Abstract

Formation of Ag–Au nanoalloy and self-organization of Ag nanoparticles into nanostructured wires under UV irradiation were reported in this work. This phenomenon was observed only in the presence of chloroauric acid. On the basis of the analysis of transmission electron microscope images and energy-dispersive X-ray spectroscopy, formation mechanism of nanostructured wires as well as of Ag–Au nanoalloy were proposed. The role of UV illumination and the presence of chloride ions were discussed. The UV–Vis spectra confirm that the synthesized material has one absorption band at 530 nm, which was related to the presence of Ag–Au nanoalloy. Moreover, the Ag–AgCl nanocomposite, in which Ag NPs are located on the edges of AgCl cubes, was successfully synthesized by the modified method.

Similar content being viewed by others

Introduction

Everyday use materials that show signs of self-organization certainly include all kinds of polymeric materials, cosmetic products (soaps), decorative and impregnating products (paints). It is the self-organization of individual mers, lipids or colloids into mesophase series that determines their final properties. In biology, we also know a number of examples of the use of self-organization to create viruses, membranes or cellular fibers. The concept of self-organization can be translated as the interdependent organization of molecules in the superstructure. Self-organization can take place in a static way, where a system in the state of equilibrium does not dissipate energy—the created structure is stable after the synthesis process. The second way of self-organization is dynamic, during which the system dissipates energy. The self-organization of materials is a result of changes in orientation and position of molecules in the system as a result of Brown’s movements. The formation of bonds between molecules is weak and is accompanied by frequent breaks and their recreation [1]. The created structures in the process of self-organization can be easily replaced by others due to the change of external factors of the system (e.g., external electric field, magnetic field, pH or temperature) [2,3,4]. The self-organization was observed for different nanostructures such as gold nanorods, chiral CdTe NPs, Fe3O4, Co NPs, PbSe NPs and Co@CoO [5, 6]. The process of self-organization of nanostructures can be divided into two steps: synthesis of NPs—best with the same geometry (anisotropy properties of NPs) and usage of agent that allows self-organization to occur [5]. It should be noted that the manipulation of external factors during self-organization processes may influence the geometry, crystallinity or chemical composition of nanoparticles.

Of all the metallic particles that are the subject of scientific research, silver is the one that attracts the greatest interest. It is certainly related to the application possibilities of nanosilver (e.g., catalysis, sensors, medicine, cosmetics or SERS). It was previously reported that the silver nanoparticles (Ag NPs) can form superstructures under self-organization [7, 8]. However, according to our knowledge, this is the first work in which the self-organization of Ag NPs into nanostructured Ag wires and Ag–Au nanoalloy under synthesis using UV irradiation was described. This phenomenon was observed only in the presence of chloroauric acid. Moreover, the Ag–AgCl nanocomposite, in which Ag NPs are located on the edges of AgCl cubes, was successfully synthesized by the modified method.

Materials and methods

Synthesis of nanoparticles

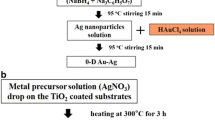

Three-step method synthesis of Ag–Au nanoalloy (Ag–Au NA) was proposed in this study. In the first step, pure Ag NPs were synthesized by the UV irradiation method [9]. For this purpose, 40 ml of 0.1 M AgNO3 was mixed with 40 ml of 0.9 mM chloramine T. Afterward, UV irradiation (365 nm) was performed by 10 min. The changes of solution color from colorless to orange were observed. In the second step, 8 ml of 1 mM HAuCl4 was added into the solution. Formation of precipitant was observed; therefore, sonication by 30 s was applied to obtain stable dispersion. Afterward, UV irradiation was performed one more time by 5 min. Prepared sample (marked as Ag–Au NA) was collected by centrifugation, washed two times by DI water, ethanol and acetone. Pure Ag NPs were synthesized by the same method without steps two and three. Moreover, to confirm the formation mechanism and the role of Cl− ions, two other samples were synthesized. First of all, pure Ag NPs were synthesized by the UV-irradiation method, and therefore 0.5 ml of 10 mM NaCl was added. The sample was marked as Ag–AgCl. The second sample was synthesized by UV irradiation of Ag–AgCl by 5 min and marked as Ag–Ag NPs. The samples were collected also by centrifugation, washed two times by DI water, ethanol and acetone.

Materials characterization

Selected area electron diffraction (SAED) patterns, scanning (STEM) and transmission electron microscopy (TEM) images as well as energy-dispersive X-ray (EDX) spectra were collected using Transmission Electron Microscope S/TEM TITAN 80-300. Samples were prepared by redispersion and sonication of synthesized nanoparticles in ultrapure ethanol. Few drops of the dispersions were next placed on the copper TEM grids with lacey carbon films. The four different samples were prepared. The first one was a sample containing only Ag NPs—precursor, marked as pure Ag NPs; the second one mixture of nanostructures synthesized by three-step method containing Ag–Au NA and Ag nanostructured wires, the third one the Ag–AgCl nanostructure obtained by addition of NaCl into as-synthesized Ag NPs (precursor) and the last one Ag–Ag NPs—sample prepared by photoreduction of Ag–AgCl. The images were recorded in bright field–dark field (BF–DF) and high-angle annular dark field (HAADF) STEM mode. Analysis of SAED patterns was performed using ringGUI tool (CrystBox software, version 1.10 (build 0066) [10, 11]). The optical properties were determined for water dispersions on the basis of analysis of UV–Vis spectra recorded using Thermo Scientific Evolution 220 spectrophotometer.

Results and discussion

Figure 1 shows the morphology and structure of pure Ag NPs and Ag–Au NA. The small, spherical-shaped, agglomerated Ag NPs were synthesized by the UV irradiation method (Fig. 1a–c). The average size of them calculated based on the TEM images was equal to 29.3 nm. After addition of HAuCl4 and additional UV irradiation process, two different nanostructures were synthesized. First of all, Ag wires formed (Fig. 1d). The formation of silver wires under synthesis of Ag NPs is well known and described in the literature [12]. Generally, the formation of Ag wires is associated with the growth of silver seeds (such as multiple-twinned particles) in controlled reaction conditions. The length of the synthesized wires can be higher than few micrometers and their diameters change from 154 up to 260 nm. Interestingly, analysis of TEM images (Fig. 1e, f) allowed to confirm that these wires are composed of Ag NPs with average diameter equal to 54 nm; therefore, this new structure can be treated as silver nanostructured wires unlike silver nanowires, which are generally composed of single crystal or multiple-twinned crystal [12]. In addition to the nanostructured wires, the areas rich in nanoparticles were also observed in the synthesized sample. The structure and morphology of these nanoparticles are presented in Fig. 1g–i.

Analysis of STEM and TEM images: a and b STEM images of pure Ag NPs, c TEM image of pure Ag NPs, d STEM image of nanostructured Ag wires, e, f TEM images of nanostructured Ag wires, g STEM image of Ag–Au NA, h TEM image of crystalline Ag–Au NA, i enlarged marked red area in h with identified d spacing between (1 1 1) lattice planes

It can be stated that these nanoparticles can be associated with the presence of different nanostructures such as Ag NPs, Au NPs, core–shell Ag@Au NPs or Ag–Au nanoalloy. According to that, chemical analysis was performed for synthesized mixture of nanostructures. The EDX spectrum collected from region rich in nanoparticles confirms the presence of silver and gold (Fig. 2a). Moreover, the 2D EDX maps presented in Fig. 2b confirm that both Ag and Au are evenly distributed throughout the analysis area. This can be associated with the formation of Ag–Au nanoalloy under UV irradiation. From the other side, the chemical analysis of nanostructured wires clearly confirms that this nanostructure is composed of pure silver nanoparticles without the existence of silver chloride (Fig. 2c). This is associated with reduction of Ag+ under UV irradiation and formation of pure Ag NPs [9]. The structure of these wires was additionally confirmed by analysis of SAED pattern (Fig. 2d). The characteristic for polycrystalline materials rings were observed and assigned to crystalline silver. Additionally, in Fig. 2e, f is shown SAED pattern of pure Ag NPs and pattern recorded for Ag–Au nanoalloy, respectively.

In order to understand the formation mechanism of Ag nanostructured wires and Ag–Au nanoalloy, the analysis of Ag–AgCl and Ag–Ag nanoparticles was performed. First of all, it was stated, that the formation of silver wires can be associated with the presence of AgCl layer on the surface of pure Ag NPs. This shell can be formed after the addition of HAuCl4. This mechanism can be associated with the formation of wires composed from Ag@AgCl, which reduce to the pure silver under second irradiation. Therefore, analysis of the sample synthesized by the usage of NaCl instead of HAuCl4 was performed. In Fig. 3a is shown the BF–DF STEM image of Ag–AgCl. As can be seen, two different particles, small with spherical and large with cubic shape, can be observed. In Fig. 3b, the presented HAADF STEM image clearly confirms that the small nanoparticles are the Ag NPs (synthesized in the first reaction step), whereas cubic particles with crystallized AgCl. Interestingly, the edges of AgCl are decorated by ultrafine Ag NPs. The absence of wires confirms that their formation is not associated only with the presence of Cl− ions. However, the cubic skeleton is shown in Fig. 3c, and therefore, the hypothesis that the wires are formed under second UV irradiation was proposed. To confirm that, the sample marked as Ag–Ag NPs was synthesized. As can be seen in Fig. 3c, d, decomposition of AgCl into Ag NPs occured, and the hollow cubic particles formed instead of nanostructured wires [13].

According to that, it was confirmed that the formation of Ag nanostructured wires is associated with presence not only Cl− ions, but with presence of HAuCl4. This can be associated with the existence of H+ ions in the solution. The schematic representation of the synthesis of Ag NPs, Ag–Au NA, Ag–AgCl nanostructure was presented in Fig. 4. It can be concluded that the addition of HAuCl4 results in the formation of AgCl, which self-organize in an acidic environment to form nanostructured Ag wires after UV irradiation. The Au3+ ions can be reduced both by the UV light and by the highly reactive surface of Ag NPs to form metallic gold. The combination of these two processes results in crystallization of Ag–Au NA.

The optical properties of synthesized Ag NPs and mixture of Ag–Au NA with Ag nanostructured wires synthesized by the UV irradiation method were determined based on the UV–Vis spectra (Fig. 5). It can be noticed that the pure Ag NPs synthesized only by the UV irradiation method has an orange color, whereas the Ag–Au nanocomposite violet color. Two SPR bands at 394 nm and 490 nm were observed in the spectrum of Ag NPs. The position of absorption band for Ag NPs is associated with their shape and size [14]. On the basis of analysis of TEM images (Fig. 1a–c), it was concluded that no other nanostructures except spherical silver nanoparticles were synthesized in the first reaction step. Therefore, first absorption band can be related to the presence of ultrafine (around 7 nm) spherical-shaped Ag NPs, whereas the second band at 490 nm with larger Ag NPs. On the spectrum of Ag–Au nanocomposite, only one SPR band at 530 nm can be observed. This absorption band is associated with Ag–Au NA; therefore, Ag NPs are optically inactive, which can be associated with their self-organization into nanostructured long wires [15, 16].

Conclusions

In this study are presented structure and formation mechanism of different nanostructures, such as Ag NPs, Ag–Au NA, nanostructured Ag wires and Ag–AgCl nanostructure. All of the listed materials were synthesized by eco-friendly, low cost, simple and short reaction reduction of Ag + and Au3+ ions by UV light. The role of Cl− ions in the synthesis of the different structures was described in detail. The self-organization of Ag NPs into nanostructured Ag wires was described, and the mechanism of this process was proposed. The formation of Ag–Au nanoalloy was related to the redox reaction between the surface of Ag NPs and Au3+ ions followed by the reduction of these Ag + ions by additional UV irradiation process. Moreover, synthesis of the nanostructure, in which cubic-shaped AgCl nanoparticles are decorated by ultrafine silver nanoparticles, was also introduced. The self-organization of Ag NPs was related to the introduction of Cl− ions in the dispersion of pure Ag NPs in water in acidic condition and removing of AgCl and reduction of Ag+ and Au+ ions was associated with UV irradiation.

References

Kelsall RW, Hamley IW, Geoghegan M (2005) Nanoscale science and technology. Wiley, Chichester

Lausser C, Zahn D, Cölfen H (2011) Barium titanate nanoparticle self-organization in an external electric field. J Mater Chem 21:16978–16982

Ivashchenko O, Peplińska B, Gapiński J et al (2018) Silver and ultrasmall iron oxides nanoparticles in hydrocolloids: effect of magnetic field and temperature on self-organization. Sci Rep 8:4041. https://doi.org/10.1038/s41598-018-22426-2

Kuroda Y, Muto I, Shimojima A et al (2017) Nanospace-mediated self-organization of nanoparticles in flexible porous polymer templates. Langmuir 33:9137–9143

Hu T, Isaacoff BP, Bahng JH et al (2014) Self-organization of plasmonic and excitonic nanoparticles into resonant chiral supraparticle assemblies. Nano Lett 14:6799–6810

Kotov NA (2011) Practical aspects of self-organization of nanoparticles: experimental guide and future applications. J Mater Chem 21:16673–16674

Harfenist SA, Wang ZL, Alvarez MM et al (1996) Highly oriented molecular Ag nanocrystal arrays. J Phys Chem 100:13904–13910

Choi S, Park S, Yang SA et al (2015) Selective self-assembly of adenine-silver nanoparticles forms rings resembling the size of cells. Sci Rep 5:17805. https://doi.org/10.1038/srep17805

Radoń A, Łukowiec D (2018) Silver nanoparticles synthesized by UV-irradiation method using chloramine T as modifier: structure, formation mechanism and catalytic activity. CrystEngComm. https://doi.org/10.1039/c8ce01379a

Klinger M (2017) More features, more tools, more CrysTBox. J Appl Crystallogr 50:1226–1234

Klinger M, Jäger A (2015) Crystallographic Tool Box (CrysTBox): automated tools for transmission electron microscopists and crystallographers. J Appl Crystallogr 48:2012–2018

Zhang P, Wyman I, Hu J et al (2017) Silver nanowires: synthesis technologies, growth mechanism and multifunctional applications. Mater Sci Eng B Solid-State Mater Adv Technol 223:1–23

Yan J, Zhou WZ, Tan H et al (2016) Ultrafine Ag/polyoxometalate-doped AgCl nanoparticles in metal-organic framework as efficient photocatalysts under visible light. CrystEngComm 18:8762–8768

Agnihotri S, Mukherji S, Mukherji S (2014) Size-controlled silver nanoparticles synthesized over the range 5–100 nm using the same protocol and their antibacterial efficacy. RSC Adv 4:3974–3983

Malkar VV, Mukherjee T, Kapoor S (2015) Aminopolycarboxylic acids and alginate composite-mediated green synthesis of Au and Ag nanoparticles. J Nanostruct Chem 5:1–6

Ristig S, Prymak O, Loza K et al (2015) Nanostructure of wet-chemically prepared, polymer-stabilized silver–gold nanoalloys (6 nm) over the entire composition range. J Mater Chem B. https://doi.org/10.1039/c5tb00644a

Funding

This study was funded by Silesian University of Technology (Grant No. 10/010/RGJ19/0266) and statutory grant of Faculty of Mechanical Engineering (Grant No. 10/990/RMT019/0139).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Łukowiec, D., Radoń, A. Self-organization of silver nanoparticles during synthesis of Ag–Au nanoalloy by UV irradiation method. J Mater Sci 55, 2796–2801 (2020). https://doi.org/10.1007/s10853-019-04136-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04136-w