Abstract

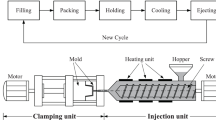

Injection molding is the most widely used processing technique for polymers. It offers several advantages over other processing conditions such as good surface finish, the ability to process complex parts without the need of secondary operations, and low cost for mass production. However, because of the complex deformation, and thermal and pressure histories that the polymer melt experiences during processing, residual stresses develop. These stresses act internally at room temperature and have the same effects on the material as externally applied stresses do, resulting in shrinkage and warpage of the product. In recent years, with the development and use of engineering plastics in an increasing number of applications, and with the tougher quality control policies in industries such as the automotive, the effects of residual stresses in product quality and performance have raised great interest. This review reports up-to-date advances in the field of residual stresses developments in polymers, with special attention given to injection molded products. Flow- and thermal-induced residual stresses are reported. Emphasis is given to the processing parameters that most influence residual stresses during injection molding as well as the effect of residual stresses not only on warpage but also on other material properties.

Similar content being viewed by others

References

Siegmann A, Buchman A, Kenig S (1982) Residual stresses in polymers III: The influence of injection-molding process conditions. Polym Eng Sci 22:560–568

Siegmann A, Buchman A, Kenig S (1982) Residual stresses in polymers I: the effect of thermal history. Polym Eng Sci 22:40–47

Siegmann A, Buchman A, Kenig S (1981) Residual stresses in polymers. II. Their effect on mechanical behavior. Polym Eng Sci 21:997–1002

Isayev AI, Crouthamel DL (1984) Residual stress development in the injection molding of polymers. Polym Plast Technol 22:177–232

Daly HB, Nguyen K, Sanschagrin B, Cole K (1998) Build-up and measurement of molecular orientation, crystalline morphology, and residual stresses in injection molded parts: a review. J Inject Molding Technol 2:59–85

Baaijens FPT (1991) Calculation of residual stresses in injection molded products. Rheol Acta 30:284–299

Zoetelief WF, Douven LFA, Ingen Housz AJ (1996) Residual thermal stresses in injection molded products. Polym Eng Sci 36:1886–1896

Young W-B (2004) Residual stress induced by solidification of thermoviscoelastic melts in the postfilling stage. J Mater Process Technol 145:317–324

Shia-Chung C, Yung-Cheng C (1994) Calculations of the flow-induced residual stress development in the injection moulded plate. Comput Struct 52:1043–1050

Jansen K (1998) Measurement and prediction of anisotropy in injection moulded PP products. Int Polym Process 13:309–317

Wimberger-Friedl R (1995) The assessment of orientation, stress and density distributions in injection-molded amorphous polymers by optical techniques. Prog Polym Sci 20:369–401

Sjönell Y, Terselius B, Jansson J-F (1995) Injection molding of polypropylene discs. I: Effect of holding pressure on orientation distribution. Polym Eng Sci 35:950–956

Chiang HH, Hieber CA, Wang KK (1991) A unified simulation of the filling and postfilling stages in injection molding. Part II: Experimental verification. Polym Eng Sci 31:125–139

Kazmer D, Barkan P (1997) Multi-cavity pressure control in the filling and packing stages of the injection molding process. Polym Eng Sci 37:1865–1879

Siegmann A, Kenig S, Buchman A (1987) Residual stresses in injection-molded amorphous polymers. Polym Eng Sci 27:1069–1078

Douven LFA, Baaijens FPT, Meijer HEH (1995) The computation of properties of injection-moulded products. Prog Polym Sci 20:403–457

Wimberger-Friedl R, Hendriks RDHM (1989) The measurement and calculation of birefringence in quenched polycarbonate specimens. Polymer 30:1143–1149

Zhou H, Li D (2005) Residual stress analysis of the post-filling stage in injection moulding. Int J Adv Manuf Technol 25:700–704

Kim KH, Isayev AI, Kwon K, van Sweden C (2005) Modeling and experimental study of birefringence in injection molding of semicrystalline polymers. Polymer 46:4183–4203

Isayev AI, Shyu GD, Li CT (2006) Residual stresses and birefringence in injection molding of amorphous polymers: simulation and comparison with experiment. J Polym Sci Pol Phys 44:622–639

Lee YB, Kwon TH (2001) Modeling and numerical simulation of residual stresses and birefringence in injection molded center-gated disks. J Mater Process Technol 111:214–218

Janeschitz-Kriegl H (1977) Injection moulding of plastics: some ideas about the relationship between mould filling and birefringence. Rheol Acta 16:327–339

Cao W, Shen C, Zhang C, Wang L (2008) Computing flow-induced stresses of injection molding based on the Phan–Thien–Tanner model. Arch Appl Mech 78:363–377

Bushko WC, Stokes VK (1995) Solidification of thermoviscoelastic melts. Part II: Effects of processing conditions on shrinkage and residual stresses. Polym Eng Sci 35:365–383

Bushko WC, Stokes VK (1996) Solidification of thermoviscoelastic melts. Part 3: Effects of mold surface temperature differences on warpage and residual stresses. Polym Eng Sci 36:322–335

Bushko WC, Stokes VK (1996) Solidification of thermoviscoelastic melts. Part 4: Effects of boundary conditions on shrinkage and residual stresses. Polym Eng Sci 36:658–675

Bushko WC, Stokes VK (1995) Solidification of thermoviscoelastic melts. Part I: Formulation of model problem. Polym Eng Sci 35:351–364

Zhang N, Gilchrist MD (2012) Characterization of thermo-rheological behavior of polymer melts during the micro injection moulding process. Polym Test 31:748–758

Baltussen MGHM, Hulsen MA, Peters GWM (2010) Numerical simulation of the fountain flow instability in injection molding. J Non Newton Fluid 165:631–640

Yang B, Ouyang J, Liu C, Li Q (2010) Simulation of non-isothermal injection molding for a non-Newtonian fluid by level set method. Chin J Chem Eng 18:600–608

Tanner RI (2003) On the flow of crystallizing polymers: I. Linear regime. J Non Newton Fluid 112:251–268

Vinogradov V (1975) Residual stresses in plastic parts. Plast Massy 4:20–31

Jansen K (1994) Residual stresses in quenched and injection moulded products. Int Polym Proc 9:82–89

Sandilands GJ, White JR (1980) Effect of injection pressure and crazing on internal stresses in injection-moulded polystyrene. Polymer 21:338–343

Mlekusch B (2001) Calculation of residual stress development in injection moulding using a nonlinear viscoelastic model. Mech Time Depend Mater 5:101–118

Wang T-H, Young W-B (2005) Study on residual stresses of thin-walled injection molding. Eur Polym J 41:2511–2517

Jansen K, Van Dijk DJ, Keizer KP (1998) Warpage of injection moulded plates and corner products. Int Polym Proc 13:417–424

Leonov AI (1976) Nonequilibrium thermodynamics and rheology of viscoelastic polymer media. Rheol Acta 15:85–98

Kabanemi KK, Aït-Kadi A, Tanguy P (1995) Prediction of residual flow and thermoviscoelastic stresses in injection molding. Rheol Acta 34:97–108

Isayev AI, Hieber CA (1980) Toward a viscoelastic modelling of the injection molding of polymers. Rheol Acta 19:168–182

Mavridis H, Hrymak AN, Vlachopoulos J (1988) The effect of fountain flow on molecular orientation in injection molding. J Rheol 32:639–663

Flaman AAM (1993) Buildup and relaxation of molecular orientation in injection molding. Part II: Experimental verification. Polym Eng Sci 33:202–210

Flaman AAM (1993) Buildup and relaxation of molecular orientation in injection molding. Part I: Formulation. Polym Eng Sci 33:193–201

Spencer R, Gilmore G (1950) Equation of state for high polymers. J Appl Phys 21:523–526

Greener J, Kesel R, Contestable BA (1989) The birefringence problem in optical disk substrates: a modeling approach. AlChE J 35:449–458

Wagner MH (1976) Analysis of stress-growth data for simple extension of a low-density branched polyethylene melt. Rheol Acta 15:133–135

Matsui M, Bogue D (1977) Studies in non-isothermal rheology. J Rheol 21:133

Xue SC, Phan-Thien N, Tanner RI (1998) Three dimensional numerical simulations of viscoelastic flows through planar contractions. J Non Newton Fluid 74:195–245

Marchal JM, Crochet MJ (1987) A new mixed finite element for calculating viscoelastic flow. J Non Newton Fluid 26:77–114

Zhou H, Xi G, Liu F (2008) Residual stress simulation of injection molding. J Mater Eng Perform 17:422–427

Yu F, Zhang H, Zheng H, Yu W, Zhou C (2008) Experimental study of flow-induced crystallization in the blends of isotactic polypropylene and poly(ethylene-co-octene). Eur Polym J 44:79–86

Keum JK, Mao Y, Zuo F, Hsiao BS (2013) Flow-induced crystallization precursor structure in high molecular weight isotactic polypropylene (HMW-iPP)/low molecular weight linear low density polyethylene (LMW-LLDPE) binary blends. Polymer 54:1425–1431

Janeschitz-Kriegl H, Ratajski E (2005) Kinetics of polymer crystallization under processing conditions: transformation of dormant nuclei by the action of flow. Polymer 46:3856–3870

Mu Y, Zhao G, Chen A, Wu X (2012) Numerical investigation of the thermally and flow induced crystallization behavior of semi-crystalline polymers by using finite element–finite difference method. Comput Chem Eng 46:190–204

Hsiung CM, Cakmak M, Ulcer Y (1996) A structure oriented model to simulate the shear induced crystallization in injection moulded polymers: a Lagrangian approach. Polymer 37:4555–4571

Nielsen LE (1954) Effect of crystallinity on the dynamic mechanical properties of polyethylenes. J Appl Phys 25:1209–1212

Brady DG (1976) The crystallinity of poly(phenylene sulfide) and its effect on polymer properties. J Appl Polym Sci 20:2541–2551

Starkweather HW, Moore GE, Hansen JE, Roder TM, Brooks RE (1956) Effect of crystallinity on the properties of nylons. J Polym Sci 21:189–204

Richards RB (1951) Polyethylene-structure, crystallinity and properties. J Appl Chem 1:370–376

Nagamatsu K, Takemura T, Yoshitomi T, Takemoto T (1958) Effect of crystallinity on the viscoelastic properties of polyethylene. J Polym Sci 33:515–518

Wright DGM, Dunk R, Bouvart D, Autran M (1988) The effect of crystallinity on the properties of injection moulded polypropylene and polyacetal. Polymer 29:793–796

Santis FD, Pantani R, Speranza V, Titomanlio G (2010) Analysis of shrinkage development of a semicrystalline polymer during injection molding. Ind Eng Chem Res 49:2469–2476

Pantani R, Coccorullo I, Speranza V, Titomanlio G (2007) Morphology evolution during injection molding: effect of packing pressure. Polymer 48:2778–2790

Zhang X, Li Z, Lu Z, Sun CC (2002) The crystallization of low-density polyethylene: a molecular dynamics simulation. Polymer 43:3223–3227

Xu JT, Wang Q, Fan ZQ (2005) Non-isothermal crystallization kinetics of exfoliated and intercalated polyethylene/montmorillonite nanocomposites prepared by in situ polymerization. Eur Polym J 41:3011–3017

Wagner J, Phillips PJ (2001) The mechanism of crystallization of linear polyethylene, and its copolymers with octene, over a wide range of supercoolings. Polymer 42:8999–9013

Mubarak Y, Harkin-Jones EMA, Martin PJ, Ahmad M (2001) Modeling of non-isothermal crystallization kinetics of isotactic polypropylene. Polymer 42:3171–3182

Lim BA, McGuire KS, Lloyd DR (1993) Non-isothermal crystallization of isotactic polypropylene in dotriacontane. II: Effects of dilution, cooling rate, and nucleating agent addition on growth rate. Polym Eng Sci 33:537–542

Brucato V, Crippa G, Piccarolo S, Titomanlio G (1991) Crystallization of polymer melts under fast cooling. I: Nucleated polyamide. Polym Eng Sci 6(31):1411–1416

Di Lorenzo ML, Silvestre C (1999) Non-isothermal crystallization of polymers. Prog Polym Sci 24:917–950

Jiao C, Wang Z, Liang X, Hu Y (2005) Non-isothermal crystallization kinetics of silane crosslinked polyethylene. Polym Test 24:71–80

Nakamura K, Katayama K, Amano T (1973) Some aspects of nonisothermal crystallization of polymers. II. Consideration of the isokinetic condition. J Appl Polym Sci 17:1031–1041

Phillips R, Manson JE (1997) Prediction and analysis of nonisothermal crystallization of polymers. J Polym Sci B 35:875–888

Pantani R, Coccorullo I, Speranza V, Titomanlio G (2005) Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog Polym Sci 30:1185–1222

Gardon R, Narayanaswamy OS (1970) Stress and volume relaxation in annealing flat glass. J Am Ceram Soc 53:380–385

Lee EH, Rogers TG, Woo TC (1965) Residual stresses in a glass plate cooled symmetrically from both surfaces. J Am Ceram Soc 48:480–487

Aggarwala B, Saibel E (1961) Tempering stresses in an infinite glass plate. Phys Chem Glasses 2:137–140

Narayanaswamy OS, Gardon R (1969) Calculation of residual stresses in glass. J Am Ceram Soc 52:554–558

Mauch F, Jäckle J (1994) Thermoviscoelastic theory of freezing of stress and strain in a symmetrically cooled infinite glass plate. J Non Cryst Solids 170:73–86

Adams LH, Williamson ED (1920) The annealing of glass. J Franklin I 190:835–870

Struik LCE (1978) Orientation effects and cooling stresses in amorphous polymers. Polym Eng Sci 18:799–811

Rigdahl M (1976) Calculation of residual thermal stresses in injection molded amorphous polymers by the finite element method. Int J Polym Mater 5:43–57

Jansen K, Titomanlio G (1996) Effect of pressure history on shrinkage and residual stresses—injection molding with constrained shrinkage. Polym Eng Sci 36:2029–2040

Zheng R, Kennedy P, Phan-Thien N, Fan XJ (1999) Thermoviscoelastic simulation of thermally and pressure-induced stresses in injection moulding for the prediction of shrinkage and warpage for fibre-reinforced thermoplastics. J Non Newton Fluid 84:159–190

Kwon Y, Kang T, Chung K, Youn J (2001) Prediction and measurement of residual stresses in injection molded parts. Fibers Polym 2:203–211

Wu H, Zhao Z, Sha J (2009) Experiments and prediction of in-cavity stress for injection molded part. Mech Time Depend Mater 13:233–244

Jacques MS (1982) An analysis of thermal warpage in injection molded flat parts due to unbalanced cooling. Polym Eng Sci 22:241–247

Jansen KMB, Van Dijk DJ, Freriksen MJA (1998) Shrinkage anisotropy in fiber reinforced injection molded products. Polym Compos 19:325–334

Jansen KMB, Pantani R, Titomanlio G (1998) As-molded shrinkage measurements on polystyrene injection molded products. Polym Eng Sci 38:254–264

Titomanlio G, Jansen KMB (1996) In-mold shrinkage and stress prediction in injection molding. Polym Eng Sci 36:2041–2049

Denizart O, Vincent M, Agassant JF (1995) Thermal stresses and strains in injection moulding: experiments and computations. J Mater Sci 30:552–560. doi:10.1007/BF00354424

Kabanemi KK, Crochet MJ (1992) Thermoviscoelastic calculation of residual stresses and residual shapes of injection molded parts. Int Polym Proc 1:60–70

Chen X, Lam YC, Li DQ (2000) Analysis of thermal residual stress in plastic injection molding. J Mater Process Technol 101:275–280

Chang RY, Tsaur BD (1995) Experimental and theoretical studies of shrinkage, warpage, and sink marks of crystalline polymer injection molded parts. Polym Eng Sci 35:1222–1230

Kamal MR, Lai-Fook RA, Hernandez-Aguilar JR (2002) Residual thermal stresses in injection moldings of thermoplastics: a theoretical and experimental study. Polym Eng Sci 42:1098–1114

Liu S-J (1996) Modeling and simulation of thermally induced stress and warpage in injection molded thermoplastics. Polym Eng Sci 36:807–818

Choi D-S, Im Y-T (1999) Prediction of shrinkage and warpage in consideration of residual stress in integrated simulation of injection molding. Compos Struct 47:655–665

Li D, Zhou H (2004) Modelling and simulation of residual stress and warpage in injection moulding. Proc Inst Mech Eng C 218:521–530

Tropsa V, Ivankovic A, Williams JG (2000) Predicting residual stresses due to solidification in cast plastic plates. Plast Rub Compos 29:468–474

Williams JG (1981) On the prediction of residual stresses in polymers. Plast Rub Proc Appl 1:369–377

Leo V, Cuvelliez C (1996) The effect of the packing parameters, gate geometry, and mold elasticity on the final dimensions of a molded part. Polym Eng Sci 36:1961–1971

Delaunay D, Le Bot P, Fulchiron R, Luye JF, Regnier G (2000) Nature of contact between polymer and mold in injection molding. Part II: Influence of mold deflection on pressure history and shrinkage. Polym Eng Sci 40:1692–1700

Huang M-C, Tai C-C (2001) The effective factors in the warpage problem of an injection-molded part with a thin shell feature. J Mater Process Technol 110:1–9

Erzurumlu T, Ozcelik B (2006) Minimization of warpage and sink index in injection-molded thermoplastic parts using Taguchi optimization method. Mater Design 27:853–861

Ozcelik B, Sonat I (2009) Warpage and structural analysis of thin shell plastic in the plastic injection molding. Mater Design 30:367–375

Song MC, Liu Z, Wang MJ, Yu TM, Zhao DY (2007) Research on effects of injection process parameters on the molding process for ultra-thin wall plastic parts. J Mater Process Technol 187–188:668–671

Öktem H (2012) Modeling and analysis of process parameters for evaluating shrinkage problems during plastic injection molding of a DVD-ROM cover. J Mater Eng Perform 21:25–32

Chen C-C, Su P-L, Lin Y-C (2009) Analysis and modeling of effective parameters for dimension shrinkage variation of injection molded part with thin shell feature using response surface methodology. Int J Adv Manuf Technol 45:1087–1095

Chiang K-T, Chang F-P (2006) Analysis of shrinkage and warpage in an injection-molded part with a thin shell feature using the response surface methodology. Int J Adv Manuf Technol 35:468–479

Mathivanan D, Parthasarathy NS (2009) Prediction of sink depths using nonlinear modeling of injection molding variables. Int J Adv Manuf Technol 43:654–663

Wang X, Zhao G, Wang G (2013) Research on the reduction of sink mark and warpage of the moulded part in rapid heat cycle moulding process. Mater Design 47:779–792

Gao Y, Wang X (2008) An effective warpage optimization method in injection molding based on the Kriging model. Int J Adv Manuf Technol 37:953–960

Lotti C, Ueki MM, Bretas RES (2002) Prediction of the shrinkage of injection molded iPP plaques using artificial neural networks. J Inject Molding Technol 6:157–176

Chen W-C, Tai P-H, Wang M-W, Deng W-J, Chen C-T (2008) A neural network-based approach for dynamic quality prediction in a plastic injection molding process. Expert Syst Appl 35:843–849

Shie J-R (2008) Optimization of injection molding process for contour distortions of polypropylene composite components by a radial basis neural network. Int J Adv Manuf Technol 36:1091–1103

Altan M (2010) Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Mater Design 31:599–604

Mathivanan D, Parthasarathy NS (2009) Sink-mark minimization in injection molding through response surface regression modeling and genetic algorithm. Int J Adv Manuf Technol 45:867–874

Sánchez R, Aisa J, Martinez A, Mercado D (2012) On the relationship between cooling setup and warpage in injection molding. Measurement 45:1051–1056

Kurt M, Saban Kamber O, Kaynak Y, Atakok G, Girit O (2009) Experimental investigation of plastic injection molding: assessment of the effects of cavity pressure and mold temperature on the quality of the final products. Mater Design 30:3217–3224

Kazakov A (1998) An automated method for the measurement of residual stress in melt-extruded plastic pipes. Polym Test 17:443–450

Glomsaker T, Larsen A, Andreassen E (2005) Experimental and numerical investigation of warpage of semicrystalline polymers in rotational molding. Polym Eng Sci 45:945–952

Xu H, Bellehumeur CT (2008) Thermal residual stress development for semi-crystalline polymers in rotational molding. Polym Eng Sci 48:283–291

Postawa P, Koszkul J (2005) Change in injection moulded parts shrinkage and weight as a function of processing conditions. J Mater Process Technol 162–163:109–115

Jansen KMB, Van Dijk DJ, Husselman MH (1998) Effect of processing conditions on shrinkage in injection molding. Polym Eng Sci 38:838–846

Aisa J, Castany J (2009) Dimensional study of thermoplastic parts made using sequential injection molding. Polym Eng Sci 49:1832–1838

Oktem H, Erzurumlu T, Uzman I (2007) Application of Taguchi optimization technique in determining plastic injection molding process parameters for a thin-shell part. Mater Design 28:1271–1278

Chen C-P, Chuang M-T, Hsiao Y-H, Yang Y-K, Tsai C-H (2009) Simulation and experimental study in determining injection molding process parameters for thin-shell plastic parts via design of experiments analysis. Expert Syst Appl 36:10752–10759

Angstadt DC, Coulter JP (1999) Cavity pressure and part quality in the injection molding process. Intell Mater Manuf Lab Lehigh Univ, Pennsylvania

Kovács JG, Sikló B (2011) Test method development for deformation analysis of injection moulded plastic parts. Polym Test 30:543–547

Hastenberg CHV, Wildervanck PC, Leenen AJH, Schennink GGJ (1992) The measurement of thermal stress distributions along the flow path in injection-molded flat plates. Polym Eng Sci 32:506–515

Akay M, Ozden S, Tansey T (1996) Prediction of process-induced warpage in injection molded thermoplastics. Polym Eng Sci 36:1839–1846

Clutton EQ, Williams JG (1995) On the measurement of residual stress in plastic pipes. Polym Eng Sci 35:1381–1386

Hassan H, Regnier N, Le Bot C, Defaye G (2010) 3D study of cooling system effect on the heat transfer during polymer injection molding. Int J Therm Sci 49:161–169

Hassan H, Regnier N, Pujos C, Arquis E, Defaye G (2010) Modeling the effect of cooling system on the shrinkage and temperature of the polymer by injection molding. Appl Therm Eng 30:1547–1557

Tang LQ, Chassapis C, Manoochehri S (1997) Optimal cooling system design for multi-cavity injection molding. Finite Elem Anal Des 26:229–251

Qiao H (2006) A systematic computer-aided approach to cooling system optimal design in plastic injection molding. Int J Mech Sci 48:430–439

Mills NJ (1982) Residual stresses in plastics, rapidly cooled from the melt, and their relief by sectioning. J Mater Sci 17:558–574. doi:10.1007/BF00591490

Thakkar BS, Broutman LJ (1980) The influence of residual stresses and orientation on the properties of amorphous polymers. Polym Eng Sci 20:1214–1219

Broutman LJ, Krishnakumar SM (1976) Impact strength of polymers: 1. The effect of thermal treatment and residual stress. Polym Eng Sci 16:74–81

So P, Broutman LJ (1976) Residual stresses in polymers and their effect on mechanical behavior. Polym Eng Sci 16:785–791

Chaoui K, Chudnovsky A, Moet A (1987) Effect of residual stress on crack propagation in MDPE pipes. J Mater Sci 22:3873–3879. doi:10.1007/BF01133334

Guevara-Morales A, Leevers P (2013) Experimental investigation of the effect of residual stresses on rapid crack propagation in polyethylene (PE100) pipes. Polym Eng Sci 53:1217–1222

Argyrakis C (2010) Department of Mechanical Engineering, Imperial College London, London, UK

Davis P (1999) Mechanical Engineering Department, Imperial College London, London, UK

Hornberger LE, Devries KL (1987) The effect of residual stress on the mechanical properties of glassy polymers. Polym Eng Sci 27:1473–1478

Hornberger LE, DeVries KL (1987) Measurement of favorable residual stresses in polycarbonate. Exp Mech 27:94–98

Sauer JA, Habibullah M, Chen CC (1981) Fatigue of high impact polystyrene and influence of surface treatments. J Appl Phys 52:5970–5976

Turnbull A, Maxwell AS, Pillai S (2000) Comparative assessment of slow strain rate, 4-pt bend and constant load test methods for measuring environment stress cracking of polymers. Polym Test 19:117–129

O’Donnell B, White JR (1994) Stress-accelerated photo-oxidation of polypropylene and glass–fibre-reinforced polypropylene. Polym Degrad Stab 44:211–222

Shyichuk AV, White JR (2000) Analysis of chain-scission and crosslinking rates in the photo-oxidation of polystyrene. J Appl Polym Sci 77:3015–3023

Tyler DR (2004) Mechanistic aspects of the effects of stress on the rates of photochemical degradation reactions in polymers. J Macromol Sci 44:351–388

Chen R, Tyler DR (2004) Origin of tensile stress-induced rate increases in the photochemical degradation of polymers. Macromolecules 37:5430–5436

Kwok CS, Tong L, White JR (1996) Generation of large residual stresses in injection moldings. Polym Eng Sci 36:651–657

Withers PJ, Bhadeshia HKDH (2001) Residual stress Part 1—measurement techniques. Mater Sci Technol 17:355–365

Ruud CO (1982) A review of selected non-destructive methods for residual stress measurement. NDT Int 15:15–23

Hughes DJ, Heeley EL, Curfs C (2011) A non-destructive method for the measurement of residual strains in semi-crystalline polymer components. Mater Lett 65:530–533

Treuting RG, Read J WT (1951) A mechanical determination of biaxial residual stress in sheet materials. J Appl Phys 22:130–134

White JR (1984) Origins and measurements of internal stress in plastics. Polym Test 4:165–191

Coxon LD, White JR (1980) Residual stresses and aging in injection molded polypropylene. Polym Eng Sci 20:230–236

White JR (1985) On the layer removal analysis of residual stress. J Mater Sci 20:2377–2387. doi:10.1007/BF00556067

Paterson MWA, White JR (1989) Layer removal analysis of residual stress. J Mater Sci 24:3521–3528. doi:10.1007/BF02385734

Haworth B, Hindle C, Sandilands G, White J (1982) Assessment of internal stresses in injection-molded thermoplastics. Plast Rub Proc Appl 2:59–71

Akay M, Ozden S (1994) Measurement of residual stresses in injection moulded thermoplastics. Polym Test 13:323–354

Pham HT, Bosnyak CP, Sehanobish K (1993) Residual stresses in injection molded polycarbonate rectangular bars. Polym Eng Sci 33:1634–1643

Jansen KMB, Orij JJW, Meijer CZ, Dijk DJV (1999) Comparison of residual stress predictions and measurements using excimer laser layer removal. Polym Eng Sci 39:2030–2041

Mathar J (1934) Determination of initial stresses by measuring the deformation around drilled holes. Trans ASME 56:249–254

ASTM E837-08 (2009) Standard test method for determining residual stresses by the hole-drilling strain-gage method, p 17

Turnbull A, Maxwell AS, Pillai S (1999) Residual stress in polymers—evaluation of measurement techniques. J Mater Sci 34:451–459. doi:10.1023/A:1004574024319

Sicot O, Gong XL, Cherouat A, Lu J (2004) Influence of experimental parameters on determination of residual stress using the incremental hole-drilling method. Compos Sci Technol 64:171–180

Kim C, Kim S, Oh H, Youn J (2007) Measurement of residual stresses in injection molded polymeric part by applying layer-removal and incremental hole-drilling methods. Fibers Polym 8:443–446

Kim CH, Youn JR (2007) Determination of residual stresses in injection-moulded flat plate: simulation and experiments. Polym Test 26:862–868

Kim SY, Kim CH, Kim SH, Oh HJ, Youn JR (2009) Measurement of residual stresses in film insert molded parts with complex geometry. Polym Test 28:500–507

Maxwell AS, Turnbull A (2003) Measurement of residual stress in engineering plastics using the hole-drilling technique. Polym Test 22:231–233

Chen J, Peng Y, Zhao S (2009) Comparison between grating rosette and strain gage rosette in hole-drilling combined systems. Opt Laser Eng 47:935–940

Chen J, Peng Y, Zhao S (2009) Hole-drilling method using grating rosette and Moiré interferometry. Acta Mech Sin 25:389–394

Shankar K, Xie H, Wei R, Asundi A, Boay CG (2004) A study on residual stresses in polymer composites using moiré interferometry. Adv Compos Mater 13:237–253

Cornélis H, Kander RG, Martin JP (1996) Solvent-induced crystallization of amorphous poly(ether ether ketone) by acetone. Polymer 37:4573–4578

Clay SB, Kander RG (2001) A new method to quantify crazing in various environments. Polym Eng Sci 41:401–407

Cornélis H, Kander RG (1996) A new method to evaluate solvent stress cracking. Polym Eng Sci 36:869–878

ASTM D1939-94 (1994) Practice for determining residual stresses in extruded or molded acrylonitrile-butadiene-styrene (ABS) parts by immersion in glacial acetic acid (withdrawn 1999)

Wales JLS, Van Leeuwen IJ, Van Der Vijgh R (1972) Some aspects of orientation in injection molded objects. Polym Eng Sci 12:358–363

Isayev AI (1983) Orientation development in the injection molding of amorphous polymers. Polym Eng Sci 23:271–284

Fernandez-Ballester L, Gough T, Meneau F et al (2008) Simultaneous birefringence, small- and wide-angle X-ray scattering to detect precursors and characterize morphology development during flow-induced crystallization of polymers. J Synchroton Radiat 15:185–190

Saffell JR, Windle AH (1980) The influence of thermal history on internal stress distributions in sheets of PMMA and polycarbonate. J Appl Polym Sci 25:1117–1129

Wiesauer K, Dufau ADS, Götzinger E, Pircher M, Hitzenberger CK, Stifter D (2005) Non-destructive quantification of internal stress in polymer materials by polarisation sensitive optical coherence tomography. Acta Mater 53:2785–2791

Stifter D, Burgholzer P, Höglinger O, Götzinger E, Hitzenberger CK (2003) Polarisation-sensitive optical coherence tomography for material characterisation and strain-field mapping. Appl Phys A 76:947–951

Hauk V, Troost A, Ley D (1987) Evaluation of (residual) stresses in semicrystalline polymers by X-rays. Adv Polym Technol 7:389–396

Barrett CS, Predecki P (1976) Stress measurement in polymeric materials by X-ray diffraction. Polym Eng Sci 16:602–608

Barrett CS, Predecki P (1980) In: Rhodes J, Barret C, Leyden D, Newkirk J, Predecki P, Ruud C (eds) Advances in X-ray analysis. Springer, New York

Sanchez LA, Hornberger LE (2002) Monitoring of residual stresses in injection-molded plastics with holographic interferometry. Opt Laser Eng 37:27–37

Colpo F, Humbert L, Giaccari P, Botsis J (2006) Characterization of residual strains in an epoxy block using an embedded FBG sensor and the OLCR technique. Composites A 37:652–661

Parlevliet PP, Bersee HEN, Beukers A (2007) Residual stresses in thermoplastic composites—a study of the literature—Part II: Experimental techniques. Composites A 38:651–665

Pak SY, Kim SY, Kim SH, Youn JR (2013) Measurement of residual stresses in polymeric parts by indentation method. Polym Test 32:946–952

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guevara-Morales, A., Figueroa-López, U. Residual stresses in injection molded products. J Mater Sci 49, 4399–4415 (2014). https://doi.org/10.1007/s10853-014-8170-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8170-y