Abstract

Thiols can diffuse and form self-assembled monolayers (SAMs) on the gold surfaces covered with polydimethylsiloxane (PDMS) stamps. For the first time, with cells as the indicator of how far alkanethiols had diffused to form SAM, we studied the growth dynamics of SAMs of HS(CH2)11(OCH2CH2)3OH (EG3) and HS(CH2)11(OCH2CH2)6OH (EG6) on the gold surfaces covered with PDMS stamps. The growth of SAMs is well described by one-dimensional diffusion from a line source of concentration, with surface diffusion coefficient of 193.4 ± 19.2 μm2/min (EG3) and 95.8 ± 18.9 μm2/min (EG6).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Self-assembled monolayers (SAMs) refer to the formation of monolayers by self-assembly of surfactant molecules at surfaces [1]. In recent years, SAMs found wide applications in chemistry, physics, and especial biology [2–5] when SAMs combined with microfluidic technology [6–10]; for example, we applied alkanethiolate SAMs on gold surface to study the relationship between the shape of mammalian cells and their migration direction [11]. Recently, when we applied alkanethiolate SAMs combined with microfluidic technology to establish interaction models for multiple types of cells [12], we found that the SAMs diffused on the surfaces of evaporation-coated gold slides which were covered with polydimethylsiloxan (PDMS) stamps [13]. It is necessary to understand the properties of SAMs diffusion in order to precisely fabricate SAMs when applying them in cellular biology and material science [14]. Many groups studied the diffusion dynamics of thiol SAMs on the interface between solid gold and gas in dip-pen nanolithography using atomic force microscopy (AFM) and learned their several properties [15–17]. But, these results are hard to directly apply to the above situation because the interface of SAM diffusion changes from that between solid–gas phases to that gold surfaces covered with PDMS stamps, which gaps in nanoscale should exist between gold surfaces and stamp surfaces considering the nanostructures in the evaporation-coated gold slide, and thiols are able to diffuse in PDMS stamps [18, 19]. Moreover, in general, biological labs are seldom equipped AFM. Therefore, it is still a large challenge for investigation of SAM diffusion in biological labs nowadays. Herein, with mammalian cells as the indicator of how far thiol SAMs diffusing, we report a strategy to study the growth dynamics of SAMs of thiols on the gold surfaces covered with PDMS stamps. Using the property of well-ordered SAMs of polyethylene terminal group of thiols on gold that can effectively resist the adhesion of mammalian cells [20, 21], and uncoated gold surfaces allow mammalian cells to adhere, we designed a simple microfluidic system including a PDMS stamp embedded a microchannel in contact with a gold covered slide to determine the distances of the diffusion of SAMs along with diffusion time.

Materials and methods

Materials

HS(CH2)11(OCH2CH2)3OH (EG3) and HS(CH2)11(OCH2CH2)6OH (EG6) were from Prochimia. Medium DMEM and fetal bovine serum (FBS) were from Gibco, and penicillin/streptomycin was from Hyclone. Cell culture dishes were from Corning.

Cell culture

3T6 fibroblasts were provided by the Institute of Biophysics, Chinese Academy of Science. The 3T6 cells were in medium DMEM with 10 % v/v FBS and penicillin/streptomycin (100 U/mL). The cultures were maintained on 60 mm cell culture dishes under 5 % CO2, at 37 °C.

Preparation of gold slides

Preparation of gold slides was accomplished using established methods [21]. Gold slides were prepared by firstly evaporating a layer of 5-nm-thick titanium, followed by a 20 nm of gold, both with a vacuum electron-beam evaporator (Edward Auto 500), on acid-rinsed glass cover slides.

Preparation of PDMS stamps

Fabrication of the master for microchannels was accomplished using established methods [6]. Patterns used in these experiments were designed by L-edit software and exported as a PS file. We printed the PS file onto a transparency mask on a high resolution printer (up to 3600 dpi). Photoresist film with a height of ~ 60 μm was cast by spin-coating SU 8-2050 (MicroChem, USA) onto silicon wafer at 2000 rpm for 30 s. The photoresist film on the wafer was baked at 65 °C for 3 min and at 95 °C for 9 min and exposed under a UV light source with the transparency mask directly on it. The wafer was post baked at 65 °C for 1 min and at 95 °C for 7 min. The exposed photoresist film was developed using MicroChem’s SU-8 Developer for 7 min. The microfeatures for these patterns were visible by the naked eye at this stage. The wafer was silanized with 1H, 1H, 2H, and 2H-perfluorodecyltriethoxysilane (Alfa Aesar, UK) overnight. To generate microfluidic channels, we replica-molded polydimethylsiloxane (PDMS) (Dow Corning, USA) from the masters. The microchannels used here had the following dimensions: width, 200 μm; depth, 60 μm; length, 1.5 cm. Holes at the inlets and outlets of the microfluidic channels (~ 800 μm in diameter) were generated by a sharpened needle tip.

Microscopy and imaging

We acquired images on a Leica inverted microscope (DMI 6000) equipped with a digital monochrome camera (Leica DFC 350 FX) and the software provided by Leica (LAS AF). Phase contrast micrographs were obtained with a 10× objective (N PLAN).

Results and discussion

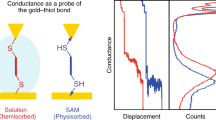

We investigated how thiols with polyethylene terminal group migrated under the PDMS to form inert SAMs on the gold surfaces. We selected HS(CH2)11(OCH2CH2)3OH (EG3) and HS(CH2)11(OCH2CH2)6OH (EG6) as examples to illustrate our strategy. In general, thiol SAMs growth on gold substrate from solution includes three steps: the first step of the chemisorption of the headgroup (SH), the fastest step; the second step of the straightening of the hydrocarbon chains to form lying-down phase, the slower step; the third and final step of the reorientation of the terminal groups to form functional standing-up phase, the slowest step [22]. SAMs of standing-up phase with the terminal groups (OH) exposure can be detected with cells as the indicator in our experiments. Only well-ordered SAMs with the polyethylene moiety of the EG3 or EG6 exposed can effectively resist cell adhesion. We identified the area without cell adhesion covered with thiol SAMs as inert area and the area with cell adhesion covered with gold as active area. To measure the inert areas on surface, we introduced an aqueous solution of EG3 or EG6 into a channel with a width of 200 μm and allowed it to incubate at room temperature for 3, 5, 7, 9, 20, 30, and 40 min and then rinsed the channel with vast PBS solution at once to get rid of residual solution of EG3 or EG6 in order to avoid residual thiol further diffusing (Fig. 1a, b). We peeled off the PDMS stamp and cultured 3T6 cells on the surface (Fig. 1c). After culturing for 3 h, a length of time that allowed the complete adhesion and spread of 3T6 cells, we measured the width of the areas which prevented cell adhesion. When EG3 or EG6 solution incubation lasted for only 3 min, we noticed that there was a stripped area without cell adhesion (inert areas formed). The longer time EG3 or EG6 solution incubated, the wider the inert areas became (Fig. 2). The measured width of the areas that resist cell adhesion was greater than that of the channel with which we introduced EG3 or EG6, for example, the width of well-ordered SAMs with EG3 or EG6 in ethanol in 200-μm-wide microchannels within 9 min was more than 300 μm. These results indicated that EG3 or EG6 migrated under the PDMS to form inert SAMs on the gold surface.

Strategy for determination of distance of EG3 or EG6 diffusion on the surfaces of a gold slide covered with a stamp of polydimethylsiloxane (PDMS). a A PDMS stamp with an embedded microfluidic channel came into contact with a gold-coated glass substrate (the thickness of the gold is only 20 nm to allow optical transparency) to form an enclosed system of the microchannel. EG3 or EG6 solution was introduced into the channel and incubated for certain minutes under room temperature to allow EG3 or EG6 to diffuse and forms SAMs (gray area in b and c). b After washing, the channel with PBS to get rid of residual solution of EG3 or EG6 in order to avoid residual thiol further diffusing, we peeled off the PDMS stamp and plated cell suspensions on the substrate (enlarged the part previously covered with microfluidic channel). c After incubation for 3–6 h, cells adhered on the substrate everywhere except for SAM areas (gray area). The areas between two neighboring dash lines were that of the previous microchannels

Determination of the extent to which EG3 or EG6 has migrated on the gold surfaces covered with PDMS stamps. The formation of SAMs by EG3 or EG6 can resist the adhesion of cells, which serves as the indicator of the distance EG3 or EG6 has migrated and formed SAMs. The area between two neighboring dashed lines was the channel (width 200 μm) that delivered EG3 or EG6. We note that EG3 or EG6 has migrated out of the area defined by the channel and formed SAMs. The incubation time was 9 min. Areas between neighboring dashed lines and cellular lines were regions where EG3 or EG6 had diffused (“D”)

To calculate the diffusion coefficient of EG6 and EG3 migrated on the gold surfaces under the PDMS, we used diffusion equation in isotropic media as the following to calculate the coefficient of diffusion [23],

where D is the coefficient of diffusion, C is the concentration of EG3 or EG6. In our experiments, measurable diffusion mainly occurred perpendicularly to the direction of the channels that introduce EG3 or EG6. As the channels were long in contrast to the diffusion distance, we can approximate the diffusion of EG3 or EG6 to form well-ordered SAMs as one-dimensional planar diffusion, and its diffusion equation could be simplified as the following:

where x is the distance along the direction of diffusion.

The solution of one-dimensional planar diffusion is

where M is the total amount of EG3 or EG6 in the diffusion process, and it is a constant.

To obtain the diffusion coefficient of EG3 and EG6 (that forms well-ordered SAMs), we utilized the least-square regression method. First, take the logarithm of equation [1] on both sides, and we will get

To form a sufficiently well-ordered SAMs to prevent cell adhesion on the surface of substrates, there is a critical concentration of thiol needed, C 0. Given the total amount M, diffusion coefficient D, and critical concentration C 0 are all constants for a certain system, the second term, \( { \ln }\left( {\frac{{2C(\pi D)^{1/2} }}{M}} \right) \), is also a constant. If we regard \( \frac{{x^{2} }}{4t} \) as the independent variable and \( - \frac{1}{2}{ \ln }(t) \) as the functional variable in equation [2], the diffusion coefficient, D, can be regarded as the inversion of slope in equation [2]. Since the difference between the well-ordered SAMs and EG3 or EG6 will only influence the concentration of EG3 or EG6, C, in equation [2] and will not change the slope in this equation.

Based on a series of diffusion distance versus diffusion time, by utilizing least-square fitting (Fig. 3), we found the diffusion coefficient (D) of EG3 and EG6 to form functional SAMs to be 193.4 ± 19.2 and 95.8 ± 18.9 μm2/min, respectively. The results have revealed that the speed of EG6 (longer chain thiols compared to EG3) diffusion to form SAMs on gold surfaces under PDMS is slower than that of EG3. These results are different from that of thiols to form SAMs on the interface between gold and gas, in which longer chain length thiols covered the gold surface more rapidly than shorter chain length thiols [24]. In previous studies of SAMs on gold surfaces, the longer chain length thiols formed the thicker SAM films [25, 26]. We speculated that the limited space between the gold surface and the PDMS stamp favors short chain length thiols diffusion to form SAMs.

The measured distance D in Fig. 2 (a measure of how much EG3 and EG6 diffused to form SAMs under the PDMS stamps) as a function of incubation time

Diffusion of thiol molecules on gold surfaces covered with PDMS stamps is a complex process. A PDMS stamp seals on the surface of an evaporation-coated gold slide to form a microfluidic channel. Considering the nanostructure in the evaporation-coated gold slide, gaps in nanoscale between the gold surface and the PDMS stamp should exist. Moreover, thiol molecules are able to diffuse in PDMS stamps. The media of the diffusion of thiol molecules are possible when the gaps between the gold surfaces and the PDMS stamps or PDMS covered on the gold surfaces or both. In this study, we focused on the SAMs formed on gold surfaces by the diffusion of thiol molecules and found that using one-dimensional diffusion from a line source of concentration thiols, the experimental and theoretical results were well fitted.

The diffusion distance x can also be expressed as an empirical function of diffusion time t according to equation [2]:

In which the unit of x is μm, and the unit of t is minute. We applied this coefficient into the equation and obtained a series of data on diffusion distance versus diffusion time. The calculated results are consistent with those from experiments (Fig. 3). Using this equation, it is straightforward to estimate that the distance EG3 or EG6 has migrated to form SAMs under the PDMS stamp in any experiment that requires specific distance of separation between different channels of cells or proteins [11, 12]. We believe that this equation will be useful for designing microfluidic channels in experiments for controlling cell adhesion and migration.

Conclusion

In summary, for the first time, using the thiol SAMs property of resisting mammalian cell adhesion and cells as the indicator, we have established a technique to determine thiol diffusion coefficients on gold surfaces covered with PDMS stamps. We have applied the technique to determine the diffusion coefficients of EG3 and EG6 to form SAMs on the surface of a gold slide covered with a PDMS stamp. Microscope imagine data show that shorter chain length EG3 diffuses more rapid than longer chain length EG6, and the diffusion coefficient of EG3 is bigger than EG6. The diffusion equation [3] established in this study is able to calculate the diffusion distance of thiol SAMs and is beneficial to design experimental procedures in the studies using thiol SAMs to modify gold surfaces under PDMS. The manipulation in this system is very simple, and the instruments required are quite common in biological labs, it is hence potentially adaptable to many types of biological labs to studying diffusion on other material surfaces (for example, glass, silver) covered with other polymer materials with more favorable properties than PDMS.

References

Ulman A (1996) Formation and structure of self-assembled monolayers. Chem Rev 96:1533–1554

Salaita K, Wang Y, Mirkin C (2007) Applications of dip-pen nanolithography. Nat Nanotechnol 2:145–155

Huck W (2007) Self-assembly meets nanofabrication: recent developments in microcontact printing and dip-pen nanolithography. Angew Chem Int Ed 46:2754–2757

Love J, Estroff L, Kriebel J, Nuzzo R, Whitesides G (2005) Self-assembled monolayers of thiolates on metals as a form of nanotechnology. Chem Rev 105:1103–1169

Leska B, Pankiewicz R, Gierczyk B, Schroeder G, Brzezinski B (2008) Structure and electrochemical reactivity of new sulphur–silicon podands adsorbed on silver or gold surfaces. J Mater Sci 43:3459–3465

Chen Z, Chen W, Yuan B, Xiao L, Liu D, Jin Y, Quan B, Wang J, Ibrahim K, Wang Z, Zhang W, Jiang X (2010) In vitro model on glass surface for complex interactions between different types of cells. Langmuir 26:17790–17794

Wang Y, Chen Z, Xiao L, Du Z, Han X, Yu X, Lu Y (2012) Evaluating cell migration in vitro by the method based on cell patterning within microfluidic channels. Electrophoresis 33:773–779

Hashimoto M, Kaji H, Kemppinent M, Nishizawa M (2008) Localized immobilization of proteins onto microstructures within a preassembled microfluidic device. Sens Actuator B Chem 128:545–551

Chen P, Gu J, Brandin E, Kim Y, Wang Q, Branton D (2004) Probing single DNA molecule transport using fabricated nanopores. Nano Lett 4:2293–2298

Huang CP, Lu J, Seon H, Lee AP, Flanagan LA, Kim HY, Putnam AJ, Jeon NL (2009) Engineering microscale cellular niches for three-dimensional multicellular co-cultures. Lab Chip 9:1740–1748

Jiang X, Bruzewicz D, Wong A, Piel M, Whitesides G (2005) Directing cell migration with asymmetric micro-patterns. Proc Natl Acad Sci USA 102:975–978

Li Y, Yuan B, Ji H, Han D, Chen SQ, Tian F, Jiang X (2007) A method for patterning multiple types of cells by using electrochemical desorption of self-assembled monolayers within microfluidic channels. Angew Chem Int Ed 46:1094–1096

Chen Z, Li Y, Liu W, Zhang D, Zhao Y, Yuan B, Jiang X (2009) Patterning multiple types of mammalian cells for modeling three types of naturally occurring cell–cell interactions. Angew Chem Int Ed 48:8303–8305

Prats-Alfonso E, Albericio F (2011) Functionalization of gold surfaces: recent developments and applications. J Mater Sci 46:7643–7648

Weeks B, Noy A, Miller A, Yoreo J (2002) Effect of dissolution kinetics on feature size in dip-pen nanolithography. Phys Rev Lett 88:255505

Schwartz P (2002) Molecular transport from an atomic force microscope tip: a comparative study of dip-pen nanolithography. Langmuir 18:4041–4046

Sheehan P, Whitman L (2002) Thiol diffusion and the role of humidity in “dip pen nanolithography”. Phys Rev Lett 88:156104

Kraus T, Stutz R, Balmer TE, Schmid H, Malaquin L, Spencer ND, Wolf H (2005) Printing chemical gradients. Langmuir 21:7796–7804

Balmer TE, Schmid H, Stutz R, Delamarche E, Michel B, Spencer ND, Wolf H (2005) Diffusion of alkanethiols in PDMS and its implications on microcontact printing (μCP). Langmuir 21:622–632

Xie Y, Zhang W, Wang L, Sun K, Sun Y, Jiang X (2011) A microchip-based model wound with multiple types of cells. Lab Chip 11:2819–2822

Sun Y, Huang Z, Liu W, Yang K, Sun K, Xing S, Wang D, Zhang W, Jiang X (2012) Surface coating as a key parameter in engineering neuronal network structures in vitro. Biointerphases 7:29

Schwartz D (2001) Mechanisms and kinetics of self-assembled monolayer formation. Annu Rev Phys Chem 52:107–137

Crank J (1975) The mathematics of diffusion. Oxford University Press, London

Xu S, Cruchon-Duperyrat S, Garno J, Liu G, Jennings G, Yong T, Laibinis P (1998) In situ studies of thiol self-assembly on gold from solution using atomic force microscopy. J Chem Phys 108:5002–5012

Valiokas R, Svedhem S, Svensson S, Liedberg B (1999) Self-assembled monolayers of oligo(ethyleneglycol)-terminated and amide group containing alkanethiolates on gold. Langmuir 15:3390–3394

Vanderah D, Pham C, Springer S, Silin V, Meuse C (2000) Characterization of a series of self-assembled monolayers of alkylated 1-thiaoligo(ethylene oxides) 4–8 on gold. Langmuir 16:6527–6532

Acknowledgments

We thank Prof. Wei Liang (Institute of Biophysics of the Chinese Academy of Science) for generously providing cells. The study was supported by National Natural Science Foundation of China (U1333132), the Ministry of Science and Technology (2012AA030308 and 2011CB933201), Beijing Natural Science Foundation (2122060), and Civil Aviation General Hospital of CAAC (2012007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Wang, X., Liu, Y., Chen, Z. et al. Diffusion of self-assembled monolayers of thiols on the gold surfaces covered with polydimethylsiloxane stamps. J Mater Sci 49, 4394–4398 (2014). https://doi.org/10.1007/s10853-014-8148-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8148-9