Abstract

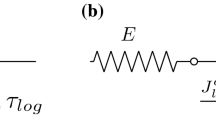

To explain the hygrothermal recovery (HTR) behavior of tension wood (TW) from the physical and chemical point of view in relation to the time, species and microfibril angle, a theoretical discussion using an analytical one-dimensional viscoelastic modeling was made. The chosen model includes an elastic element, a deformation mechanism and two viscoelastic elements called also as Kelvin–Voigt model. In this analysis, a top-down approach between the model and the experimental data was introduced to find the realistic parameters for the model. It enables us to fit the model to the HTR experimental data for three wood species: konara oak (Quercus serrata Murray), urihada maple (Acer rufinerve Siebold et Zucc.) and keyaki wood (Zelkova serrata Makino). The fitted experimental data show that the two compliances of the two viscoelastic elements are the most important parameters that explain the evolution of TW longitudinal strain during the thermal treatment.

Similar content being viewed by others

References

Archer RR (1986) Growth stresses and strains in trees. Springer series in wood science. Springer, Berlin

Onaka F (1949) Studies on compression and tension wood. Wood Res 1:1–88 (translation from Japanese)

Jourez B, Riboux A, Leclercq A (2001) Anatomical characteristics of tension wood and opposite wood in young inclined stems of poplar (Populus euramericana cv Ghoy). IAWA J 22:133–157

Fang CH, Clair B, Gril J, Liu SQ (2008) Growth stresses are highly controlled by the amount of G-layer in poplar tension wood. IAWA J 29:237–246

Gorshkova TA, Gurjanov OP, Mikshina PV, Ibragimova NN, Mokshina NE, Salnikov VV, Ageeva MV, Amenitskii SI, Chernova TE, Chemikosova SB (2010) Specific type of secondary cell wall formed by plant fibers. Russ J Plant Physiol 57:328–341

Pilate G, Chabbert B, Cathala B, Yoshinaga A, Lepl JC, Laurans F, Lapierre C, Ruel K (2004) Lignification and tension wood. C R Biol 327:889–901

Fujita M, Saiki H, Harada H (1974) Electron microscopy of microtubules and cellulose microfibrils in secondary wall formation of poplar tension wood fibers. Mokuzai Gakkaishi 20:147–156

Gril J, Thibaut B (1994) Tree mechanics and wood mechanics: relating hygrothermal recovery of green wood to the maturation process. Ann For Sci 51:329–336

Kubler H (1987) Growth stresses in trees and related wood properties. For Prod Abstr 10(3):61–119

Sujan KC, Yamamoto H, Matsuo M, Yoshida M, Naito K, Shirai T (2015) Continuum contraction of tension wood fiber induced by repetitive hygrothermal treatment. Wood Sci Technol 49(6):1157–1169

Gril J, Fournier M (1993) Contraintes d’élaboration du bois dans l’arbre: un modèle multicouche viscolastique. Actes du 11e congrès français de Mécanique (Lille-Villeneuve d’Ascq, France) 4:165–168

Terashima N (1990) A new mechanism for formation of a structurally ordered protolignin macromolecule in the cell wall of tree xylem. J Pulp Pap Sci 16(5):150–155

Alméras T, Gril J, Yamamoto H (2005) Modelling anisotropic maturation strains in wood in relation to fibre boundary conditions, microstructure and maturation kinetics. Holzforschung 59(3):347–353

Yamamoto H (1998) Generation mechanism of growth stresses in wood cell walls: roles of lignin deposition and cellulose microfibril during cell wall maturation. Wood Sci Technol 32(3):171–182

Clair B (2012) Evidence that release of internal stress contributes to drying strains of wood. Holzforschung 66(3):349–353

Tanaka M, Yamamoto H, Kojima M, Yoshida M, Miyuki M, Abubakar ML, Ichiro H, Takeshi A (2014) The interrelation between microfibril angle (MFA) and hygrothermal recovery (HTR) in compression wood and normal wood of Sugi and Agathis. Holzforschung 68(7):823–830

Ueda Matsuo M, Niimi G, Sujan KC, Yoshida M, Yamamoto H (2016) Hygrothermal recovery of compression wood in relation to elastic growth stress and its physicochemical characteristics. J Mater Sci 51:7956–7965. doi: 10.1007/s10853-016-0065-7

Yoshida M, Ohta H, Yamamoto H, Okuyama T (2002) Tensile growth stress and lignin distribution in the cell walls of yellow poplar, Liriodendron tulipifera Linn. Trees 16(7):457–464

Yamamoto H, Okuyama T, Yoshida M (1993) Method of determining the mean microfibril angle of wood over wide range by the improved Caves method. Mokuzai Gakkaishi 39:375–381

Gril J (1992) Maturation and viscoelasticity: rheology of wood in formation and hygrothermal recovery of growth strains. In: IUFRO All-division 5 conference (Nancy, France)

Colmars J (2011) Hygromécanique du matériau bois appliquée à la conservation du patrimoine culturel. Ph.D. Dissertation, Univ. Montpellier

Linard L (2011) Modélisation numérique tridimensionnelle du comportement viscoélastique d’un composite multicouche à base de bois. Ph.D. Dissertation, Univ. Montpellier

Randriambololona H (2003) Modélisation du comportement différé du bois en environnement variable. Ph.D. Dissertation, Univ. Limoges

Hirashima Y, Sugihara M, Sasaki Y, Ando K, Yamasaki M (2015) Strength properties of aged wood III: static and impact bending strength properties of aged keyaki and akamatsu woods. Mokuzai Gakkaishi 51(3):146–152

Guitard D, El Amri F (1987) Modèles prévisionnels de comportement élastique tridimensionnel pour les bois feuillus et les bois résineux. Annales des Sciences Forestières 44(3):335–358

Guitard D (1987) Mécanique du matériaux bois et composites. Cépaduès Editions, Toulouse

Sujan KC, Yamamoto H, Matsuo M, Yoshida M, Naito K, Suzuki Y, Yamashita N, Yamaji FM (2016) Is hygrothermal recovery of tension wood temperature-dependent? Wood Sci Technol 50(4):759–772

Barnett JR, Bonham VA (2004) Cellulose microfibril angle in the cell wall of wood fibres. Biol Rev 79(2):461–472

Acknowledgements

We would like to acknowledge the “JSPS International Research Fellows” who have support financially this work.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

First case: \(\epsilon = 0\)

During the two first steps of the modeling, the stress is null (\(\epsilon = 0\)). On a step time \({\Delta }t=t_i-t_{i-1}\), we can write that:

From this Eq. 18, it is possible to write \({\Delta }\sigma \):

In this case, \({\Delta }\epsilon =0\), so we obtain:

with \({\Delta }\epsilon ^V_k\) from Eq. 15. So the equation will become:

Using Eq. 20, we can write that \(\sigma (t_i)=\sigma (t_{i-1}) + {\Delta }\sigma \).

Second case: \(\sigma = 0\)

During the fourth step of the modeling \({\Delta }\sigma =0\), Eq. 19 becomes:

with \({\Delta }\epsilon ^V_k\) from Eq. 15.

Using equation 22, we can write that \(\epsilon (t_i)=\epsilon (t_{i-1}) + {\Delta }\epsilon \).

Rights and permissions

About this article

Cite this article

Capron, M., Bardet, S., Sujan, K.C. et al. Viscoelastic modeling of wood in the process of formation to clarify the hygrothermal recovery behavior of tension wood. J Mater Sci 53, 1487–1496 (2018). https://doi.org/10.1007/s10853-017-1573-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1573-9