Abstract

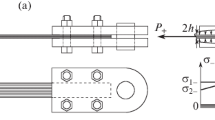

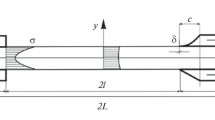

Single poly(p-phenylene terephthalamide) (PPTA) fiber tensile tests were carried out under quasi-static and high strain rate loading conditions using poly(methyl methacrylate) and rubber grips to investigate effects of grip materials and loading rates on fiber tensile properties. Differences in ultimate tensile strengths, failure strains, and moduli of PPTA fibers obtained by two different grip materials were insignificant. On the other hand, the fiber tensile properties showed significantly rate-dependent behaviors, which were graphically confirmed by kernel density plots as a non-parametric statistical analysis. Strength models considering three aspects (stochastic, fracture mechanics, and polymer chain domain behaviors) were also shown to link the loading rate effect in relation to fracture mechanisms.

Similar content being viewed by others

Notes

Certain commercial equipment, instruments, or materials are identified in this paper in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

References

Tan VBC, Zeng XS, Shim VPW (2008) Characterization and constitutive modeling of aramid fibers at high strain rates. Int J Impact Eng 35:1303–1313

Languerand DL, Zhang H, Murthy NS, Ramesh KT, Sansoz F (2009) Inelastic behavior and fracture of high modulus polymeric fiber bundles at high strain-rates. Mater Sci Eng A 500:216–224

Cheng M, Chen WN, Weerasooriya T (2005) Mechanical properties of Kevlar KM2 single fiber. J Eng Mater-T AMSE 127:197–203

Lim J, Chen WNW, Zheng JQ (2010) Dynamic small strain measurements of Kevlar 129 single fibers with a miniaturized tension Kolsky bar. Polym Test 29:701–705

Thomason JL, Kalinka G (2001) A technique for the measurement of reinforcement fibre tensile strength at sub-millimetre gauge lengths. Compos Part A Appl Sci Manuf 32:85–90

KIM JH, Heckert NA, Leigh SD, Kobayashi H, McDonough WG, Rice KD, Holmes GA (2013) Effects of fiber gripping methods on the single fiber tensile test: I. Non parametric statistical analysis. J Mater Sci 48:3623–3637. doi:10.1007/s10853-013-7142-y

Mulliken AD, Boyce MC (2006) Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int J Solids Struct 43:1331–1356

Sutton MA, Orteu J-J, Schreier HW (2009) Image correlation for shape, motion and deformation measurements: basic concepts theory and applications. Springer, Berlin

Ferry JD (1980) Viscoelastic properties of polymers. Wiley, New York

Fried JR (1995) Polymer science and technology. Prentice-Hall, New Jersey

Li G, Zhang C, Wang Y, Li P, Yu YH, Jia XL, Liu HY, Yang XP, Xue ZM, Ryu S (2008) Interface correlation and toughness matching of phosphoric acid functionalized Kevlar fiber and epoxy matrix for filament winding composites. Compos Sci Technol 68:3208–3214

ASTM C1557-03. Standard tenst method for tensile strength and young’s modulus of fibers. ASTM International, West Conshohocken, PA. doi:10.1520/C1557-03R08

Lim J, Zheng JQ, Masters K, Chen WNW (2011) Effects of gage length, loading rates, and damage on the strength of PPTA fibers. Int J Impact Eng 38:219–227

Graham JF, McCague C, Warren OL, Norton PR (2000) Spatially resolved nanomechanical properties of Kevlar (R) fibers. Polymer 41:4761–4764

Mera H, Takata T (2012) High-performance fibers. Ulmann’s Encycl Ind Chem 17:573–597

Rebouillat S (2001) Aramids. In: Hearle JWS (ed) High-performance fibres. CRC Press, New York

Yang QD, Rosakis A, Cox BN (2006) Dynamic fibre sliding along debonded, frictional interfaces. Proc R Soc A Math Phys Eng Sci 462:1081–1106

Heckert A, Filliben J (2010) Dataplot reference manual. http://www.itl.nist.gov/div898/software/dataplot/refman1/auxillar/kernplot.htm

Grujicic M, Glomski PS, Pandurangan B, Bell WC, Yen CF, Cheeseman BA (2011) Multi-length scale computational derivation of Kevlar® yarn-level material model. J Mater Sci 46:4787–4802. doi:10.1007/s10853-011-5389-8

Kausch H-H (1986) Polyr fracture. Springer, Berlin

Chou Tsu-Wei (1992) Microstructural design of fiber composites. Cambridge University Press, Cambridge

Xia YM, Yuan JM, Yang BC (1994) A statistical-model and experimental-study of the strain-rate dependence of the strength of fibers. Compos Sci Technol 52:499–504

Kim JH, Heckert NA, Leigh SD, Rhorer RL, Kobayashi H, McDonough WG, Rice KD, Holmes GA (2014) Statistical analysis of PPTA fiber strengths measured under high strain rate condition. Compos Sci Technol 98:93–99

Smook J, Hamersma W, Pennings AJ (1984) The fracture process of ultrahigh strength polyethylene fibers. J Mater Sci 19:1359–1373. doi:10.1007/BF01120049

Northolt MG, Baltussen JJM (2002) The tensile and compressive deformation of polymer and carbon fibers. J Appl Polym Sci 83:508–538

Shioya M, Kimura Y, Kawazoe T (2004) Analysis of defects in poly(ethylene terephthalate) fibers. Fiber (Sen-I Gakkaishi) 60:346–351

Termonia Y, Meakin P, Smith P (1985) Theoretical-study of the influence of the molecular-weight on the maximum tensile-strength of polymer fibers. Macromolecules 18:2246–2252

Northolt MG, den Decker P, Picken SJ, Baltussen JJM, Schlatmann R (2005) The tensile strength of polymer fibres. Springer, Berlin

Grujicic M, Bell WC, Glomski PS, Pandurangan B, Yen CF, Cheeseman BA (2011) Filament-level modeling of aramid-based high-performance structural materials. J Mater Eng Perform 20:1401–1413

Giesa T, Pugno NM, Wong JY, Kaplan DL, Buehler MJ (2013) What’s inside the box? Length-scales that govern fracture processes of polymer fibers. Adv Mater 26:412–417

Alcock B, Cabrera NO, Barkoula NM, Wang Z, Peijs T (2008) The effect of temperature and strain rate on the impact performance of recyclable all-polypropylene composites. Compos Part B Eng 39:537–547

Acknowledgements

The authors would like to thank to Prof. Weinong Chen and Dr. Jaeyoung Lim at Purdue University for their support on building the laser optical system, as well as Stefan Leigh for his comments and discussions in preparation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Official contribution of the National Institute of Standards and Technology; not subject to copyright in the United States.

Rights and permissions

About this article

Cite this article

Kim, J.H., Heckert, N.A., Mates, S.P. et al. Effect of fiber gripping method on the single fiber tensile test: II. Comparison of fiber gripping materials and loading rates. J Mater Sci 50, 2049–2060 (2015). https://doi.org/10.1007/s10853-014-8736-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8736-8