Abstract

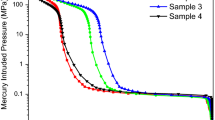

With advancements in additive manufacturing, now 3D-printed core plugs can be duplicated in order to replace natural rock samples. This can help us to control their parameters to be used in different types of experiments for model verifications. However, prior to such substitutions, we should ensure they can represent natural rock samples through characterizing their physical properties. In this paper, synthetic samples made up of gypsum powder are 3D-printed and then characterized for essential pores properties. The analysis included structures of the pores, quantitative porosity evaluation, pore size distribution, pore surface area, pore shape distribution, and corresponding anisotropy. Mercury injection porosimetry (MIP) and helium porosimetry (HP) combined with X-ray micro-computed tomography were performed to provide us with detailed information about the pores. Porosity was measured 32.66% from micro-CT based on watershed thresholding, which was found comparable with MIP and HP results, 27.90 and 28.86%, respectively. Most of the pores lay in the range from 4 to 10 μm in diameter with relative frequency of 92.04%. The pore shape distribution indicates that 3D-printed gypsum rocks host more spherical pores and fewer blade-shaped pores. In addition, pore anisotropy of the sample that was analyzed by collecting pore orientation in orthogonal axes represented the vertical transverse isotropy.

. Modified from Sezer et al. [67]

. Modified from Rassouli et al. [56]

Similar content being viewed by others

References

Aghajanpour A, Fallahzadeh SH, Khatibi S, Hossain MM, Kadkhodaie A (2017) Full waveform acoustic data as an aid in reducing uncertainty of mud window design in the absence of leak-off test. J Nat Gas Sci Eng 45:786–796

Al-Amri SS, Kalyankar NV (2010) Image segmentation by using threshold techniques. arXiv preprint arXiv:1005.4020

Alman J, Chan TM, Williams R (2016) Polynomial representations of threshold functions and algorithmic applications. In: 2016 IEEE 57th annual symposium on foundations of computer science (FOCS). IEEE, pp 467–476

Alexeyev A, Ostadhassan M, Mohammed RA et al (2017) Well log based geomechanical and petrophysical analysis of the bakken formation. American Rock Mechanics Association

Andrew M, Bijeljic B, Blunt M (2015) Reservoir condition pore-scale imaging of multiple fluid phases using X-ray microtomography. J Vis Exp. https://doi.org/10.3791/52440

Arena A, Delle Piane C, Sarout J (2014) A new computational approach to cracks quantification from 2D image analysis: application to micro-cracks description in rocks. Comput Geosci 66:106–120

Aslanidi OV, Nikolaidou T, Zhao J, Smaill BH, Gilbert SH, Holden AV, Lowe T, Withers PJ, Stephenson RS, Jarvis JC, Hancox JC (2013) Application of micro-computed tomography with iodine staining to cardiac imaging, segmentation, and computational model development. IEEE Trans Med Imaging 32:8–17

ASTM E1441-11 (2011) Standard guide for computed tomography (CT) imaging. ASTM International, West Conshohocken

Barrett P (1980) The shape of rock particles, a critical review. Sedimentology 27:291–303

Benson P, Meredith P, Platzman E, White R (2005) Pore fabric shape anisotropy in porous sandstones and its relation to elastic wave velocity and permeability anisotropy under hydrostatic pressure. Int J Rock Mech Min Sci 42:890–899

Bernard S, Wirth R, Schreiber A et al (2013) FIB-SEM and TEM investigations of an organic-rich shale maturation series from the lower Toarcian Posidonia Shale, Germany: Nanoscale pore system and fluid-rock interactions. In: Camp W, Diaz E, Wawak B (eds) Electron microscopy of shale hydrocarbon reservoirs: AAPG memoir, vol 102, pp 53–66

Beucher S, Lantuéjoul C (1979) Use of watersheds in contour detection. International Workshop on Image Processing: Real-time Edge and Motion Detection/Estimation

Biao Z, Tianyu Y, Wenfeng D, Xianying L (2017) Effects of pore structure and distribution on strength of porous Cu-Sn-Ti alumina composites. Chin J Aeronaut 30:2004–2015

Bieniek A, Moga A (2000) An efficient watershed algorithm based on connected components. Pattern Recogn 33:907–916

Bleau A, Leon LJ (2000) Watershed-based segmentation and region merging. Comput Vis Image Underst 77:317–370

Cnudde V, Boone MN (2013) High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth Sci Rev 123:1–17

Condurache AP, Aach T (2005) Vessel segmentation in angiograms using hysteresis thresholding. In: Proceedings of the ninth IAPR conference on Machine vision applications 2005, Tsukuba Science City, Japan

Cone MP, Kersey DG (1992) Porosity: Part 5. Laboratoy methods. ME 10: Development geology reference manual, pp 204–209

dos Reis PJ, Nagata R, Appoloni CR (2017) Pore size distributions convolution for microtomographic images applied to Shark Bay’s oolite. Micron 98:49–54

Espalin D, Muse DW, MacDonald E, Wicker RB (2014) 3D Printing multifunctionality: structures with electronics. Int J Adv Manuf Technol 72:963–978

Fereshtenejad S, Song J-J (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49:2065–2074

Gallegos DP, Munn K, Smith DM, Stermer DL (1987) A NMR technique for the analysis of pore structure: application to materials with well-defined pore structure. J Colloid Interface Sci 119:127–140

Gea SL, Decraemer WF, Dirckx JJ (2005) Region of interest micro-CT of the middle ear: a practical approach. J X-ray Sci Technol 13:137–147

Gibson I, Rosen D, Stucker B (2014) Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing. Springer, Berlin

Giesche H (2006) Mercury porosimetry: a general (practical) overview. Part Part Syst Charact 23:9–19

Grathoff GH (2016) Porosity and permeability determination of organic-rich Posidonia shales based on 3-D analyses by FIB-SEM microscopy. Solid Earth 7:1145

Iassonov P, Gebrenegus T, Tuller M (2009) Segmentation of X-ray computed tomography images of porous materials: A crucial step for characterization and quantitative analysis of pore structures. Water Resour Res 45:W09415

Ishutov S, Hasiuk FJ, Harding C, Gray JN (2015) 3D printing sandstone porosity models. Interpretation 3:SX49–SX61

Jiang C, Zhao G-F (2015) A preliminary study of 3D printing on rock mechanics. Rock Mech Rock Eng 48:1041–1050

Jiang Q, Feng X, Song L, Gong Y, Zheng H, Cui J (2016) Modeling rock specimens through 3D printing: tentative experiments and prospects. Acta Mech Sin 32:101–111

Jin L, Pu H, Wang Y, Li Y (2015) The consideration of pore size distribution in organic-rich unconventional formations may increase oil production and reserve by 25%, eagle ford case study. Unconventional Resources Technology Conference (URTEC)

Ju Y, Wang L, Xie H, Ma G, Zheng Z, Mao L (2017) Visualization and transparentization of the structure and stress field of aggregated geomaterials through 3D printing and photoelastic techniques. Rock Mech Rock Eng 50:1383–1407

Khatibi S, Ostadhassan M, Tuschel D, Gentzis T, Bubach B, Carvajal-Ortiz H (2017) Raman spectroscopy to study thermal maturity and elastic modulus of kerogen. Int J Coal Geol 185:103–118

Kong L, Ostadhassan M, Li C, Tamimi N (2017) Rock physics and geomechanics of 3-D printed rocks. American Rock Mechanics Association

Lai WK, Phoon ZH, Chew KH, Goh KM, Chua PY (2016) Image multi-thresholding to characterise the mechanical stability of rubber latex concentrate. In: 2016 international conference on digital image computing: techniques and applications (DICTA). IEEE, pp 1–8

Lee BY, Kurtis KE (2017) Effect of pore structure on salt crystallization damage of cement-based materials: consideration of w/b and nanoparticle use. Cem Concr Res 98:61–70

Lee VK, Lanzi AM, Ngo H, Yoo S-S, Vincent PA, Dai G (2014) Generation of multi-scale vascular network system within 3D hydrogel using 3D bio-printing technology. Cell Mol Bioeng 7:460–472

Lei T, Sewchand W (1992) Statistical approach to X-ray CT imaging and its applications in image analysis. I. Statistical analysis of X-ray CT imaging. IEEE Trans Med Imaging 11:53–61

Li C, Ostadhassan M, Kong L (2017) Nanochemo-mechanical characterization of organic shale through AFM and EDS. Society of Exploration Geophysicists

Li D, Zhang G, Wu Z, Yi L (2010) An edge embedded marker-based watershed algorithm for high spatial resolution remote sensing image segmentation. IEEE Trans Image Process 19:2781–2787

Li Y, Biondi B, Clapp R, Nichols D (2016) Integrated VTI model building with seismic data, geologic information, and rock-physics modeling—Part 1: theory and synthetic test. Geophysics 81(5):C177–C191

Liu J, Pereira GG, Liu Q, Regenauer-Lieb K (2016) Computational challenges in the analyses of petrophysics using microtomography and upscaling: a review. Comput Geosci 89:107–117

Liu K, Ostadhassan M, Kong L (2017) Pore structure heterogeneity in Middle Bakken formation. In: ARMA-2017-0068. American Rock Mechanics Association, ARMA

Loucks RG, Reed RM, Ruppel SC, Hammes U (2012) Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull 96:1071–1098

Malik S, Smith L, Sharman J, Holt EM, Rigby SP (2016) Pore structural characterization of fuel cell layers using integrated mercury porosimetry and computerized X-ray tomography. Ind Eng Chem Res 55:10850–10859

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook: tools for seismic analysis of porous media. Cambridge University Press, Cambridge

McCormack DA, Kroes G-J, Neuhauser D (1998) Resonance affected scattering: comparison of two hybrid methods involving filter diagonalization and the Lanczos method. J Chem Phys 109:5177–5186

Murphy SV, Atala A (2014) 3D bioprinting of tissues and organs. Nat Biotechnol 32:773–785

Nelson PH (2009) Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull 93:329–340

Okazaki K, Noda H, Uehara S, Shimamoto T (2014) Permeability, porosity and pore geometry evolution during compaction of Neogene sedimentary rocks. J Struct Geol 62:1–12

Ostadhassan M, Zeng Z, Zamiran S (2012) Geomechanical modeling of an anisotropic formation-Bakken case study. In: 46th US rock mechanics/geomechanics symposium. American Rock Mechanics Association

Pape H, Clauser C, Iffland J (1999) Permeability prediction based on fractal pore-space geometry. Geophysics 64:1447–1460

Park K-B, Noguchi T (2017) Effects of mixing and curing temperature on the strength development and pore structure of fly ash blended mass concrete. Adv Mater Sci Eng 2017:11

Peng S, Hu Q, Dultz S, Zhang M (2012) Using X-ray computed tomography in pore structure characterization for a Berea sandstone: resolution effect. J Hydrol 472:254–261

Pyka G, Kerckhofs G, Schrooten J, Wevers M (2014) The effect of spatial micro-CT image resolution and surface complexity on the morphological 3D analysis of open porous structures. Mater Charact 87:104–115

Rassouli F, Ross C, Zoback M, Andrew M (2017) Shale Rock characterization using multi-scale imaging. In: 51st US rock mechanics/geomechanics symposium. American Rock Mechanics Association

Ringrose-Voase A, Bullock P (1984) The automatic recognition and measurement of soil pore types by image analysis and computer programs. Eur J Soil Sci 35:673–684

Rosenkrantz AB, Matza BW, Portnoy E, Melamed J, Taneja SS, Wehrli NE (2014) Impact of size of region-of-interest on differentiation of renal cell carcinoma and renal cysts on multi-phase CT: preliminary findings. Eur J Radiol 83:239–244

Ruzyla K (1986) Characterization of pore space by quantitative image analysis. SPE Form Eval 1(04):389–398

Saleh AA, Castagna JP (2004) Revisiting the Wyllie time average equation in the case of near-spherical pores. Geophysics 69:45–55

Sarmadivaleh M, Rasouli V (2015) Test design and sample preparation procedure for experimental investigation of hydraulic fracturing interaction modes. Rock Mech Rock Eng 48:93–105

Sarout J, Cazes E, Delle Piane C, Arena A, Esteban L (2017) Stress-dependent permeability and wave dispersion in tight cracked rocks: Experimental validation of simple effective medium models. J Geophys Res Solid Earth 122:6180–6201

Schaefer C, Towne R, Lazouskaya V, Bishop M, Dong H (2012) Diffusive flux and pore anisotropy in sedimentary rocks. J Contam Hydrol 131:1–8

Schmitt M, Halisch M, Müller C, Fernandes CP (2016) Classification and quantification of pore shapes in sandstone reservoir rocks with 3-D X-ray micro-computed tomography. Solid Earth 7:285–300

Schön JH (2015) Physical properties of rocks: fundamentals and principles of petrophysics. Elsevier, Amsterdam

Seiphoori A, Whittle AJ, Krakowiak KJ, Einstein HH (2017) Insights into diagenesis and pore structure of opalinus shale through comparative studies of natural and reconstituted materials. Clays Clay Miner 65:135–153

Sezer Gİ, Ramyar K, Karasu B et al (2008) Image analysis of sulfate attack on hardened cement paste. Mater Des 29:224–231

Silin DB, Jin G, Patzek TW (2003) Robust determination of the pore space morphology in sedimentary rocks. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers

Sun K, Wei T-S, Ahn BY, Seo JY, Dillon SJ, Lewis JA (2013) 3D printing of interdigitated Li-Ion microbattery architectures. Adv Mater 25:4539–4543

Szekely J, Neumann AW, Chuang YK (1971) The rate of capillary penetration and the applicability of the Washburn equation. J Colloid Interface Sci 35(2):273–278

Taquet J, Labit C (2010) Optimized decomposition basis using Lanczos filters for lossless compression of biomedical images. In: 2010 IEEE international workshop on multimedia signal processing (MMSP). IEEE, pp 122–127

Tiab D, Donaldson EC (2015) Petrophysics: theory and practice of measuring reservoir rock and fluid transport properties. Gulf professional publishing

Tsukada K, Kawajiri A, Hashimoto Y, Makihara K, Tominaga R, Fujita M, Sato T (2017) Functional inkjet 3D printing system for customized electronics. In: 2017 international conference on electronics packaging (ICEP). IEEE, pp 5–6

Usui S, Amidror I (1982) Digital low-pass differentiation for biological signal processing. IEEE Trans Biomed Eng 6(10):686–693

Vafai K (2015) Handbook of porous media. CRC Press, Boca Raton

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40:443–451

Wang Y, Li X, Li C, Yang M, Wei Q (2015) Binder droplet impact mechanism on a hydroxyapatite microsphere surface in 3D printing of bone scaffolds. J Mater Sci 50:5014–5023. https://doi.org/10.1007/s10853-015-9050-9

Washburn EW (1921) Note on a method of determining the distribution of pore sizes in a porous material. Proc Natl Acad Sci 7:115–116

Webb PA (2001) An introduction to the physical characterization of materials by mercury intrusion porosimetry with emphasis on reduction and presentation of experimental data. Micromeritics Instrum Corp, Norcross, GA

Zhao B, Shang Y, Jin L, Jia B (2017) Characterizing connectivity of multiscale pore structure in unconventional reservoirs by the complex network theory. Unconventional Resources Technology Conference (URTEC)

Zingg T (1935) Beitrag zur schotteranalyse

Acknowledgements

The authors greatly appreciates the AAPG Foundation for awarding me the 2017 Grand-in-aid. The authors also would like to acknowledge Bruker for the micro-CT data and FEI for providing us with the Avizo software for processing and interpretation of the micro-CT data. Funding was provided by American Association of Petroleum Geologists (Grant No. J. Ben Carsey, Sr. Memorial Grant).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

I certify that there is no actual or potential conflict of interest in relation to this article.

Rights and permissions

About this article

Cite this article

Kong, L., Ostadhassan, M., Li, C. et al. Pore characterization of 3D-printed gypsum rocks: a comprehensive approach. J Mater Sci 53, 5063–5078 (2018). https://doi.org/10.1007/s10853-017-1953-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1953-1