Abstract

A titanium nitride-polytetrafluoroethylene (TiN-PTFE) composite film was developed on Q235 steel surface to achieve the superhydrophobic property. The morphology and wettability of TiN-PTFE films were regulated by changing the deposition thickness during electron beam deposition, resulting in the optimized hydrophobicity with a water contact angle of ~ 157.8° and a sliding angle down to ~ 3.6°. The superhydrophobic TiN-PTFE film could easily clean the surface contaminations by water dropping, given the excellent self-cleaning performance. Electrochemical measurement results showed that the TiN-PTFE surface could efficiently strengthen the corrosion resistance of carbon steel in 3.5 wt% NaCl solution through the protective barrier and the air cushion trapped inside the coating. Besides, the superhydrophobic film exhibited good chemical stability in acid and alkaline solutions as well as remarkable mechanical durability against abrasion. This work offers an efficient and cost-effective strategy for the large-scale fabrication of superhydrophobic films. It is expected that the superhydrophobic TiN-PTFE film has promising prospects for self-cleaning and corrosion protection applications.

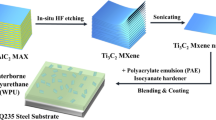

Graphic abstract

Similar content being viewed by others

References

Ding C, Tai Y, Wang D, Tan L, Fu J (2019) Superhydrophobic composite coating with active corrosion resistance for AZ31B magnesium alloy protection. Chem Eng J 357:518–532. https://doi.org/10.1016/j.cej.2018.09.133

Xu S, Wang Q, Wang N, Zheng X (2019) Fabrication of superhydrophobic green surfaces with good self-cleaning, chemical stability and anti-corrosion properties. J Mater Sci 54:13006–13016. https://doi.org/10.1007/s10853-019-03789-x

He T, Chen X, Wang Y et al (2020) Fabrication of durable superhydrophobic surfaces of polyester fabrics via fluorination-induced grafting copolymerization. Appl Surf Sci 515:146006. https://doi.org/10.1016/j.apsusc.2020.146006

Jiang C, Liu W, Yang M, Zhang F, Shi H, Xie Y, Wang Z (2019) Robust fabrication of superhydrophobic and photocatalytic self-cleaning cotton textiles for oil-water separation via thiol-ene click reaction. J Mater Sci 54(9):7369–7382. https://doi.org/10.1007/s10853-019-03373-3

Zhang B, Xu W, Zhu Q, Li Y, Hou B (2018) Ultrafast one step construction of non-fluorinated superhydrophobic aluminum surfaces with remarkable improvement of corrosion resistance and anti-contamination. J Colloid Interface Sci 532:201–209. https://doi.org/10.1016/j.jcis.2018.07.136

Zheng S, Li C, Fu Q et al (2015) Fabrication of self-cleaning superhydrophobic surface on aluminum alloys with excellent corrosion resistance. Surf Coat Technol 276:341–348. https://doi.org/10.1016/j.surfcoat.2015.07.002

Ma L, Wang J, Zhao F et al (2019) Plasmon-mediated photothermal and superhydrophobic TiN-PTFE film for anti-icing/deicing applications. Compos Sci Technol 181:107696. https://doi.org/10.1016/j.compscitech.2019.107696

Yin X, Zhang Y, Wang D, Liu Z, Liu Y, Pei X, Yu B, Zhou F (2015) Integration of self-lubrication and near-infrared photothermogenesis for excellent anti-icing/deicing performance. Adv Funct Mater 25:4237–4245. https://doi.org/10.1002/adfm.201501101

Hu D, Yu Q, Yang Y, Weng L (2020) Fabrication and wetting behaviour of micro/nanostructured mushroom-shaped silver pillar surface. Nanotechnol 31:175701. https://doi.org/10.1088/1361-6528/ab674b

Selim M, El-Safty S, Fatthallah N, Shenashen M (2018) Silicone/graphene oxide sheet-alumina nanorod ternary composite for superhydrophobic antifouling coating. Prog Org Coat 121:160–172. https://doi.org/10.1016/j.porgcoat.2018.04.021

Erbil H, Demirel A, Avci Y, Mert O (2003) Transformation of a simple plastic into a superhydrophobic surface. Science 299:1377–1380. https://doi.org/10.1126/science.1078365

Sun T, Wang G, Feng L, Liu B, Ma Y, Jiang L, Zhu D (2004) Reversible switching between superhydrophilicity and superhydrophobicity. Angew Chem Int Ed 43:357–360. https://doi.org/10.1002/anie.200352565

Aurélie L, David Q (2003) Superhydrophobic states. Nat Mater 2:457–460. https://doi.org/10.1038/nmat924

Wilhelm B, Matthias M, Bharat B, Kerstin K (2017) Plant surfaces: structures and functions for biomimetic innovations. Nano-micro Lett 9:23. https://doi.org/10.1007/s40820-016-0125-1

Guo Z, Liu W, Su B (2011) Superhydrophobic surfaces: from natural to biomimetic to functional. J Colloid Interface Sci 353:335–355. https://doi.org/10.1016/j.jcis.2010.08.047

Lu Z, Xu L, He Y, Zhou J (2019) One-step facile route to fabricate functionalized nano-silica and silicone sealant based transparent superhydrophobic coating. Thin Solid Films 692:137560. https://doi.org/10.1016/j.tsf.2019.137560

Lee K, Park H, Kim J, Chun D (2019) Fabrication of a superhydrophobic surface using a fused deposition modeling (FDM) 3D printer with poly lactic acid (PLA) filament and dip coating with silica nanoparticles. Appl Surf Sci 467:979–991. https://doi.org/10.1016/j.apsusc.2018.10.205

Elzaabalawy A, Verberne P, Meguid S (2019) Multifunctional silica-silicone nanocomposite with regenerative superhydrophobic capabilities. ACS Appl Mater Interfaces 11:42827–42837. https://doi.org/10.1021/acsami.9b15445

Yousefi E, Ghadimi M, Amirpoor S, Dolati A (2018) Preparation of new superhydrophobic and highly oleophobic polyurethane coating with enhanced mechanical durability. Appl Surf Sci 454:201–209. https://doi.org/10.1016/j.apsusc.2018.05.125

Lin D, Zeng X, Li H, Lai X, Wu T (2019) One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J Colloid Interface Sci 533:198–206. https://doi.org/10.1016/j.jcis.2018.08.060

Liu E, Yin X, Hu J, Yu S, Zhao Y, Xiong W (2020) Fabrication of a biomimetic hierarchical superhydrophobic Cu–Ni coating with self-cleaning and anti-corrosion properties. Colloid Surf A 586:124223. https://doi.org/10.1016/j.colsurfa.2019.124223

Xu W, Song J, Sun J, Dou Q, Fan X (2011) Fabrication of superhydrophobic surfaces on aluminum substrates using NaNO3 electrolytes. J Mater Sci 46:5925–5930. https://doi.org/10.1007/s10853-011-5546-0

Sakalak H, Yilmaz K, Gürsoy M, Karaman M (2020) Roll-to roll initiated chemical vapor deposition of super hydrophobic thin films on large-scale flexible substrates. Chem Eng Sci 215:115466. https://doi.org/10.1016/j.ces.2019.115466

Hou W, Shen Y, Tao J, Xu Y, Jiang J, Chen H, Jia Z (2020) Anti-icing performance of the superhydrophobic surface with micro-cubic array structures fabricated by plasma etching. Colloid Surf A 586:124180. https://doi.org/10.1016/j.colsurfa.2019.124180

Cho S, Kim J, Lee H, Chae H, Kim C (2016) Superhydrophobic Si surfaces having microscale rod structures prepared in a plasma etching system. Surf Coat Technol 306:82–86. https://doi.org/10.1016/j.surfcoat.2016.05.009

Li X, Zhang D, Liu Z, Li Z, Du C, Dong C (2015) Materials science: Share corrosion data. Nature 527:441–442. https://doi.org/10.1038/527441a

Zeng Y, Li K (2020) Influence of SO2 on the corrosion and stress corrosion cracking susceptibility of supercritical CO2 transportation pipelines. Corros Sci 165:108404. https://doi.org/10.1016/j.corsci.2019.108404

Li X, Shi T, Li B, Chen X, Zhang C, Guo Z, Zhang Q (2019) Subtractive manufacturing of stable hierarchical micro-nano structures on AA5052 sheet with enhanced water repellence and durable corrosion resistance. Mater Des 183:108152. https://doi.org/10.1016/j.matdes.2019.108152

Bagheri H, Aliofkhazraei M, Forooshani HM, Rouhaghdam A (2018) Facile fabrication of uniform hierarchical structured (UHS) nanocomposite surface with high water repellency and self-cleaning properties. Appl Surf Sci 436:1134–1146. https://doi.org/10.1016/j.apsusc.2017.12.156

Ma L, Wang J, Ren C et al (2020) Detection of corrosion inhibitor adsorption via a surface-enhanced Raman spectroscopy (SERS) silver nanorods tape sensor. Sensor Actuator B Chem 321:128617. https://doi.org/10.1016/j.snb.2020.128617

Ma L, Wu H, Huang Y, Zou S, Li J, Zhang Z (2016) High-performance real-time SERS detection with recyclable Ag nanorods@HfO2 substrates. ACS Appl Mater Interfaces 8:7162–27168. https://doi.org/10.1021/acsami.6b10818

Chen C, Tsai H, Wang Y et al (2019) Rear-passivated ultrathin Cu(In, Ga)Se2 films by Al2O3 nanostructures using glancing angle deposition toward photovoltaic devices with enhanced efficiency. Adv Funct Mater 29:1905040. https://doi.org/10.1002/adfm.201905040

Ma L, Wang J, Huang H, Zhang Z, Li X, Fan Y (2019) Simultaneous thermal stability and ultrahigh sensitivity of heterojunction SERS substrates. Nanomaterials 9:830. https://doi.org/10.3390/nano9060830

Ma L, Zhang Z, Li X (2019) Effects of Ti transition layers and thermal annealing on the adhesive property of Ag nanorods-based SERS sensors. Appl Surf Sci 476:363–368. https://doi.org/10.1016/j.apsusc.2019.01.129

Damerchi E, Abdollah-zadeh A, Poursalehi R, Mehr M (2019) Effects of functionally graded TiN layer and deposition temperature on the structure and surface properties of TiCN coating deposited on plasma nitrided H13 steel by PACVD method. J Alloys Compd 772:612–624. https://doi.org/10.1016/j.jallcom.2018.09.083

Quirama A, Echavarría A, Meza J, Osorio J, Bejarano G (2017) Improvement of the mechanical behavior of the calcium phosphate coatings deposited onto Ti6Al4V alloy using an intermediate TiN/TiO2 bilayer. Vacuum 146:22–30. https://doi.org/10.1016/j.vacuum.2017.09.024

Wei H, Wu M, Dong Z et al (2017) Composition, microstructure and SERS properties of titanium nitride thin film prepared via nitridation of sol–gel derived titania thin films. J Raman Spectrosc 48:578–585. https://doi.org/10.1002/jrs.5080

Reddy C, Shailaja D (2015) Improving hydrophobicity of polyurethane by PTFE incorporation. J Appl Polym Sci 132:42779. https://doi.org/10.1002/app.42779

Naddaf M, Alkhawwam A (2016) Characterization of superhydrophobic a-C:F thin film deposited on porous silicon via laser ablation of a PTFE target. Diam Relat Mater 64:57–63. https://doi.org/10.1016/j.diamond.2016.01.010

Zhang B, Zhu Q, Li Y, Hou B (2018) Facile fluorine-free one step fabrication of superhydrophobic aluminum surface towards self-cleaning and marine anticorrosion. Chem Eng J 352:625–633. https://doi.org/10.1016/j.cej.2018.07.074

Natarajan K, Natarajan T, Bajaj H, Tayade R (2011) Photocatalytic reactor based on UV-LED/TiO2 coated quartz tube for degradation of dyes. Chem Eng J 178:40–49. https://doi.org/10.1016/j.cej.2011.10.007

Jo W, Tayade R (2016) Facile photocatalytic reactor development using nano-TiO2 immobilized mosquito net and energy efficient UVLED for industrial dyes effluent treatment. J Environ Chem Eng 4:319–327. https://doi.org/10.1016/j.jece.2015.11.024

Ghosh P, Jasra R, Shukla D, Bhatt A, Tayade R (2013) Photocatalytic auto-cleaning process of stains. US Patent 8343282 B2

Xu C, Song F, Wang X, Wang Y (2017) Surface modification with hierarchical CuO arrays toward a flexible, durable superhydrophobic and self-cleaning material. Chem Eng J 313:1328–1334. https://doi.org/10.1016/j.cej.2016.11.024

Guo D, Chen J, Wen L et al (2018) A superhydrophobic polyacrylate film with good durability fabricated via spray coating. J Mater Sci 53:15390–15400. https://doi.org/10.1007/s10853-018-2730-5

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51901015), the China Postdoctoral Science Foundation (2018M641189), the Fund of Key Laboratory of Advanced Materials of Ministry of Education (2020AML08), and the Research Fund of State Key Laboratory for Marine Corrosion and Protection, Luoyang Ship Material Research Institute (LSMRI) under the contract No. KFJS1902.

Author information

Authors and Affiliations

Contributions

LM: Conceptualization, Methodology, Writing- Original draft preparation. JW: Data curation, Investigation. ZZ: Supervision. Yue Kang: Visualization. MS: Supervision. LM: Writing–Reviewing and Editing.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Handling Editor: Chris Cornelius.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, L., Wang, J., Zhang, Z. et al. Preparation of a superhydrophobic TiN/PTFE composite film toward self-cleaning and corrosion protection applications. J Mater Sci 56, 1413–1425 (2021). https://doi.org/10.1007/s10853-020-05364-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05364-1