Abstract

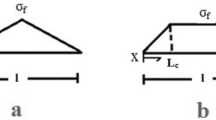

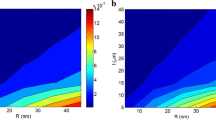

The interphase thickness in polymer carbon nanotube (CNT) nanocomposites (PCNT) is expressed by CNT characteristics and interfacial conductivity between CNT and polymer matrix. Also, the effective length and concentration of CNT are defined supposing interfacial conductivity to suggest the percolation threshold and the fraction of networked CNT. Furthermore, a simple model is developed to predict the conductivity of PCNT assuming tunneling effect, interphase region and interfacial conductivity. The influences of all parameters on the interphase thickness, percolation threshold, the fraction of networked CNT and the conductivity of PCNT are studied. In addition, some experimental results are provided to compare the predictions of developed model to the experimental measurements. The high levels of CNT radius, CNT length, CNT conductivity, interfacial conductivity and conductivity transferring can produce a thick interphase, but the waviness cannot change it. Moreover, the developed model can properly calculate the conductivity of studied samples. A desirable conductivity is obtained by thin and long CNT, medium CNT conductivity, poor waviness, high interfacial conductivity and good conductivity transferring, because they provide high effective CNT concentration and low percolation threshold in nanocomposites.

Similar content being viewed by others

References

Jiang M, Zhou H, Cheng X (2019) Effect of rare earth surface modification of carbon nanotubes on enhancement of interfacial bonding of carbon nanotubes reinforced epoxy matrix composites. J Mater Sci 54(14):10235–10248. https://doi.org/10.1007/s10853-019-03631-4

Tran XT, Park SS, Song S, Haider MS, Imran SM, Hussain M et al (2019) Electroconductive performance of polypyrrole/reduced graphene oxide/carbon nanotube composites synthesized via in situ oxidative polymerization. J Mater Sci 54(4):3156–3173. https://doi.org/10.1007/s10853-018-3043-4

Bakhtiari SSE, Karbasi S, Tabrizi SAH, Ebrahimi-Kahrizsangi R (2019) Chitosan/MWCNTs composite as bone substitute: Physical, mechanical, bioactivity, and biodegradation evaluation. Polym Compos 40:E1622–E1632

Tanabi H, Erdal M (2019) Effect of CNTs dispersion on electrical, mechanical and strain sensing properties of CNT/epoxy nanocomposites. Results Phys 12:486–503

An R, Zhang B, Han L, Wang X, Zhang Y, Shi L et al (2019) Strain-sensitivity conductive MWCNTs composite hydrogel for wearable device and near-infrared photosensor. J Mater Sci 54(11):8515–8530. https://doi.org/10.1007/s10853-019-03438-3

Fu X, Ramos M, Al-Jumaily AM, Meshkinzar A, Huang X (2019) Stretchable strain sensor facilely fabricated based on multi-wall carbon nanotube composites with excellent performance. J Mater Sci 54(3):2170–2180. https://doi.org/10.1007/s10853-018-2954-4

Kumanek B, Janas D (2019) Thermal conductivity of carbon nanotube networks: a review. J Mater Sci 54(10):7397–7427. https://doi.org/10.1007/s10853-019-03368-0

Zare Y, Rhee KY (2019) Expression of normal stress difference and relaxation modulus for ternary nanocomposites containing biodegradable polymers and carbon nanotubes by storage and loss modulus data. Compos Part B Eng 158:162–168

Zare Y, Rhee KY (2019) Modeling of viscosity and complex modulus for poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes nanocomposites assuming yield stress and network breaking time. Compos B Eng 156:100–107

Zare Y, Park SP, Rhee KY (2019) Analysis of complex viscosity and shear thinning behavior in poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes biosensor based on Carreau–Yasuda model. Results Phys 13:102245

Zare Y, Rhee KY (2019) Following the morphological and thermal properties of PLA/PEO blends containing carbon nanotubes (CNTs) during hydrolytic degradation. Compos Part B Eng 175:107132

Zare Y, Rhee KY (2019) Effects of interphase regions and filler networks on the viscosity of PLA/PEO/carbon nanotubes biosensor. Polym Compos 40:4135–4141

Rostami A, Eskandari F, Masoomi M, Nowrouzi M (2019) Evolution of microstructure and physical properties of PMMA/MWCNTs nanocomposites upon the addition of organoclay. J Oil Gas Petrochem Technol 6:28–38

Kumar A, Sharma K, Dixit AR (2019) A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J Mater Sci 54(8):5992–6026. https://doi.org/10.1007/s10853-018-03244-3

Kumar A, Sharma K, Dixit AR (2019) Carbon nanotube-and graphene-reinforced multiphase polymeric composites: review on their properties and applications. J Mater Sci. https://doi.org/10.1007/s10853-019-04196-y

Kalkhoran AHZ, Vahidi O, Naghib SM (2018) A new mathematical approach to predict the actual drug release from hydrogels. Eur J Pharm Sci 111:303–310

Naghib SM, Parnian E, Keshvari H, Omidinia E, Eshghan-Malek M (2018) Synthesis, characterization and electrochemical evaluation of polyvinylalchol/graphene oxide/silver nanocomposites for glucose biosensing application. Int J Electrochem Sci 13(1):1013–1026

Rostami A, Moosavi MI (2019) High-performance thermoplastic polyurethane nanocomposites induced by hybrid application of functionalized graphene and carbon nanotubes. J Appl Polym Sci 137:48520

Broda J, Baczek M, Fabia J, Binias D, Fryczkowski R (2019) Nucleating agents based on graphene and graphene oxide for crystallization of the β-form of isotactic polypropylene. J Mater Sci. https://doi.org/10.1007/s10853-019-04045-y

Wang X, Shi Z, Meng F, Zhao Y, Wu Z, Lei Y et al (2019) Interfacial interaction-induced temperature-dependent mechanical property of graphene-PDMS nanocomposite. J Mater Sci. https://doi.org/10.1007/s10853-019-04126-y

Kalkhoran AHZ, Naghib SM, Vahidi O, Rahmanian M (2018) Synthesis and characterization of graphene-grafted gelatin nanocomposite hydrogels as emerging drug delivery systems. Biomed Phys Eng Express 4(5):055017

Tian X, Hu Y, Zhang J, Guo X, Bai R, Zhao L (2019) Blends of poly (l-lactide), poly (propylidene carbonate) and graphene oxide compatibilized with poly (ethylene glycol), and their mechanical properties. J Mater Sci 54(24):14975–14985. https://doi.org/10.1007/s10853-019-03905-x

Qiu Y, Ma X (2019) Crystallization, mechanical and UV protection properties of graphene oxide/poly (3-hydroxybutyrate-co-3-hydroxyhexanoate) biocomposites. J Mater Sci 54(23):14388–14399. https://doi.org/10.1007/s10853-019-03951-5

Naghib SM (2019) Two dimensional functionalized methacrylated graphene oxide nanosheets as simple and inexpensive electrodes for biosensing applications. Micro Nano Lett 14:462–465

Naghib SM (2016) Fabrication of nafion/silver nanoparticles/reduced graphene nanosheets/glucose oxidase nanobiocomposite for electrochemical glucose biosensing. Anal Bioanal Electrochem 8(4):453–465

Zare Y, Rhee K (2018) Evaluation and development of expanded equations based on Takayanagi model for tensile modulus of polymer nanocomposites assuming the formation of percolating networks. Phys Mesomech 21(4):351–357

Zare Y, Rhim S, Garmabi H, Rhee KY (2018) A simple model for constant storage modulus of poly (lactic acid)/poly (ethylene oxide)/carbon nanotubes nanocomposites at low frequencies assuming the properties of interphase regions and networks. J Mech Behav Biomed Mater 80:164–170

Baxter SC, Robinson CT (2011) Pseudo-percolation: critical volume fractions and mechanical percolation in polymer nanocomposites. Compos Sci Technol 71(10):1273–1279

Qiao R, Brinson LC (2009) Simulation of interphase percolation and gradients in polymer nanocomposites. Compos Sci Technol 69(3):491–499

Kim S, Zare Y, Garmabi H, Rhee KY (2018) Variations of tunneling properties in poly (lactic acid)(PLA)/poly (ethylene oxide)(PEO)/carbon nanotubes (CNT) nanocomposites during hydrolytic degradation. Sens Actuators A 274:28–36

Razavi R, Zare Y, Rhee KY (2019) The roles of interphase and filler dimensions in the properties of tunneling spaces between CNT in polymer nanocomposites. Polym Compos 40:801–810

Takeda T, Shindo Y, Kuronuma Y, Narita F (2011) Modeling and characterization of the electrical conductivity of carbon nanotube-based polymer composites. Polymer 52(17):3852–3856

Lazzeri A, Phuong VT (2014) Dependence of the Pukánszky’s interaction parameter B on the interface shear strength (IFSS) of nanofiller-and short fiber-reinforced polymer composites. Compos Sci Technol 93:106–113

Zare Y, Rhee KY, Park S-J (2019) A developed equation for electrical conductivity of polymer carbon nanotubes (CNT) nanocomposites based on Halpin-Tsai model. Results Phys 14:102406

Zare Y, Rhee KY (2019) Significances of interphase conductivity and tunneling resistance on the conductivity of carbon nanotubes nanocomposites. Polym Compos. https://doi.org/10.1002/pc.25405

Ji XL, Jiao KJ, Jiang W, Jiang BZ (2002) Tensile modulus of polymer nanocomposites. Polym Eng Sci 42(5):983

Zare Y, Rhee KY (2019) The effective conductivity of polymer carbon nanotubes (CNT) nanocomposites. J Phys Chem Solids 131:15–21

Feng C, Jiang L (2013) Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)–polymer nanocomposites. Compos A Appl Sci Manuf 47:143–149

Deng F, Zheng Q-S (2008) An analytical model of effective electrical conductivity of carbon nanotube composites. Appl Phys Lett 92(7):071902

Zare Y, Rhee KY (2019) Tensile strength prediction of carbon nanotube reinforced composites by expansion of cross-orthogonal skeleton structure. Compos B Eng 161:601–607

Zare Y, Rhee KY (2019) Evaluation of the tensile strength in carbon nanotube-reinforced nanocomposites using the expanded Takayanagi model. JOM 71:3980–3988

Zare Y, Rhee KY (2019) Tensile modulus prediction of carbon nanotubes-reinforced nanocomposites by a combined model for dispersion and networking of nanoparticles. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2019.10.025

Lisunova M, Mamunya YP, Lebovka N, Melezhyk A (2007) Percolation behaviour of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur Polym J 43(3):949–958

Logakis E, Pissis P, Pospiech D, Korwitz A, Krause B, Reuter U et al (2010) Low electrical percolation threshold in poly (ethylene terephthalate)/multi-walled carbon nanotube nanocomposites. Eur Polym J 46(5):928–936

Kim YJ, Shin TS, Do Choi H, Kwon JH, Chung Y-C, Yoon HG (2005) Electrical conductivity of chemically modified multiwalled carbon nanotube/epoxy composites. Carbon 43(1):23–30

Gojny FH, Wichmann MH, Fiedler B, Kinloch IA, Bauhofer W, Windle AH et al (2006) Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 47(6):2036–2045

Zare Y, Rhee KY, Park S-J (2019) Modeling the roles of carbon nanotubes and interphase dimensions in the conductivity of nanocomposites. Results Phys 15:102562

Zare Y, Rhee KY (2019) Simplification and development of McLachlan model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the networking of interphase regions. Compos B Eng 156:64–71

Funding

No funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zare, Y., Rhee, K.Y. Interphase thickness and electrical conductivity of polymer carbon nanotube (CNT) nanocomposites assuming the interfacial conductivity between polymer matrix and nanoparticles. J Mater Sci 55, 5402–5414 (2020). https://doi.org/10.1007/s10853-020-04366-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04366-3