Abstract

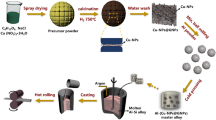

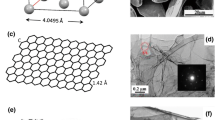

In this work, a novel copper nanoparticles-modified graphene (Cu-NPs@GN)-reinforced Al matrix composites were fabricated. The Cu-NPs@GN hybrids were firstly synthesized by an NaCl template-assisted in situ CVD method and then incorporated into the Al matrix to fabricate Cu-NPs@GN/Al bulk composites by cold-press sintering and hot extrusion. With the merit of the unique characteristic of Cu-NPs@GN hybrid, the Cu-NPs@GN/Al composites exhibited homogeneously dispersed GNs and a strong GN–Al interfacial bonding. It was found that the in situ grown Cu-NPs@GN showed much better strengthening effect than that of the ex situ grown counterparts, which might be attributed to the pinning effect of Al2Cu at the interface and thus promote the load transfer efficiency. Compared with pure Al, the composites with only 0.75 wt% Cu-NPs@GN exhibited a 68% increase in tensile strength (224 MPa) as well as had a total elongation of 17.5%.

Similar content being viewed by others

References

Rabadia CD, Liu YJ, Wang L et al (2018) Laves phase precipitation in Ti–Zr–Fe–Cr alloys with high strength and large plasticity. Mater Des 154:228–238

Ehtemam-Haghighi S, Liu Y, Cao G et al (2016) Influence of Nb on the β → α martensitic phase transformation and properties of the newly designed Ti–Fe–Nb alloys. Mater Sci Eng C Mater Biol Appl 60:503–510

Yu P, Zhang LC, Zhang WY et al (2007) Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al based MMCs. Mater Sci Eng, A 444:206–213

Zhou W, Yamaguchi T, Kikuchi K et al (2017) Effectively enhanced load transfer by interfacial reactions in multi-walled carbon nanotube reinforced Al matrix composites. Acta Mater 125:369–376

Zhao M, Xiong DB, Tan Z et al (2017) Lateral size effect of graphene on mechanical properties of aluminum matrix nanolaminated composites. Scripta Mater 139:44–48

Feng S, Guo Q, Li Z et al (2017) Strengthening and toughening mechanisms in graphene-Al nanolaminated composite micro-pillars. Acta Mater 125:98–108

Lee C, Wei X, Kysar JW et al (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Chen SJ, Li CY, Wang Q et al (2017) Reinforcing mechanism of graphene at atomic level: friction, crack surface adhesion and 2D geometry. Carbon 114:557–565

Shin SE, Choi HJ, Shin JH et al (2015) Strengthening behavior of few-layered graphene/aluminum composites. Carbon 82:143–151

Yan SJ, Dai SL, Zhang XY et al (2014) Investigating aluminum alloy reinforced by graphene nanoflakes. Mater Sci Eng, A 612:440–444

Wang J, Li Z, Fan G et al (2012) Reinforcement with graphene nanosheets in aluminum matrix composites. Scr Mater 66:594–597

Bartolucci SF, Paras J, Rafiee MA et al (2011) Graphene–aluminum nanocomposites. Mater Sci Eng, A 528:7933–7937

Zhao ZY, Guan RG, Guan XH et al (2015) Microstructures and properties of graphene-Cu/Al composite prepared by a novel process through clad forming and improving wettability with copper. Adv Eng Mater 7:663–668

Li M, Che H, Liu X et al (2014) Highly enhanced mechanical properties in Cu matrix composites reinforced with graphene decorated metallic nanoparticles. J Mater Sci 49:3725–3731. https://doi.org/10.1007/s10853-014-8082-x

Fadavi Boostani A, Tahamtan S, Jiang ZY et al (2015) Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos Part A Appl Sci 68:155–163

Zhang Y, Li X (2017) Bioinspired, Graphene/Al2O3 doubly reinforced aluminum composites with high strength and toughness. Nano Lett 17:6907–6915

Zhang X, Li S, Pan D et al (2018) Microstructure and synergistic-strengthening efficiency of CNTs-SiCp dual-nano reinforcements in aluminum matrix composites. Compos Part A Appl Sci 105:87–96

Tang Y, Yang X, Wang R et al (2014) Enhancement of the mechanical properties of graphene–copper composites with graphene–nickel hybrids. Mater Sci Eng, A 599:247–254

Zhang D, Zhan Z (2016) Preparation of graphene nanoplatelets-copper composites by a modified semi-powder method and their mechanical properties. J Alloy Compd 658:663–671

Liu G, Zhao N, Shi C et al (2017) In-situ synthesis of graphene decorated with nickel nanoparticles for fabricating reinforced 6061Al matrix composites. Mater Sci Eng, A 699:185–193

Jiang C, Liu Z-K (2003) Computational investigation of constitutional liquation in Al–Cu alloys. Acta Mater 51:4447–4459

Zhang L, Wang J, Du Y et al (2009) Thermodynamic properties of the Al–Fe–Ni system acquired via a hybrid approach combining calorimetry, first-principles and CALPHAD. Acta Mater 57:5324–5341

Zhang X, Shi C, Liu E et al (2017) In-situ space-confined synthesis of well-dispersed three-dimensional graphene/carbon nanotube hybrid reinforced copper nanocomposites with balanced strength and ductility. Compos Part A Appl Sci 103:178–187

Zhang X, Shi C, Liu E et al (2017) Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network. Nanoscale 9:11929–11938

Qin J, He C, Zhao N et al (2014) Graphene networks anchored with Sn@graphene as lithium ion battery anode. ACS Nano 8:1728–1738

Zhou J, Qin J, Zhang X et al (2015) 2D space-confined synthesis of few-layer MoS2 anchored on carbon nanosheet for lithium-ion battery anode. ACS Nano 9:3837–3848

Qin J, Wang T, Liu D et al (2018) A top-down strategy toward SnSb in-plane nanoconfined 3D N-doped porous graphene composite microspheres for high performance Na-Ion battery anode. Adv Mater 3:1704670

Yang M, Weng L, Zhu H et al (2017) Simultaneously enhancing the strength, ductility and conductivity of copper matrix composites with graphene nanoribbons. Carbon 118:250–260

Qu X, Wang F, Shi C et al (2018) In situ synthesis of a gamma-Al2O3 whisker reinforced aluminium matrix composite by cold pressing and sintering. Mater Sci Eng, A 709:223–231

Xin L, Yang W, Zhao Q et al (2017) Strengthening behavior in SiC nanowires reinforced pure Al composite. J Alloy Compd 695:2406–2412

Jiang L, Li Z, Fan G et al (2012) Strong and ductile carbon nanotube/aluminum bulk nanolaminated composites with two-dimensional alignment of carbon nanotubes. Scr Mater 66:331–334

Rashad M, Pan F, Tang A et al (2014) Effect of Graphene Nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog Nat Sci 24:101–108

Zhao L, Lu H, Gao Z (2015) Microstructure and mechanical properties of Al/Graphene composite produced by high-pressure Torsion. Adv Eng Mater 17:976–981

Li Z, Guo Q, Li Z et al (2015) Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure. Nano Lett 15:8077–8083

George R, Kashyap KT, Rahul R et al (2005) Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr Mater 53:1159–1163

Zhang H, Xu C, Xiao W et al (2016) Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion. Mater Sci Eng, A 658:8–15

Chen B, Shen J, Ye X et al (2017) Length effect of carbon nanotubes on the strengthening mechanisms in metal matrix composites. Acta Mater 140:317–325

Fu K, Zhang X, Shi C et al (2018) An approach for fabricating Ni@graphene reinforced nickel matrix composites with enhanced mechanical properties. Mater Sci Eng, A 715:108–116

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scr Mater 51:801–806

Chu K, Wang F, Li Y et al (2018) Interface and mechanical/thermal properties of graphene/copper composite with Mo2C nanoparticles grown on graphene. Compos Part A Appl Sci 109:267–279

Munoz-Morris MA, Garcia-Oca C, Morris DG (2002) An analysis of strengthening mechanisms in a mechanically alloyed, oxide dispersion strengthened iron aluminide intermetallic. Acta Mater 50:2825–2836

Zhang D, Zhan Z (2016) Strengthening effect of graphene derivatives in copper matrix composites. J Alloy Compd 654:226–233

Acknowledgements

The authors gratefully acknowledge the financial support by the National Natural Science Funds for Excellent Young Scholar (Grant No. 51422104), the National Natural Science Foundation of China (Grant Nos. 51531004, 51771130 and 51472177), the Tianjin Youth Talent Support Program, the Tianjin Natural Science Funds for Distinguished Young (Grant No. 17JCJQJC44300) and the Tianjin Science and Technology Support Project (Grant No. 17ZXCLGX00060).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, J., Zhang, X., Zhao, N. et al. In situ synthesis of copper-modified graphene-reinforced aluminum nanocomposites with balanced strength and ductility. J Mater Sci 54, 5498–5512 (2019). https://doi.org/10.1007/s10853-018-03245-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-03245-2