Abstract

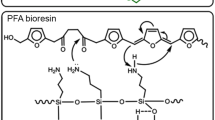

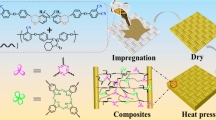

Fiberglass-reinforced composites composed of a matrix based on novolac-type phenol-hydroxymethylfurfural (PHMF) resins were developed. Using hexamethylenetetramine (HMTA) as a cross-linker, the curing process of the PHMF–HMTA was monitored by thermogravimetric analysis–FTIR analysis, and no formaldehyde emission was detected. The influence of hardener addition from 10–20 wt% was evaluated by mechanical properties, thermal stabilities, and thermochemical properties. Tensile and flexural strengths were as high as 115 and 145 MPa, respectively. The results revealed that the addition of HMTA to PHMF resin led to higher thermal stability of the resin, increased FRC tensile strength and crosslink density. Dynamic mechanical analysis indicated that ~15 wt% HMTA addition is optimal. This study demonstrated that PHMF resin can be used as a polymer matrix for the production of green composites with zero formaldehyde emission upon heating.

Similar content being viewed by others

References

Daoutidis P, Marvin WA, Rangarajan S et al (2013) Engineering biomass conversion processes: a systems perspective. AIChE J 59:3–18

Klemm D, Heublein B, Fink HP et al (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Rosatella AA, Simeonov SP, Frade RFM et al (2011) 5-Hydroxymethylfurfural (HMF) as a building block platform: biological properties, synthesis and synthetic applications. Green Chem 13:754–793

Röper H (2002) Renewable raw materials in Europe—industrial utilisation of starch and sugar [1]. Starch Stärke 54:89–99

Kowatsch S (2010) In: Pilato L (ed) Phenolic resins: a century of progress. Springer, Berlin

Manjula S, Pavithran C, Pillai CKS et al (1991) Synthesis and mechanical properties of cardanol-formaldehyde (CF) resins and CF-poly (methylmethacrylate) semi-interpenetrating polymer networks. J Mater Sci 26:4001–4007. doi:10.1007/BF02402940

Mutlu I, Alma MH, Basturk MA et al (2005) Preparation and characterization of brake linings from modified tannin-phenol formaldehyde resin and asbestos-free fillers. J Mater Sci 40:3003–3005. doi:10.1007/s10853-005-2396-7

Yuan Z, Zhang Y, Xu C (2014) Synthesis and thermomechanical property study of Novolac phenol-hydroxymethyl furfural (PHMF) resin. RSC Adv 4:31829–31835

Shibata S, Cao Y, Fukumoto I (2008) Flexural modulus of the unidirectional and random composites made from biodegradable resin and bamboo and kenaf fibres. Compos Part A 39:640–646

Suharty NS, Wirjosentono B, Firdaus M et al (2008) Synthesis of degradable bio-composites based on recycle polypropylene filled with bamboo powder using a reactive process. J Phys Sci 19:105–115

Zhang X, Looney MG, Solomon DH et al (1997) The chemistry of novolac resins: 3. 13C and 15N n.m.r. studies of curing with hexamethylenetetramine. Polymer 38:5835–5848

Zhang X, Potter AC, Solomon DH (1998) The chemistry of novolac resins: part 7. Reactions of para-hydroxybenzylamineintermediates. Polymer 39:1957–1966

Lim ASC, Solomon DH, Zhang X (1999) Chemistry of novolac resins. X. Polymerization studies of HMTA and strategically synthesized model compounds. J Appl Polym Sci 37:1347–1355

Markovic S, Dunjic B, Zlatanic A et al (2001) Dynamic mechanical analysis study of the curing of phenol-formaldehyde novolac resins. J Appl Polym Sci 81:1902–1913

Wan J, Wang S, Li C et al (2011) Effect of molecular weight and molecular weight distribution on cure reaction of novolac with hexamethylenetetramine and properties of related composites. Thermochim Acta 530:32–41

Lytle CA, Bertsch W, McKinley M (1998) Determination of novolac resin thermal decomposition products by pyrolysis-gas chromatography-mass spectrometry. J Anal Appl Pyrolysis 45:121–131

Pichelin F, Kamoun C, Pizzi A (1999) Hexamine hardener behaviour: effects on wood glueing, tannin and other wood adhesives. Eur J Wood Wood Prod 57:305–317

Hatfield GR, Maciel GE (1987) Solid-state NMR study of the hexamethylenetetramine curing of phenolic resins. Macromolecules 20:608–615

Pilato L (2010) Phenolic resins: A century of progress. Springer, New York

Mouritz AP, Leong KH, Herszberg I (1997) A review of the effect of stitching on the in-plane mechanical properties of fibre-reinforced polymer composites. Compos Part A 28:979–991

George J, Sreekala MS, Thomas S (2001) A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym Eng Sci 41:1471–1485

Anseth KS, Kline LM, Walker TA et al (1995) Reaction kinetics and volume relaxation during polymerizations of multiethylene glycol dimethacrylates. Macromolecules 28:2491–2499

Zhu J, Chandrashekhara K, Flanigan V et al (2004) Curing and mechanical characterization of a soy-based epoxy resin system. J Appl Polym Sci 91:3513–3518

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58:80–86

Espinosa MA, Cádiz V, Galia M (2003) Synthesis and characterization of benzoxazine-based phenolic resins: crosslinking study. J Appl Polym Sci 90:470–481

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Crane LW, Dynes PJ, Kaelble DH (1973) Analysis of curing kinetics in polymer composites. J Polym Sci Polym Phys Ed 11:533–540

De Medeiros ES, Agnelli JAM, Joseph K et al (2003) Curing behavior of a novolac-type phenolic resin analyzed by differential scanning calorimetry. J Appl Polym Sci 90:1678–1682

Zhang Y, Yuan Z, Xu CC (2015) Engineering biomass into formaldehyde-free phenolic resin for composite materials. AIChE J 61:1275–1283

Acknowledgements

The authors are grateful for the financial support of the NSERC/FPInnovations Industrial Research Chair Program in Forest Biorefinery, Grant IRCSA413630-09, and funding of the Ontario Research Fund-Research Excellence (ORF-RE), Grant IRCPJ413631-09. They are grateful also for the support of the industrial partners including FPInnovations, Arclin Canada, and BioIndustrial Innovation Centre is also acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Y., Nanda, M., Tymchyshyn, M. et al. Mechanical, thermal, and curing characteristics of renewable phenol-hydroxymethylfurfural resin for application in bio-composites. J Mater Sci 51, 732–738 (2016). https://doi.org/10.1007/s10853-015-9392-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9392-3