Abstract

An as-cast Al–7 % Si alloy was processed by high-pressure torsion (HPT) for up to 10 turns at temperatures of 298 or 445 K. The HPT-processed samples had ultrafine-grained structures and they were tested in tension at room temperature at various strain rates in the range from 1.0 × 10−4 to 1.0 × 10−2 s−1. The contributions of grain boundary sliding (GBS) to the total strain were measured directly using atomic force microscopy. Samples simultaneously showing both high strength and high ductility contained the highest fractions of high-angle grain boundaries (HAGB) and exhibited the highest contributions from GBS, whereas samples showing high strength but low ductility gave negligible values for the sliding contributions. It is concluded that high strength and high ductility require both an ultrafine grain size and a high fraction of HAGB.

Similar content being viewed by others

Notes

Since the strain datum points were not infinitesimally close, dσ/dε was approximated as Δσ/Δε where Δε is the difference between the finitely spaced strains over which the values of stress changed by Δσ.

References

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr Mater 39:1221

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103

Horita Z, Furukawa M, Nemoto M, Barnes AJ, Langdon TG (2000) Superplastic forming at high strain rates after severe plastic deformation. Acta Mater 48:3633

Furukawa M, Horita Z, Nemoto M, Langdon TG (2001) Processing metals by simple shear: principles of equal-channel angular pressing. J Mater Sci 36:2835. doi:10.1023/A:1017932417043

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanostructured materials. Prog Mater Sci 51:427

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58(4):33

Hoppel HW, Kautz M, Xu C, Murashkin MA, Langdon TG, Valiev RZ, Mughrabi H (2006) An overview: fatigue behaviour of ultrafine-grained metals and alloys. Int J Fatigue 28:1001

Kawasaki M, Langdon TG (2007) Principles of superplasticity in ultrafine-grained materials. J Mater Sci 42:1782. doi:10.1007/s10853-006-0954-2

Langdon TG (2013) Twenty-five years of ultrafine-grained materials: achieving exceptional properties through grain refinement. Acta Mater 61:7035

Langdon TG (2013) Achieving superplasticity in ultrafine-grained metals. Mech Mater 67:2

Valiev RZ, Gertsman VYu, Kaibyshev OA, Khannanov ShKh (1983) Non-equilibrium state and recovery of grain-boundary structure. 1. General analysis, crystallageometrical aspects. Phys Stat Solidi (a) 77:97

Valiev RZ, Korznikov AV, Mulyukov RR (1993) Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater Sci Eng A 168:141

Horita Z, Smith DJ, Furukawa M, Nemoto M, Valiev RZ, Langdon TG (1996) An investigation of grain boundaries in submicrometer-grained Al–Mg solid solution alloys using high-resolution electron microscopy. J Mater Res 11:1880

Horita Z, Smith DJ, Nemoto M, Valiev RZ, Langdon TG (1998) Observations of grain boundary structure in submicrometer-grained Cu and Ni using high-resolution electron microscopy. J Mater Res 13:446

Huang JY, Zhu YT, Jiang JH, Lowe TC (2001) Microstructures and dislocation configurations in bulk nanostructred Cu processed by repetitive corrugation and straightening. Acta Mater 49:1497

Fujita T, Horita Z, Langdon TG (2002) Characteristics of diffusion in Al–Mg alloys with ultrafine grain sizes. Philos Mag A 82:2249

Wang ZB, Lu K, Wilde G, Divinski SV (2010) Interfacial diffusion in Cu with a gradient nanostructured surface layer. Acta Mater 58:2376

Gifkins RC, Langdon TG (1965) On the question of low-temperature sliding at grain boundaries. J Inst Metals 93:347

Vinogradov A, Hashimoto S, Patlan V, Kitagawa K (2001) Atomic force microscopic study on surface morphology of ultra-fine grained materials after tensile testing. Mater Sci Eng A 319–321:862

Chinh NQ, Szommer P, Horita Z, Langdon TG (2006) Experimental evidence for grain boundary sliding in ultrafine-grained aluminum processed by severe plastic deformation. Adv Mater 18:34

Chinh NQ, Szommer P, Csanádi T, Langdon TG (2006) Flow processes at low temperatures in ultrafine-grained aluminum. Mater Sci Eng A 434:326

Valiev RZ, Murashkin MY, Kilmametov K, Straumal B, Chinh NQ, Langdon TG (2010) Unusual super-ductility at room temperature in an ultrafine-grained aluminum alloy. J Mater Sci 45:4718. doi:10.1007/s10853-010-4588-z

Chinh NQ, Györi T, Valiev RZ, Szommer P, Varga G, Havancsák K, Langdon TG (2012) Observations of unique plastic behavior in micro-pillars of an ultrafine-grained alloy. MRS Comm 2:75

Chinh NQ, Valiev RZ, Sauvage X, Varga G, Havancsák K, Kawasaki M, Straumal BB, Langdon TG (2014) Grain boundary phenomena in an ultrafine-grained Al-Zn alloy with improved mechanical behavior for micro-devices. Adv Eng Mater 16:1000

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) Paradox of strength and ductility in metals processed by severe plastic deformation. J Mater Res 17:5

Huang Y, Langdon TG (2002) Characterization of deformation processes in a Zn-22 % Al alloy using atomic force microscopy. J Mater Sci 37:4993. doi:10.1023/A:1021071228521

Huang Y, Langdon TG (2003) Using atomic force microscopy to evaluate the development of mesoscopic shear planes in materials processed by severe plastic deformation. Mater Sci Eng A 358:114

Zhao YH, Bingert JE, Liao XZ, Cui BZ, Han K, Sergueeva AV, Mukherjee AK, Valiev RZ, Langdon TG, Zhu YT (2006) Simultaneously elevating the strength and ductility of ultra-fine-grained pure copper. Adv Mater 18:2949

Kumar P, Xu C, Langdon TG (2009) Influence of strain rate on strength and ductility in an aluminum alloy processed by ECAP. J Mater Sci 44:3913. doi:10.1007/s10853-009-3535-3

Mungole T, Kumar P, Kawasaki M, Langdon TG (2014) A critical examination of the paradox of strength and ductility in ultrafine-grained metals. J Mater Res 29:2534

Valiev RZ, Kozlov EV, Ivanov YuF, Lian J, Nazarov AA, Baudelet B (1994) Deformation behaviour of ultra-fine-grained copper. Acta Metall Mater 42:2467

Sabirov I, Estrin Y, Barnett MR, Timokhina I, Hodgson PD (2008) Tensile deformation of an ultrafine-grained aluminium alloy: micro shear banding and grain boundary sliding. Acta Mater 56:2223

Ivanov KV, Naydenkin EV (2012) Grain boundary sliding in ultrafine grained aluminum under tension at room temperature. Scr Mater 66:511

Ivanov KV, Naydenkin EV (2014) Tensile behavior and deformation mechanisms of ultrafine-grained aluminum processed using equal-channel angular pressing. Mater Sci Eng A606:313

Hafok M, Pippan R (2007) Post-shear deformation of high pressure torsion-deformed nickel under hydrostatic pressure. Scr Mater 56:757

Langdon TG (1972) The effect of surface configuration on grain boundary sliding. Metall Trans 3:797

Bell RL, Graeme-Barber C, Langdon TG (1967) The contribution of grain boundary sliding to the overall strain of a polycrystal. Trans Met Soc AIME 239:1821

Clarisse L, Bataille A, Pennec Y, Crampon J, Duclos R (1999) Investigation of grain boundary sliding during superplastic deformation of a fine-grained alumina by atomic force microscopy. Ceram Int 25:389

Clarisse L, Petit F, Crampon J, Duclos R (2000) Characterization of grain boundary sliding in a fine-grained alumina–zirconia ceramic composite by atomic force microscopy. Ceram Int 26:295

Sato E, Matsunaga T (2010) Grain boundary sliding below ambient temperature in H.C.P. metals. Key Eng Mater 433:299

Kini M, Chokshi AH (2010) The influence of titania on creep in superplastic zirconia. J Am Ceram Soc 93:1725

Han JH, Mohamed FA (2011) Quantitative measurements of grain boundary sliding in an ultrafine-grained Al alloy by atomic force microscopy. Metall Mater Trans A 42:3969

Ghosh S, Chokshi AH (2014) Creep in nanocrystalline zirconia. Scr Mater 86:13

Yang K, Fecht HJ, Ivanisenko Y (2014) First direct in situ observation of grain boundary sliding in ultrafine grained noble metal. Adv Eng Mater 16:517

Figueiredo RB, Cetlin PR, Langdon TG (2011) Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion. Mater Sci Eng A 528:8198

Figueiredo RB, Pereira PHR, Aguilar MTP, Cetlin PR, Langdon TG (2012) Using finite element modelling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater 60:3190

Kawasaki M, Langdon TG (2008) The significance of strain reversals during processing by high-pressure torsion. Mater Sci Eng A 498:341

Mungole T, Naresh N, Dawara K, Kumar P, Kawasaki M, Langdon TG (2013) Evolution of microhardness and microstructure in a cast Al–7 % Si alloy during high-pressure torsion. J Mater Sci 48:4671. doi:10.1007/s10853-012-7061-3

Weinberg F (1958) Grain boundary shear in aluminum. Trans Met Soc AIME 212:808

Bell RL, Langdon TG (1967) An investigation of grain boundary sliding during creep. J Mater Sci 2:313. doi:10.1007/BF00572414

Eaton P, West P (2010) Atomic Force Microscopy. Oxford University Press, Oxford, UK

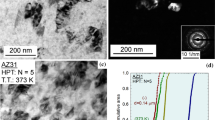

Figueiredo RB, Langdon TG (2014) Evaluating the superplastic flow of a magnesium AZ31 alloy processed by equal-channel angular pressing. Metall Mater Trans 45A:3197

Hancock JW (1976) Creep cavitation without vacancy flux. Metal Sci 10:319

Ishikawa H, Bhat DG, Mohamed FA, Langdon TG (1977) Evidence for cavitation in the superplastic Zn-22Pct Al eutectoid. Metall Mater Trans A 8:523

Miller DA, Langdon TG (1978) Evidence for cavitation in superplastic Zn-22Pct Al of very high purity. Metall Mater Trans A 9:1688

Chokshi AH, Langdon TG (1989) The influence of rolling direction on the mechanical behavior and formation of cavity stringers in the superplastic Zn 22 % Al alloy. Acta Metall 37:715

Kawasaki M, Xu C, Langdon TG (2005) An investigation of cavity development in a superplastic aluminum alloy processed by ECAP. Acta Mater 53:5353

Figueiredo RB, Terzi S, Langdon TG (2010) Using X-ray microtomography to evaluate cavity formation in a superplastic magnesium alloy processed by equal-channel angular pressing. Acta Mater 58:5737

Kawasaki M, Langdon TG (2012) An investigation of cavity development during superplastic flow in a zinc-aluminum alloy processed using severe plastic deformation. Mater Trans 53:87

Van Riet C, De Meester P (1985) Cavitation in a dilute superplastic Zn-0.5 % A1 alloy—a cascade mechanism for cavity generation. Scr Metall 19:795

Lee EU, Kranzlein HH, Underwood EE (1971) Dynamic recovery in aluminum. Mater Sci Eng 7:348

Zhao YH, Guo YZ, Wei Q, Dangelewicz AM, Xu C, Zhu YT, Langdon TG, Zhou YZ, Lavernia EJ (2008) Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr Mater 59:627

Zhao YH, Guo YZ, Wei Q, Topping TD, Dangelewicz AM, Zhu YT, Langdon TG, Lavernia EJ (2009) Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater Sci Eng A 525:68

Acknowledgements

The authors acknowledge the help of Mr. Devi Lal and Mr. Amit Kumar in GBS data analysis and SEM of fractured surfaces, respectively, and they thank Dr. Sarath Menon of the Naval Postgraduate School, Monterey, CA, USA, for providing the cast Al–7 % Si samples. This work was partially funded by IISc-STC Grant # ISTC0305 and a Seed Grant (Indian Institute of Science, Bangalore) to PK. The work was supported in part by the National Science Foundation of the United States under Grant No. DMR-1160966 and in part by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS (TGL).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mungole, T., Kumar, P., Kawasaki, M. et al. The contribution of grain boundary sliding in tensile deformation of an ultrafine-grained aluminum alloy having high strength and high ductility. J Mater Sci 50, 3549–3561 (2015). https://doi.org/10.1007/s10853-015-8915-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-8915-2