Abstract

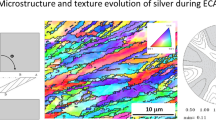

The high-temperature thermal stability of the ultrafine-grained (UFG) microstructures in low stacking fault energy silver was studied by differential scanning calorimetry (DSC). The UFG microstructures were achieved by equal-channel angular pressing (ECAP) and high-pressure torsion (HPT) at room temperature (RT). The defect structure in the as-processed samples was examined by electron microscopy and X-ray line profile analysis. The stored energy calculated from the defect densities was compared to the heat released during DSC. The sum of the energies stored in grain boundaries and dislocations in the ECAP-processed samples agreed with the heat released experimentally within the experimental error. The temperature of the DSC peak maximum decreased while the released heat increased with increasing numbers of ECAP passes. The released heat for the specimen processed by one revolution of HPT was much smaller than after 4–8 passes of ECAP despite the 2 times larger dislocation density measured by X-ray line profile analysis. This dichotomy was caused by the heterogeneous sandwich-like microstructure of the HPT-processed disk: about 175 μm wide surface layers on both sides of the disk exhibited a UFG microstructure while the internal part was recrystallized, thereby yielding a relatively small released heat.

Similar content being viewed by others

References

Segal VM (1999) Mater Sci Eng A 271:322

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Cao WQ, Godfrey A, Liu W, Liu Q (2003) Mater Sci Eng A360:420

Molodova X, Gottstein G, Winning M, Hellmig RJ (2007) Mater Sci Eng A 460–461:204

Cao WQ, Gu CF, Pereloma EV, Davies CHJ (2008) Mater Sci Eng A 492:74

Zhilyaev AP, Nurislamova GV, Surinach S, Baró MD, Langdon TG (2002) Mater Phys Mech 5:23

Gubicza J, Dobatkin SV, Khosravi E, Kuznetsov AA, Lábár LJ (2011) Mater Sci Eng A 528:1828

Gubicza J, Nam NH, Balogh L, Hellmig RJ, Stolyarov VV, Estrin Y, Ungár T (2004) J Alloys Compd 378:248

Gubicza J, Balogh L, Hellmig RJ, Estrin Y, Ungár T (2005) Mater Sci Eng A 400–401:334

Huang YK, Menovsky AA, de Boer FR (1993) Nanostruct Mater 2:587

Kumpmann A, Günther B, Kunze H-D (1993) Mater Sci Eng A 168:165

Zhilyaev AP, Nurislamova GV, Valiev RZ, Baro MD, Langdon TG (2002) Metall Mater Trans A 33:1865

Cizek J, Prochazka I, Cieslar M, Kuzel R, Kuriplach J, Chmelik F, Stulikova I, Becvar F, Melikhova O (2002) Phys Rev B 65:094106

Zhilyaev AP, Gubicza J, Nurislamova G, Révész Á, Suriñach S, Baró MD, Ungár T (2003) Phys Stat Sol A 198:263

Zhilyaev AP, Kim B-K, Szpunar JA, Baro MD, Langdon TG (2005) Mater Sci Eng A 391:377

Lugo N, Llorca N, Sunol JJ, Cabrera JM (2010) J Mater Sci 45:2264

Hegedűs Z, Gubicza J, Kawasaki M, Chinh NQ, Süvegh K, Fogarassy Z, Langdon TG (2013) J Mater Sci 48:1675

Tjong SC, Chen H (2004) Mater Sci Eng R 45:1

Kuo C-M, Lin C-S (2007) Scr Mater 57:667

Setman D, Schafler E, Korznikova E, Zehetbauer MJ (2008) Mater Sci Eng A 493:116

Setman D, Kerber MB, Schafler E, Zehetbauer MJ (2010) Metall Mater Trans A 41:810

Wang G, Wu SD, Zuo L, Esling C, Wang ZG, Li GY (2003) Mater Sci Eng A 346:83

Estrin Y, Isaev NV, Lubenets SV, Malykhin SV, Pugachov AT, Pustovalov VV, Reshetnyak EN, Fomenko VS, Fomenko LS, Shumilin SE, Janecek M, Hellmig RJ (2006) Acta Mater 54:5581

Matsunaga M, Horita Z (2009) Mater Trans 50:1633

Gubicza J, Chinh NQ, Lábár LJ, Hegedűs Z, Langdon TG (2010) Mater Sci Eng A 527:752

Hegedűs Z, Gubicza J, Kawasaki M, Chinh NQ, Fogarassy Z, Langdon TG (2011) Mater Sci Eng A 528:8694

Furukawa M, Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Mater Sci Eng A 257:328

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scr Mater 35:143

Ribárik G, Gubicza J, Ungár T (2004) Mater Sci Eng A 387–389:343

Balogh L, Ribárik G, Ungár T (2006) J Appl Phys 100:023512

Schafler E, Steiner G, Korznikova E, Kerber M, Zehetbauer MJ (2005) Mater Sci Eng A 410–411:169

Hirth JP, Lothe J (1982) Theory of dislocations. Wiley, New York

Murr LE (1975) Interfacial phenomena in metals and alloys. Addison Wesley, Reading

Gubicza J, Chinh NQ, Lábár LJ, Hegedűs Z, Langdon TG (2009) J Mater Sci 44:1656

Müllner P, Solenthaler C (1997) Mater Sci Eng A 230:107

Zhu YT, Wu XL, Liao XZ, Narayan J, Mathaudhu SN, Kecskés LJ (2009) Appl Phys Lett 95:031909

Liddicoat PV, Liao X-Z, Zhao Y, Zhu Y, Murashkin MY, Lavernia EJ, Valiev RZ, Ringer SP (2010) Nat Commun 1:63

Dalla Torre F, Lapovok R, Sandlin J, Thomson PF, Davies CHJ, Pereloma EV (2004) Acta Mater 52:4819

Gubicza J, Chinh NQ, Lábár LJ, Hegedűs Z, Szommer P, Tichy G, Langdon TG (2008) J Mater Sci 43:5672

Mencik J, Swain MV (1995) J Mater Res 10:1491

Li H, Bradt RC (1993) J Mater Sci 28:917

Nix WD, Gao H (1998) J Mech Phys Solids 46:411

Jeong HJ, Yoon EY, Lee DJ, Kim NJ, Lee S, Kim HS (2012) J Mater Sci 47:7828

Sakai G, Nakamura K, Horita Z, Langdon TG (2005) Mater Sci Eng A 406:268

Figueiredo RB, Aguilar MTP, Cetlin PR, Langdon TG (2011) Metall Mater Trans A 42A:3013

Figueiredo RB, Langdon TG (2011) Mater Sci Eng A 528:4500

Kawasaki M, Figueiredo RB, Langdon TG (2012) J Mater Sci 47:7719

Geist D, Rentenberger C, Karnthaler HP (2011) Acta Mater 59:4578

Figueiredo RB, Aguilar MTP, Cetlin PR, Langdon TG (2012) J Mater Sci 47:7807

Kawasaki M, Figueiredo RB, Langdon TG (2011) Acta Mater 59:308

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Oxford

Wolf D (1984) Acta Metall 32:735

Kawasaki M, Horita Z, Langdon TG (2009) Mater Sci Eng A 524:143

An XH, Wu SD, Zhang ZF, Figueiredo RB, Gao N, Langdon TG (2010) Scr Mater 63:560

Acknowledgements

This study was supported in part by the Hungarian Scientific Research Fund, OTKA, Grant No. K-81360, in part by the National Science Foundation of the United States under Grant No. DMR-1160966 (MK and TGL) and in part by the European Research Council under ERC Grant Agreement No. 267464-SPDMETALS (TGL). The authors thank Ms. Noémi Szász for preparation of the TEM samples as well as Dr. Zoltán Dankházi, Dr. Károly Havancsák and Mr. Gábor Varga for performing SEM/EBSD experiments. The help of Mr. Péter Szommer in nanohardness experiments is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hegedűs, Z., Gubicza, J., Kawasaki, M. et al. Stability of the ultrafine-grained microstructure in silver processed by ECAP and HPT. J Mater Sci 48, 4637–4645 (2013). https://doi.org/10.1007/s10853-012-7124-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7124-5