Abstract

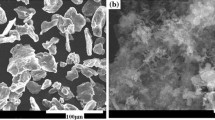

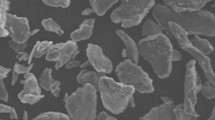

This study investigated mechanical properties and deformation mechanisms of porous magnesium–carbon nanofiber composites with different porosities manufactured through powder metallurgy. Compressive stress–strain curves of the samples exhibit three phases: Phase I of linear elastic deformation at low stress state, Phase II of a stress plateau, and Phase III of densification. The manufactured porous composites with different porosities show different deformation mechanisms. The composites with low porosity (i.e., 24 and 34%) manifest stretch-dominated deformation with hard (i.e., tension, compression) modes, while the composite with high porosity (i.e., 50%) demonstrates bending-dominated deformation with soft (i.e., bending) modes. The yield strength and the ultimate compressive strength decreased at an increasing rate with the increase in the porosity from 24 to 50%. Theoretical estimations were obtained for the yield strength of dense magnesium composites based on Gibson and Ashby model.

Similar content being viewed by others

References

Friedrich H, Schumann S (2001) Research for a “new age of magnesium” in the automotive industry. J Mater Process Technol 117:276–281

Li Q, Chen EY, Bice DR, Dunand DC (2008) Mechanical properties of cast Ti-6Al-4V lattice block structures. Metall Mater Trans A 39:441–449

Li Q, Chen EY, Bice DR, Dunand DC (2008) Mechanical properties of cast Ti-6Al-2Sn-4Zr-2Mo lattice block structures. Adv Eng Mater 10:939–942

Thornton PH, Magee CL (1975) The deformation of aluminum foams. Metall Trans A 6:1253–1263

Vinod Kumar GS, Mukherjee M, Garcia-Moreno F, Banhart J (2013) Reduced-pressure foaming of aluminum alloys. Metall Mater Trans A 44:419–426

Fan X, Chen X, Liu X, Zhang H, Li Y (2013) Bubble formation at a submerged orifice for aluminum foams produced by gas injection method. Metall Mater Trans A 44:729–737

Cao Z, Yu Y, Li M, Luo H (2016) Cell structure evolution of aluminum foams under reduced pressure foaming. Metall Mater Trans A 47:4378–4381

Habibnejad-Korayem M, Mahmudi R, Poole W (2009) Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater Sci Eng A 519:198–203

Hassan S, Gupta M (2006) Effect of different types of nano-size oxide particulates on microstructural and mechanical properties of elemental Mg. J Mater Sci 41:2229–2236. https://doi.org/10.1007/s10853-006-7178-3

Thakur SK, Kwee GT, Gupta M (2007) Development and characterization of magnesium composites containing nano-sized silicon carbide and carbon nanotubes as hybrid reinforcements. J Mater Sci 42:10040–10046. https://doi.org/10.1007/s10853-007-2004-0

Li Q, Tian B (2013) Compression behavior of magnesium/carbon nanotube composites. J Mater Res 28:1877–1884

Fukuda H, Kondoh K, Umeda J, Fugetsu B (2011) Fabrication of magnesium based composites reinforced with carbon nanotubes having superior mechanical properties. Mater Chem Phys 127:451–458

Kondoh K, Fukuda H, Umeda J, Imai H, Fugetsu B, Endo M (2010) Microstructural and mechanical analysis of carbon nanotube reinforced magnesium alloy powder composites. Mater Sci Eng A 527:4103–4108

Cay H, Xu H, Li Q (2013) Mechanical behavior of porous magnesium/alumina composites with high strength and low density. Mater Sci Eng A 574:137–142

Li Q (2014) Carbon nanotube reinforced porous magnesium composite: 3D nondestructive microstructure characterization using x-ray micro-computed tomography. Mater Lett 133:83–86

Li Q (2016) Effect of porosity and carbon composition on pore microstructure of magnesium/carbon nanotube composite foams. Mater Des 89:978–987

Zou N, Li Q (2016) Compressive mechanical property of porous magnesium composites reinforced by carbon nanotubes. J Mater Sci 51:5232–5239. https://doi.org/10.1007/s10853-016-9824-8

Xu H, Zou N, Li Q (2017) Effect of ball milling time on microstructure and hardness of porous magnesium/carbon nanofiber composites. JOM 69:1236–1243

Xu H, Li Q (2017) Effect of carbon nanofiber concentration on mechanical properties of porous magnesium composites: experimental and theoretical analysis. Mater Sci Eng A 706:249–255

Tibbetts G, Beetz C Jr (1987) Mechanical properties of vapour-grown carbon fibres. J Phys D Appl Phys 20:292

Zhou Y, Pervin F, Rangari VK, Jeelani S (2006) Fabrication and evaluation of carbon nano fiber filled carbon/epoxy composite. Mater Sci Eng A 426:221–228

Al-Saleh MH, Sundararaj U (2011) Review of the mechanical properties of carbon nanofiber/polymer composites. Compos A Appl Sci Manuf 42:2126–2142

Bal S (2010) Experimental study of mechanical and electrical properties of carbon nanofiber/epoxy composites. Mater Des 31:2406–2413

Breuer O, Sundararaj U (2004) Big returns from small fibers: a review of polymer/carbon nanotube composites. Polym Compos 25:630–645

Natsuki T, Ni Q-Q, Wu S-H (2008) Temperature dependence of electrical resistivity in carbon nanofiber/unsaturated polyester nanocomposites. Polym Eng Sci 48:1345

Galiyev A, Sitdikov O, Kaibyshev R (2003) Deformation behavior and controlling mechanisms for plastic flow of magnesium and magnesium alloy. Mater Trans 44:426–435

Li Q, Tian B (2012) Mechanical properties and microstructure of pure polycrystalline magnesium rolled by different routes. Mater Lett 67:81–83

Armstrong RW, Li Q (2015) Dislocation mechanics of high-rate deformations. Metall Mater Trans 46:4438–4453

Liu B, Zheng YF, Ruan L (2011) In vitro investigation of Fe30Mn6Si shape memory alloy as potential biodegradable metallic material. Mater Lett 65:540–543

Wu W, An K (2016) Understanding low-cycle fatigue life improvement mechanisms in a pre-twinned magnesium alloy. J Alloy Compd 656:539–550

Tian B, Chen F, Tong YX, Li L, Zheng YF, Liu Y, Li Q (2011) Phase transition of Ni–Mn–Ga alloy powders prepared by vibration ball milling. J Alloys Compd 509:4563–4568

Kingery W (1959) Densification during sintering in the presence of a liquid phase. I. Theory. J Appl Phys 30:301–306

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Ashby M (2006) The properties of foams and lattices. Philos Trans R Soc Lond A Math Phys Eng Sci 364:15–30

Ashby MF, Evans T, Fleck NA, Hutchinson J, Wadley H, Gibson L (2000) Metal foams: a design guide. Elsevier, New York

Avedesian MM, Baker H (1999) ASM specialty handbook: magnesium and magnesium alloys. Materials Park, ASM International

Acknowledgement

The support for the research from the National Science Foundation under Award No. 1449607 is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, H., Li, Q. Deformation mechanisms and mechanical properties of porous magnesium/carbon nanofiber composites with different porosities. J Mater Sci 53, 14375–14385 (2018). https://doi.org/10.1007/s10853-018-2649-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2649-x