Abstract

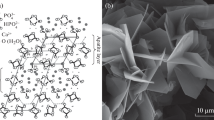

Porous crystalline calcium polyphosphate (CPP) is under investigation as a candidate bone substitute/augmentation material including incorporation in implants intended for repair of osteochondral defects. Previous studies of biphasic implants (i.e., cartilage-CPP constructs) for osteochondral defect repair have shown that porous CPP has the required features for this application including the bone substitute portion of the biphasic implant, but the porous CPP degradation rate is lower than preferred. This study investigated the effect of doping with MgCO3, MgCl2, K2CO3, or KCl at a molar ratio of M/Ca = 0.02 on properties and in vitro degradation behavior of CPP. Doping with magnesium or potassium resulted in changes in the crystallization and melting temperatures, which required adjustment of the sintering conditions for forming samples of the desired porosity level. This, in turn, resulted in higher compressive and diametral compressive (i.e., tensile) strengths of the porous-doped CPP samples compared with undoped CPP prepared to a given porosity level. For samples prepared in this study, the chemical degradation rate of porous Mg-doped CPP samples was the fastest while K doping resulted in a lower degradation rate than undoped CPP.

Similar content being viewed by others

References

Arden N, Nevitt MC (2006) Best Pract Res Clin Rheumatol 20(1):3

Damien CJ (1991) J Appl Biomater 2(3):187

Bohner M (2010) Mater Today 13(1–2):24

Basu D, De DK, Kundu B, Mukherjee P, Nandi SK, Roy S (2010) Indian J Med Res 132(7):15

Bobyn JD, Poggie RA, Krygier JJ, Lewallen DG, Hanssen AD, Lewis RJ et al (2004) J Bone Joint Surg Am 86(2):123

Zhou J, Xia Q, Dong J, Li X, Zhou X, Fang T et al (2011) Acta Neurochir 153(1):115

Singh R, Lee PD, Dashwood RJ, Lindley TC (2010) Mater Technol 25(3–4):127

Ferretti C (2008) Int J Oral Maxillofac Surg 37(3):242

Barber FA, Dockery WD, Hrnack SA (2011) Arthroscopy 27(5):637

Friedmann A, Dard M, Kleber B, Bernimoulin J, Bosshardt DD (2009) Clin Oral Implants Res 20(7):708

Mangano C, Scarano A, Iezzi G, Orsini G (2006) J Oral Implantol 32(3):122

Grynpas MD, Pilliar RM, Kandel RA, Renlund R, Filiaggi M, Dumitriu M (2002) Biomaterials 23(9):2063

Kandel RA, Grynpas M, Pilliar R, Lee J, Wang J, Waldman S et al (2006) Biomaterials 27(22):4120

Pilliar RM, Kandel RA, Grynpas MD, Zalzal P, Hurtig M (2007) Technol Health Care 15(1):47

Pilliar RM, Hong J and Santerre JP, assignees (2009) Method of manufacture of porous inorganic structures. United States Patent 7494614, 24 Feb 2009

Qiu K, Wan CX, Zhao CS, Chen X, Tang CW, Chen YW (2006) J Mater Sci 41(8):2429. doi:10.1007/s10853-006-5182-2

Ding YL, Chen YW, Qin YJ, Shi GQ, Yu XX, Wan CX (2008) J Mater Sci 19(3):1291. doi:10.1007/s10856-007-3235-y

Porter NL, Pilliar RM, Grynpas MD (2001) J Biomed Mater Res 56(4):504

Wang K, Chen F, Liu C, Rüssel C (2008) Mater Sci Eng C 28(8):1572

Omelon S, Baer A, Coyle T, Pilliar RM, Kandel R, Grynpas M (2008) Mater Res Bull 43(1):68

Pilliar RM, Filiaggi MJ, Wells JD, Grynpas MD, Kandel RA (2001) Biomaterials 22(9):963

Chen F, Wang K, Liu C (2008) Appl Surf Sci 255(2):270

Song W, Tian M, Chen F, Tian Y, Wan C, Yu X (2009) J Biomed Mater Res 89(2):430

Song W, Wang Q, Wan C, Shi T, Markel D, Blaiser R et al (2011) J Biomed Mater Res 98B(2):255

Ue J (2009) The effect of sodium doping on calcium polyphosphate. University of Toronto, Canada

Griffith EJ (1995) Phosphate fibers. Plenum Press, New York

Abbarin N (2011) Effect of potassium and magnesium doping on sintering and properties of calcium polyphosphate. University of Toronto, Canada

Omelon SJ (2006) Material properties, and in vitro and in vivo degradation of calcium polyphosphate. University of Toronto, Canada

Ropp RC (1992) Inorganic polymeric glasses. Elsevier, New York

Barsoum MW (2003) Fundamentals of ceramics. Taylor & Francis, Bristol

Callister WD (2005) Fundamentals of materials science and engineering: an integrated approach, 2nd ed. John Wiley & Sons, Hoboken, NJ

Acknowledgements

This study was supported by National Sciences and Engineering Research Council of Canada (NSERC) and Canadian Institutes of Health Research (CIHR). N. A received a scholarship from Canadian arthritis network (CAN).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abbarin, N., Coyle, T.W. & Grynpas, M.D. Effect of potassium and magnesium doping on mechanical properties and in vitro degradation behavior of calcium polyphosphate. J Mater Sci 48, 1604–1613 (2013). https://doi.org/10.1007/s10853-012-6917-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6917-x