Abstract

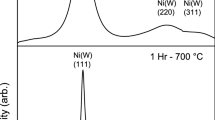

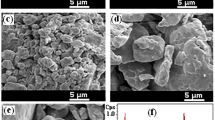

Nanocrystalline Ni and Ni–Fe alloys produced by electrodeposition were characterized using high-resolution transmission electron microscopy (HR-TEM) and X-ray diffraction (XRD). The grain sizes for these materials spanned a range of about 81–10 nm. HR-TEM analysis on a series of images revealed the presence of local strains at both high-angle and low-angle grain boundaries and twin boundaries. In addition to this, stacking faults and twins of the growth type (growth faults) were observed in both the nanocrystalline Ni and Ni–Fe alloys. The growth fault density increased with increasing Fe concentration, which is consistent with a decrease in the stacking fault energy. The microstrain for the samples was determined from XRD pattern analysis based on line broadening. A general increasing microstrain trend with decreasing grain size was observed and considered to be related to the local strains observed at grain boundaries in the HR-TEM image analysis. With respect to grain size, the microstrain values for the nanocrystalline Ni–Fe samples were noticeably higher than some of the Ni samples. Further XRD pattern analysis was performed to determine the growth fault probabilities for each of the samples and analyze their influence on the microstrain. Increasing Fe was accompanied by an increase in growth fault probability, which was consistent with the HR-TEM image analysis. In addition to the effect of grain size, there is likely a contributing effect on microstrain-induced XRD line broadening due to the presence of growth faults.

Similar content being viewed by others

References

Eckert J, Holzer JC, Krill CE, Johnson WL (1992) J Mater Res 7:1751

Weissmuller J, Loffler J, Kleber M (1995) Nanostruct Mater 6:105

Eastman JA, Beno MA, Knapp GS, Thompson LJ (1995) Nantostruct Mater 6:543

Sanders PG, Witney AB, Weertman JR, Valiev RZ, Siegel RW (1995) Mat Sci Eng A 204:7

Sun NX, Zhang K, Zhang XH, Liu XD, Lu K (1996) Nanostructur Mater 7:637

Malow TR, Koch CC (1997) Acta Mater 45:2177

Zhao YH, Sheng HW, Lu K (2001) Acta Mater 49:365

Li H, Ebrahimi F (2003) Mater Sci Eng A 347:93

Mishra R, Basu B, Balasubramaniam R (2004) Mater Sci Eng A 373:370

Derlet PM, Van Petegem S, Van Swygenhoven H (2005) Phys Rev B 71:024114

Qin W, Szpunar JA (2005) Phil Mag Lett 85:649

Biju V, Sugathan N, Vrinda V, Salini SL (2008) J Mater Sci 43:1175. doi:10.1007/s10853-007-2300-8

Mehta SC, Smith DA, Erb U (1995) Mat Sci Eng A 204:227

Palumbo G, Thorpe SJ, Aust KT (1990) Scripta Metall Mater 24:1347

Wunderlich W, Ishida Y, Maurer R (1990) Scripta Metall Mater 24:403

Ping DH, Li DX, Ye HQ (1995) J Mater Sci Lett 14:1536

Li DX, Ping DH, Huang JY, Yu YD, Ye HQ (2000) Micron 31:581

Valiev RZ, Islamagaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Ungar T (2007) J Mater Sci 42:1584. doi:10.1007/s10853-006-0696-1

Stukowski A, Markmann J, Weissmuller J, Albe K (2009) Acta Mater 57:1648

Qin W, Nagase T, Umakoshi Y, Szpunar JA (2008) Phil Mag Lett 88:169

Wagner CNJ (1957) Acta Metall 5:427

Paterson MS (1952) J Appl Phys 23:805

Hinton RW, Schwartz LH, Cohen JB (1963) J Electrochem Soc 110:103

Hofer EM, Hintermann HE (1965) J Electrochem Soc 112:167–173

Suoninen EJ (1967) J Mater Sci 2:40. doi:10.1007/BF00550051

Nakahara S (1981) J Cryst Growth 55:281

Anderson RL, Gangulee A, Romankiw LT (1973) J Electron Mater 2:161

Giallonardo JD, Erb U, Palumbo G, Aust KT (2011) Phil Mag 91:4594

Brooks I, Palumbo G, Hibbard GD, Wang Z, Erb U (2011) J Mater Sci 46:7713. doi:10.1007/s10853-011-5751-x

Balzar D (1999) In: Snyder RL, Bunge HJ, Fiala J (eds) Defect and microstructure analysis from diffraction International Union of Crystallography, Monographs on Crystallography No. 10. Oxford University Press, New York

Wilson AJC (1962) X-Ray optics. Methuen, London

Cohen JB, Wagner CNJ (1962) J Appl Phys 33:2073

He J, Schoenung JM (2002) Mater Sci Eng A 366:274

Van Petegem S, Dalla Torre F, Segers D, Van Swygenhoven H (2003) Scripta Mater 48:17

Haasz TR, Aust KT, Palumbo G, El-Sherik AM, Erb U (1995) Scripta Metall Mater 32:423

Zhou Y, Van Petegem S, Segers D, Erb U, Aust KT, Palumbo G (2009) Mater Sci Eng A 512:39

Giallonardo JD, Erb U, Palumbo G, Botton GA, Andrei C (2012) Mater Sci Forum 706–709:1607

Wu X, Ma E, Zhu YT (2007) J Mater Sci 42:1427. doi:10.1007/s10853-006-1229-7

Reed-Hill RE, Abbaschian R (1994) Physical metallurgy principles, 3rd edn. PWS Publishing Company, Boston

Ebrahimi F, Li HQ (2003) Rev Adv Mater Sci 5:134

Valiev RZ, Gertsman VYu, Kaibyshev OA (1986) Phys Stat Sol A 97:11

Williams DB, Carter CB (2009) Transmission electron microscopy, 2nd edn. Springer Science, New York

Yang F, Tian W, Feng C, Wang B (2009) Acta Metall Sin (Engl Lett) 22:383

Wu X-L, Zhu YT, Ma E (2006) App Phys Lett 88:121905

Murr LE (1975) Interfacial phenomena in metals and alloys. Addison-Wesley, London

Nie X, Wang R, Ye Y, Zhou Y, Wang D (1995) Solid State Commun 96:729

Charnock W, Nutting J (1967) Met Sci J 1:123

Suryanarayana C, Norton MG (1998) X-ray diffraction—a practical approach. Plenum Press, New York

Carter CB, Holmes SM (1977) Phil Mag 35:1161

Sambongi T (1965) J Phys Soc Jpn 20:1370

Ni HT, Zhang XY (2012) Mater Sci Eng A541:216

Acknowledgements

Financial support from the Natural Sciences and Engineering Research Council of Canada, the Ontario Graduate Scholarship, and the Ontario Research Fund (ORF-RE) is gratefully acknowledged. The authors would also like to thank Mr. E. Gongtao Liu; Dr. S. Petrov of the Department of Chemistry, University of Toronto; and Prof. G.A. Botton and Dr. C. Andrei of the Canadian Center for Electron Microscopy, Brockhouse Institute for Materials Research, McMaster University, for their contributions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giallonardo, J.D., Avramovic-Cingara, G., Palumbo, G. et al. Microstrain and growth fault structures in electrodeposited nanocrystalline Ni and Ni–Fe alloys. J Mater Sci 48, 6689–6699 (2013). https://doi.org/10.1007/s10853-013-7469-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7469-4