Abstract

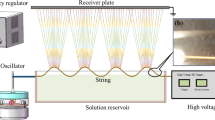

Preparation of high-quality nanofibers by electrospinning with low applied voltage and industrial scales remains challenging. A novel differential electrospinning technology for nanofiber preparation was proposed, with which multiple jets are generated from the string by plucking. The spinning principles were investigated, and the operation parameters were optimized. Results showed that lower threshold electric field was required for jets generation by plucked string electrospinning compared with the conventional needleless electrospinning. The finest average diameter of nanofibers with a narrow distribution range of 143 ± 16 nm was obtained at an applied voltage of 25 kV, a PVA concentration of 8 wt%, a rotational speed of 150 rpm and a spinning distance of 7 cm. The maximum yield for single string was as high as 2.64 g h−1 at a PVA concentration of 12 wt%. It was demonstrated that the proposed technology is feasible for manufacturing of nanofibers with lower voltage and high productivity as the string could be modularly extended.

Similar content being viewed by others

References

Macdiarmid AG, WEJ Jr, Norris ID, Gao J, ATJ Jr, Pinto NJ, Hone J, Han B, Ko FK, Okuzaki H, Llaguno M (2001) Electrostatically-generated nanofibers of electronic polymers. Synth Met 119:27–30

Ramakrishna S, Jose R, Archana PS, Nair AS, Balamurugan R, Venugopal J, Venugopal J, Teo WE (2010) Science and engineering of electrospun nanofibers for advances in clean energy, water filtration, and regenerative medicine. J Mater Sci 45:6283–6312. https://doi.org/10.1007/s10853-010-4509-1

Nikmaram N, Roohinejad S, Hashemi S, Koubaa M, Barba FJ, Abbaspourrad A, Greiner R (2017) Emulsion-based systems for fabrication of electrospun nanofibers: food, pharmaceutical and biomedical applications. RSC Adv 7:28951–28964

Xie J, MacEwan MR, Schwartz AG, Xia Y (2010) Electrospun nanofibers for neural tissue engineering. Nanoscale 2:35–44

Sundarrajan S, Tan KL, Lim SH, Ramakrishna S (2014) Electrospun nanofibers for air filtration applications. Proc Eng 75:159–163

Kaur S, Rana D, Matsuura T, Sundarrajan S, Ramakrishna S (2012) Preparation and characterization of surface modified electrospun membranes for higher filtration flux. J Membr Sci 390:235–242

Mendes AC, Stephansen K, Chronakis IS (2017) Electrospinning of food proteins and polysaccharides. Food Hydrocoll 68:53–68

Tang W, Wang J (2015) Methanol sensing micro-gas sensors of SnO2-ZnO nanofibers on Si/SiO2/Ti/Pt substrate via stepwise-heating electrospinning. J Mater Sci 50:4209–4220. https://doi.org/10.1007/s10853-015-8972-6

Yao PJ, Wang J, Qiao Q, Du HY (2015) Direct fabrication of La0.7Sr0.3FeO3 nanofibers with tunable hollow structures by electrospinning and their gas sensing properties. J Mater Sci 50:1338–1349. https://doi.org/10.1007/s10853-014-8694-1

Mirjalili M, Zohoori S (2016) Review for application of electrospinning and electrospun nanofibers technology in textile industry. J Nanostruct Chem 6:207–213

Fang W, Yang S, Wang XL, Yuan TQ, Sun RC (2017) Manufacture and application of lignin-based carbon fibers (LCFs) and lignin-based carbon nanofibers (LCNFs). Green Chem 19:1794–1827

Xu H, Hu X, Sun Y, Luo W, Chen C, Liu Y, Huang Y (2014) Highly porous Li4Ti5O12/C nanofibers for ultrafast electrochemical energy storage. Nano Energy 10:163–171

Li L, Peng S, Lee JKY, Ji D, Srinivasan M, Ramakrishna S (2017) Electrospun hollow nanofibers for advanced secondary batteries. Nano Energy 39:111–139

He J, Qin T, Liu Y, Li X, Li D, Jin Z (2014) Electrospinning of nanofibrous scaffolds with continuous structure and material gradients. Mater Lett 137:393–397

Nayak R, Padhye R, Kyratzis IL, Truong YB, Arnold L (2012) Recent advances in nanofibre fabrication techniques. Text Res J 82:129–147

Yu M, Dong RH, Yan X, Yu GF, You MH, Ning X, Long YZ (2017) Recent advances in needleless electrospinning of ultrathin fibers: from academia to industrial production. Macromol Mater Eng 302:1700002

Lukas D, Sarkar A, Pokorny P (2008) Self-organization of jets in electrospinning from free liquid surface: a generalized approach. J Appl Phys 103:084309

Miloh T, Spivak B, Yarin AL (2009) Needleless electrospinning: electrically driven instability and multiple jetting from the free surface of a spherical liquid layer. J Appl Phys 106:114910

Li H, Chen H, Zhong X, Wu W, Ding Y, Yang W (2014) Interjet distance in needleless melt differential electrospinning with umbellate nozzles. J Appl Polym Sci. https://doi.org/10.1002/app.40515

Li H, Wu W, Bubakir MM, Chen H, Zhong X, Liu Z, Ding Y, Yang W (2014) Polypropylene fibers fabricated via a needleless melt-electrospinning device for marine oil-spill cleanup. J Appl Polym Sci. https://doi.org/10.1002/app.40080

Liu Y, He JH, Yu JY (2008) Bubble-electrospinning: a novel method for making nanofibers. J Phys Conf Ser 96:012001

Liu Y, He JH, Xu L, Yu JY (2008) The principle of bubble electrospinning and its experimental verification. J Polym Eng 28:55–66

Yang R, He J, Xu L, Yu J (2009) Bubble-electrospinning for fabricating nanofibers. Polymer 50:5846–5850

He JH, Liu Y (2012) Control of bubble size and bubble number in bubble electrospinning. Comput Math Appl 64:1033–1035

He JH, Kong HY, Yang RR, Hao D (2012) Review on fiber morphology obtained by bubble electrospinning and blown bubble spinning. Therm Sci 16:1263–1279

Niu H, Lin T, Wang X (2009) Needleless electrospinning. I. A comparison of cylinder and disk nozzles. J Appl Polym Sci 114:3524–3530

Yan G, Niu H, Shao H, Zhao X, Zhou H, Lin T (2017) Curved convex slot: an effective needleless electrospinning spinneret. J Mater Sci 52:11749–11758. https://doi.org/10.1007/s10853-017-1315-z

Wei L, Yu H, Jia L, Qin X (2018) High-throughput nanofiber produced by needleless electrospinning using a metal dish as the spinneret. Text Res J 88:80–88

Lu B, Wang Y, Liu Y, Duan H, Zhou J, Zhang Z, Wang Y, Li X, Wang W, Lan W, Xie E (2010) Superhig-throughput needleless electrospinning using a rotary cone as spinneret. Small 6:1612–1616

Thoppey NM, Bochinski JR, Clarke LI, Gorga RE (2010) Unconfined fluid electrospun into high quality nanofibers from a plate edge. Polymer 51:4928–4936

Wang X, Lin T, Wang X (2014) Scaling up the production rate of nanofibers by needleless electrospinning from multiple ring. Fibers Polym 15:961–965

Holopainen J, Penttinen T, Santala E, Ritala M (2014) Needleless electrospinning with twisted wire spinneret. Nanotechnology 26:025301

Ali U, Niu H, Aslam S, Jabbar A, Rajput AW, Lin T (2017) Needleless electrospinning using sprocket wheel disk spinneret. J Mater Sci 52:1–11. https://doi.org/10.1007/s10853-017-0989-6

Liu Z, Zhao J, Liu P, He J (2016) Tunable surface morphology of electrospun PMMA fiber using binary solvent. Appl Surf Sci 364:516–521

Liu Z, Chen R, He J (2016) Active generation of multiple jets for producing nanofibres with high quality and high throughput. Mater Des 94:496–501

Liu Z, Ang KKJ, He J (2016) Needle-disk electrospinning inspired by natural point discharge. J Mater Sci 52:1–8. https://doi.org/10.1007/s10853-016-0472-9

Hsiao HY, Huang CM, Liu YY, Kuo YC, Chen H (2012) Effect of air blowing on the morphology and nanofiber properties of blowing-assisted electrospun polycarbonates. J Appl Polym Sci 124:4904–4914

Zhang X, Lu Y (2014) Centrifugal spinning: an alternative approach to fabricate nanofibers at high speed and low cost. Polym Rev 54:677–701

Weinberger HF (2012) A first course in partial differential equations: with complex variables and transform methods. Courier Corporation, North Chelmsford

Rwei SP, Huang CC (2012) Electrospinning PVA solution-rheology and morphology analyses. Fibers Polym 13:44–50

Dosunmu OO, Chase GG, Kataphinan W, Reneker DH (2006) Electrospinning of polymer nanofibres from multiple jets on a porous tubular surface. Nanotechnology 17:1123

Dai Y, Sun LL, Ren SL, Ma RD (2013) Finite element optimization of electric field structure in electrospinning. Adv Mater Res 765:456–459

Acknowledgements

This work was supported by the National Key Research and Development Program (Grant No. 2016YFB0302002) and National Science Foundation of China (Grant No. 51603009). The reviewers’ valuable comments are appreciated and Dr Yiqiang Fan was thanked for the grammar modifications of manuscript. We thank Dr Lisheng Cheng for the major revision improvement and Dr Jiahao Liang for the figures revision and manuscript improvement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, X., Zhang, Y., He, X. et al. Electrospinning on a plucked string. J Mater Sci 54, 901–910 (2019). https://doi.org/10.1007/s10853-018-2870-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2870-7