Abstract

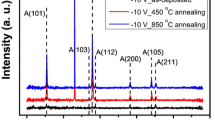

A novel plasma exposure technique has been introduced into conventional magnetron sputtering process to enhance the crystallization of indium oxide (In2O3) films at room temperature. The effect of plasma exposure technique with different pulsed DC voltages on the electrical and mechanical properties of In2O3 films was investigated. It is observed that film crystallization can be significantly enhanced when the pulsed DC voltage (|V p|) is higher than |−500 V| (|V p| > |−500 V|). By applying the plasma exposure process, In2O3 films prepared at room temperature with thickness of 135 nm shows low resistivity of 4.11 × 10−4 Ω cm, mobility of 42.1 cm2/Vs, and transmittance over 80 % in the visible range. Compared with the In2O3 films without plasma exposure process, the In2O3 films with plasma exposure show better crystallization and remarkably higher nanohardness. The plasma exposure technique is a useful candidate technique for enhancing film crystallization at low temperature.

Similar content being viewed by others

References

Thomas G (1997) Invisible circuits. Nature 389:907–908

King PD, Veal TD (2011) Conductivity in transparent oxide semiconductors. J Phys Condens Matter 23:334214

Ellmer K (2012) Past achievements and future challenges in the development of optically transparent electrodes. Nat Photonics 6:809–817

Kim H, Horwitz JS, Kushto GP, Kafafi ZH, Chrisey DB (2001) Indium tin oxide thin films grown on flexible plastic substrates by pulsed-laser deposition for organic light-emitting diodes. Appl Phys Lett 79:284–286

Choi MC, Kim Y, Ha CS (2008) Polymers for flexible displays: from material selection to device applications. Prog Polym Sci 33:581–630

Yang ZW, Han SH, Yang TL, Ye L, Zhang DH, Ma HL, Cheng CF (2000) Bias voltage dependence of properties for depositing transparent conducting ITO films on flexible substrate. Thin Solid Films 366:4–7

Zhang K, Wen M, Meng QN, Hu CQ, Li X, Zheng WT (2012) Effects of substrate bias voltage on the microstructure, mechanical properties and tribological behavior of reactive sputtered niobium carbide films. Surf Coat Technol 212:185–191

Vygranenko Y, Wang K, Vieira M, Nathan A (2008) Indium oxide thin-film transistor by reactive ion beam assisted deposition. Phys Status Solidi A 205:1925–1928

Dudek M, Amassian A, Zabeida O, Sapienha JEK, Martinu L (2009) Ion bombardment-induced enhancement of the properties of indium tin oxide films prepared by plasma-assisted reactive magnetron sputtering. Thin Solid Films 517:4576–4582

Lee DY, Bailk HK (2008) Room temperature deposition of crystalline indium tin oxide films by cesium-assisted magnetron sputtering. Appl Surf Sci 254:6313–6317

Sittinger V, Ruske F, Werner W, Jacobs C, Szyszka B, Christie DJ (2008) High power pulsed magnetron sputtering of transparent conducting oxides. Thin Solid Films 516:5847–5859

Wakeham SJ, Thwaites MJ, Holton BW, Tsakonas C, Cranton WM, Koutsogeorgis DC, Ranson R (2009) Low temperature remote plasma sputtering of indium tin oxide for flexible display applications. Thin Solid Films 518:1355–1358

Zhang XP, Zhu JQ, Zhang LX, Kishimoto K, Du SY, Yin XB (2013) Crystallization of alumina films deposited by reactive magnetron sputtering with resputtering technique at low temperature. Surf Coat Technol 228:S393–S396

Zhang XP, Zhu JQ, Zhang LX, Han JC, Du SY (2013) Low-temperature crystallization and hardness enhancement of alumina films using the resputtering technique. J Non Cryst Solids 362:34–39

Qiao Z, Latz R, Mergel D (2004) Thickness dependence of In2O3:Sn film growth. Thin Solid Films 466:250–258

Yu LS, Harper JME, Cuomo JJ, Smith DA (1985) Alignment of thin films by glancing angle ion bombardment during deposition. Appl Phys Lett 47:932–933

Kamei M, Shigesato Y, Takaki S (1995) Origin of characteristic grain–subgrain structure of tin-doped indium oxide films. Thin Solid Films 259:38–45

Uvarov V, Popov I (2007) Metrological characterization of X-ray diffraction methods for determination of crystallite size in nano-scale materials. Mater Charact 58:883–891

Manoj PK, Gopchandran KG, Koshy P, Vaidyan VK, Joseph B (2006) Growth and characterization of indium oxide thin films prepared by spray pyrolysis. Opt Mater 28:1405–1411

Li X, Yan Y, Mason A, Gessert TA, Coutts TJ (2001) High mobility CdO films and their dependence on structure. Electrochem Solid State Lett 4:C66–C68

Weiher RL, Ley RP (1966) Optical properties of indium oxide. J Appl Phys 37:299–302

Cock BA, Harrina JL, Vining CB (1998) Electrical properties of Ga and ZnS doped ZnO prepared by mechanical alloying. J Appl Phys 83:5858–5861

Acknowledgements

The support from the National Natural Science Foundation of China (Grant Nos. 51072039 and 51222205), the Aeronautical Science Foundation of China (Grant No. 20120177002) and Program for New Century Excellent Talents in University (NCET-10-0070) is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Zhu, J., Bai, J. et al. Plasma exposure inducing crystallization of indium oxide film with improved electrical and mechanical properties at room temperature. J Mater Sci 49, 5955–5960 (2014). https://doi.org/10.1007/s10853-014-8314-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8314-0