Abstract

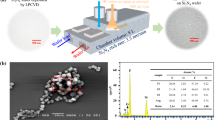

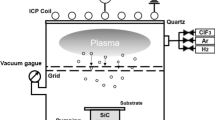

The Si3N4 layers in a 3D NAND flash patterned wafer are generally removed by hot phosphoric acid. However, the abnormal deposition of silicate which is the by-product from Si3N4 etching onto the neighboring SiO2 layers will cause a serious problem in the subsequent process. In this work, the abnormal deposition phenomenon was investigated by a simple system containing a narrow gap (~ 80 μm) between two blanket wafers. To understand the mechanism, the influences of various factors on the chemical etching dynamics were examined, including the water content and the extent of mechanical agitation. It is found that the growth rate of SiO2 decreases as the water content or the extent of agitation is increased. Our experimental results reveal that the abnormal growth on SiO2 layers is a consequence of the competition between chemical deposition and mass transfer in a confined space (reaction–diffusion system).

Similar content being viewed by others

References

Cho S et al (2012) Development of high selectivity phosphoric acid and its application to flash STI pattern. Electrochem Soc Trans 45:251–256

Derek B, Printz W, Furukawa T (2015) Etching of silicon nitride in 3D NAND structures. Electrochem Soc Trans 69:159–167

Hong et al (2015) Compositions for etching and methods of forming a semiconductor device. United States patent US8940182B2

Yu TY, Su YS, Hsu LT, Liang JL, Yeh SC, Su PC (2009) Method and system for improving wet chemical bath process stability and productivity in semiconductor manufacturing. United States patent US20090087929A1

Seo D, Sung SJ, Oh SBE, Kim S, Lim S (2014) Selective wet etching of Si3N4/SiO2 in phosphoric acid with the addition of fluoride and silicic compounds. Microelectron Eng 118:66–71

Derek WB, Antonio LPR (2016) Silica formation during etching of silicon nitride in phosphoric acid. In: SSP, vol 255, pp 285–290

Glenn WG (2018) Industry context for semiconductor wet etch and surface preparation. In: Solid state phenomena, vol 282, pp 3–9

Gelder WV, Hauser VE (1967) The etching of silicon nitride in phosphoric acid with silicon dioxide as a mask. J Electrochem Soc 114:869–872

Chang YH, Hu CC, Yang CM (2018) A design for selective wet etching of Si3N4/SiO2 in phosphoric acid using a single wafer processor. J Electrochem Soc 165:H3187–H3191

Fogler HS (2005) Elements of chemical reaction engineering, 3rd edn. Prentice Hall, Englewood Cliffs

Buttet C et al (2015) Alternative to H3PO4 for Si3N4 removal by using chemical downstream etching. Electrochem Soc Trans 64:1–9

Morita K, Ohnaka K (2000) Novel selective etching method for silicon nitride films on silicon substrates by means of subcritical water. Ind Eng Chem Res 39:4684–4688

Morosanu CE (1980) The preparation, characterization and applications of silicon nitride thin films. Thin Solid Films 65:171–208

Paul WM, Marc M, Marc H (2016) Silica formation during etching of silicon nitride in phosphoric acid. In: SSP, vol 255, pp 285–290

Chien VC, Yang CM, Hu CC (2019) The etching of silicon nitride in phosphoric acid with novel single wafer processor. In: IEEE, vol 18888741, pp 2376–6697

Long X et al (2016) Reactive hot pressing and mechanical properties of B4C/Li2O–Al2O3–SiO2 composites. J Non-Cryst Solids 432:510–518

Huang CC et al (2017) Magnetic property enhancement of cobalt-free M-type strontium hexagonal ferrites by CaCO3 and SiO2 addition. Intermetallics 89:111–117

Shigeru TE et al (2015) Plasma processing method and manufacturing method of semiconductor device United States patent US9177781B2

Kim KH et al (2017) Substrate treating apparatus and method of treating substrate United State patent US9852921B2

Acknowledgements

The authors thank the Ministry of Science and Technology of Taiwan (Grant No. 108-2622-E-008-003-CC2) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Teng, KW., Tu, SH., Hu, SW. et al. Abnormal redeposition of silicate from Si3N4 etching onto SiO2 surfaces in flash memory manufacturing. J Mater Sci 55, 1126–1135 (2020). https://doi.org/10.1007/s10853-019-04119-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04119-x