Abstract

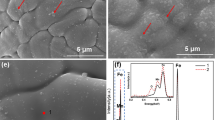

This paper presents the effects of aqueous processing of WC–Co powders on their sinterability and mechanical properties. WC–Co powders have been milled in aqueous media (distilled water + corrosion inhibitor). The as-milled samples have been compacted and sintered in vacuum at 1380 °C. The investigations performed on the two components, carbide and binder, reveal different oxidation behaviour in water, with a further effect on the properties of the sintered product. The decrease of the saturation magnetisation of the compacts corroborated with the microstructure reveals the oxidation of the samples milled for a longer duration. The magnetic properties, hardness and microstructure suggest that the used corrosion inhibitor is effective for short milling durations.

Similar content being viewed by others

References

Upadhyaya GS (1998) 1—introduction. William Andrew Publishing, Westwood, pp 1–6

Lassner E, Schubert W-D (2012) Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. Springer, New York

Marshall JM, Giraudel M (2015) The role of tungsten in the Co binder: effects on WC grain size and hcp–fcc Co in the binder phase. Int J Refract Metals Hard Mater 49:57–66

Upadhyaya GS (1998) 2—crystal structure and phase equilibria. William Andrew Publishing, Westwood, pp 7–54

Kurlov AS, Gusev AI (2013) Tungsten carbides. Springer Ser Mater Sci 184:34–36

Borgh I et al (2014) Microstructure, grain size distribution and grain shape in WC–Co alloys sintered at different carbon activities. Int J Refract Metals Hard Mater 43:205–211

Upadhyaya GS (1998) 4—consolidation of cemented carbides. William Andrew Publishing, Westwood, pp 89–137

Lassner E, Schubert W-D (1999) Tungsten in hardmetals. Springer, Boston, pp 321–363

Xueming M, Gang J, Ling Z, Yuanda D (1998) Structure and properties of bulk nano-structured WC–CO alloy by mechanical alloying. J Alloys Compd 264(1–2):267–270

Sun Y, Su W, Yang H, Ruan J (2015) Effects of WC particle size on sintering behavior and mechanical properties of coarse grained WC–8Co cemented carbides fabricated by unmilled composite powders. Ceram Int 41(10):14482–14491

Spriggs GE (1995) A history of fine grained hardmetal. Int J Refract Metals Hard Mater 13(5):241–255

Mandel K, Krüger L, Schimpf C (2014) Particle properties of submicron-sized WC–12Co processed by planetary ball milling. Int J Refract Metals Hard Mater 42:200–204

Wang H, Webb T, Bitler JW (2015) Different effects of Cr3C2 and VC on the sintering behavior of WC–Co materials. Int J Refract Metals Hard Mater 53(Part B):117–122

Andersson KM, Bergström L (2000) Oxidation and dissolution of tungsten carbide powder in water. Int J Refract Metals Hard Mater 18(2–3):121–129

Hewitt SA, Kibble KA (2009) Effects of ball milling time on the synthesis and consolidation of nanostructured WC–Co composites. Int J Refract Metals Hard Mater 27(6):937–948

Laarz E, Bergström L (2000) Dispersing WC–Co powders in aqueous media with polyethylenimine. Int J Refract Metals Hard Mater 18(6):281–286

Su B-L, Sanchez C, Yang X-Y (2012) Hierarchically structured porous materials: from nanoscience to catalysis, separation, optics, energy, and life science. Wiley, New York

Chivot J, Mendoza L, Mansour C, Pauporté T, Cassir M (2008) New insight in the behaviour of Co–H2O system at 25–150 °C, based on revised Pourbaix diagrams. Corros Sci 50(1):62–69

Andersson KM (2004) Aqueous processing of WC–Co powders

Tang C-W, Wang C-B, Chien S-H (2008) Characterization of cobalt oxides studied by FT-IR, Raman, TPR and TG-MS. Thermochim Acta 473(1):68–73

Warren A, Nylund A, Olefjord I (1996) Oxidation of tungsten and tungsten carbide in dry and humid atmospheres. Int J Refract Metals Hard Mater 14(5–6):345–353

Zhang FL, Wang CY, Zhu M (2003) Nanostructured WC/Co composite powder prepared by high energy ball milling. Scr Mater 49(11):1123–1128

Neamţu BV, Chicinaş HF, Marinca TF, Isnard O, Chicinaş I (2016) Preparation and characterisation of Co–Fe–Ni–M–Si–B (M = Zr, Ti) amorphous powders by wet mechanical alloying. J Alloys Compd 673C:80–85

Huang J, Wu Y, Ye H (1996) Allotropic transformation of cobalt induced by ball milling. Acta Mater 44(3):1201–1209

Upadhyaya GS (1998) 8—magnetic properties. William Andrew Publishing, Westwood, pp 227–236

Hashe NG, Neethling JH, Berndt PR, Andrén H-O, Norgren S (2007) A comparison of the microstructures of WC–VC–TiC–Co and WC–VC–Co cemented carbides. Int J Refract Metals Hard Mater 25(3):207–213

Yang Q, Yang J, Yang H, Ni G, Ruan J (2017) Synthesis of ultrafine WC–10Co composite powders with carbon boat added and densification by sinter-HIP. Int J Refract Metals Hard Mater 62:104–109

Fabijanić TA, Alar Ž, Ćorić D (2016) Influence of consolidation process and sintering temperature on microstructure and mechanical properties of near nano- and nano-structured WC–Co cemented carbides. Int J Refract Metals Hard Mater 54:82–89

Acknowledgements

This work was made possible by the generous support of Gühring Company.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists.

Rights and permissions

About this article

Cite this article

Chicinaş, H.F., Marinca, T.F., Götze, P. et al. Influence of aqueous milling duration on the sintered WC–10Co hard metal powders. J Mater Sci 53, 2901–2910 (2018). https://doi.org/10.1007/s10853-017-1701-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1701-6