Abstract

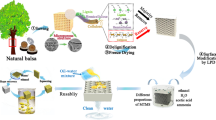

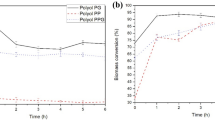

Wood can be used for the in situ preparation of wood sponge using chemical treatment, which can be employed as absorbent for sewage treatment and exhibits the advantage of low cost, low density, high porosity, and environmental friendliness. Previous researches on wood sponge mainly focused on its various applications, while the influence rule and mechanism of treatment conditions such as pH and concentration of NaClO2 solution, as well as concentration of NaOH solution have not been fully understood. This challenge limits the manufacturing efficiency and further application of wood sponge for the production of absorption materials and so on. The study presented an effective strategy for preparing wood sponges via using a top–down chemical treatment on low-density balsa wood and paid more attention to the controlling rule of preparation parameters. At the condition that pH of 4.0 (NaClO2 solution), NaOH concentration of 7 wt%, and NaClO2 concentration of 3 wt%, wood sponge with a porosity of 96.47% can be obtained with good resilience and excellent absorption capacity. Excessive concentration of NaOH and NaClO2 will significantly affect the skeletal structure of the wood sponge. After the silylation treatment, the optimal wood sponge was endowed with oil and organic solvents absorption capacity of 2441–17,300 mg g−1; it can be also recycled by simple extrusion. This highly resilient and recyclable wood sponge with high porosity and oil absorption capacity can be potentially applied for environmental protection.

Similar content being viewed by others

References

Yong JL, Chen F, Yang Q, Bian H, Du GQ, Shan C, Huo JL, Fang Y, Hou X (2016) Oil-water separation: a gift from the desert. Adv Mater Interfaces 3:1500650. https://doi.org/10.1002/admi.201500650

Ren XY, Zeng GM, Tang L, Wang JJ, Wan J, Liu YN, Yu JF, Yi H, Ye SJ, Deng R (2018) Sorption, transport and biodegradation-an insight into bioavailability of persistent organic pollutants in soil. Sci Total Environ 610–611:1154–1163

Zhao X, Liu W, Fu J, Cai ZQ, O’Reilly SE, Zhao DY (2016) Dispersion, sorption and photodegradation of petroleum hydrocarbons in dispersant-seawater-sediment systems. Mar Pollut Bull 109:526–538

Kiama N, Ponchio C (2020) Photoelectrocatalytic reactor improvement towards oil-in-water emulsion degradation. J Environ Manage: 111568. https://doi.org/10.1016/j.jenvman.2020.111568

Duan B, Gao HM, He M, Zhang LN (2014) Hydrophobic modification on surface of chitin sponges for highly effective separation of oil. ACS Appl Mater Inter 6: 19933–19942

Li ZZ, Wang B, Qin XM, Wang YK, Liu CT, Shao Q, Wang N, Zhang JX, Wang ZK, Shen CY, Guo ZH (2018) Superhydrophobic/superoleophilic polycarbonate/carbon nanotubes porous monolith for selective oil adsorption from water. ACS Sustain Chem Eng 6:13747–13755

Wang KL, Liu XR, Tan Y, Zhang W, Zhang SF, Li JZ (2019) Two-dimensional membrane and three-dimensional bulk aerogel materials via top-down wood nanotechnology for multibehavioral and reusable oil/water separation. Chem Eng J 371: 769–780

Villacanas F, Pereira MFR, Orfao JJM, Figureueiredo JL (2006) Adsorption of simple aromatic compounds on activated carbons. J Colloid Interf Sci 293: 128–136

Chen B, Ma QL, Tan CL, Lim TT, Huang L, Zhang H (2015) Carbon-based sorbents with three-dimensional architectures for water remediation. Small 11: 3319–3336

Li QQ, Deng WJ, Li CH, Sun QY, Huang FZ, Zhao Y, Li SK (2018) High-flux oil/water separation with interfacial capillary effect in switchable superwetting Cu(OH)2@ZIF-8 nanowire membranes. ACS Appl Mater Inter 10: 40265–40273

Shi MB, Huang RL, Qi W, Su RX, He ZM (2020) Synthesis of superhydrophobic and high stable Zr-MOFs for oil-water separation. Colloid Surface A 602: 125102. https://doi.org/10.1016/j.colsurfa.2020.125102

Xiang C, Guo RH, Lan JW, Jiang SX, Wang C, Du ZF, Cheng C (2017) Self-assembling porous 3D titanium dioxide-reduced graphene oxide aerogel for the tunable absorption of oleic acid and RhodamineB dye. J Alloy Compd 735: 246–252

Jiang JX, Zhang QH, Zhan XL, Chen FQ (2019) A multifunctional gelatin-based aerogel with superior pollutants adsorption, oil/water separation and photocatalytic properties. Chem Eng J 358: 1539–1551

Zhang H, Li YQ, Shi RH, Chen LH, Fan MZ (2018) A robust salt-tolerant superoleophobic chitosan/nanofibrillated cellulose aerogel for highly efficient oil/water separation. Carbohyd Polym 200: 611–615

Gong XY, Wang YX, Zeng HB, Betti M, Chen LY (2019) Highly porous, hydrophobic, and compressible cellulose nanocrystals/PVA aerogels as recyclable absorbents for oil-water separation. ACS Sustain Chem Eng 7: 11118–11128

Parmar KR, Dora DTK, Pant KK, Roy S (2019) An ultra-light flexible aerogel-based on methane derived CNTs as a reinforcing agent in silica-CMC matrix for efficient oil adsorption. J Hazard Mater 375:206–215

Zhu H, Yang X, Cranston ED, Zhu SP (2016) Flexible and porous nanocellulose aerogels with high loadings of metal-organic-framework particles for separations applications. Adv Mater 28: 7652–7657

Peng HL, Wang H, Wu JN, Meng GH, Wang YX, Shi YL, Liu ZY, Guo XH (2016) Preparation of superhydrophobic magnetic cellulose sponge for removing oil from water. Ind Eng Chem Res 55: 832–838

Li YQ, Guo CF, Shi RH, Zhang H, Gong LZ, Dai LB (2019) Chitosan/nanofibrillated cellulose aerogel with highly oriented microchannel structure for rapid removal of Pb (II) ions from aqueous solution. Carbohyd Polym 223: 115048. https://doi.org/10.1016/j.carbpol.2019.115048

Zhang Z, Sèbe G, Rentsch D, Zimmermann T, Tingaut P (2014) Ultralightweight and flexible silylated nanocellulose sponges for the selective removal of oil from water. Chem Mater 26: 2659–2668

Liu K, Chen LH, Huang LL, Lin S, Cao SL, Wang HP (2018) Adsorption behaviors of acidic and basic dyes by thiourea-modified nanocomposite aerogels based on nanofibrillated cellulose. Bioresources 13: 5836–5849

Zhu HL, Luo W, Ciesielski PN, Fang ZQ, Zhu JY, Henriksson G, Himmel ME, Hu LB (2016) Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev 116: 9305–9374

Chen CJ, Song JW, Cheng J, Pang ZQ, Gan WT, Chen GG, Kuang YD, Huang H, Ray U, Li T, Hu LB (2020) Highly elastic hydrated cellulosic materials with durable compressibility and tunable conductivity. ACS Nano 14: 16723−16734

Zhang Q, Li L, Jiang B, Zhang HT, He N, Yang S, Tang DW, Song YC (2020) Flexible and mildew-resistant wood-derived aerogel for stable and efficient solar desalination. ACS Appl Mater Inter 12: 28179–28187

Garemark J, Yang X, Sheng X, Cheung O, Sun LC, Berglund LA, Li YY (2020) Top-down approach making anisotropic cellulose aerogels as universal substrates for multifunctionalization. ACS Nano 14: 7111–7120

Hou DX, Li T, Chen X, He SM, Dai JQ, Mofid SA, Hou DY, Iddya A, Jassby D, Yang RG, Hu LB, Ren ZJ (2019) Hydrophobic nanostructured wood membrane for thermally efficient distillation. Sci Adv 5: eaaw3203. https://doi.org/10.1126/sciadv.aaw3203

Huang DF, Wu JY, Chen CJ, Fu XX, Brozena AH, Zhang Y, Gu P, Li C, Yuan CS, Ge HX, Lu MH, Zhu MW, Hu LB, Chen YF (2019) Precision imprinted nanostructural wood. Adv Mater 31: 1903270. https://doi.org/10.1002/adma.201903270

Li T, Zhu MW, Yang Z, Song JW, Dai JQ, Yao YG, Luo W, Pastel G, Yang B, Hu LB (2016) Wood composite as an energy efficient building material: guided sunlight transmittance and effective thermal insulation. Adv Energy Mater 6: 1601122. https://doi.org/10.1002/aenm.201601122

Zhu MW, Li T, Davis CS, Yao YG, Dai JQ, Wang YB, AlQatari F, Gilman JW, Hu LB (2016) Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 26: 332–339

He SM, Chen CJ, Li T, Song JW, Zhao XP, Kuang YD, Liu Y, Pei Y, Hitz E, Kong WQ, Gan WT, Yang B, Yang RG, Hu LB (2019) An energy-efficient, wood-derived structural material enabled by pore structure engineering towards building efficiency. Small Methods 4: 1900747. https://doi.org/10.1002/smtd.201900747

Gan WT, Chen CJ, Wang ZY, Song JW, Kuang YD, He SM, Mi RY, Sunderland PB, Hu LB (2019) Dense, self-formed char layer enables a fire-retardant wood structural material. Adv Funct Mater 29: 1807444. https://doi.org/10.1002/adfm.201807444

Chen ZH, Zhuo H, Hu YJ, Lai HH, Liu LX, Zhong LX, Peng XW (2020) Wood-derived lightweight and elastic carbon aerogel for pressure sensing and energy storage. Adv Funct Mater 30: 1910292. https://doi.org/10.1002/adfm.201910292

Fu QL, Chen Y, Sorieul M (2020) Wood-based flexible electronics. ACS Nano 14: 3528–3538

Fu QL, Ansari F, Zhou Q, Berglund LA (2018) Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano 12: 2222–2230

Chen CJ, Kuang YD, Zhu SZ, Burgert I, Keplinger T, Gong A, Li T, Berglund L, Eichhorn SJ, Hu LB (2020) Structure-property-function relationships of natural and engineered wood. Nat Rev Mater 5: 642–666

Chen CJ, Kuang YD, Hu LB (2019) Challenges and opportunities for solar evaporation. Joule 3: 683–718

Liu H, Chen CJ, Chen G, Kuang YD, Zhao XP, Song JW, Jia C, Xu X, Hitz H, Xie H, Wang S, Jiang F, Li T, Li YJ, Gong A, Yang RG, Das S, Hu LB (2017) High-performance solar steam device with layered channels: artificial tree with a reversed design. Adv Energy Mater 8: 1701616. https://doi.org/10.1002/aenm.201701616

Jia C, Jiang F, Hu P, Kuang YD, He SM, Li T, Chen CJ, Murphy A, Yang CP, Yao YG, Dai JQ, Raub CB, Luo XL, Hu LB (2018) Anisotropic, mesoporous microfluidic frameworks with scalable, aligned cellulose nanofibers. ACS Appl Mater Inter 10: 7362–7370

Chen FJ, Gong AS, Zhu MW, Chen G, Lacey SD, Jiang F, Li YF, Wang YB, Dai JQ, Yao YG, Song JW, Liu BY, Fu K, Das S, Hu LB (2017) Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano 11: 4275–4282

Guan H, Cheng ZY, Wang XQ (2018) Highly compressible wood sponges with a spring-like lamellar structure as effective and reusable oil absorbents. ACS Nano 12: 10365–10373

Meng YJ, Young TM, Liu PZ, Contescu CI, Huang B, Wang SQ (2018) Ultralight carbon aerogel from nanocellulose as a highly selective oil absorption material. Cellulose 22: 435–447

Wan CC, Jiao Y, Wei S, Li XJ, Tian WY, Wu YQ, Li J (2019) A scalable top-to-bottom design on low tortuosity of anisotropic carbon aerogels for fast and reusable passive capillary absorption and separation of organic leakages. ACS Appl Mater Inter 11: 47846–47857

Focher B, Palma MT, Canetti M, Torri G, Cosentino C, Gastaldi G (2001) Structural differences between non-wood plant celluloses: evidence from solid state NMR, vibrational spectroscopy and X-ray diffractometry. Ind Crops Prod 13: 193–208

Li YY, Fu QL, Yu S, Yan M, Berglund L (2016) Optically transparent wood from a nanoporous cellulosic template: combining functional and structural performance. Biomacromol 17: 1358–1364

Kolar JJ, Lindgren BO, Birgitta P (1983) Chemical reactions in chlorine dioxide stages of pulp bleaching. Wood Sci Technol 17: 117–128

Xing LD, Hu CS, Zhang WW, Guan LT, Gu J (2020) Transition of cellulose supramolecular structure during concentrated acid treatment and its implication for cellulose nanocrystal yield. Carbohyd Polym 229: 115539. https://doi.org/10.1016/j.carbpol.2019.115539

Håkansson H, Ahlgren P, Germgård U (2005) The degree of disorder in hardwood kraft pulps studied by means of LODP. Cellulose 12: 327–335

Sun RC, Fang JM, Goodwin A, Lawther JM, Bolton AJ (1998) Fractionation and characterization of polysaccharides from abaca fibre. Carbohyd Polym 37: 351–359

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15: 25–33

Mishra S, Mohanty AK, Drzal LT, Misra M, Parija S, Nayak SK, Tipathy SS (2003) Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos Sci Technol 63: 1377–1385

Hubbell CA, Ragauskas AJ. (2010) Effect of acid-chlorite delignification on cellulose degree of polymerization. Bioresource Technol 101: 7410–7415

Yue YY, Han JQ, Han GP, Aita GM, Wu QL (2015) Cellulose fibers isolated from energycane bagasse using alkaline and sodium chlorite treatments: structural, chemical and thermal properties. Ind Crop Prod 76: 355–363

Chen CJ, Song JW, Zhu SZ, Li YJ, Kuang YD, Wan JY, Kirsch D, Xu LS, Wang YB, Gao TT, Wang YL, Huang H, Gan WT, Gong A, Li T, Xie J, Hu LB (2018) Scalable and sustainable approach toward highly compressible, anisotropic, lamellar carbon sponge. Chem 4: 544–554

Song JW, Chen CJ, Yang Z, Kuang YD, Li T, Li YJ, Huang H, Kierzewski I, Liu BY, He SM, Gao TT, Yuruker SU, Gong A, Yang B, Hu LB (2018) Highly compressible, anisotropic aerogel with aligned cellulose nanofibers. ACS Nano 12: 140–147

Shamsuri AA, Daik R (2012) Plasticizing effect of choline chloride/urea eutectic-based ionic liquid on physicochemical properties of agarose films. Bioresources 7: 4760–4775

Guo AF, Sun ZH, Satyavolu J (2019) Impact of chemical treatment on the physiochemical and mechanical properties of kenaf fibers. Ind Crop Prod 141: 111726. https://doi.org/10.1016/j.indcrop.2019.111726

Vázquez G, Antorrena G, González J, Freire S (1997) FTIR, 1H and 13C NMR characterization of acetosolv-solubilized pine and eucalyptus lignins. Holzforschung 51:158–166

Nuopponen M, Vuorinen T, Jämsä S, Viitaniemi P (2005) Thermal modifications in softwood studied by FT‐IR and UV resonance raman spectroscopies. J Wood Chem Technol 24: 13–26

Sammons RJ, Harper DP, Labbé N, Bozell JJ, Elder T, Rials TG (2013) Characterization of organosolv lignins using thermal and FT-IR spectroscopic analysis. Bioresources 8: 2752–2767

Horikawa Y, Hirano S, Mihashi A, Kobayashi Y, Zhai SC, Sugiyama J (2019) Prediction of lignin contents from infrared spectroscopy: chemical digestion and lignin/biomass ratios of cryptomeria japonica. Appl Biochem Biotech 188: 1066–1076

Kuo YN, Hong J (2005) Investigation of solubility of microcrystalline cellulose in aqueous NaOH. Polym Advan Technol 16:425–428

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84: 2222–2234

Carrillo F, Colom X, Suñol JJ, Saurina J (2004) Structural FTIR analysis and thermal characterisation of lyocell and viscose-type fibres. Eur Polym J 40: 2229–2234

Xu Z, Wang QH, Jiang ZH, Yang XX, Ji YZ (2007) Enzymatic hydrolysis of pretreated soybean straw. Biomass Bioenergy 31:162–167

He YF, Pang YZ, Liu YP, Li XJ, Wang KS (2008) Physicochemical characterization of rice straw pretreated with sodium hydroxide in the solid state for enhancing biogas production. Energ Fuel 22: 2775–2781

Liu YP, Hu H (2008) X-ray diffraction study of bamboo fibers treated with NaOH. Fiber Polym 9: 735–739

Carrillo-Varela I, Pereira M, Mendonça RT (2018) Determination of polymorphic changes in cellulose from Eucalyptus spp. fibres after alkalization. Cellulose 25: 6831–6845

Awadel-Karim S, Nazhad MM, Paszner L (1999) Factors affecting crystalline structure of cellulose during solvent purification treatment. Holzforschung 53: 1–8

Hua X, Kaliaguine S, Kokta BV, Adnot A (1993) Surface analysis of explosion pulps by ESCA Part 1. Carbon (1s) spectra and oxygen-to-carbon ratios. Wood Sci Technol 27: 449–459

Ahmed A, Adnot A, Kaliaguine S (1987) ESCA study of the solid residues of supercritical extraction of populus tremuloïdes in methanol. J Appl Polym Sci 34:359–375

Kamdem DP, Riedl B, Adnot A, Kaliaguine S (1991) ESCA spectroscopy of poly(methyl methacrylate) grafted onto wood fibers. J Appl Polym Sci 43: 1901–1912

Östenson M, Järund H, Toriz G, Gatenholm P (2006) Determination of surface functional groups in lignocellulosic materials by chemical derivatization and ESCA analysis. Cellulose 13: 157–170

Kazayawoko M, Balatinecz JJ, Sodhi RNS (1999) X-ray photoelectron spectroscopy of maleated polypropylene treated wood fibers in a high-intensity thermokinetic mixer. Wood Sci Technol 33: 359–372

Wang ZQ, Jin PX, Wang M, Wu GH, Dong C, Wu AG (2016) Biomass-derived porous carbonaceous aerogel as sorbent for oil-spill remediation. ACS Appl Mater Inter 8: 32862–32868

Dai JD, Zhang RL, Ge WN, Xie AT, Chang ZS, Tian SJ, Zhou ZP, Yan YS (2018) 3D macroscopic superhydrophobic magnetic porous carbon aerogel converted from biorenewable popcorn for selective oil-water separation. Mater Design 139: 122–131

Karatum O, Steiner SA, Griffin JS, Shi WB, Plata DL (2016) Flexible, mechanically durable aerogel composites for oil capture and recovery. ACS Appl Mater Inter 8: 215−224

Bi HC, Xie X, Yin KB, Zhou YL, Wan S, He LB, Xu F, Banhart F, Sun LT, Ruoff RS (2012) Spongy graphene as a highly efficient and recyclable sorbent for oils and organic solvents. Adv Funct Mater 22: 4421–4425

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC) (Project No. 31700496), the Guangxi Natural Science Foundation of China (Project No. 2017GXNSFBA198015) and the Guangxi Innovation-Driven Development Special Fund Project of China (Project No. AA17204087-18).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, Z., Lin, S., Li, X. et al. Optimization and absorption performance of wood sponge. J Mater Sci 56, 8479–8496 (2021). https://doi.org/10.1007/s10853-020-05547-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05547-w