Abstract

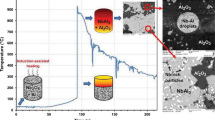

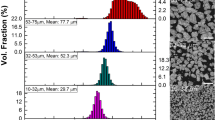

Reactive Al–Ni composites are of interest for combustion synthesis, for joining, and as components of energetic formulations. Mechanical milling is one of the most practical techniques used for their preparation. This study investigated the effect of ball milling at cryogenic temperatures on the reactivity and structure of Al–Ni composites. Stoichiometric mixtures of Al and Ni powders were milled both at room temperature and cooled by liquid nitrogen. Products were characterized using scanning electron microscopy, differential scanning calorimetry, and x-ray diffraction. Aluminum and nickel were mixed on a finer scale in cryogenically milled powders compared to those prepared at room temperature. DSC traces of the cryogenically milled powder showed three exothermic peaks, while only two clearly resolved peaks were observed for the powders milled at room temperature. A low-temperature reaction preceding the first peak was detected only for the cryomilled material. Apparent activation energies, obtained by model-free analysis, were consistent with previous work on nanofoils. Ignition temperatures of powders prepared at room temperature decreased with increasing structural refinement. This effect was even stronger for the cryogenically milled powder. Energetic characteristics of the prepared materials were correlated with their respective structural refinement. These correlations suggest that the cryomilled material has a narrower zone separating Al and Ni in which the elements are mixed together compared to the similar material prepared by room temperature milling.

Similar content being viewed by others

References

Zhu P, Li JCM, Liu CT (2002) Reaction mechanism of combustion synthesis of NiAl. Mater Sci Eng A 329–331:57–68

Anselmi-Tamburini U, Munir ZA (1989) The propagation of a solid-state combustion wave in Ni–Al foils. J Appl Phys 66(10):5039–5045

Hunt EM, Granier JJ, Plantier KB, Pantoya ML (2004) Nickel aluminum superalloys created by the self-propagating high-temperature synthesis of nanoparticle reactants. J Mater Res 19(10):3028–3036

Lebrat JP, Varma A (1993) Self-propagating high-temperature synthesis of Ni3Al. Combust Sci Technol 88(3–4):211–222

Manukyan KV, Mason BA, Groven LJ, Lin YC, Cherukara M, Son SF, Strachan A, Mukasyan AS (2012) Tailored reactivity of Ni + Al nanocomposites: microstructural correlations. J Phys Chem C 116(39):21027–21038

Wang J, Duckham A, Spey SJ, Reiss ME, Weihs TP, Besnoin E, Knio OM (2004) Joining of stainless-steel specimens with nanostructured Al/Ni foils. J Appl Phys 95(1):248–256

Swiston AJ Jr, Hufnagel TC, Weihs TP (2003) Joining bulk metallic glass using reactive multilayer foils. Scr Mater 48(12):1575–1580

Mason BA, Sippel TR, Groven LJ, Gunduz IE, Son SF (2015) Combustion of mechanically activated Ni/Al reactive composites with microstructural refinement tailored using two-step milling. Intermetallics 66:88–95

Mason BA, Groven LJ, Son SF (2013) The role of microstructure refinement on the impact ignition and combustion behavior of mechanically activated Ni/Al reactive composites. J Appl Phys 114(11):113501

Gibbins JD, Stover AK, Krywopusk NM, Woll K, Weihs TP (2015) Properties of reactive Al: Ni compacts fabricated by radial forging of elemental and alloy powders. Combust Flame 162(12):4408–4416

Manukyan KV, Tan W, Deboer RJ, Stech EJ, Aprahamian A, Wiescher M, Rouvimov S, Overdeep KR, Shuck CE, Weihs TP, Mukasyan AS (2015) Irradiation-enhanced reactivity of multilayer Al/Ni nanomaterials. ACS Appl Mater Interfaces 7(21):11272–11279

Sraj I, Specht PE, Thadhani NN, Weihs TP, Knio OM (2014) Numerical simulation of shock initiation of Ni/Al multilayered composites. J Appl Phys 115(2):023515

Alman DE, Stoloff NS (1991) Powder fabrication of monolithic and composite NiAl. Int J Powder Metall Princet N J 27(1):29–41

Battezzati L, Pappalepore P, Durbiano F, Gallino I (1999) Solid state reactions in Al/Ni alternate foils induced by cold rolling and annealing. Acta Mater 47(6):1901–1914

Stover AK, Krywopusk NM, Gibbins JD, Weihs TP (2014) Mechanical fabrication of reactive metal laminate powders. J Mater Sci 49(17):5821–5830. doi:10.1007/s10853-014-8187-2

Adams DP (2014) Reactive multilayers fabricated by vapor deposition: a critical review. Thin Solid Films (Copyright (C) 2014 American Chemical Society (ACS). All Rights Reserved.), Ahead of Print

Duckham A, Spey SJ, Wang J, Reiss ME, Weihs TP, Besnoin E, Knio OM (2004) Reactive nanostructured foil used as a heat source for joining titanium. J Appl Phys 96(4):2336–2342

Noro J, Ramos AS, Vieira MT (2008) Intermetallic phase formation in nanometric Ni/Al multilayer thin films. Intermetallics 16(9):1061–1065

Andrzejak TA, Shafirovich E, Varma A (2007) Ignition mechanism of nickel-coated aluminum particles. Combust Flame 150(1–2):60–70

Rosenband V, Gany A (2005) Agglomeration and ignition of aluminum particles coated by nickel. In: Advancements in Energetic Materials and Chemical Propulsion, pp 141–149

Vummidi SL, Aly Y, Schoenitz M, Dreizin EL (2010) Characterization of fine nickel-coated aluminum powder as potential fuel additive. J Propuls Power 26(3):454–460

Hadjiafxenti A, Gunduz IE, Doumanidis CC, Rebholz C (2014) Spark ignitable ball milled powders of Al and Ni at NiAl composition. Vacuum 101:275–278

Hadjiafxenti A, Gunduz IE, Tsotsos C, Kyratsi T, Doumanidis CC, Rebholz C (2010) Synthesis of reactive Al/Ni structures by ball milling. Intermetallics 18(11):2219–2223

Simões S, Viana F, Ramos AS, Vieira MT, Vieira MF (2011) Anisothermal solid-state reactions of Ni/Al nanometric multilayers. Intermetallics 19(3):350–356

Stover AK, Krywopusk NM, Fritz GM, Barron SC, Gibbins JD, Weihs TP (2013) An analysis of the microstructure and properties of cold-rolled Ni: Al laminate foils. J Mater Sci 48(17):5917–5929. doi:10.1007/s10853-013-7387-5

Simes S, Viana F, Ramos AS, Vieira MT, Vieira MF (2010) TEM characterization of as-deposited and annealed Ni/Al multilayer thin film. Microsc Microanal 16(6):662–669

Fan G, Geng L, Feng Y, Cui X, Yan X (2015) Solid state reaction mechanism and microstructure evolution of Ni-Al powders during high energy ball milling revisited by TEM. Microsc Microanal 21(4):953–960

Whittenberger JD, Arzt E, Luton MJ (1990) Preliminary investigation of a NiAl composite prepared by cryomilling. J Mater Res 5(2):271–277

Santhanam PR, Dreizin EL (2012) Predicting conditions for scaled-up manufacturing of materials prepared by ball milling. Powder Technol 201:401–411

Witkin DB, Lavernia EJ (2006) Synthesis and mechanical behavior of nanostructured materials via cryomilling. Prog Mater Sci 51(1):1–60

Santhanam PR, Ermoline A, Dreizin EL (2013) Discrete element model for an attritor mill with impeller responding to interactions with milling balls. Chem Eng Sci 101:366–373

Shoshin YL, Trunov MA, Zhu X, Schoenitz M, Dreizin EL (2006) Ignition of aluminum-rich Al–Ti mechanical alloys in air. Combust Flame 144(4):688–697

Ward TS, Trunov MA, Schoenitz M, Dreizin EL (2006) Experimental methodology and heat transfer model for identification of ignition kinetics of powdered fuels. Int J Heat Mass Transf 49(25–26):4943–4954

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520(1–2):1–19

Michaelsen C, Barmak K, Weihs TP (1997) Investigating the thermodynamics and kinetics of thin film reactions by differential scanning calorimetry. J Phys D Appl Phys 30(23):3167–3186

Vyazovkin S, Wight CA (1999) Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta 340–341:53–68

Rzyman K, Moser Z, Watson RE, Weinert M (1998) Enthalpies of formation of AlNi: experiment versus theory. J Phase Equilibria 19(2):106–111

Nash P, Kleppa O (2001) Composition dependence of the enthalpies of formation of NiAl. J Alloy Compd 321(2):228–231

Michaelsen C, Lucadamo G, Barmak K (1996) The early stages of solid-state reactions in Ni/Al multilayer films. J Appl Phys 80(12):6689–6698

Blobaum KJ, Van Heerden D, Gavens AJ, Weihs TP (2003) Al/Ni formation reactions: characterization of the metastable Al9Ni2 phase and analysis of its formation. Acta Mater 51(13):3871–3884

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) Review: ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19

Nathani H, Wang J, Weihs TP (2007) Long-term stability of nanostructured systems with negative heats of mixing. J Appl Phys 101(10):104315

Gavens AJ, Van Heerden D, Mann AB, Reiss ME, Weihs TP (2000) Effect of intermixing on self-propagating exothermic reactions in Al/Ni nanolaminate foils. J Appl Phys 87(3):1255–1263

Barmak K, Michaelsen C, Lucadamo G (1997) Reactive phase formation in sputter-deposited Ni/Al multilayer thin films. J Mater Res 12(1):133–146

Čelko L, Klakurková L, Švejcar J (2010) Diffusion in Al-Ni and Al-NiCr interfaces at moderate temperatures. Defect Diffus Forum 297–301:771–777

Ustinov AI, Demchenkov SA (2017) Influence of metastable Al9Ni2 phase on the sequence of phase transformations initiated by heating of Al/Ni multilayer foils produced by EBPVD method. Intermetallics 84:82–91

Acknowledgements

This work was supported by the US Defense Threat Reduction Agency.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lagoviyer, O.S., Schoenitz, M. & Dreizin, E.L. Effect of milling temperature on structure and reactivity of Al–Ni composites. J Mater Sci 53, 1178–1190 (2018). https://doi.org/10.1007/s10853-017-1591-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1591-7