Abstract

The development of novel manufacturing techniques of nano-/micromaterials, especially metallodielectric materials, has enabled dynamic development of such fields as nanoplasmonics. However, the fabrication methods are still mostly based on time-consuming and costly top-down techniques limited to two-dimensional materials. Recently, directional solidification has been proposed and utilized for manufacturing of volumetric nanoplasmonic materials using the example of a Bi2O3–Ag eutectic-based nanocomposite. Here, we explain the evolution of silver in this composite, from the crystal growth through the post-growth annealing processes. Investigation with tunneling electron microscopy shows that silver initially enters the composite as an amorphous AgBiO3 phase, which is formed as a wetting layer between the grains of Bi2O3 primary phase. The post-growth annealing leads to decomposition of the amorphous phase into Bi2O3 nanocrystals and intergranular Ag nanoparticles, providing the tunable localized surface plasmon resonance at yellow light wavelengths.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plasmonics [1, 2] is currently one of the rapidly developing fields due to its role in enhancing optical properties, which makes it useful for application in solar cell efficiency enhancement [3, 4], cancer treatment [5], improved hard disks [6], lasers [7] and home-used diagnostics [8]. To achieve plasmonic effects on local field enhancement, localized surface plasmon resonance (LSPR) or surface plasmon propagation, an interface between two media—plasmonic (metallic-like) and dielectric—is needed [9]. Due to the collective oscillations of free charges, which are responsible for negative real permittivity, metals like silver and gold are currently the most used materials in plasmonics [10]. However, though other plasmonic materials have been considered [11, 12], it is still silver in the visible wavelengths, which is most widely used due to its lowest optical losses [13] and highest electrical conductivity at room temperature [14].

Recently, eutectic solidification [15, 16] has been proposed as one of the most promising bottom-up methods for manufacturing of metamaterials [17,18,19,20], plasmonic materials [21, 22] and photonic crystals [23, 24]. Eutectic solidification enables crystallization of a two-phase solid, often with an interesting self-organized micro-/nanostructure (typical are rod-like and lamellar structures) from a miscible liquid phase at a certain temperature [25]. Eutectic composites have been investigated for various applications such as solar energy conversion [26,27,28], power generation gas turbines [29], scintillators [30, 31] or second-harmonic generators [32]. The plasmonic effect was presented in a eutectic composite for the first time with a Bi2O3–Ag composite [21, 22]. After annealing the Bi2O3–Ag eutectic material, metal nanoparticles (silver and bismuth) are formed, which are responsible for the occurrence of plasmonic resonance in the visible wavelength range, at ~595 nm. Using different annealing conditions such as the atmosphere, time and temperature, it is possible to control the peak frequency of the LSPR [22]. However, the development of metallic silver in this material is not yet well understood. Here, we demonstrate the evolution of silver in a Bi2O3–Ag eutectic starting from the crystal growth, and formation of the microstructure, through the influence of the post-growth annealing of the samples on its micro-/nanostructure and thus the optical properties. The analysis is based on high-resolution transmission electron microscopy (HRTEM) and selected area diffraction (SAD).

Materials and methods

The Bi2O3–Ag material was obtained by the micro-pulling down method [33, 34] in a nitrogen atmosphere from pure powders of bismuth oxide (Alfa Aesar, 99.99% purity) and silver (Alfa Aesar, 99.95% purity). Detailed growth and preparation methods have been described elsewhere [21]. After growth, the samples were annealed in vacuum at 600 °C for 60 min [22]. The obtained Bi2O3–Ag composites were characterized by the following methods: high-resolution transmission electron microscopy (HRTEM) connected with selected area electron diffraction and with scanning transmission electron microscopy (STEM) with energy-dispersive X-ray spectroscopy (EDX). Samples for transmission electron microscope analysis were prepared by a focused ion beam (FIB) lift-out technique using a 30-keV Ga+ ion beam in an AURIGA CrossBeam Workstation (Carl Zeiss) equipped with a Canion FIB column (Orsay Physics). TEM investigations were conducted with the use of a Tecnai F20ST (FEI) TEM-STEM microscope with field emission gun and electron beam energy of 200 keV and coupled to a high-angle annular detector (HAADF) and a EDAX X-ray energy-dispersive spectrometer (EDX). The software “TE Imaging & Analysis” (EI) was used to provide standardless semiquantitative analyses of the EDX spectra. These analyses take into account the thickness and the chemical elements of the thin foil (ZAF corrections) and use preregistered K factors. Differential scanning calorimetry/thermogravimetry (DSC/TG) measurements were taken on an STA 449 (NETZSCH) with a platinum furnace under argon flow with different amounts of purge oxygen. Stoichiometric portions of powders were measured out and mixed manually with minor addition of isopropyl alcohol until a homogeneous color was achieved. The mixture was subsequently dried at 80 °C to remove the alcohol. The signals were measured with a Pt–Rh thermocouple using platinum crucibles in a temperature range from room temperature to 1173 K with a heating/cooling rate of 10 K min−1. Bi2O3–Ag powder mixtures were heated to 1173 K and cooled to 923 K. The process was repeated three times in each atmosphere to ensure homogeneity of the melt. The solidus temperatures were extracted from the heating curves as onset values, whereas liquidus temperatures were extracted from the cooling curves as the end temperatures. The influence of oxygen content on the phase diagram was investigated using powder samples of mixed bismuth oxide (99.9% purity) with silver (99.95% purity) in the range of 0–10 mol% in steps of 1 mol%.

Results and discussion

From the Ag–½(Bi2O3) phase diagram [35] in the mentioned system, several transformations at an oxygen partial pressure of 1.01 × 105 Pa are observed (1) allotropic of Bi2O3, α-Bi2O3 → δ-Bi2O3), (2) monotectic (Ag) + Liq2 ↔ Liq1 at 939 °C and eutectic reaction (Ag) + α-Bi2O3 ↔ Liq2 at 687 °C with a composition of 18.54 mol% Ag and 81.46 mol% 1/2Bi2O3 (~8.6 vol% Ag). With the decrease in oxygen content in the atmosphere, the composition of the eutectic point shifts toward lower content of silver (12.3 mol% Ag for pO2 = 2.1 × 104 Pa, ~5.5 vol% Ag). In our growth experiments, the successful composition that led to good-quality Bi2O3–Ag rods was 15.4 mol% Ag and 84.5 mol% 1/2Bi2O3 (~7.8 vol% Ag). This composition is between the eutectic points determined by Assal et al. [35] for different oxygen partial pressures, as shown in Fig. 1. We have confirmed part of the phase diagrams investigated by Assal et al. with DSC/TG measurements for different partial pressures of oxygen: pO2 = 0.32 × 104, 0.77 × 104, 1.43 × 104 and 2 × 104 Pa. It can be noticed that the liquidus line is in a very good agreement; however, the solidus line yielded a slightly lower temperature.

The as-grown Bi2O3–Ag composite is characterized by a three-dimensional micro-/nanostructure of silver-containing phase in a Bi2O3 matrix. Silver is located in a second phase wetting the Bi2O3 grain boundaries and at triple points where it adopts a triangular shape. Between two Bi2O3 grains, silver is in the form of plates with lengths of several tens of microns and thicknesses of a few nanometers.

To investigate the phase in which silver is placed in the Bi2O3–Ag composite during growth and to understand the processes which lead to the formation of silver nanoparticles after the annealing of the material, high-resolution transmission electron microscopy has been performed on the as-grown and annealed-in-vacuum samples. Both the selected area electron diffraction and the energy-dispersive X-ray spectroscopy confirmed that the as-grown material consists of two phases. In the region analyzed, the dominant phase is γ-Bi2O3 (bcc, a = 1.027 nm), which was detected in the larger grains. These grains enclosed smaller grains, which were probably the α-Bi2O3 phase. However, the second phase previously not recognized by other techniques is an amorphous (halo in the SAD pattern) phase containing Bi, Ag and O, with an atomic ratio Bi/Ag ≈ 1, as shown in Fig. 2. The shape of this second phase, forming triangles at Bi2O3 triple points and wetting the Bi2O3 grain boundaries, is consistent with the solidification of a liquid after the crystallization of the major primary phase, in this case Bi2O3. The radius of the halo in Fig. 2e provides the distance of the first neighbors in the amorphous phase, which is 0.32 nm (superimposed with the d310 = 0.325 nm of γ-Bi2O3). This distance does not match with the strongest reflections of silver or silver oxides but with the strongest reflections of γ-Bi2O3 as well as with those of an ilmenite-type, AgBiO3 phase [36]. The amorphous phase might enclose clusters of atoms prefiguring an ilmenite crystal. Ilmenite-type oxides have two kinds of combinations of metal cations: A2+M4+O3 and A+M5+O3 [37], where AgBiO3 corresponds to the second one.

Structural analysis of the as-grown Bi2O3–Ag eutectic material. a Bright-field image of the entire FIB cut of the sample with selected phases. b, c STEM-HAADF images of chains of Bi2O3 nanocrystals within the γ-Bi2O3 matrix, potentially also γ-Bi2O3. The γ-Bi2O3 larger grain encloses chains of smaller α-Bi2O3 grains. d STEM-HAADF image and e SAD pattern across Bi2O3- and Ag-based phase. Spots corresponding to the γ-Bi2O3 are in [001] zone axis. The halo is formed by the second phase and is typical of an amorphous phase. f Chain of probable α-Bi2O3 grains within bigger grains of γ-Bi2O3. EDX spectrum of g the AgBiO3 phase, h γ-Bi2O3 matrix and i Bi2O3 larger grains

Due to a strong dependence of the eutectic point on the content of oxygen in the atmosphere, it is not clear whether the composition of the Bi2O3–Ag composite we have grown is shifted to a higher abundance of Bi2O3 or Ag, as shown in Fig. 1. From the phase diagram of Bi2O3–Ag [35], if the composition is shifted from the eutectic point to a higher abundance of Bi2O3, it is the Bi2O3 phase that should crystallize first in contact with a liquid phase. While, if the composition is shifted toward a higher abundance of Ag, the Ag phase should crystallize first, and then, the eutectic will be made of Bi2O3 and Ag. The geometry of the Ag–Bi–O phase placed in between the grains of Bi2O3 is typical of a liquid phase that solidified after the main grains, though potentially it could be a Ag-containing phase in which the grains were squeezed by growing Bi2O3 grains. The AgBiO3 phase is probably formed in the following reactions [38]: 4AgO + Bi2O3 → 2AgBiO3 + Ag2O, and Ag2O + Bi2O3 → 2AgBiO2.

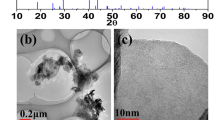

The amorphous Ag–Bi–O phase is not stable when irradiated by the electron beam and partially decomposes into ca. 50-nm-diameter γ-Bi2O3 nanocrystallites and metallic silver particles a few nanometers in size. Nanocrystals of bismuth oxide up to 50 nm in size are clearly seen in the dark-field image (Fig. 3a) and as bright spots at the SAD image (Fig. 3b). The first internal ring is from the amorphous Ag–Bi–O phase. A second finer halo at 0.23 nm is clearly observed, which may correspond to metallic nanosilver (strongest reflection 111 Ag fcc) exsoluted from the Ag–Bi–O phase, with sizes of a few nm, as shown in Fig. 3b.

Decomposition of the amorphous AgBiO3 phase under electron beam irradiation into nanocrystalline γ-Bi2O3 precipitates and metallic silver to a γ-Bi2O3 seen as bright grains in the dark-field image and b as spots in the indexed SAD. SAD showing the formation of Ag–Bi–O amorphous phase (first smaller ring at 0.32 nm) and nanocrystals of silver (second finer ring at 0.23 nm)

Concerning the optical properties of the Bi2O3–Ag composite, it has been previously confirmed that only the annealed samples demonstrate LSPR, due to the formation of Ag nanoparticles after the post-growth annealing [21]. The best of the investigated annealing conditions, which led to the most intensive LSPR peak, was annealing at 600 °C for 60 min in vacuum [22]. That is why such samples were investigated here further, as shown in Fig. 4. In the vacuum-annealed samples in comparison with the as-grown (un-annealed) samples, it can be seen that the large Bi2O3 grains did not change, while the amorphous phase transformed during the annealing into γ-Bi2O3 grains several hundreds of nm in size, as shown in Fig. 4a–c, and intergranular precipitates of Ag a few nm in size (Fig. 4d, red circle), as confirmed by EDX.

Both the annealing and irradiation with the electron beam during the TEM experiments resulted in phase and structural change of the material, which can be the result of a few processes. Thermal stability studies of AgBiO3 [39] performed in argon show weight loss from AgBiO3, which corresponds to two transitions such as:

As a result of the final decomposition of AgBiO3, a mixture of metallic silver and bismuth can be obtained. The formation of both Ag and Bi nanoparticles was already previously observed by us in this material [22]. This suggests that it is the decomposition of AgBiO3 into Ag and Bi nanoparticles in between the big Bi2O3 grains, which probably causes the formation of the smaller (ca. few hundred nanometers in size) Bi2O3 grains. The few-hundred-nm-in-size Bi2O3 grains have grown from the nano-Bi2O3 grains seen in Fig. 3a, with decomposition of the amorphous phase. In Fig. 5, we illustrate the proposed mechanism of silver evolution in the Bi2O3–Ag system.

Silver evolution mechanism in Bi2O3–Ag system, starting from the crystal growth through the post-growth annealing processes. Blue arrows represent processes, red rectangles—the resulting micro-/nanostructure. SEM pictures of the microstructures a before and c after annealing. STEM-HAADF image b across Bi2O3- and Ag-based phase and d intergranular precipitates of Ag

Conclusions

In summary, an explanation of the evolution of silver in a Bi2O3–Ag eutectic composite from the crystal growth through the post-growth annealing processes has been presented. In the as-grown samples, silver is inserted in an amorphous phase enclosing AgBiO3 clusters, which is formed as intergranular films and triple points wetting the grains of Bi2O3 primary phase. After the post-growth annealing, the AgBiO3 phase decomposes into Bi2O3 nanocrystals and intergranular Ag. These studies give us an explanation for the origin of silver nanoparticles in the Bi2O3–Ag eutectic-based material after the annealing procedure and thus the localized surface plasmon resonance at yellow light wavelengths.

References

Maradudin AA, Sambles JR, Barnes WL (2014) Modern plasmonics. Elsevier, Amsterdam, pp 1–36

Yao K, Liu Y (2014) Plasmonic metamaterials. Nanotechnol Rev 3(2):177–210

Atwater HA, Polman A (2010) Plasmonics for improved photovoltaic devices. Nat Mater 9:205–213

Polman A (2008) Plasmonics applied. Science 322:868–869

Lal S, Clare SE, Halas NJ (2008) Nanoshell-enabled photothermal cancer therapy: impending clinical impact. Acc Chem Res 41:1842–1851

Stipe BC et al (2010) Magnetic recording at 1.5 pb m−2 using an integrated plasmonic antenna. Nat Photon 4:484–488

Stockman M (2008) Spasers explained. Nat Photon 2:327–329

Stockman M (2011) Nanoplasmonics: the physics behind the applications. Phys Today 64:39–44

Maier SA (2007) Plasmonics: fundamentals and applications. Springer, Berlin, pp 65–88

West PR et al (2010) Searching for better plasmonic materials. Laser Photon Rev 4:795–808

Naik GV, Shalaev VM, Boltasseva A (2013) Alternative plasmonic materials: beyond gold and silver. Adv Mater 25:3264–3294

Boltasseva A, Atwater H (2011) Low-loss plasmonic metamaterials. Science 331(6015):290–291

Palik ED (1991) Handbook of optical constants of solids. Elsevier Science, Amsterdam, vol 1, 350–356

Serway RA (1998) Principles of physics, 2nd edn. Saunders College Pub, Fort Worth, Texas: London, p 602

Akamatsu S, Plapp M (2016) Eutectic and peritectic solidification patterns. Curr Opin Solid State Mater Sci 20(1):46–54

Rátkai L, Szállás A, Pusztai T, Mohri T, Gránásy L (2015) Ternary eutectic dendrites: pattern formation and scaling properties. J Chem Phys 142:154501–154513

Pawlak DA, Kolodziejak K, Turczynski S, Kisielewski J, Rożniatowski K, Diduszko R, Kaczkan M, Malinowski M (2006) Self-organized, rod-like, micron-scale microstructure of Tb3Sc2Al3O12–TbScO3: Pr eutectic. Chem Mater 18(9):2450–2457

Pawlak DA, Turczynski S, Gajc M, Kolodziejak K, Diduszko R, Rozniatowski K, Smalc J, Vendik I (2010) How far are we from making metamaterials by self-organization? The microstructure of highly anisotropic particles with an SRR-like geometry. Adv Funct Mater 20(7):1116–1124

Massaouti M, Basharin AA, Kafesaki M, Acosta MF, Merino RI, Orera VM, Economou EN, Soukoulis CM, Tzortzakis S (2013) Eutectic epsilon-near-zero metamaterial terahertz waveguides. Opt Lett 38:1140–1142

Myroshnychenko V, Stefanski A, Manjavacas A, Kafesaki M, Merino RI, DA OreraVM P, Garcia de Abajo FJ (2012) Interacting plasmon and phonon polaritons in aligned nano- and micro-wires. Opt Express 20:10879–10887

Sadecka K, Gajc M, Orlinski K, Surma HB, Jóźwik-Biała I, Klos A, Sobczak K, Dłużewski P, Toudert J, Pawlak DA (2015) When eutectics meet plasmonics: nanoplasmonic volumetric, self-organized silver-based eutectic. Adv Opt Mater 3(3):381–389

Sadecka K, Toudert J, Surma HB, Pawlak DA (2015) Temperature and atmosphere tunability of the nanoplasmonic resonance of a volumetric eutectic-based Bi2O3–Ag metamaterial. Opt Exp 23(15):19098–19111

Pawlak DA, Lerondel G, Dmytruk I, Kagamitani Y, Durbin S, Fukuda T (2002) Second order self-organized pattern of terbium–scandium–aluminum garnet terbium–scandium perovskite eutectic. J Appl Phys 91(12):9731–9736

Kim J, Aagesen LK, Choi JH, Choi J, Kim HS, Liu J, Cho C, Kang JG, Ramazani A, Thornton K, Braun PV (2015) Template-directed directionally solidified three-dimensionally mesostructured AgCl–KCl eutectic photonic crystals. Adv Mater 27:4551–4559

LLorca J, Orera VM (2006) Directionally solidified eutectic ceramic oxides. Prog Mater Sci 51(6):711–809

Oliete PB, Mesa MC, Merino RI, Orera VM (2016) Directionally solidified Al2O3–Yb3Al5O12 eutectics for selective emitters. Sol Energy Mater Sol Cells 144:405–410

Wysmulek K, Sar J, Osewski P, Orlinski K, Kolodziejak K, Trenczek-Zajac A, Radecka M, Pawlak DA (in review) A SrTiO3–TiO2 eutectic composite as a stable photoanode material for photoelectrochemical hydrogen production. Appl. Catalysis B

Kolodziejak K, Sar J, Wysmulek K, Osewski P, Orlinski K, Warczak M, Sadkowski A, Radecka M, Pawlak DA (submitted) When eutectic composites meet photoelectrochemistry—highly stable and efficient UV–visible hybrid photoanodes. Nanoscale

Waku Y, Nakagawa N, Wakamoto T, Ohtsubo H, Shimizu K, Kohtoku Y (1998) High-temperature strength and thermal stability of a unidirectionally solidified Al2O3/YAG eutectic composite. J Mater Sci 5:1217–1225. doi:10.1023/A:1004377626345

Yasui N, Ohashi Y, Kobayashi T, Den T (2012) Development of phase-separated scintillators with light-guiding properties. Adv Mater 24:5464–5469

Hishinuma K, Kamada K, Kurosawa S, Yamaji A, Pejchal J, Yokota Y, Ohashi Y, Yoshikawa A (2015) LiF/CaF2/LiBaF3 ternary fluoride eutectic scintillator. Jpn J Appl Phys 54(4S):04DH04

Simon F, Clevers S, Gbabode G, Couvrat N, Agasse-Peulon V, Sanselme M, Dupray V, Coquerel G (2015) Enhanced second harmonic generation from an organic self-assembled eutectic binary mixture: a case study with 3-nitrobenzoic and 3,5-dinitrobenzoic acids. Cryst Growth Des 15(2):946–960

Fukuda T, Rudolph P, Uda S (2004) Fiber crystal growth from melt. Springer-Verlag Berlin Heidelberg, New York, pp 1–46

Fukuda T, Chani VI (2007) Shaped crystals growth by micro-pulling-down technique. Springer-Verlag Berlin Heidelberg, New York, pp 3–36

Assal J et al (1999) Experimental phase diagram study and thermodynamic optimization of the Ag–Bi–O system. J Am Ceram Soc 82(3):711–715

Kumada N (2000) Neutron powder diffraction refinement of ilmenite-type bismuth oxides: ABiO3 (A = Na, Ag). Mater Res Bull 35(14):2397–2402

Wells AF (1975) Structural inorganic chemistry, 4th edn. Claredon Press, Oxford, p 479

Passaniti et al (1995) United States Patent, Patent Number: 5,389,469. Date of Patent: 14 Feb 1995

Sharma R (2004) Characterization of AgBiO3 with the cubic KSbO3 structure. Indian J Chem Sect 43A(1):11–17

Acknowledgements

The authors thank the Preludium Project 2012/07/N/ST5/02428 and Maestro Project 2011/02/A/ST5/00471 from the National Science Centre and the US Air Force Office of Scientific Research under Grant FA9550-14-1-0061 for support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sadecka, K., Berger, M.H., Orlinski, K. et al. Evolution of silver in a eutectic-based Bi2O3–Ag metamaterial. J Mater Sci 52, 5503–5510 (2017). https://doi.org/10.1007/s10853-016-0746-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0746-2