Abstract

To improve the corrosion resistance of biomedical titanium alloys, Ta-modified layer was prepared on Ti6Al4V substrate by double-glow plasma surface alloying technique (DGPSAT) at 750 °C. The effects of alloying time of Ta coating on the microstructure, film cohesion strength, as well as the electrochemical corrosion property had been investigated. Results showed that there were mainly β-Ta phase formed at 750 °C, the crystal grew bigger without phase transition and the layer thickness increases with the prolongation of alloying time. However, the cohesion strength and corrosion resistance of the film increase first and then decrease with the prolonging alloying time. In particular, the sample with alloying time of 30 min maintains the best cohesion strength and corrosion resistance. These are attributed to the following factors: a denser and more homogeneous coating with high cohesion strength formed on the substrate, higher positive Ecorr and lower Icorr in phosphate buffered saline (PBS) solution. Both of these accelerate the formation of tantalum oxides protective layers on metal surface and thus maintain the excellent properties.

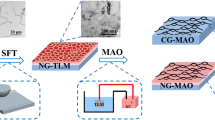

modified by β-Ta coatings with different alloying time

modified by β-Ta coatings with different alloying time: a 10 min, b 30 min, c 60 min, and d 120 min

modified by β-Ta coatings with different alloying time in different magnification: a, e 10 min, b, f 30 min, c, g 60 min, and d, h 120 min. The I, II, and III regions marked in the FESEM images are the deposition layer, the diffusion layer, and the Ti6Al4V substrates, respectively

modified by β-Ta coatings with different alloying time

modified by β-Ta coatings with different alloying time, a Nyquist plots and b Bode plots

modified by β-Ta coatings with different alloying time: a Ti6Al4V, b 10 min, c 30 min, d 60 min, and e 120 min

modified by β-Ta coatings with alloying time of 30 min. a FESEM images, b Ta element, c O element, d Ti element, e Al element, f V element, and g element concentration

modified by β-Ta coatings with different alloying time

Similar content being viewed by others

References

Li J, Cui XL, Hooper GJ, Lim KS, Woodfield TBF (2020) Rational design, bio-functionalization and biological performance of hybrid additive manufactured titanium implants for orthopaedic applications: a review. J Mech Behav Biomed 105:103671

Harun WSW, Manam NS, Kamariah MSIN, Sharif S, Zulkifly AH, Ahmad I, Miura H (2018) A review of powdered additive manufacturing techniques for Ti-6Al-4V biomedical applications. Powder Technol 331:74–97

Rack HJ, Qazi JI (2006) Titanium alloys for biomedical applications. Mat Sci Eng C-Mater 26:1269–1277

Matusiewicz H (2014) Potential release of in vivo trace metals from metallic medical implants in the human body: From ions to nanoparticles—a systematic analytical review. Acta Biomater 10:2379–2403

Zhang LC, Chen LY, Wang L (2020) Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv Eng Mater 22:1901258

Yu XM, Tan LL, Yang HZ, Yang K (2015) Surface characterization and preparation of Ta coating on Ti6Al4V alloy. J Alloy Compd 644:698–703

Liu X, Chu PK, Ding C (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng: R: Reports 47:49–121

Hee AC, Zhao Y, Jamali SS, Martin PJ, Bendavid A, Peng H, Cheng XW (2017) Corrosion behaviour and microstructure of tantalum film on Ti6Al4V substrate by filtered cathodic vacuum arc deposition. Thin Solid Films 636:54–62

Liu L, Xu J, Lu XL, Munroe PR, Xie Z (2016) Electrochemical corrosion behavior of nanocrystalline β-Ta coating for biomedical applications. ACS Biomater Sci Eng 2:579–594

Fattah-alhosseini A, Elmkhah H, Ansari G, Attarzadeh F, Imantalab O (2018) A comparison of electrochemical behavior of coated nanostructured Ta on Ti substrate with pure uncoated Ta in Ringer’s physiological solution. J Alloy Compd 739:918–925

Kuo TY, Chin WH, Chien CS, Hsieh YH (2019) Mechanical and biological properties of graded porous tantalum coatings deposited on titanium alloy implants by vacuum plasma spraying. Surf Coat Tech 372:399–409

Hee AC, Jamali SS, Bendavid A, Martin PJ, Kong C, Zhao Y (2016) Corrosion behaviour and adhesion properties of sputtered tantalum coating on Ti6Al4V substrate. Surf Coat Tech 307:666–675

Zhang LC, Chen LY (2019) A review on biomedical titanium alloys: recent progress and prospect. Adv Eng Mater 21:1801215

Hee AC, Zhao Y, Jamali SS, Bendavid A, Martin PJ, Guo HB (2019) Characterization of tantalum and tantalum nitride films on Ti6Al4V substrate prepared by filtered cathodic vacuum arc deposition for biomedical applications. Surf Coat Tech 365:24–32

Li X, Wang L, Yu XM, Feng Y, Wang CT, Yang K, Su D (2013) Tantalum coating on porous Ti6Al4V scaffold using chemical vapor deposition and preliminary biological evaluation. Mat Sci Eng C-Mater 33:2987–2994

Rahmati B, Sarhan AAD, Basirun WJ, Abas WABW (2016) Ceramic tantalum oxide thin film coating to enhance the corrosion and wear characteristics of Ti6Al4V alloy. J Alloy Compd 67:369–376

Liu X, Chu PK, Ding C (2004) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R Rep 47:49–121

Xu Z, Liu X, Zhang P, Zhang Y, Zhang G, He Z (2007) Double glow plasma surface alloying and plasma nitriding. Surf Coat Tech 201:4822–4825

Xu Z, Xiong FF (2017) Plasma surface metallurgy: with double glow discharge technology. Science Press, Beijing, pp 33–62

Wei D, Zhang P, Yao Z, Chen X, Li F (2018) Double-glow plasma surface Cr-Ni alloying of Ti6Al4V alloys: Mechanical properties and impact of preparing process on the substrate. Vacuum 155:233–241

Ren B, Miao Q, Liang W, Yao Z, Zhang P (2013) Characteristics of Mo-Cr duplex-alloyed layer on Ti6Al4V by double glow plasma surface metallurgy. Surf Coat Tech 228:S206–S209

Wei D, Li F, Li S, Wang S, Ding F, Liang H, Yan Y, Zhang P (2020) A combined experimental and first-principle study on the effect of plasma surface Ta-W co-alloying on the oxidation behavior of γ-TiAl at 900 °C. J Mater Res 35:516–526

Zhang L, Shen Z, Xu J (2003) Glass formation in a (Ti, Zr, Hf)-(Cu, Ni, Ag)-Al high-order alloy system by mechanical alloying. J Mater Res 18:2141–2149

Chen LY, Xu T, Lu S, Wang ZX, Chen S, Zhang LC (2018) Improved hardness and wear resistance of plasma sprayed nanostructured NiCrBSi coating via short-time heat treatment. Surf Coat Technol 350:436–444

Periassamy M, Krishnaswamy PR (1975) Corrosion rate and tafel slopes from polarization curves. Electro Chem lnter Electro 61:349–352

Yu YH, Lin YY, Lin CH, Chan CC, Huang YC (2014) High-performance polystyrene/graphene-based nanocomposites with excellent anti-corrosion properties. Poly Chem 5(2):535–550

Maeng S, Axe L, Tyson TA et al (2006) Corrosion behaviour of magnetron sputtered α-and β-Ta coatings on AISI 4340 steel as a function of coating thickness. Corros sci 48(8):2154–2171

Jiang A, Tyson TA, Axe L et al (2005) The structure and stability of β-Ta thin films. Thin Solid Films 479(1–2):166–173

Patterson AL (1939) The scherrer formula for X-ray particle size determination. Phys Rev 56:978–982

Tomaszewski PE (2013) The uncertainty in the grain size calculation from X-ray diffraction data. Phase Trans Multinat 86(2–3):260–266

Lieberman MA, Lichtenberg AJ (2005) Principles of plasma discharges and materials processing. Wiley, Hoboken

Floro JA, Hearne SJ, Hunter JA, Kotula P, Chason E, Seel SC, Thompson CV (2001) The dynamic competition between stress generation and relaxation mechanisms during coalescence of Volmer-Weber thin films. J Appl Phys 89:4886–4897

Koch R (1994) The intrinsic stress of polycrystalline and epitaxial thin metal films. J Phys Condens Matter 6:9519–9550

Hogmark S, Jacobson S, Larsson M (2000) Design and evaluation of tribological coatings. Wear 246:20–33

Khun NW, Liu E (2011) Investigation of structure, adhesion strength, wear performance and corrosion behavior of platinum/ruthenium/nitrogen doped diamond-like carbon thin films with respect to film thickness. Mater Chem Phys 126:220–226

Ahmed BR, Sarhanad AD, Zalnezhadb E, Kamiaba Z, Dabbagha A, Choudhuryc D, Abas WABW (2016) Development of tantalum oxide (Ta-O) thin film coating on biomedical Ti-6Al-4V alloy to enhance mechanical properties and biocompatibility. Ceram Int 42:466–480

Rahmatia B, Sarhana AAD, Basirunb WJ, Abasc WABW (2016) Ceramic tantalum oxide thin film coating to enhance the corrosion and wear characteristics of Ti-6Al-4V alloy. J Alloy Compd 676:369–376

Xu J, Hu W, Xu S, Munroe P, Xie ZH (2016) Electrochemical properties of a novel β-Ta2O5 nanoceramic coating exposed to simulated body solutions. ACS Biomater Sci Eng 2:73–89

Cafferty EM (2005) Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci 47:3202–3215

Liu Y, Yan D, Li Y, Wu Z, Zhuo R, Li S, Feng J, Wang J, Yan P, Geng Z (2014) Manganese dioxide nanosheet arrays grown on graphene oxide as an advanced electrode material for supercapacitors. Electrochim Acta 117:528–533

Zhang H, Man C, Wang L, Dong C, Wang L, Kong D, Wang X (2020) Different corrosion behaviors between α and β phases of Ti6Al4V in fluoride-containing solutions: influence of alloying element Al. Corros Sci 169:108605

Barranco V, Escudero ML, García-Alonso MC (2007) 3D, chemical and electrochemical characterization of blasted Ti6Al4V surfaces: its influence on the corrosion behaviour. Electrochim Acta 52:4374–4384

Luo J, Hein C, Pierson JF, Mücklich F (2019) Localised corrosion attacks and oxide growth on copper in phosphate buffered saline. Mater Charact 158:109985

Li Y, Macdonald DD, Yang J, Qiu J, Wang S (2020) Point defect model for the corrosion of steels in supercritical water: part I, film growth kinetics. Corros Sci 163:108280

Zhang XY, Shi MH, Li C, Liu NF, Wei YM (2007) The influence of grain size on the corrosion resistance of nanocrystalline zirconium metal. Mater Sci Eng A-Struct 448:259–263

Liu L, Li Y, Wang F (2008) Influence of grain size on the corrosion behavior of a Ni-based superalloy nanocrystalline coating. Electrochem Acta 53:2453–2462

Ralston KD, Birbilis N, Davies CHJ (2010) Revealing the relationship between grain size and corrosion rate of metals. Scripta Mater 63:1201–1204

Sivakumar B, Pathak LC, Singh R (2017) Role of surface roughness on corrosion and fretting corrosion behaviour of commercially pure titanium in Ringer’s solution for bio-implant application. Appl Surf Sci 401:385–398

Pradhan D, Mahobia GS, Chattopadhyay K, Singh V (2018) Effect of surface roughness on corrosion behavior of the superalloy IN718 in simulated marine environment. J Alloy Compd 740:250–263

Cruza V, Chaoc Q, Birbilise N, Fabijanicc D, Hodgsonc PD, Thomas S (2020) Electrochemical studies on the effect of residual stress on the corrosion of 316L manufactured by selective laser melting. Corros Sci 164:108314

Hosaka T, Yoshihara S, Amanina I, MacDonald BJ (2017) Influence of grain refinement and residual stress on corrosion behavior of AZ31 magnesium alloy processed by ECAP in RPMI-1640 medium. Procedia Eng 184:432–441

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant Nos. 51801133, 51901154), the Science and Technology Major Project of Shanxi (Grant No. 20181102013), “1331 Project” Engineering Research Center of Shanxi (PT201801) and the Young Scholar Foundation of Shanxi Province (No. 201801D221135, 201901D211092) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Zhou, B., Wang, H. et al. Corrosion properties of β-Ta alloyed Ti6Al4V by double-glow plasma surface alloying technique. J Mater Sci 56, 6487–6498 (2021). https://doi.org/10.1007/s10853-020-05626-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05626-y