Abstract

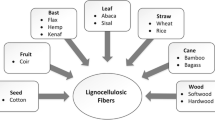

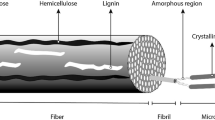

Cellulose nanocrystals (CNCs) have been derived by sulfuric acid hydrolysis (64–65 wt% H2SO4, 10 mL/g cellulose, 45 °C) of pure cellulose isolated from cotton, rice straw and grape skin, producing relatively consistent products in 60, 45 and 30 min, respectively, and generally reflecting the extent of crystallinity and crystallite sizes of these cellulose sources. CNCs in nanorod forms are observed from all three cellulose sources and, in the case of cotton and grape skin, in the presence of more dominant forms of nanoparticles. Cotton CNCs are <10-nm-wide nanorods at up to 40 aspect ratios, whereas rice straw CNCs are flat ribbon cross-sectional shaped in 10:2:1–44:5:1 length/width/thickness ratios, and those from grape skin are abundant nanoparticles but fewer nanorods, all of very different nanoscale dimensions. Freezing (−196 °C) and freeze-drying (−50 °C) of dilute CNC suspensions induce self-assembling of these CNC populations into yet further distinctly different morphologies. Self-assembled cotton CNCs are loosely organized nanorods and nanospheres, whereas grape skin CNCs are mainly nanospheres of 5-nm-sized nanoparticles clusters around nanorod cores. Uniquely, rice straw CNCs assembled anisotropically into ultra-thin non-porous fibers. These source-linked unique CNC geometries and the ability of CNCs to self-assemble into different morphologies present wide ranging dimensions of these renewable cellulose nanomaterial building blocks from by-products of the world largest fiber, cereal and fruit crops.

Similar content being viewed by others

References

Saxena IM, Brown RM Jr (2005) Ann Bot 96(1):9. doi:10.1093/aob/mci155

Hanley SJ, Giasson J, Revol JF, Gray DG (1992) Polymer 33(21):4639. doi:10.1016/0032-3861(92)90426-W

Terech P, Chazeau L, Cavaille JY (1999) Macromolecules 32(6):1872. doi:10.1021/ma9810621

Grunert M, Winter WT (2002) J Polym Environ 10(1/2):27. doi:10.1023/A:1021065905986

Beck-Candanedo S, Roman M, Gray DG (2005) Biomacromolecules 6(2):1048. doi:10.1021/bm049300p

Lu P, Hsieh Y-L (2010) Carbohydr Polym 82(1):329. doi:10.1016/j.carbpol.2010.04.073

Samir MASA, Alloin F, Dufresne A (2005) Biomacromolecules 6(2):612. doi:10.1021/bm0493685

Helbert W, Cavaille JY, Dufresne A (1996) Polym Compost 17(4):604. doi:10.1002/pc.10650

Sakurada I, Nukushina Y, Ito T (1962) J Polym Sci 57(165):651. doi:10.1002/pol.1962.1205716551

Sturcova A, Davies GR, Eichhorn SJ (2005) Biomacromolecules 6(2):1055. doi:10.1021/bm049291k

Wong EW, Sheehan PE, Lieber CM (1997) Science 277(5334):1971. doi:10.1126/science.277.5334.1971

Yu M-F, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000) Science 287(5453):637. doi:10.1126/science.287.5453.637

Klemm D, Kramer F, Moritz S, Lindström Ankerfors TM, Gray D et al (2011) Angew Chem Int Ed 50:5438. doi:10.1002/anie.201001273

Production Statistics, Food and Agriculture Organization of the United Nations, http://faostat.fao.org

Hsieh Y-L (2006) In: Gordon S, Hsieh Y-L (eds) Cotton science and technology. Woodhead Publishing Ltd, Cambridge

Karimi K, Kheradmandinia S, Taherzadeh MJ (2006) Biomass Bioenergy 30(3):247. doi:10.1016/j.biombioe.2005.11.015

Spigno G, Pizzorno T, De Faveri DM (2008) Bioresour Technol 99(10):4329. doi:10.1016/j.biortech.2007.08.044

Prozil SO, Evtuguin DV, Lopes LPC (2012) Ind Crops Prod 35(1):178. doi:10.1016/j.indcrop.2011.06.035

Lu P, Hsieh Y-L (2012) Carbohydr Polym 87(1):564. doi:10.1016/j.carbpol.2011.08.022

Lu P, Hsieh Y-L (2012) Carbohydr Polym 87(4):2546. doi:10.1016/j.carbpol.2011.11.023

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux JL, Heux L, Dubreuil F, Rochas C (2008) Biomacromolecules 9(1):57. doi:10.1021/bm700769p

Jiang F, Esker AR, Roman M (2010) Langmuir 26(23):17919. doi:10.1021/la1028405

Lahiji RR, Xu X, Reifenberger R, Raman A, Rudie A, Moon RJ (2010) Langmuir 26(6):4480. doi:10.1021/la903111j

Cheng RS, Wang N, Ding E (2008) Langmuir 24(1):5. doi:10.1021/la702923w

Ragauskas AJ, Zhang JG, Elder TJ, Pu YQ (2007) Carbohydr Polym 69(3):607. doi:10.1016/j.carbpol.2007.01.019

Acknowledgements

The author appreciates the fine experimental work by Ping Lu and Feng Jiang and funding from the California Rice Research Board, the National Textile Center and US Department of Agriculture, National Institute of Food and Agriculture.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hsieh, YL. Cellulose nanocrystals and self-assembled nanostructures from cotton, rice straw and grape skin: a source perspective. J Mater Sci 48, 7837–7846 (2013). https://doi.org/10.1007/s10853-013-7512-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7512-5