Abstract

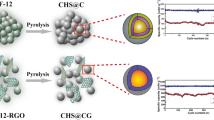

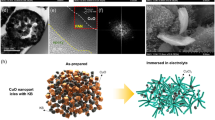

Developing an efficient cathode catalyst material is the most intrinsic requisite to acquire rechargeable Li-O2 batteries with long cycling life and high rate capacity. Here, yolk-shell structured Cu2O spheres were facilely synthesized using a wet-chemistry method with the PEG-500 as the surfactant. As catalyst cathode materials, yolk-shell structured Cu2O spheres show a low discharge/charge potential platform of 1.28 V with current density of 500 mA g−1. Compared with cubic-like Cu2O nanoparticles, yolk-shell structured Cu2O spheres have indicated a long and stable cycling life of 84 cycles with a high current density of 500 mA g−1, and which may be benefited to the porous structure and the large specific surface area. The introduction of Cu2O provides an effective solution to the problem of low round-trip efficiency in the Li-O2 battery.

Similar content being viewed by others

References

Bruce PG, Freunberger SA, Hardwick LJ, Tarascon J-M (2012) Li-O2 and Li–S batteries with high energy storage. Nat Mater 11:19–29

Lu J, Li L, Park J-B, Sun Y-K, Wu F, Amine K (2014) Aprotic and aqueous Li–O2 batteries. Chem Rev 114:5611–5640

Balaish M, Kraytsberg A, Ein-Eli Y (2014) A critical review on lithium-air battery electrolytes. Phys Chem Chem Phys 16:2801–2822

Oh D, Qi J, Lu Y-C, Zhang Y, Shao-Horn Y, Belcher AM (2013) Biologically enhanced cathode design for improved capacity and cycle life for lithium-oxygen batteries. Nat Commun 4:2756

Lim H, Lee B, Bae Y, Park H, Ko Y, Kim H, Kim J, Kang K (2017) Reaction chemistry in rechargeable Li-O2 batteries. Chem Soc Rev 46:2873–2888

Lu J, Jung Lee Y, Luo X, Chun Lau K, Asadi M, Wang H-H, Brombosz S, Wen J, Zhai D, Chen Z, Miller DJ, Sub Jeong Y, Park J-B, Zak Fang Z, Kumar B, Salehi- Khojin A, Sun Y-K, Curtiss LA, Amine K (2016) A lithium–oxygen battery based on lithium superoxide. Nature 529:377–382

Hu X, Li Z, Chen J (2017) Flexible Li-CO2 batteries with liquid-free electrolyte. Angew Chem Int Ed 56:5785–5789

Luo WB, Gao XW, Chou SL, Wang JZ, Liu HK (2015) Porous Ag Pd–Pd composite nanotubes as highly efficient electrocatalysts for lithium–oxygen batteries. Adv Mater 27:6862–6869

Jian Z, Liu P, Li F, He P, Guo X, Chen M, Zhou H (2014) Core–shell-structured CNT@RuO2 composite as a high-performance cathode catalyst for rechargeable Li–O2 Batteries. Angew Chem Int Ed 53:442–446

Ma L, Luo X, Kropf AJ, Wen J, Wang X, Lee S, Myers DJ, Miller D, Wu T, Lu J, Amine K (2016) Insight into the catalytic mechanism of bimetallic platinum–copper core–shell nanostructures for nonaqueous oxygen evolution reactions. Nano Lett 16:781–785

Peng Z, Freunberger SA, Chen Y, Bruce PG (2012) A reversible and higher-rate Li-O2 battery. Science 337:563–566

Liu X, Dai L (2016) Carbon-based metal-free catalysts. Nat Rev Mater 1:16064

Cheng F, Chen J (2012) Metal–air batteries: from oxygen reduction electrochemistry to cathode catalysts. Chem Soc Rev 41:2172–2192

Wang C, Zhao Y, Liu J, Gong P, Li X, Zhao Y, Yue GH, Zhou Z (2016) Highly hierarchical porous structures constructed from NiO nanosheets act as Li ion and O2 pathways in long cycle life, rechargeable Li–O2 batteries. Chem Commun 52:11772–11774

McCloskey BD, Speidel A, Scheffler R, Miller DC, Viswanathan V, Hummelshøj JS, Nørskov JK, Luntz AC (2012) Twin problems of interfacial carbonate formation in nonaqueous Li–O2 batteries. J Phys Chem Lett 3:997–1001

Fu LJ, Gao J, Zhang T, Cao Q, Yang LC, Wu YP (2007) R. Holze b, H.Q. Wu, Preparation of Cu2O particles with different morphologies and their application in lithium ion batteries. J Power Sourc 174:1197–1200

Xiang JY, Wang XL, Xia XH, Zhang L, Zhou Y, Shi SJ, Tu JP (2010) Enhanced high rate properties of ordered porous Cu2O film as anode for lithium ion batteries. Electrochim Acta 55:4921–4925

Park JC, Kim J, Kwon H, Song H (2009) Gram-scale synthesis of Cu2O nanocubes and subsequent oxidation to Cu2O hollow nanostructures for lithium-ion battery anode materials. Adv Mater 21:803–807

Yue GH, Zhang Y, Zhang XQ, Wang CG, Zhao YC, Peng DL (2015) Synthesis of Cu2O mesocrystal and its application in photocatalysis. Appl Phys A 118:763–767

Xu H, Wang W, Zhu W (2006) A facile strategy to porous materials: coordination-assisted heterogeneous dissolution route to the spherical Cu2O single crystallites with hierarchical pores. Micropor Mesopor Mater 95:321–328

Kuo CH, Chu YT, Song YF, Huang MH (2011) Cu2O Nanocrystal-templated growth of Cu2S nanocages with encapsulated Au nanoparticles and In-Situ transmission X-ray microscopy study. Adv Funct Mater 21:792–797

Biesingera MC, Laua LWM, Gersonb AR, Smart RSC (2010) Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Sc, Ti, V, Cu and Zn. Appl Surf Sci 257:887–898

Liu L, Wang J, Hou Y, Chen J, Liu HK, Wang J, Wu Y (2015) Self-assembled 3D foam-like NiCo2O4 as efficient catalyst for lithium oxygen batteries. Small 12:602–611

Tong S, Zheng M, Lu Y, Lin Z, Li J, Zhang X, Zhou H (2015) Mesoporous NiO with a single-crystalline structure utilized as a noble metal-free catalyst for non-aqueous Li–O 2 batteries. J Mater Chem A 3:16177–16182

Liu Q, Jiang Y, Xu J, Xu D, Chang Z, Yin Y, Zhang X (2015) Hierarchical Co3O4 porous nanowires as an efficient bifunctional cathode catalyst for long life Li-O2 batteries. Nano Res 8:576–583

Cui ZH, Fan WG, Guo XX (2013) Lithium–oxygen cells with ionic-liquid-based electrolytes and vertically aligned carbon nanotube cathodes. J Power Sourc 235:251–255

Park JE, Lee GH, Shim HW, Kim DW, Kang Y, Kim DW (2015) Examination of graphene nanoplatelets as cathode materials for lithium–oxygen batteries by differential electrochemical mass spectrometry. Electrochem Commun 57:39–42

Zhao Y, Li X, Liu J, Wang C, Zhao Y, Yue GH (2016) MOF-derived ZnO/Ni3ZnC0.7/C hybrids yolk–shell microspheres with excellent electrochemical performances for lithium ion batteries. ACS Appl Mater Interfaces 8:6472–6480

Acknowledgements

This work was financially supported by K.C. Wong Magna Fund in Ningbo University, Ningbo natural science fund (Project No. 201701HJ-B01019) and college students of science and technology innovation projects in Zhejiang province (Project No. 2017R405008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qiu, Xy., Liu, Sj. & Xu, Dz. Yolk-shell structured Cu2O as a high-performance cathode catalyst for the rechargeable Li-O2 batteries. J Mater Sci 53, 1318–1325 (2018). https://doi.org/10.1007/s10853-017-1555-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1555-y