Abstract

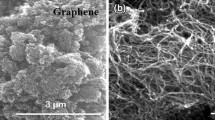

Aluminium (Al) matrix composites reinforced with either 0.5 wt% graphene oxide (GO) or 0.5 wt% carbon nanotubes (CNTs) were hot extruded from ball-milled powders. A control, pure Al bar was also fabricated. Microstructural examination, including Raman mapping, showed a relatively poor dispersion of the carbon nanomaterials within the Al matrix, particularly in the case of the CNTs. Consequently, while the mean grain size of the Al matrix remains invariant with the addition of CNTs, the Al/GO composite exhibits reduced grain size compared to pure Al due to the pinning effect of the reinforcement. Moreover, the addition of both carbonaceous materials resulted in a slight decrease in the typical extrusion duplex <111> + <100> fibre texture intensity. This weakening of the texture was more pronounced in the Al/GO composite, partly due to the pinning effect of the reinforcement. In agreement with their relative mean grain sizes, the Al/GO composite shows an improved mechanical performance over pure Al. Despite the similarity of the mean grain sizes, the Al/CNT composite displays comparable hardness and a decreased compressive yield stress relative to the pure Al. In the absence of chemical reactions at the interfaces, this was attributed to a low efficiency of load transfer from the Al matrix to the reinforcement resulting from the large extent of agglomeration of CNTs.

Similar content being viewed by others

References

Starke EA Jr, Staley JT (1996) Applications of modern aluminium alloys to aircraft. Prog Aerosp Sci 32:131–172

Williams JC, Starke EA Jr (2003) Progress in structural materials for aerospace systems. Acta Mater 51:5775–5799

Miller WS, Zhuang L, Bottema J, Wittebrood AJ, De Smet P, Haszler A, Vieregge A (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280:37–49

Li JL, Xiong YC, Wang XD, Yan SJ, Yang C, He WW, Chen JZ, Wang SQ (2015) Microstructure and tensile properties of bulk nanostructured aluminium/graphene composites prepared via cryomilling. Mater Sci Eng A 626:400–405

Yan SJ, Dai SL, Zhang XY, Yang C, Hong QH, Chen JZ, Lin ZM (2014) Investigating aluminium alloy reinforced by graphene nanoflakes. Mater Sci Eng A 612:440–444

Ibrahim IA, Mohamed FA, Lavernia EJ (1991) Particulate reinforced metal matrix composites: a review. J Mater Sci 26:1137–1156. doi:10.1007/BF00544448

Miracle DB (2005) Metal matrix composites—from science to technological significance. Compos Sci Technol 65:2526–2540

Mortensen A, Llorca J (2010) Metal matrix composites. Annu Rev Mater Res 40:243–270

Ritchie RO (2011) The conflicts between strength and toughness. Nat Mater 10:817–822

Mavhungu ST, Akinlabi ET, Onitiri MA, Varachia FM (2016) Aluminium matrix composites for industrial use: advances and trends. Procedia Manuf 7:178–182

Xiong D-B, Cao M, Guo Q, Tan Z, Fan G, Li Z, Zhang D (2015) Graphene-and-copper artificial nacre fabricated by a preform impregnation process: bioinspired strategy for strengthening–toughening of metal matrix composite. ACS Nano 9:6934–6943

Tjong SC (2013) Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater Sci Eng R 74:281–350

Li Z, Guo Q, Li ZQ, Fan GL, Xiong DB, Su YS, Zhang J, Zhang D (2015) Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure. Nano Lett 15:8077–8083

Young RJ, Kinloch IA, Gong L, Novoselov KS (2012) The mechanics of graphene nanocomposites: a review. Compos Sci Technol 72:1459–1476

Bakshi SR, Lahiri D, Agarwal A (2010) Carbon nanotube reinforced metal matrix composites: a review. Int Mater Rev 55:41–64

Zhou W, Yamaguchi T, Kikuchi K, Nomura N, Kawasaki A (2017) Effectively enhanced load transfer by interfacial reactions in multi-walled carbon nanotube reinforced Al matrix composites. Acta Mater 125:369–376

El-Ghazaly A, Anis G, Salem HG (2017) Effect of graphene addition on the mechanical and tribological behavior of nanostructured AA2124 self-lubricating metal matrix composite. Compos Part A Appl Sci Manuf 95:325–336

Corrochano J, Hidalgo P, Lieblich M, Ibáñez J (2010) Matrix grain characterisation of powder metallurgy aluminium matrix composites reinforced with MoSi2 intermetallic particles. Mater Charact 61:1294–1298

Corrochano J, Walker JC, Lieblich M, Ibáñez J, Rainforth WM (2011) Dry sliding wear behavior of powder metallurgy Al–Mg–Si alloy–MoSi2 composites and the relationships with the microstructure. Wear 270:658–665

Dillamore IL, Roberts WT (1965) Preferred orientation in wrought and annealed metals. Metall Rev 10:271–380

Jiang X, Galano M, Audebert F (2014) Extrusion textures in Al, 6061 alloy and 6061/SiCp nanocomposites. Mater Charact 88:111–118

Humphreys FJ, Kalu PN (1990) The plasticity of particle-containing polycrystals. Acta Metall Mater 38:917–930

Hidalgo-Manrique P, Yi SB, Bohlen J, Letzig D, Pérez-Prado MT (2013) Effect of Nd additions on extrusion texture development and on slip activity in a Mg-Mn alloy. Metall Mater Trans A 44:4819–4829

Li Z, Young RJ, Kinloch IA (2013) Interfacial stress transfer in graphene oxide nanocomposites. ACS Appl Mater Interfaces 5:456–463

Poirier D, Gauvin R, Drew RAL (2009) Structural characterization of a mechanically milled nanotube/aluminium mixture. Compos Part A Appl Sci Manuf 40:1482–1489

Li ZL, Young RJ, Kinloch IA, Wilson NR, Marsden AJ, Raju APA (2015) Quantitative determination of the spatial orientation of graphene by polarized Raman spectroscopy. Carbon 88:215–224

Bartolucci SF, Paras J, Rafiee MA, Rafiee J, Lee S, Kapoor D, Koratkar N (2011) Graphene–aluminium nanocomposites. Mater Sci Eng A 528:7933–7937

Kuzumaki T, Miyazawa K, Ichinose H, Ito K (1998) Processing of carbon nanotube reinforced aluminum composite. J Mater Res 13:2445–2449

Salas W, Alba-Baena NG, Murr LE (2007) Explosive shock-wave consolidation of aluminum powder/carbon nanotube aggregate mixtures: optical and electron microscopy. Metall Mater Trans A 38:2928–2935

Acknowledgements

Much appreciated is the strong support received from Beijing Institute of Aeronautical Materials (BIAM). The research was performed at the BIAM-Manchester Technical Centre for Graphene Aerospace Materials at the University of Manchester.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflicts of interest related to this work.

Rights and permissions

About this article

Cite this article

Hidalgo-Manrique, P., Yan, S., Lin, F. et al. Microstructure and mechanical behaviour of aluminium matrix composites reinforced with graphene oxide and carbon nanotubes. J Mater Sci 52, 13466–13477 (2017). https://doi.org/10.1007/s10853-017-1450-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1450-6