Abstract

The bubble formation at a submerged orifice in the process of aluminum foams produced by gas injection method is investigated. The experimental results show that the increase of the gas flow rate and the orifice diameter can lead to increasing of the bubble size. The large orifice can make the frequency of bubble formation decrease by slowing down the increase of the gas chamber pressure when the gas flow rate increases. The effect of the gas chamber volume on the bubble size can be ignored in the experiment when it expands from 1 to 125 cm3. A theoretical model of bubble formation, expansion, and detachment under constant flow conditions is established to predict the bubble size. The theoretical predictions for air-aluminum melt systems are consistent with the experimental results.

Similar content being viewed by others

Abbreviations

- R e :

-

Reynolds number

- C d :

-

resistance coefficient

- D ni :

-

inner diameter of orifice, m

- Q :

-

gas flow rate, m3/s

- V c :

-

gas chamber volume, m3

- p :

-

pressure, Pa

- T c :

-

temperature of nozzles, K

- m :

-

virtual mass, kg

- v :

-

velocity of bubble, m/s

- t :

-

time, s

- x :

-

distance between the center of bubble and orifice, m

- h e :

-

distance between the center of bubble and orifice at the end of the expansion stage, m

- r :

-

radius of bubble, m

- V :

-

volume of bubble, m3

- V e :

-

volume of bubble at the end of the first stage, m3

- r e :

-

radius of bubble at the end of the first stage, m

- V B :

-

volume of bubble at the end of the second stage, m3

- r B :

-

radius of bubble at the end of the second stage, m

- L :

-

chord length of cell size, m

- ρ l :

-

liquid density, kg/m3

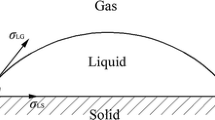

- σ:

-

surface tension, N/m

- η:

-

viscosity, Pa·s

- θ:

-

angle, rad

References

T.S. Ao, F. Oeters, and N.R. Ming: Steel Metallurgy, 1st ed., Metallurgy Industry Press, Beijing, China, 1997.

M. Zhu and Z. Xiao: Mathematical and Physical Simulation in the Refining Process of the Steel, 1st ed., Metallurgy Industry Press, Beijing, China, 1998.

G.Q. Yang, B. Du, and L.S. Fan: Chem. Eng. Sci., 2007, vol. 62, pp. 2–27.

A.A. Kulkarni and J.B. Joshi: Ind. Eng. Chem. Res., 2005, vol. 44, pp. 5873–5931.

S. Gnyloskurenko, A. Byakova, T. Nakamura, and O. Raychenko: J. Mater. Sci., 2005, vol. 40, pp. 2437–41.

Y. Park, A.L. Tyler, and N.D. Nevers: Chem. Eng. Sci., 1977, vol. 32, pp. 907–16.

W.X. Zhang and R.B.H. Tan: Chem. Eng. Sci., 2000, vol. 55, pp. 6243–50.

X. Liu, Y. Li, X. Chen, Y. Liu, and X. Fan: J. Mater. Sci., 2010, vol. 45, pp. 6481–93.

M. Martin, F.J. Montes, and M.A. Galan: Chem. Eng. Sci., 2006, vol. 61, pp. 5196–5203.

K. Terasaka and H. Tsuge: Chem. Eng. Sci., 2001, vol. 56, pp. 3237–45.

R.R. Hughes, A.E. Handlos, H.D. Evans, and R.L. Maycock: Chem. Eng. Prog., 1955, vol. 51, pp. 557–63.

G.A. Irons and R. Guthrie: Metall. Trans. B, 1978, vol. 9B, pp. 101–10.

M. Sano and K. Mori: Trans. Jpn. Inst. Metall., 1976, vol. 17, pp. 344–52.

S.H. Hsu, W.H. Lee, Y.M. Yang, C.H. Chang, and J.R. Maa: Ind. Eng. Chem. Res., 2000, vol. 39, pp. 1473–79.

L. Davidson and E.H. Amick: Am. Inst. Chem. Eng. J., 1956, vol. 2, pp. 337–42.

D.J. McCann and R. Prince: Chem. Eng. Sci., 1971, vol. 26, pp. 1505–12.

D. Gerlach, G. Biswas, F. Durst, and V. Kolobaric: Int. J. Heat. Mass. Trans., 2005, vol. 48, pp. 425–38.

D. Gerlach, N. Alleborn, V. Buwa, and E. Durst: Chem. Eng. Sci., 2007, vol. 62, pp. 2109–25.

M. Martin, F.J. Montes, and M.A. Galan: Chem. Eng. Sci., 2006, vol. 61, pp. 363–69.

S. Ramakrishnan, R. Kumar, and N.R. Kuloor: Chem. Eng. Sci., 1969, vol. 24, pp. 731–47.

A. Satyanarayan, R. Kumar, and N.R. Kuloor: Chem. Eng. Sci., 1969, vol. 24, pp. 749–61.

A.K. Khurana and R. Kumar: Chem. Eng. Sci., 1969, vol. 24, pp. 1711–23.

A.E. Wraith: Chem. Eng. Sci., 1971, vol. 26, pp. 1659–71.

S.V. Gnyloskurenko and T. Nakamura: Mater. Trans., 2003, vol. 44, pp. 2298–2302.

E.E. Michaelides: Particles, Bubbles and Drops: Their Motion, Heat and Mass Transfer, World Scientific, Hackensack, NJ, 2006.

J.F. Davidson and B. Schuler: Chem. Eng. Res. Des., 1997, vol. 75S, pp. S105–15.

J.N. Newman: Marine Hydrodynamics, MIT Press, Cambridge, MA, 1977.

J. Banhart: Adv. Eng. Mater., 2006, vol. 8, pp. 781–94.

N. Babcsán, D. Leitlmeier, and H.P. Degischer: Materialwiss. Werkst., 2003, vol. 34, pp. 22–29.

Acknowledgments

The authors gratefully acknowledge financial support from the scientific research program of Zhejiang Province No. 2009C31049.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 7, 2011.

Rights and permissions

About this article

Cite this article

Fan, X., Chen, X., Liu, X. et al. Bubble Formation at a Submerged Orifice for Aluminum Foams Produced by Gas Injection Method. Metall Mater Trans A 44, 729–737 (2013). https://doi.org/10.1007/s11661-012-1418-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1418-8