Abstract

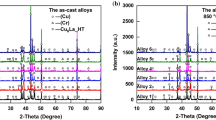

Phase relations in Cu–Ti–Hf ternary system have been studied by diffusion triple technique supplemented with typical alloy sampling method. Based on results from electron-probe microscopy analysis and X-ray diffraction, isothermal sections of the Cu–Ti–Hf system at 800 and 700 °C were established, which consist of ten and nine three-phase regions, respectively. It is observed that Ti can completely substitute Hf in the CuHf2 phase, indicating formation of a continuous solid solution Cu(Ti,Hf)2. Hf can substitute about 20% Ti in the phase CuTi, while solubility of Ti in Cu10Hf7 and Cu51Hf14 phases reaches to 14 and 11 at.% at 800 °C, respectively. The Cu8Hf3 phase in existence at 800 °C was proved to be unstable at 700 °C. In addition, the elastic modulus and hardness of solid solution Cu(Ti,Hf)2 were determined by using nano-indentation techniques.

Similar content being viewed by others

References

Gargarella P, Pauly S, De Oliveira MF, Kuhn U, Eckert J (2015) Glass formation in the Ti–Cu system with and without Si additions. J Alloy Compd 618:413–420

Jia P, Guo H, Li Y, Xu J, Ma E (2006) A new Cu–Hf–Al ternary bulk metallic glass with high glass forming ability and ductility. Scrip Mater 54:2165–2168

Pan Y, Zeng YQ, Jing LJ, Zhang L, Pi JH (2014) Composition design and mechanical properties of ternary Cu–Zr–Ti bulk metallic glasses. Mater Des 55:773–777

Wu JL, Li WH, Pan Y, Qi JY, Wang JG (2016) Microalloying and microstructures of Cu-based bulk metallic glasses and composites and relevant mechanical properties. Mater Des 89:1130–1136

Ristic R, Cooper JR, Zadro K, Pajic D, Ivkov J, Babic E (2015) Ideal solution behaviour of glassy Cu–Ti. Zr, Hf alloys and properties of amorphous copper. J Alloys Compd 621:136–145

Inoue A, Zhang W (2004) Formation, thermal stability and mechanical properties of Cu–Ti and Cu–Zr binary glass alloy robs. Mater Trans 45:584–587

Duan G, Xu D, Johnson WL (2005) High copper content bulk glass formation in bimetallic Cu–Hf system. Metall Mater Transact A 36:455–458

Choi-Yim H, Conner RD (2008) Amorphous alloys in the Cu–Hf–Ti system. J Alloy Compd 459:160–162

Damonte LC, Pasquevich AF, Mendoza-Zelis LA, Vargas IAF, Davies HA, Todd I (2007) Structural and thermal properties of Cu–Hf–Ti ternary metallic glasses. Phys B Condens Matter 398:480–483

Liang D, Liu YJ (2006) Reevaluation of the Cu–Hf binary system. J Alloy Compd 426:101–105

Turchanin MA, Agraval PG (2008) Thermodynamic assessment of the copper-hafnium system. Powder Metall Met Ceram 47:223–233

Zhong Y, Saengdeejing A, Kecskes L, Klotz B, Liu ZK (2013) Experimental and computational studies of the Cu–Hf binary system. Acta Mater 61:660–669

Massalski TB, Okamoto H, Subramanian PR, Kacprczak L (2001) Binary alloy phase diagrams. ASM, Materials Park

Murray JL (1987) Phase diagrams of binary titanium alloys. ASM International, Materials Park

Okamato H (2007) Cu–Hf (copper–hafnium). J Phase Equilib Diffus 28:583–584

Kumar K, Ansara I, Wollants P, Delaey L (1996) Thermodynamic optimisation of the Cu–Ti system. Zeitschrift Fur Metallkunde 87:666–672

Turchanin MA, Agraval PG, Abdulov AR (2008) Thermodynamic assessment of the Cu–Ti–Zr system, I. Cu–Ti system. Powder Metall Metal Ceram 47:344–360

Okamoto H (2002) Cu–Ti (copper–titanium). J Phase Equilib 26:549–550

Yi GH, Zhang XY, Qin JQ, Ning JL, Zhang SH, Ma MZ, Liu RP (2015) Mechanical, electronic and thermal properties of Cu5Zr and Cu5Hf by first-principles calculations. J Alloy Compd 640:455–461

Xie ZY, Lv KL, Liu HS, Cai GM, Jin ZP (2015) Experimental investigation of phase equilibria in Cu–Ge–Ti system. J Alloy Compd 651:590–597

Bsenko L (1975) Crystallographic data for intermediate phases in the copper–zirconium and copper–hafnium systems. J Less-Common Met 40:365–366

van Essen RM, Buschow KHJ (1979) Hydrogen absorption in various zirconium- and hafnium-based intermetallic compounds. J Less-Common Metals 64:277–284

Ecob RC, Bee JV, Ralph B (1979) The cellular reaction in dilute copper–titanium alloys. Phys Status Solidi A Appl Mater 52:201–201

Voo Loo FJJ, Bastin GF, Leenen AJH (1978) Phase relations in the ternary Ti–Ni–Cu system at 800 and 870°C. J Less-Common Metals 57:111–121

Eremenko VN, Buyanov YuI, Prima SB (1966) Phase diagram of the system Ti–Cu. Soviet Powder Metall Metal Ceram 5:494–502

Buschow KHJ (1983) Thermal stability of amorphous Ti–Cu alloys. Acta Metall 31:155–160

Kodentsov AA, Bastin GF, Van Loo FJJ (2001) The diffusion couple technique in phase diagram determination. J Alloy Compd 320:207–217

Zhu LL, Wei CD, Qi HY, Jiang LA, Jin ZP, Zhao JC (2017) Experimental investigation of phase equilibria in the Co-rich part of the Co–Al–X (X = W, Mo, Nb, Ni, Ta) ternary systems using diffusion multiples. J Alloy Compd 691:110–118

Zeng Y, Zhu LL, Cai GM, Liu HS, Huang JW, Jin ZP (2017) Investigation of phase equilibria in the Ti–Co–Zr ternary system. Calphad Comput Coupling Phase Diagr Thermochem 56:260–269

Huang XM, Zhu LL, Cai GM, Liu HS, Jin ZP (2017) Experimental investigation of phase equilibria in the Ti–Al–Mo ternary system. J Mater Sci 52:2270–2284. https://doi.org/10.1007/s10853-016-0520-5

Huang SX, Zhang XD, Jiang Y, Jiang YR, Mao C, Wu D, Zhang LG, Liu LB (2017) Experimental investigation of Ti–Nb–Co ternary system at 1000 degrees C. Mater Des 115:170–178

Liu JL, Zhu LL, Huang XM, Cai GM, Jin ZP (2017) Investigation of the phase equilibria in Ti–Ni–Hf system using diffusion triples and equilibrated alloys. Calphad Comput Coupling Phase Diagr Thermochem 58:160–168

Zhao JC (2004) Reliability of the diffusion-multiple approach for phase diagram mapping. J Mater Sci 39:3913–3925. https://doi.org/10.1023/B:JMSC.0000031472.25241.c5

Van Loo FJJ, Rieck GD (1973) Diffusion in the titanium-aluminium system—I. Interdiffusion between solid Al and Ti or Ti–Al alloys. Acta Metall 21:61–71

Van Loo FJJ, Rieck GD (1973) Diffusion in the titanium–aluminium system—II. Interdiffusion in the composition range between 25 and 100 at.% Ti. Acta Metall 21:73–84

Jin ZP (1981) A study of the range of stability of sigma phase in some ternary systems. Scand J Metall 10:279–287

Liu HS, Wang YM, Zhang LG, Chen Q, Zheng F, Jin ZP (2006) Determination of phase relations in the Co–Cu–Ti system by the diffusion triple technique. J Mater Res 21:2493–2503

Qin PG, Wang H, Zhang LG, Liu HS, Jin ZP (2008) The isothermal section of the Cu–Ti–Zr system at 1023 K measured with diffusion-triple approach. Mater Sci Eng A 476:83–88

Wang JA, Liu CL, Leinenbach C, Klotz UE, Uggowitzer PJ, Loffler JF (2011) Experimental investigation and thermodynamic assessment of the Cu–Sn–Ti ternary system. Calphad Comput Coupling Phase Diagr Thermochem 35:82–94

Wang YM, Liu HS, Chen Q, Zheng F, Jin ZP (2007) The isothermal section at 923 K of the Co–Cu–Ti ternary system measured by using diffusion triple. J Alloy Compd 439:196–200

Zhao JC, Zheng XA, Cahill DG (2011) High-throughput measurements of materials properties. JOM 63:40–44

Acknowledgment

Financial supports by grants from the National Key Research and Development Plan (No. 2016YFB0701301) and Major State Basic Research Development Programs of China (No. 2014CB6644002) are gratefully acknowledged. The Project of Innovation-driven Plan in Central South University (No. 2015CX004) and Project supported by State Key Laboratory of Powder Metallurgy (Central South University, Changsha, China) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J.L., Huang, X.M., Li, G.H. et al. Experimental investigation on phase equilibria of Cu–Ti–Hf system and performance of Cu(Ti, Hf)2 phase. J Mater Sci 53, 7809–7821 (2018). https://doi.org/10.1007/s10853-018-2058-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2058-1