Abstract

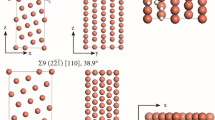

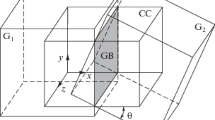

The nonlinear migration of C atom between nearest interstitial sites in fcc iron has been studied in the paper. It reveals an optimum migration pathway in the preferred crowdion direction in its infancy; the pathway is finally along the tetrahedral direction. This nonlinear tendency can be intensified by a repulsive force from another near neighbor C atom in the crowdion direction. We introduce an interaction model based on Coulomb’s force, which indicates that this nonlinear migration mechanism is a foregone conclusion with a certain atomic geometric configuration. However, for a multiple-C system, we find that there exists a typical preferred orientation, which is a continuously stable structure maintained by the C atoms migrating in the crowdion direction. The first neighbor migrated structure is the main formation as a result of this preferential orientation. Based on this, we derive a novel diffusion equation by introducing a proportionality coefficient \( K_{\rho } \), which can be closely related to the C structures absorbed on the surface during carburization. The diffusion coefficient will increase dramatically with a small perturbation of \( K_{\rho } \). Moreover, a spatially heterogeneous occupation is introduced on a much larger scale. The results not only show that it is a relatively stable state but that the C diffusion coefficient is significantly larger than that of the other disorder-free C states. Meanwhile, it provides a repulsive force for nonlinear migration in the micro-cell. As a result, a greater diffusion rate will be achieved from both spatial heterogeneity and the nonlinear migration of C atoms.

Similar content being viewed by others

References

Sarıkaya Y, Önal M (2012) High temperature carburizing of a stainless steel with uranium carbide. J Alloy Compd 542:253–256

Bhadeshia HKDH (2010) A commentary on: “Diffusion of carbon in austenite with a discontinuity in composition”. Metall Mater Trans A 41(7):1605–1615

Cheeseman JR, Frisch MJ, Devlin FJ, Stephens PJ (1996) Ab initio calculation of atomic axial tensors and vibrational rotational strengths using density functional theory. Chem Phys Lett 252(3–4):211–220

Fuchs M, Scheffler M (1999) Ab initio pseudopotentials for electronic structure calculations of poly-atomic systems using density-functional theory. Comput Phys Commun 119(1):67–98

Jiang DE, Carter EA (2005) Carbon atom adsorption on and diffusion into Fe(110) and Fe(100) from first principles. Phys Rev B 71(4):045402

Jiang DE, Carter EA (2003) Carbon dissolution and diffusion in ferrite and austenite from first principles. Phys Rev B 67(21):214103

Simonetti S, Pronsato ME, Brizuela G, Juan A (2007) The C–C pair in the vicinity of a bcc Fe bulk vacancy: electronic structure and bonding. Physica Status Solidi (b) 244(2):610–618

Asaro R, Farkas D, Kulkarni Y (2008) The Soret effect in diffusion in crystals. Acta Mater 56(6):1243–1256

Hepburn DJ, Ackland GJ (2008) Metallic-covalent interatomic potential for carbon in iron. Phys Rev B 78(16):165115

Ruda M, Farkas D, Garcia G (2009) Atomistic simulations in the Fe–C system. Comput Mater Sci 45(2):550–560

Liu X, Huo C, Li Y, Wang J, Jiao H (2012) Energetics of carbon deposition on Fe(100) and Fe(110) surfaces and subsurfaces. Surf Sci 606(7–8):733–739

Domain C, Becquart CS, Foct J (2004) Ab initio study of foreign interstitial atom (C, N) interactions with intrinsic point defects in α-Fe. Phys Rev B 69(14):144112

Becquart CS, Domain C, Foct J (2005) Ab initio calculations of some atomic and point defect interactions involving C and N in Fe. Philos Mag 85(4–7):533–540

Ohnuma T, Soneda N, Iwasawa M (2009) First-principles calculations of vacancy–solute element interactions in body-centered cubic iron. Acta Mater 57(20):5947–5955

Hepburn DJ, Ferguson D, Gardner S, Ackland GJ (2013) First-principles study of helium, carbon, and nitrogen in austenite, dilute austenitic iron alloys, and nickel. Phys Rev B 88(2):024115

Bhadeshia HKDH (2004) Carbon–carbon interactions in iron. J Mater Sci Technol 39(12):3949–3955

Barouh C, Schuler T, Fu C-C, Jourdan T (2015) Predicting vacancy-mediated diffusion of interstitial solutes in α-Fe. Phys Rev B 92(10):104102

Tapasa K, Barashev A, Bacon D, Osetsky Y (2007) Computer simulation of carbon diffusion and vacancy–carbon interaction in α-iron. Acta Mater 55(1):1–11

Forst CJ, Slycke J, Van Vliet KJ, Yip S (2006) Point defect concentrations in metastable Fe–C alloys. Phys Rev Lett 96(17):175501

Paxton AT, Elsässer C (2013) Analysis of a carbon dimer bound to a vacancy in iron using density functional theory and a tight binding model. Phys Rev B 87(22):224110

Liu P, Xing W, Cheng X, Li D, Li Y, Chen X-Q (2014) Effects of dilute substitutional solutes on interstitial carbon in α-Fe: interactions and associated carbon diffusion from first-principles calculations. Phys Rev B 90(2):024103

Qiao L, Zhang X, Wang S, Yu S, Hu X, Wang L, Zeng Y, Zheng W (2014) First-principles investigations on the adsorption and diffusion of carbon atoms on the surface and in the subsurface of Co (111) related to the growth of graphene. RSC Adv 4(65):34237–34243

Hu X, Björkman T, Lipsanen H, Sun L, Krasheninnikov AV (2015) Solubility of boron, carbon, and nitrogen in transition metals: getting insight into trends from first-principles calculations. J Phys Chem Lett 6(16):3263–3268

Aguiar-Hualde J-M, Magnin Y, Amara H, Bichara C (2017) Probing the role of carbon solubility in transition metal catalyzing single-walled carbon nanotubes growth. Carbon 120:226–232

Cao Y, Ernst F, Michal GM (2003) Colossal carbon supersaturation in austenitic stainless steels carburized at low temperature. Acta Mater 51(14):4171–4181

Michal G, Ernst F, Kahn H, Cao Y, Oba F, Agarwal N, Heuer A (2006) Carbon supersaturation due to paraequilibrium carburization: stainless steels with greatly improved mechanical properties. Acta Mater 54(6):1597–1606

Michal GM, Ernst F, Heuer AH (2006) Carbon paraequilibrium in austenitic stainless steel. Metall Mater Trans A 37(6):1819–1824

Ernst F, Avishai A, Kahn H, Gu X, Michal GM, Heuer AH (2009) Enhanced carbon diffusion in austenitic stainless steel carburized at low temperature. Metall Mater Trans A 40(8):1768–1780

Gu X, Michal GM, Ernst F, Kahn H, Heuer AH (2014) Concentration-dependent carbon diffusivity in austenite. Metall Mater Trans A 45(9):3790–3799

Fernandes FAP, Christiansen TL, Winther G, Somers MAJ (2017) Measurement and tailoring of residual stress in expanded austenite on austenitic stainless steel. Mater Sci Eng A 701:167–173

Li W, Guo W, Zhu X, Jin X, Li X, Dong H (2017) The effect of applied compressive stress on the diffusion of carbon in carbon supersaturated S-phase layer. Surf Coat Technol 331:1–6

Peng Y, Gong J, Chen C, Liu Z, Jiang Y (2018) Numerical analysis of stress gradient and traps effects on carbon diffusion in AISI 316L during low temperature gas phase carburization. Metals 8(4):214

Jespersen FN, Hattel JH, Somers MAJ (2016) Modelling the evolution of composition-and stress-depth profiles in austenitic stainless steels during low-temperature nitriding. Modell Simul Mater Sci Eng 24(2):025003

Brink BK, Ståhl K, Christiansen TL, Oddershede J, Winther G, Somers MAJ (2017) On the elusive crystal structure of expanded austenite. Scripta Mater 131:59–62

Jang JH, Bhadeshia HKDH, Suh D-W (2013) Solubility of carbon in tetragonal ferrite in equilibrium with austenite. Scripta Mater 68(3–4):195–198

Cermak J, Kral L (2014) Carbon diffusion in carbon-supersaturated ferrite and austenite. J Alloy Compd 586:129–135

Enomoto M, Hayashi K (2015) Simulation of the growth of austenite during continuous heating in low carbon iron alloys. J Mater Sci 50(20):6786–6793. https://doi.org/10.1007/s10853-015-9234-3

Wang J, Li Z, Wang D, Qiu S, Ernst F (2017) Thermal stability of low-temperature-carburized austenitic stainless steel. Acta Mater 128:235–240

Tao Q, Wang J, Fu L, Chen Z, Shen C, Zhang D, Sun Z (2017) Ultrahigh hardness of carbon steel surface realized by novel solid carburizing with rapid diffusion of carbon nanostructures. J Mater Sci Technol 33(10):1210–1218. https://doi.org/10.1016/j.jmst.2017.04.022

Hohenberg P, Kohn W (1964) Inhomogeneous electron gas. Phys Rev 136(3B):B864–B871

Sham LJ, Schlüter M (1983) Density-functional theory of the energy gap. Phys Rev Lett 51(20):1888–1891

Segall MD, Lindan PJ, Probert MA, Pickard CJ, Hasnip PJ, Clark SJ, Payne MC (2002) First-principles simulation: ideas, illustrations and the CASTEP code. J Phys Condens Matter 14(11):2717–2744

Clark SJ, Segall MD, Pickard CJ, Hasnip PJ, Probert MI, Refson K, Payne MC (2005) First principles methods using CASTEP. Zeitschrift für Kristallographie Cryst Mater 220(5/6):567–570

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77(18):3865–3868

Monkhorst HJ, Pack JD (1976) Special points for Brillouin-zone integrations. Phys Rev B 13(12):5188–5192

Fischer TH, Almlof J (1992) General methods for geometry and wave function optimization. J Phys Chem 96(24):9768–9774

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Lee BJ (2006) A modified embedded-atom method interatomic potential for the Fe–C system. Acta Mater 54(3):701–711

Bonny G, Terentyev D, Pasianot RC, Poncé S, Bakaev A (2011) Interatomic potential to study plasticity in stainless steels: the FeNiCr model alloy. Modell Simul Mater Sci Eng 19(8):085008

Lee SJ, Matlock DK, Van Tyne CJ (2013) Comparison of two finite element simulation codes used to model the carburizing of steel. Comput Mater Sci 68:47–54

Eto Y, Umemoto M, Yoshida M (2015) Mechanism of abnormal surface carbon content reduction in Nb-bearing case hardening steel gas carburized after machining. ISIJ Int 55(1):227–234

Kim DW, Cho HH, Lee WB, Cho KT, Cho YG, Kim SJ, Han HN (2016) A finite element simulation for carburizing heat treatment of automotive gear ring incorporating transformation plasticity. Mater Des 99:243–253

Dal’Maz Silva W, Dulcy J, Ghanbaja J, Redjaïmia A, Michel G, Thibault S, Belmonte T (2017) Carbonitriding of low alloy steels: mechanical and metallurgical responses. Mater Sci Eng A 693:225–232

Veiga RGA, Becquart CS, Perez M (2014) Comments on “Atomistic modeling of an Fe system with a small concentration of C”. Comput Mater Sci 82:118–121

Restrepo OA, Mousseau N, El-Mellouhi F, Bouhali O, Trochet M, Becquart CS (2016) Diffusion properties of Fe–C systems studied by using kinetic activation–relaxation technique. Comput Mater Sci 112:96–106

Restrepo OA, Becquart CS, El-Mellouhi F, Bouhali O, Mousseau N (2017) Diffusion mechanisms of C in 100, 110 and 111 Fe surfaces studied using kinetic activation-relaxation technique. Acta Mater 136:303–314

Sahputra IH, Chakrabarty A, Restrepo O, Bouhali O, Mousseau N, Becquart CS, El-Mellouhi F (2017) Carbon adsorption on and diffusion through the Fe(110) surface and in bulk: developing a new strategy for the use of empirical potentials in complex material set-ups. Physica Status Solidi (b) 254(2):1600408

Sheppard D, Terrell R, Henkelman G (2008) Optimization methods for finding minimum energy paths. J Chem Phys 128(13):134106

Becquart CS, Raulot J, Bencteux G (2007) Atomistic modeling of an Fe system with a small concentration of C. Comput Mater Sci 40(1):119–129

Liu WJ, Brimacombe JK, Hawbolt EB (1991) Influence of composition on the diffusivity of carbon in steels—I. Non-alloyed austenite. Acta Metallurgica Et Materialia 39(10):2373–2380

McLellan RB (1996) The diffusion of heavy interstitial atoms in the absence of a particle density gradient. Acta Mater 44(10):4181–4185

Tibbetts GG (1980) Diffusivity of carbon in iron and steels at high temperatures. J Appl Phys 51(9):4813–4816

Acknowledgements

This research is financially supported by the National Natural Science Foundation of China (No. 51641109), the Fundamental Research Funds for the Central Universities (No. 2017XKZD08).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Tao, Q., Fu, L. et al. Greater diffusion rate of carbon atoms from nonlinear migration in micro-cell and spatially heterogeneous stable states in FCC iron. J Mater Sci 53, 15952–15968 (2018). https://doi.org/10.1007/s10853-018-2755-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2755-9