree of polymerization on antimicrobial properties for block copolymers. Polym Chem 11:84–90. https://doi.org/10.1039/c9py01435g

Ding X, Yang C, Peng T et al (2012) Biomaterials Antibacterial and antifouling catheter coatings using surface grafted PEG-b-cationic polycarbonate diblock copolymers. Biomaterials 33:6593–6603. https://doi.org/10.1016/j.biomaterials.2012.06.001

Nejadnik MR, Van Der MHC, Norde W, Busscher HJ (2008) Bacterial adhesion and growth on a polymer brush-coating. Biomaterials 29:4117–4121. https://doi.org/10.1016/j.biomaterials.2008.07.014

Lee H, Dellatore SM, Miller WM (2007) Mussel-inspired surface chemistry for multifunctional coatings. Science 318:426–431. https://doi.org/10.1126/science.1149504

Kamber NE, Jeong W, Waymouth RM et al (2007) Organocatalytic ring-opening polymerization. Chem Rev 107:5813–5840. https://doi.org/10.1021/cr068415b

Kaur S, Harjai K, Chhibber S (2014) Local delivery of linezolid from poly-d,l-lactide (PDLLA )– linezolid–coated orthopaedic implants to prevent MRSA mediated post-arthroplasty infections. Diagn Microbiol Infect Dis 43300:1–6. https://doi.org/10.1016/j.diagmicrobio.2014.01.026

Gollwitzer H, Ibrahim K, Meyer H et al (2003) Antibacterial poly(d,l-lactic acid) coating of medical implants using a biodegradable drug delivery technology. J Antimicrob Chemother. https://doi.org/10.1093/jac/dkg105

Lee H, Park H, Kim K et al (2011) Effect of garlic on bacterial biofilm formation on orthodontic wire. Angle Orthonist. https://doi.org/10.2319/121010-713.1

McMillan D, Lutton C, Rosenzweig N, Sriprakash KS, Goss B, Stemberger M, Schuetz M, Steck R (2011) Prevention of Staphylococcus aureus biofilm formation on metallic surgical implants via controlled release of gentamicin. J Biomed Sci Eng 4(8):535–542. https://doi.org/10.4236/jbise.2011.48069

Dinjaski N, Fernández-gutiérrez M, Selvam S et al (2013) Biomaterials PHACOS, a functionalized bacterial polyester with bactericidal activity against methicillin-resistant Staphylococcus aureus. Biomaterials. https://doi.org/10.1016/j.biomaterials.2013.09.059

Escapa IF, Morales V, Martino VP, Pollet E, Avérous L, García JL, Prieto MA (2011) Disruption of β-oxidation pathway in Pseudomonas putida KT2442 to produce new functionalized PHAs with thioester groups. Appl Microbiol Biotechnol 89(5):1583–1598. https://doi.org/10.1007/s00253-011-3099-4

Moscoso M, García E, López R (2006) Biofilm formation by Streptococcus pneumoniae: role of choline, extracellular DNA, and capsular polysaccharide in microbial accretion. J Bacteriol 188(22):7785–7795. https://doi.org/10.1128/JB.00673-06

Weintraub S, Harris LG, Thevissen K, Lewitus DY (2018) Materialia polyastaxanthin-based coatings reduce bacterial colonization in vivo. Materialia 3:15–20. https://doi.org/10.1016/j.mtla.2018.10.002

Weintraub S, Shpigel T, Harris LG et al (2017) Astaxanthin-based polymers as new antimicrobial compounds. Polym Chem 8:4182–4189. https://doi.org/10.1039/c7py00663b

Kou PM, Pallassana N, Bowden R et al (2012) Predicting biomaterial property-dendritic cell phenotype relationships from the multivariate analysis of responses to polymethacrylates. Biomaterials 33:1699–1713. https://doi.org/10.1016/j.biomaterials.2011.10.066

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kanth, S., Nagaraja, A. & Puttaiahgowda, Y.M. Polymeric approach to combat drug-resistant methicillin-resistant Staphylococcus aureus. J Mater Sci 56, 7265–7285 (2021). https://doi.org/10.1007/s10853-021-05776-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-05776-7