Abstract

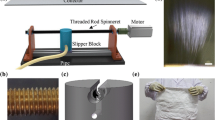

Multi-needle electrospinning is an effective method to increase the productivity of nanofibers. In this paper, the number of single-needle jets was increased to further improve the production efficiency. As the traditional method for increasing the number of single-needle jets has poor controllability and persistence, we proposed a gas-assisted method to increase the yield of nanofibers. A coaxial gas auxiliary needle was designed with an intermediate shaft supplied gas and the outer shaft supplied solution. Innovatively using pulse gas to produce continuous and stable bubbles which are ruptured on the needle. The liquid film is continuously disturbed, which generates jets in the electric field, thereby increasing the number of jets of a single needle. After optimization of the single-needle gas-assisted electrospinning process, the stable spraying process of 16-pin multi-needle electrospinning has been realized. The gas-assisted electrospinning productivity was 4.7 times higher than that of without gas assistance. It provided a new idea for improving the stable production of the multi-needle electrospinning.

Graphical abstract

Similar content being viewed by others

References

Poellmann MJ, Johnson AJW (2014) Multimaterial polyacrylamide: fabrication with electrohydrodynamic jet printing, applications, and modeling. Biofabrication 6(3):12. https://doi.org/10.1088/1758-5082/6/3/035018

Luzio A, Canesi EV, Bertarelli C, Caironi M (2014) Electrospun polymer fibers for electronic applications. Materials 7(2):906–947. https://doi.org/10.3390/ma7020906

Wendorff JH, Agarwal S, Greiner A (2012) Electrospinning: materials, processing, and applications, vol 1. Wiley-VCH, Hoboken

Garg K, Bowlin GL (2011) Electrospinning jets and nanofibrous structures. Biomicrofluidics 5(1). https://doi.org/10.1063/1.3567097

Jiang G, Zhang S, Qin X (2016) Effect of processing parameters on free surface electrospinning from a stepped pyramid stage. J Ind Text 45(4):483–494. https://doi.org/10.1177/1528083714537101

Shin HU, Li Y, Paynter A, Nartetamrongsutt K, Chase GG (2015) Vertical rod method for electrospinning polymer fibers. Polymer 65:26–33. https://doi.org/10.1016/j.polymer.2015.03.052

Holopainen J, Penttinen T, Santala E, Ritala M (2015) Needleless electrospinning with twisted wire spinneret. Nanotechnology 26(2):025301

Salehhudin HS, Mohamad EN, Wan NLM, Afifi AM (2017) Multiple-jet electrospinning methods for nanofiber processing: a review. Mater Manuf Process 33:479–498. https://doi.org/10.1080/10426914.2017.1388523

Zhang CC, Gao CC, Chang MW, Ahmad Z, Li JS (2016) Continuous micron-scaled rope engineering using a rotating multi-nozzle electrospinning emitter. Appl Phys Lett 109(15):151903

Xu J, Liu C, Hsu PC, Liu K, Zhang R, Liu Y, Cui Y (2016) Roll-to-roll transfer of electrospun Nanofiber film for high-efficiency transparent air filter. Nano Lett 16(2):1270

Wang H, Li M, Chen X, Zheng J, Chen X, Zhu Z (2015) Study of deposition characteristics of multi-nozzle near-field electrospinning in electric field crossover interference conditions. AIP Adv 5(4). https://doi.org/10.1063/1.4902173

Reneker DH, Yarin AL (2008) Electrospinning jets and polymer nanofibers. Polymer 49(10):2387–2425. https://doi.org/10.1016/j.polymer.2008.02.002

YAMASHITA Y, Ko F, TANAKA A, MIYAKE H (2007) Characteristics of elastomeric nanofiber membranes produced by electrospinning. J Text Eng 53(4):137–142

Vaseashta A (2007) Controlled formation of multiple Taylor cones in electrospinning process. Appl Phys Lett 90(9):093115

Paruchuri S, Brenner MP (2007) Splitting of a liquid jet. Phys Rev Lett 98(13):134502

Wang X, Lin T, Wang X (2015) Use of airflow to improve the nanofibrous structure and quality of nanofibers from needleless electrospinning. J Ind Text 45(2):310–320. https://doi.org/10.1177/1528083714537100

Liu Y, He J-H (2007) Bubble electrospinning for mass production of nanofibers. Int J Nonlin Sci Numer Simul 8(3):393–396

Huang X, Wu D, Zhu Y, Sun D, Ieee (2007) Needleless Electrospinning of Multiple Nanofibers. 2007 7th Ieee conference on nanotechnology, Vol 1–3

Bird JC, de Ruiter R, Laurent C, Stone HA (2010) Daughter bubble cascades produced by folding of ruptured thin films. Nature 465(7299):759–762

Byakova AV, Gnyloskurenko SV, Nakamura T, Raychenko OI (2003) Influence of wetting conditions on bubble formation at orifice in an inviscid liquid : mechanism of bubble evolution. Colloids Surf A Physicochem Eng Asp 218(1):73–87

Chen R, Wan Y, Si N, He J-H, Ko F, Wang S-Q (2015) Bubble rupture in bubble electrospinning. Therm Sci 19(4):1141–1149

Chen RX (2015) On surface tension of a bubble under presence of electrostatic force. Therm Sci 19(1):353–355. https://doi.org/10.2298/tsci141214149c

He J-H (2008) Nano bubble dynamics in spider spinning system. J Anim Vet Adv 7(2):207–209

He J-H (2012) Effect on temperature on surface tension of a bubble and hierarchical ruptured bubbles for nanofiber fabrication. Therm Sci 16(1):327–330

He J-X, Qi K, Zhou Y-M, Cui S-Z (2014) Fabrication of continuous nanofiber yarn using novel multi-nozzle bubble electrospinning. Polym Int 63(7):1288–1294. https://doi.org/10.1002/pi.4672

Jian Z, Yong Y, Chen Q, Yu Z (2017) Experimental study and numerical simulation of periodic bubble formation at submerged micron-sized nozzles with constant gas flow rate. Chem Eng Sci 168:1–10

Li Z-B, Liu H-Y, Dou H (2014) On air blowing direction in the blown bubble-spinning. Materia-Brazil 19(4):345–349

Liu F-J, Dou H (2013) A modified Yang-Laplace equation for the bubble electrospinning considering the effect of humidity. Therm Sci 17(2):629–630

Nahra HK, Kamotani Y (2000) Bubble formation from wall orifice in liquid cross-flow under low gravity. Chem Eng Sci 55(20):4653–4665

Vafaei S, Angeli P, Wen D (2011) Bubble growth rate from stainless steel substrate and needle nozzles. Colloids Surf A Physicochem Eng Asp 384(1):240–247

Vafaei S, Wen D (2010) Bubble formation on a submerged micronozzle. J Colloid Interface Sci 343(1):291–297

Yuewen D (2016) Experimental study on the formation and movement of bubbles in water. Xinjiang University

Nieminen HJ, Laidmäe I, Salmi A, Rauhala T, Paulin T, Heinämäki J, Hæggström E (2018) Ultrasound-enhanced electrospinning. Sci Rep-Uk 8(1):4437

Delnoij E, Kuipers JAM, Swaaij WPMV (1997) Dynamic simulation of gas-liquid two-phase flow: effect of column aspect ratio on the flow structure. Chem Eng Sci 52(21–22):3759–3772

Russell TP, Lin Z, Schäffer E, Steiner U (2003) Aspects of electrohydrodynamic instabilities at polymer interfaces. Fibers Polym 4(1):1–7

Schäffer E, ThurnAlbrecht T, Russell TP, Steiner U (2001) Electrohydrodynamic instabilities in polymer films. Epl 53(4):518–524

Xie S (2003) Quantitative discussion on the static induction law of spherical conductors in a uniform electric field. J Binzhou Univ 19(2):45–47

Qu C, Yu Y, Zhang J (2017) Experimental study of bubbling regimes on submerged micro-orifices. Int J Heat Mass Transf 111:17–28

Yuanping H (2015) Study on the mechanism of charged droplet breakage and electrohydrodynamic characteristics. Jiangsu University

Funding

This work was financially supported by Science and Technology Project of Guangdong Province (2017B090911012), University Innovation and Entrepreneurship Education Major Project of Guangzhou City (Item Number: 201709P05), Project of Science and Technology of Foshan City(2015IT100152), Key Laboratory Construction Projects in Guangdong (2017B030314178), Project of Jihua Laboratory (No.X190071UZ190), and Science and Technology Program of Guangzhou, China (No.201803010065).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, G., Chen, X., Zhu, Z. et al. Pulse gas-assisted multi-needle electrospinning of nanofibers. Adv Compos Hybrid Mater 3, 98–113 (2020). https://doi.org/10.1007/s42114-019-00129-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-019-00129-0