Abstract

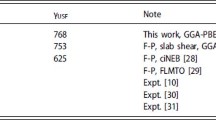

In the present work, the effect of solute atoms on the lattice parameters, atomic volume, stacking fault energies (\( \gamma_{\text{SF}} \)), bulk modulus, and bonding structures of HCP Ti is studied comprehensively by first-principles calculations. Here, the alloying effects on the growth fault (I1), deformation fault (I2) and extrinsic fault (EF) are considered, with the solute atoms (X = Al, Cr, Mo, Nb, and V) commonly utilized in the high-strength Ti-7333 and Ti-5553 alloys selected. It is found that the stacking fault energies of pure Ti increase in the order of \( \gamma_{\text{I1}} \) < \( \gamma_{\text{I2}} \) < \( \gamma_{\text{EF}} \), which is proportional to their corresponding numbers of fault layers. The variation tendencies of \( \gamma_{\text{SF}} \) of the binary Ti–X alloys are in the order of Al > V > Cr > Mo > Nb for I1 and I2 and V > Al > Cr > Nb > Mo for EF, respectively. The bonding charge density is utilized to characterize the electronic redistributions caused by the fault layers and the lattice distortions. It is presented that the rod-type bonds of the non-fault layers change into the tetrahedral-shaped bonds of fault layers, displaying the local HCP–FCC-type phase transformation. With the addition of various solute atoms with different atomic size and valance electrons, the bond strengths of Ti–Al and Ti–Nb are weaker than those of Ti–Cr and Ti–Mo as there are fewer densities of bonding electrons. This work gains some insights into the atomic and electronic basis for the solid-solution strengthened bulk and stacking faults of HCP Ti, providing fundamental information to the development of advanced high-strength Ti alloys.

Similar content being viewed by others

References

Banerjee D, Williams JC (2013) Perspectives on titanium science and technology. Acta Mater 61:844–879

Chen G, Peng Y, Zheng G, Qi Z, Wang M, Yu H, Dong C, Liu CT (2016) Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat Mater 15:876–881

Hao YL, Li SJ, Sun BB, Sui ML, Yang R (2007) Ductile titanium alloy with low Poisson’s ratio. Phys Rev Lett 98:216405

Fan JK, Kou HC, Lai MJ, Tang B, Chang H, Li JS (2013) Characterization of hot deformation behavior of anew near beta titanium alloy: Ti-7333. Mater Design 49:945–952

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants: a review. Prog Mater Sci 54:397–425

Li T, Kent D, Sha G, Stephenson LT, Ceguerra AV, Ringer SP, Dargusch MS, Cairney JM (2016) New insights into the phase transformations to isothermal ω and ω-assisted α in near β–Ti alloys. Acta Mater 106:353–366

Nakashima PNH, Smith AE, Etheridge J, Muddle BC (2011) The bonding electron density in aluminum. Science 331:1583–1586

Ogata S, Li J, Yip S (2002) Ideal pure shear strength of aluminum and copper. Science 298:807–811

Yu Q, Qi L, Tsuru T, Traylor R, Rugg D, Morris JW Jr, Asta M, Chrzan DC, Minor AM (2015) Origin of dramatic oxygen solute strengthening effect in titanium. Science 347:635–639

Curtarolo S, Hart GLW, Nardelli MB, Mingo N, Sanvito S, Levy O (2013) The high-throughput highway to computational materials design. Nat Mater 12:191–201

Hu QM, Yang R (2006) Mechanical properties of structural materials from first-principles. Curr Opin Solid State Mater Sci 10:19–25

Editorial (2013) Fuelling discovery by sharing. Nat Mater 12:173

Kwasniak P, Garbacz H, Kurzydlowski KJ (2016) Solid solution strengthening of hexagonal titanium alloys: restoring forces and stacking faults calculated from first principles. Acta Mater 102:304–314

Jiang S, Wang H, Wu Y, Liu X, Chen H, Yao M, Gault B, Ponge D, Raabe D, Hirata A, Chen M, Wang Y, Lu Z (2017) Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 544:460–464

Vitos L, Abrikosov IA, Johansson B (2001) Anisotropic lattice distortions in random alloys from first-principles theory. Phys Rev Lett 87:156401

Meher S, Carroll LJ, Pollock TM, Carroll MC (2016) Solute partitioning in multi-component γ/γ’ Co-Ni-base superalloys with near-zero lattice misfit. Scr Mater 113:185–189

Wang WY, Xue F, Zhang Y, Shang S-L, Wang Y, Darling KA, Kecskes LJ, Li J, Hui X, Feng Q, Liu Z-K (2017) Atomic and electronic basis for the solutes strengthened (010) anti-phase boundary of L12 Co3(Al, TM): a comprehensive first-principles study. Acta Mater 145:30–40

Minor AM (2015) Metallurgy: Starting and stopping dislocations. Nat Mater 14:866–867

Li X, Lu K (2017) Playing with defects in metals. Nat Mater 16:700–701

Trinkle DR, Woodward C (2005) The chemistry of deformation: how solutes soften pure metals. Science 310:1665–1667

Wang WY, Wang Y, Shang SL, Darling KA, Kim H, Tang B, Kou HC, Mathaudhu SN, Hui XD, Li JS, Kecskes LJ, Liu Z-K (2017) Strengthening Mg by self-dispersed nano-lamellar faults. Mater Res Lett 5:415–425

Salloom R, Banerjee R, Srinivasan SG (2016) Effect of beta-stabilizer elements on stacking faults energies and ductility of alpha-titanium using first-principles calculations. J Appl Phys 120:175105

Zong H, Ding X, Lookman T, Sun J (2016) Twin boundary activated α → ω phase transformation in titanium under shock compression. Acta Mater 115:1–9

McLaughlin R, Sun D, Zhang C, Groesbeck M, Vardeny ZV (2017) Optical detection of transverse spin-Seebeck effect in permalloy film using Sagnac interferometer microscopy. Phys Rev B 95:180401

Hennig RG, Trinkle DR, Bouchet J, Srinivasan SG, Albers RC, Wilkins JW (2005) Impurities block the alpha to omega martensitic transformation in titanium. Nat Mater 4:129–133

Gilman J (2003) Electronic basis of the strength of materials. Cambridge U. Press, New York

Wang WY, Shang SL, Wang Y, Han F, Darling KA, Wu Y, Xie X, Senkov ON, Li J, Hui XD, Dahmen KA, Liaw PK, Kecskes LJ, Liu Z-K (2017) Atomic and electronic basis for the serrations of refractory high-entropy alloys. NPJ Comput Mater 3:23

Kioussis N, Herbranson M, Collins E, Eberhart ME (2002) Topology of electronic charge density and energetics of planar faults in FCC metals. Phys Rev Lett 88:125501

Shang SL, Wang WY, Zhou BC, Wang Y, Darling KA, Kecskes LJ, Mathaudhu SN, Liu ZK (2014) Generalized stacking fault energy, ideal strength and twinnability of dilute Mg-based alloys: a first-principles study of shear deformation. Acta Mater 67:168–180

Brozek C, Sun F, Vermaut P, Millet Y, Lenain A, Embury D, Jacques PJ, Prima F (2016) A β–titanium alloy with extra high strain-hardening rate: design and mechanical properties. Scr Mater 114:60–64

Abdel-Hady M, Hinoshita K, Morinaga M (2006) General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr Mater 55:477–480

Saito T, Furuta T, Hwang J-H, Kuramoto S, Nishino K, Suzuki N, Chen R, Yamada A, Ito K, Seno Y, Nonaka T, Ikehata H, Nagasako N, Iwamoto C, Ikuhara Y, Sakuma T (2003) Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 300:464–467

Zhang X, Kou H, Li J, Zhang F, Zhou L (2013) Evolution of the secondary α phase morphologies during isothermal heat treatment in Ti-7333 alloy. J Alloy Compd 577:516–522

Hua K, Li J, Kou H, Fan J, Sun M, Tang B (2016) Phase precipitation behavior during isothermal deformation in β-quenched near beta titanium alloy Ti-7333. J Alloy Compd 671:381–388

Shekhar S, Sarkar R, Kar SK, Bhattacharjee A (2015) Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy, Ti-5Al-5V-5Mo-3Cr. Mater Des 66:596–610

Nag S, Banerjee R, Srinivasan R, Hwang JY, Harper M, Fraser HL (2009) ω-Assisted nucleation and growth of a precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe β titanium alloy. Acta Mater 57:2136–2147

Kolli RP, Joost WJ, Ankem S (2015) Phase stability and stress-induced transformations in beta titanium alloys. JOM 67:1273–1280

Zhan H, Zeng W, Wang G, Kent D, Dargusch M (2015) On the deformation mechanisms and strain rate sensitivity of a metastable β Ti-Nb alloy. Scr Mater 107:34–37

Xing H, Sun J (2008) Mechanical twinning and omega transition by <111> {112} shear in a metastable β titanium alloy. Appl Phys Lett 93:031908

Hu Q-M, Yang R (2013) Basal-plane stacking fault energy of hexagonal close-packed metals based on the Ising model. Acta Mater 61:1136–1145

Van Swygenhoven H, Derlet PM, Froseth AG (2004) Stacking fault energies and slip in nanocrystalline metals. Nat Mater 3:399–403

Wang WY, Shang SL, Wang Y, Mei Z-G, Darling KA, Kecskes LJ, Mathaudhu SN, Hui XD, Liu Z-K (2014) Effects of alloying elements on stacking faults energies and electronic structures of binary Mg alloys: a first-principles study. Mater Res Lett 2:29–36

Kresse G, Furthmuller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54:11169–11186

Kresse G, Furthmuller J (1996) Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci 6:15–50

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77:3865–3868

Kresse G, Joubert D (1999) From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B 59:1758–1775

Wang Y, Chen LQ, Liu ZK, Mathaudhu SN (2010) First-principles calculations of twin-boundary and stacking-fault energies in magnesium. Scr Mater 62:646–649

Methfessel M, Paxton AT (1989) High-precision sampling for Brillouin-zone integration in metals. Phys Rev B 40:3616–3621

Blochl PE, Jepsen O, Andersen OK (1994) Improved tetrahedron method for Brillouin-zone integrations. Phys Rev B 49:16223–16233

Birch F (1978) Finite strain isotherm and velocities for single-crystal and polycrystalline NaCl at high-pressures and 300 degree K. J Geophys Res 83:1257–1268

Shang SL, Saengdeejing A, Mei ZG, Kim DE, Zhang H, Ganeshan S, Wang Y, Liu ZK (2010) First-principles calculations of pure elements: equations of state and elastic stiffness constants. Comput Mater Sci 48:813–826

Wang WY, Darling KA, Wang Y, Shang S-L, Kecskes LJ, Hui XD, Liu Z-K (2016) Power law scaled hardness of Mn strengthened nanocrystalline AlMn non-equilibrium solid solutions. Scr Mater 120:31–36

Momma K, Izumi F (2011) VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystallogr 44:1272–1276

Nie JF, Zhu YM, Liu JZ, Fang XY (2013) Periodic segregation of solute atoms in fully coherent twin boundaries. Science 340:957–960

Yoo MH (1981) Slip, twinning, and fracture in hexagonal close-packed metals. Metall Trans A 12:409–418

Wang Y, Curtarolo S, Jiang C, Arroyave R, Wang T, Ceder G, Chen LQ, Liu ZK (2004) Ab initio lattice stability in comparison with CALPHAD lattice stability. CALPHAD 28:79–90

Salem AA, Kalidindi SR, Doherty RD (2003) Strain hardening of titanium: role of deformation twinning. Acta Mater 51:4225–4237

Zhang H, Shang SL, Wang Y, Saengdeejing A, Chen LQ, Liu ZK (2010) First-principles calculations of the elastic, phonon and thermodynamic properties of Al12Mg17. Acta Mater 58:4012–4018

Wang WY, Shang SL, Wang Y, Darling KA, Mathaudhu SN, Hui XD, Liu ZK (2012) Electron localization morphology of the stacking faults in Mg: a first-principles study. Chem Phys Lett 551:121–125

Dai Y, Li JH, Liu BX (2009) Long-range empirical potential model: extension to hexagonal close-packed metals. J Phys Condes Matter 21:385402

Wang WY, Shang SL, Wang Y, Darling KA, Kecskes LJ, Mathaudhu SN, Hui XD, Liu Z-K (2014) Electronic structures of long periodic stacking order structures in Mg: A first-principles study. J Alloy Compd 586:656–662

Yan J-Y, Olson GB (2016) Computational thermodynamics and kinetics of displacive transformations in titanium-based alloys. J Alloy Compd 673:441–454

Poty A, Raulot JM, Xu H, Bai J, Schuman C, Lecomte JS, Philippe MJ, Esling C (2011) Classification of the critical resolved shear stress in the hexagonal-close-packed materials by atomic simulation: application to alpha-zirconium and alpha-titanium. J Appl Phys 110:014905

Yin B, Wu Z, Curtin WA (2017) Comprehensive first-principles study of stable stacking faults in hcp metals. Acta Mater 123:223–234

Magali B, Nathalie T, Joseph M (2013) Density functional theory investigations of titanium γ-surfaces and stacking faults. Model Simul Mater Sci 21:15009–15025

Wu X, Wang R, Wang S (2010) Generalized-stacking-fault energy and surface properties for HCP metals: a first-principles study. Appl Surf Sci 256:3409–3412

Hennig RG, Lenosky TJ, Trinkle DR, Rudin SP, Wilkins JW (2008) Classical potential describes martensitic phase transformations between the α, β, and ω titanium phases. Phys Rev B 78:054121

Ghazisaeidi M, Trinkle DR (2014) Interaction of oxygen interstitials with lattice faults in Ti. Acta Mater 76:82–86

Kwasniak P, Muzyk M, Garbacz H, Kurzydlowski KJ (2013) Influence of C, H, N, and O interstitial atoms on deformation mechanism in titanium: first principles calculations of generalized stacking fault energy. Mater Lett 94:92–94

Domain C (2006) Ab initio modelling of defect properties with substitutional and interstitials elements in steels and Zr alloys. J Nucl Mater 35:11–19

Guo Z, Miodownik AP, Saunders N, Schille JP (2006) Influence of stacking-fault energy on high temperature creep of alpha titanium alloys. Scr Mater 54:2175–2178

Kittel C, McEuen P, McEuen P (1996) Introduction to solid state physics. Wiley, New York

Acknowledgements

This work was financially supported by National Key Research and Development Program of China (2016YFB0701304 and 2016YFB0701303), National Natural Science Foundation of China (51690163), and Fundamental Research Funds for the Central Universities in China (G2016KY0302). First-principles calculations were carried out on the clusters at the Northwestern Polytechnical University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, W.Y., Zhang, Y., Li, J. et al. Insight into solid-solution strengthened bulk and stacking faults properties in Ti alloys: a comprehensive first-principles study. J Mater Sci 53, 7493–7505 (2018). https://doi.org/10.1007/s10853-018-2140-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2140-8