Abstract

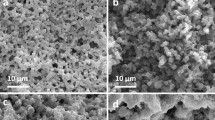

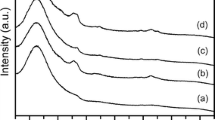

Carbon nanotubes with few walls (FWCNTs) are prepared by catalytic chemical vapor deposition. Transmission electron microscopy investigations for each sample show the average number of walls (3, 4 and 8) as well as the internal and external diameter distributions. Binder-free FWCNT monoliths are prepared by spark plasma sintering (SPS) at temperatures in the range 1000–1600 °C. A combination of techniques including Raman spectroscopy, scanning- and transmission electron microscopy, electron microdiffraction is used to characterize the samples. Compared to the FWCNT powders, the high temperatures used for SPS favor the elimination of surface defects in CNT walls but also some limited amorphization, without dramatic damage to the CNTs. Increasing the SPS temperatures produces an increase in densification. N2 adsorption–desorption cycles revealed that the powders and monoliths show microporosity and, mostly, mesoporosity. Some monoliths show a specific surface area equal to about 500 m2/g. The 4WCNTs when consolidated into monoliths by SPS at 1000 or 1100 °C are able to retain a high amount of mesoporosity that contributes to a high porous volume of the order of 0.8 cm3/g.

Similar content being viewed by others

References

Ma RZ, Xu CL, Wei BQ, Liang J, Wu DH, Li DJ (1999) Electrical conductivity and field emission characteristics of hot-pressed sintered carbon nanotubes. Mater Res Bull 34:741–747

Zhang HL, Li JF, Yao KF, Chen LD (2005) Spark plasma sintering and thermal conductivity of carbon nanotube bulk materials. J Appl Phys 97:114310-1–114310-4

Qin C, Shi X, Bai SQ, Chen LD, Wang LJ (2006) High temperature electrical and thermal properties of the bulk carbon nanotube prepared by SPS. Mater Sci Eng A 420:208–211

Yang K, He J, Su Z, Reppert JB, Skove MJ, Tritt TM, Rao AM (2010) Inter-tube bonding, graphene formation and anisotropic transport properties in spark plasma sintered multi-wall carbon nanotube arrays. Carbon 48:756–762

Zhang HL, Lia JF, Yao KF, Chen LD (2005) Spark plasma sintering and thermal conductivity of carbon nanotube bulk materials. J Appl Phys 97:114310-1–114310-4

Marinho B, Ghislandi M, Tkalya E, Koning CE, de With G (2012) Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol 221:351–358

Cha SI, Kim KT, Lee KH, Mo CB, Jeong YJ, Hong SH (2008) Mechanical and electrical properties of cross-linked carbon nanotubes. Carbon 46:482–488

Li JL, Bai GZ, Feng JW, Jiang W (2005) Microstructure and mechanical properties of hot-pressed carbon nanotubes compacted by spark plasma sintering. Carbon 43:2649–2653

Li JL, Wang LJ, He T, Jiang W (2007) Surface graphitization and mechanical properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon 45:2636–2642

Yamamoto G, Sato Y, Takahashi T, Omori M, Okubo A, Tohji K, Hashida T (2006) Mechanical properties of binder-free single-walled carbon nanotubes solids. Scr Mater 54:299–303

Wang W, Yokoyama A, Liao S, Omori M, Zhu Y, Uo M, Akasaka T, Watari F (2008) Preparation and characteristics of a binderless carbon nanotube monolith and its biocompatibility. Mater Sci Eng C 28:1082–1086

Uo M, Hasegawa T, Akasaka T, Tanaka I, Munekane F, Omori M, Kimura H, Nakatomi R, Soga K, Kogo Y, Watari F (2009) Multiwalled carbon nanotube monoliths prepared by spark plasma sintering (SPS) and their mechanical properties. Bio-Med Mater Eng 19:11–17

Sato Y, Nishizaka H, Sawano S, Yoshinaka A, Hirano K, Hashiguchi S, Arie T, Akita S, Yamamoto G, Hashida T, Kimura H, Motomiya K, Tohji K (2012) Influence of the structure of the nanotube on the mechanical properties of binder-free multi-walled carbon nanotube solids. Carbon 50:34–39

Amadou J, Begin D, Nguyen P, Tessonnier JP, Dintzer T, Vanhaecke E, Ledoux MJ, Pham-Huu C (2006) Synthesis of a carbon nanotube monolith with controlled macroscopic shape. Carbon 44:2587–2592

Laurent Ch, Chevallier G, Weibel A, Peigney A, Estournès C (2008) Spark plasma sintering of double-walled carbon nanotubes. Carbon 46:1812–1816

Liu YF, Ba H, Nguyen DL, Ersen O, Romero T, Zafeiratos S, Begin D, Janowska I, Pham-Huu C (2013) Synthesis of porous carbon nanotubes foam composites with a high accessible surface area and tunable porosity. J Mater Chem A 1:9508–9516

Chiodarelli N, Richard O, Bender H, Heyns M, De Gendt S, Groeseneken G, Vereecken PM (2012) Correlation between number of walls and diameter in multiwall carbon nanotubes grown by chemical vapor deposition. Carbon 50:1748–1752

Preston C, Song D, Taillon J, Cumings J, Hu L (2016) Boron-doped few-walled carbon nanotubes: novel synthesis and properties. Nanotechnology 27:445601-1–445601-9

Jeong HJ, Kim KK, Jeong SY, Park MH, Yang CW, Lee YH (2004) High-yield catalytic synthesis of thin multiwalled carbon nanotubes. J Phys Chem B 108:17695–17698

Lukic B, Seo JW, Bacsa RR, Delpeux S, Béguin F, Bister G, Fonseca A, Nagy JB, Kis A, Jeney S, Kulik AJ, Forro L (2005) Catalytically grown carbon nanotubes of small diameter have a high Young’s modulus. Nano Lett 5:2074–2077

Qian C, Qi H, Gao B, Cheng Y, Qiu Q, Zhou O, Liu JJ (2006) Fabrication of small diameter few-walled carbon nanotubes with enhanced field emission property. J Nanosci Nanotechnol 6:1346–1349

Hou Y, Tang J, Zhang HB, Qian C, Feng YY, Liu J (2009) Functionalized few-walled carbon nanotubes for mechanical reinforcement of polymeric composites. ACS Nano 3:1057–1062

Flahaut E, Peigney A, Bacsa WS, Bacsa RR, Laurent Ch (2004) CCVD synthesis of carbon nanotubes from (Mg Co, Mo)O catalysts: influence of the proportions of cobalt and molybdenum. J Mater Chem 14:646–653

Flahaut E, Laurent Ch, Peigney A (2005) Catalytic CVD synthesis of double and triple-walled carbon nanotubes by the control of catalyst preparation. Carbon 43:375–383

Flahaut E, Peigney A, Laurent Ch, Rousset A (2000) Synthesis of single-walled carbon nanotubes –Co–MgO composite powders and extraction of the nanotubes. J Mater Chem 10:49–52

Osswald S, Flahaut E, Gogotsi Y (2005) Elimination of D-band in Raman spectra of double-wall carbon nanotubes by oxidation. Chem Phys Lett 402:422–427

Bortolamiol T, Lukanov P, Galibert AM, Soula B, Lonchambon P, Datas L, Flahaut E (2014) Double-walled carbon nanotubes: quantitative purification assessment, balance between purification and degradation and solution filling as an evidence of opening. Carbon 78:79–90

Guiderdoni Ch, Pavlenko E, Turq V, Weibel A, Puech P, Estournès C, Peigney A, Bacsa W, Laurent Ch (2013) The preparation of carbon nanotube (CNT)/copper composites and the effect of the number of CNT walls on their hardness, friction and wear properties. Carbon 58:185–197

Flahaut E, Peigney A, Laurent C (2003) Double-walled carbon nanotubes in composite powders. J Nanosci Nanotechnol 3:151–158

Peigney A, Laurent Ch, Dobigeon F, Rousset A (1997) Carbon nanotubes grown in situ by a novel catalytic method. J Mater Res 12:613–615

Cordier A, de Resende VG, Weibel A, De Grave E, Peigney A, Laurent Ch (2010) Catalytic chemical vapor deposition synthesis of double-walled and few-walled carbon nanotubes by using a MoO3-supported conditioning catalyst to control the formation of iron catalytic particles within a α-Al1.8Fe0.2O3 self-supported foam. J Phys Chem C 114:19188–19193

Kasperski A, Weibel A, Datas L, De Grave E, Peigney A, Laurent Ch (2015) Large-diameter single-wall carbon nanotubes formed alongside small-diameter double-walled carbon nanotubes. J Phys Chem C 119:1524–1535

Zhang Q, Yu H, Liu Y, Qian W, Wang Y, Luo G, Wei F (2008) Few walled carbon nanotube production in large-scale by nano-agglomerate fluidized-bed process. NANO 3:45–50

Laurent Ch, Flahaut E, Peigney A (2010) The weight and density of carbon nanotubes versus the number of walls and diameter. Carbon 48:2994–2996

Kim DY, Yang CM, Park YS, Kim KK, Jeong SY, Han JH, Lee YH (2005) Characterization of thin multi-walled carbon nanotubes synthesized by catalytic chemical vapor deposition. Chem Phys Lett 413:135–141

Babu DJ, Lange M, Cherkashinin G, Issanin A, Staudt R, Schneider JJ (2013) Gas adsorption studies of CO2 and N2 in spatially aligned double-walled carbon nanotube arrays. Carbon 61:616–623

Yang CM, Kaneko K, Yudasaka M, Iijima S (2002) Effect of purification on pore structure of HiPco single-walled carbon nanotube aggregates. Nano Lett 2:385–388

Hu YH, Ruckenstein E (2004) Pore size distribution of single-walled carbon nanotubes. Ind Eng Chem Res 43:708–711

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem 57:603–619

Peigney A, Laurent Ch, Flahaut E, Bacsa RR, Rousset A (2001) Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 39:507–514

Andrews R, Jacques D, Qian D, Dickey EC (2001) Purification and structural annealing of multiwalled carbon nanotubes at graphitization temperatures. Carbon 39:1681–1687

Huang W, Wang Y, Luo G, Wei F (2003) 99.9% purity multi-walled carbon nanotubes by vacuum high-temperature annealing. Carbon 41:2585–2590

Goncharov AF, Andreev VD (1991) Raman scattering in carbon films at high pressures. Sov Phys JETP 73:140–142

Aguiar AL, Capaz RB, Souza Filho AG, San-Miguel A (2012) Structural and phonon properties of bundled single- and double-wall carbon nanotubes under pressure. J Phys Chem C 116:22637–22645

Puech P, Hubel H, Dunstan DJ, Bacsa RR, Laurent C, Bacsa WS (2004) Discontinuous tangential stress in doublewall carbon nanotubes. Phys Rev Lett 93:095506-1–095506-4

Baaziz W, Begin-Colin S, Pichon BP, Florea I, Ersen O, Zafeiratos S, Barbosa R, Begin D, Pham-Huu C (2012) High density monodisperse cobalt nanoparticles (NPs) filling of multi-walled carbon nanotubes. Chem Mater Commun 24:1549–1551

Yamamoto G, Sato Y, Takahashi T, Omori M, Hashida T, Okubo A, Tohji K (2006) Single-walled carbon nanotube-derived novel structural material. J Mater Res 21:1537–1542

Du R, Zhao Q, Zhang N, Zhang J (2015) Macroscopic carbon nanotube-based 3D monoliths. Small 11:3263–3289

Klepel O, Danneberg N, Dräger M, Erlitz M, Taubert M (2016) Synthesis of porous carbon monoliths using hard templates. Materials 9:1–14

Gupta J, Tai NH (2016) Carbon materials as oil sorbent: a review on the synthesis and performance. J Mater Chem A 4:1550–1565

Acknowledgements

The authors thank Ch. Chauvin for CNT synthesis and test samples preparation. Electron microscopy was performed at “Centre de microcaractérisation Raimond Castaing—UMS 3623” (Toulouse) and the authors thank C. Josse and A. Descamps-Mandine for FIB preparation and help with the TEM observations. The SPS was performed at the Plateforme Nationale CNRS de Frittage-Flash (PNF2, Toulouse). This work is made in part under the contract ANR 2011-NANO-025 TRI-CO.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laurent, C., Dinh, T.M., Barthélémy, MC. et al. Mesoporous binder-free monoliths of few-walled carbon nanotubes by spark plasma sintering. J Mater Sci 53, 3225–3238 (2018). https://doi.org/10.1007/s10853-017-1784-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1784-0