Abstract

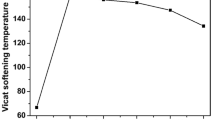

In this paper, the damping property of thermoplastic polyurethane (TPU) was firstly regulated by introducing the phenolic resin (PR) with more active hydroxyl group and larger molecular weight. The mechanism of enhanced damping property was systematically elucidated through the combination of molecular dynamic (MD) simulation and experimental methods. The MD simulation results showed the hydrogen bonds (H-bonds), binding energy, and fractional free volume (FFV) in the quantitative way. When the PR content increased to 40%, it had the largest number of H-bonds, highest binding energy, and relative small FFV. Meanwhile, the experimental results showed that there indeed existed H-bonds interaction between PR and TPU polymer chains. Furthermore, the glass transition temperature (Tg) as well as the loss factor (tan δ) was remarkably improved with increasing the PR content, the effective damping temperature range was broadened, the peak position was also moved to room temperature. This study can provide some reference for designing high-performance TPU-based damping materials.

Similar content being viewed by others

References

Zhou XQ, Yu DY, Shao XY, Zhang SQ, Wang S (2016) Research and applications of viscoelastic vibration damping materials: a review. Compos Struct 136:460–480

Sperling LH (1991) Factors which affect the glass transition and damping capability of polymers. Polym Adv Technol 2(1):49–52

Zhu YC, Zhou W, Wang JJ, Wang B, Wu JR, Huang GS (2007) Study on damping mechanism based on the free volume for CIIR by PALS. J Phys Chem B 111(39):11388–11392

Wu JR, Huang GS, Wang XA, He XJ, Xu B (2012) Changes in the viscoelastic mechanisms of polyisobutylene by plasticization. Macromolecules 45(19):8051–8057

Wang YQ, Wang Y, Zhang HF, Zhang LQ (2006) A novel approach to prepare a gradient polymer with a wide damping temperature range by in-situ chemical modification of rubber during vulcanization. Macromol Rapid Commun 27(14):1162–1167

Zhang FS, He GS, Xu KM, Wu H, Guo SY, Zhang CL (2014) Damping mechanism and different modes of molecular motion through the glass transition of chlorinated butyl rubber and petroleum resin blends. J Appl Polym Sci 131(13):40464

Qu LL, Huang GS, Wu JR, Tang ZH (2007) Damping mechanism of chlorobutyl rubber and phenolic resin vulcanized blends. J Mater Sci 42(17):7256–7262. https://doi.org/10.1007/s10853-006-1466-9

Huang GS, He XR, Wu JR, Pan QY, Zhen J, Zhuo H (2006) Effect of miscibility and forced compatibility on damping properties of CIIR/PAc blend. J Appl Polym Sci 102(4):3127–3133

Lu X, Li XJ, Tian M (2014) Preparation of high damping elastomer with broad temperature and frequency ranges based on ternary rubber blends. Polym Adv Technol 25(1):21–28

Su C, Zong DZ, Xu LH, Zhang C (2014) Dynamic mechanical properties of semi-interpenetrating polymer network-based on nitrile rubber and poly(methyl methacrylate-co-butyl acrylate). J Appl Polym Sci 131(9):40217

Liu MJ, Song GJ, Yi J, Xu YG (2013) Damping analysis of polyurethane/polyacrylate interpenetrating polymer network composites filled with graphite particles. Polym Compos 34(2):288–292

Qin CL, Zhao DY, Bai XD, Zhang XG, Zhang B, Jin Z, Niu HJ (2006) Vibration damping properties of gradient polyurethane/vinyl ester resin interpenetrating polymer network. Mater Chem Phys 97(2–3):517–524

Li Y, Lian QS, Lin ZR, Cheng J, Zhang JY (2017) Epoxy/polysiloxane intimate intermixing networks driven by intrinsic motive force to achieve ultralow-temperature damping properties. J Mater Chem A 5(33):17549–17562

Lv XS, Huang ZX, Huang C, Shi MX, Gao GB, Gao QQ (2016) Damping properties and the morphology analysis of the polyurethane/epoxy continuous gradient IPN materials. Compos Part B Eng 88:139–149

Wang D, Zhang H, Guo J, Cheng BC, Cao Y, Lu SJ, Zhao N, Xu J (2016) Biomimetic gradient polymers with enhanced damping capacities. Macromol Rapid Commun 37(7):655–661

Zhang FS, Guo ML, Xu KM, He GS, Wu H, Guo SY (2014) Multilayered damping composites with damping layer/constraining layer prepared by a novel method. Compos Sci Technol 101:167–172

Zhang FS, He GS, Xu KM, Wu H, Guo SY (2015) The damping and flame-retardant properties of poly(vinyl chloride)/chlorinated butyl rubber multilayered composites. J Appl Polym Sci 132(2):41259

Wu CF, Yamagishi T, Nakamoto Y, Ishida S, Nitta K, Kubota S (2000) Viscoelastic properties of an organic hybrid of chlorinated polyethylene and a small molecule. J Polym Sci Polym Phys 38(10):1341–1347

Liu BZ, Gao XY, Zhao YF, Dai LN, Xie ZM, Zhang ZJ (2017) Prospect of 9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane in the preparation of high damping methyl phenyl vinyl silicone rubbers with broad temperature range. J Mater Sci 52(22):13307–13317. https://doi.org/10.1007/s10853-017-1433-7

Yang DW, Zhao XY, Chan T, Zhang LQ, Wu SZ (2016) Investigation of the damping properties of hindered phenol AO-80/polyacrylate hybrids using molecular dynamics simulations in combination with experimental methods. J Mater Sci 51(12):5760–5774. https://doi.org/10.1007/s10853-016-9878-7

Liu BZ, Gao XY, Zhao YF, Dai LN, Xie ZM, Zhang ZJ (2017) 9,10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane as a promising damping additive for methyl vinyl silicone rubber (VMQ). J Mater Sci 52(14):8603–8617. https://doi.org/10.1007/s10853-017-1085-7

Kenji U, Takashi M, Toshikazu T, Shinzo K (2004) Damping elastomer based on model irregular networks of end-linked poly(dimethylsiloxane). Chem Mater 16(1):173–178

Yamazaki H, Takeda M, Kohno Y, Ando H, Urayama K, Takigawa T (2011) Dynamic viscoelasticity of poly(butyl acrylate) elastomers containing dangling chains with controlled lengths. Macromolecules 44(22):8829–8834

Yu WW, Zhang DZ, Du M, Zheng Q (2013) Role of graded length side chains up to 18 carbons in length on the damping behavior of polyurethane/epoxy interpenetrating polymer networks. Eur Polym J 49(6):1731–1741

Li ZP, Lu X, Tao G, Guo JH, Jiang HW (2016) Damping elastomer with broad temperature range based on irregular networks formed by end-linking of hydroxyl-terminated poly(dimethylsiloxane). Polym Eng Sci 56(1):97–102

Wang JJ, Li GZ, Feng LJ, Chao XL, Zhao K, Feng YN (2017) Nano-graphite controlling properties of novel composites with damping-absorption functions and storage-loss behaviors: nano-graphite/PZT-PMN-PNN/RTV. Curr Appl Phys 17(2):130–136

Sharma SK, Gaur H, Kulkarni M, Patil G, Bhattacharya B, Sharma A (2013) PZT–PDMS composite for active damping of vibrations. Compos Sci Technol 77:42–51

Wu CF, Otani Y, Namiki N, Emi H, Nitta K-H, Kubota S (2001) Dynamic properties of an organic hybrid of chlorinated polyethylene and hindered phenol compound. J Appl Polym Sci 82(7):1788–1793

Lewis CL, Stewart K, Anthamatten M (2014) The influence of hydrogen bonding side-groups on viscoelastic behavior of linear and network polymers. Macromolecules 47(2):729–740

Xu KM, Zhang FS, Zhang XL, Hu QM, Wu H, Guo SY (2014) Molecular insights into hydrogen bonds in polyurethane/hindered phenol hybrids: evolution and relationship with damping properties. J Mater Chem A 2(22):8545

Wu CY, Wei CY, Guo WH, Wu CF (2008) Dynamic mechanical properties of acrylic rubber blended with phenolic resin. J Appl Polym Sci 109(4):2065–2070

Gao Y, Wang XP, Liu MJ, Xi X, Zhang X, Jia DM (2014) Effect of montmorillonite on carboxylated styrene butadiene rubber/hindered phenol damping material with improved extraction resistance. Mater Des 58:316–323

Zhang JH, Zao WT, Wang LF, Zhao YF (2013) Preparation and characterization of low-temperature hydrogenated nitrile butadiene rubber hybrid with hydrogen bonds for the sealing applications. Mater Des 52:896–904

Topf M, Varnai P, Richards WG (2002) Ab initio QM/MM dynamics simulation of the tetrahedral intermediate of serine proteases: insights into the active site hydrogen-bonding network. J Am Chem Soc 124(49):14780–14788

Tamai Y, Tanaka H (1996) Molecular dynamics study of polymer–water interaction in hydrogels. 2. Hydrogen-bond dynamics. Macromolecules 29(21):6761–6769

Zhao XY, Xiang P, Tian M, Fong H, Jin RG, Zhang LQ (2007) Nitrile butadiene rubber/hindered phenol nanocomposites with improved strength and high damping performance. Polymer 48(20):6056–6063

Qiao B, Zhao XY, Yue DM, Zhang LQ, Wu SZ (2012) A combined experiment and molecular dynamics simulation study of hydrogen bonds and free volume in nitrile-butadiene rubber/hindered phenol damping mixtures. J Mater Chem A 22(24):12339

Sun H (1998) COMPASS: an ab initio force-field optimized for condensed-phase applications—overview with details on alkane and benzene compounds. J Phys Chem B 102(38):7338–7364

Ma XF, Zhu WH, Xiao JJ, Xiao HM (2008) Molecular dynamics study of the structure and performance of simple and double bases propellants. J Hazard Mater 156(1–3):201–207

Solimannejad M, Alkorta I (2006) Competition between nonclassical hydrogen-bonded acceptor sites in complexes of neutral AH2 radicals (A) B, Al, and Ga): a theoretical investigation. J Phys Chem A 110:10817–10821

Wu CF (2010) Cooperative behavior of poly(vinyl alcohol) and water as revealed by molecular dynamics simulations. Polymer 51(19):4452–4460

Li W, Liu J, Hao C, Jiang K, Xu D, Wang D (2008) Interaction of thermoplastic polyurethane with polyamide 1212 and its influence on the thermal and mechanical properties of TPU/PA1212 blends. Polym Eng Sci 48(2):249–256

Lu Q-W, Macosko CW (2004) Comparing the compatibility of various functionalized polypropylenes with thermoplastic polyurethane (TPU). Polymer 45(6):1981–1991

Yang J, Chen X, Fu R, Zhang M, Chen H, Wang J (2008) Dynamic rheological and morphological study of the compatibility of thermoplastic polyurethane/ethylene–octene copolymer blends. J Appl Polym Sci 109(6):3452–3457

Acknowledgements

Financial support of the National Natural Science Foundation of China (U1630139, 51573118 and 51227802), Program for New Century Excellent Talents in University (NCET-13-0392), Sichuan Province Youth Science Fund (2015JQ0015), and the Program for Changjiang Scholars and Innovative Research Team in University (IRT-15R48) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhou, R., Gao, W., Xia, L. et al. The study of damping property and mechanism of thermoplastic polyurethane/phenolic resin through a combined experiment and molecular dynamics simulation. J Mater Sci 53, 9350–9362 (2018). https://doi.org/10.1007/s10853-018-2218-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2218-3