Abstract

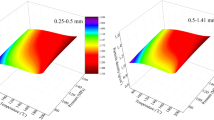

In this study, the influence of processing and storage parameters on the strength of oil palm kernel shell pellets was determined. The strength of the pellets increased with compaction pressure but pelletizing pressures above 188 MPa had little effect on the pellet strength. At these high pressures, the pellets achieved no or near-zero porosities, indicating that the maximum strength was achieved. The diametrical tensile strengths of the pellets were much weaker than the compressive strengths when compacted at the same compaction pressure. The pellet strengths were found to increase with longer hold times during the compaction process. This was due to a continuous decrease in porosities until near-zero porosities were achieved, when increasing the hold time no longer led to further strengthening of the pellets. The time-dependent characteristic of the pellet strength was also reflected in the reduction in strength as compaction speed was increased. The strength of the pellets decreased significantly after 1 day (24 h) of storage, with a higher decrease observed when the pellets were stored under a higher humidity condition. These changes during storage could create difficulties during handling and transportation and may affect gasification performance.

Similar content being viewed by others

Abbreviations

- A :

-

Initial contact area

- D :

-

Diameter of the pellet

- F :

-

Peak crushing force

- L :

-

Length of the pellet after ejection

- L 0 :

-

Length of the pellet at maximum compaction

- ER :

-

Elastic rebound

- k :

-

Bonding constant

- t :

-

Hold time

- t s :

-

Storage time

- σ :

-

Compressive strength

- σ T :

-

Tensile strength

- σ 0 :

-

Compressive strength at zero porosity

- σ i :

-

Compressive strength at zero storage time

- ε :

-

Porosity during compaction

- ρ c :

-

Bulk density of the pellet at maximum compaction

- ρ T :

-

True density of the powder

- α :

-

Fitted constant

- β :

-

Fitted constant

- ε 0 :

-

Fitted constant

- λ :

-

Fitted constant

References

Shuit SH, Tan KT, Lee KT et al (2009) Energy 34:1225

Sumathi S, Chai SP, Mohamed AR (2008) Renew Sustain Energy Rev 12:2404

Aznar MP, Caballero MA, Corella J et al (2006) Energy Fuels 20:1305

Belgiorno V, De Feo G, Rocca CD, Napoli RMA (2003) Waste Manage (Oxford) 23:1

Bridgwater AV (1994) Appl Catal A 116:5

Faaij A, Van Ree R, Waldheim L et al (1997) Biomass Bioenergy 12:387

Gil MV, Oulego P, Casal MD et al (2010) Bioresour Technol 101:8859

McKendry P (2002) Bioresour Technol 83:55

Feng Y, Xiao B, Goerner K et al (2011) Smart Grid Renew Energy 2:158

Moghiman M, Hashemi T, Zahmatkesh I et al (2007) J Energy Inst 80:29

Tumuluru JS, Wright CT, Hess JR et al (2011) Biofuels Bioprod Biorefining 5:683

Mani S, Tabil LG, Sokhansanj S (2006) Biomass Bioenergy 30:648

Kaliyan N, Morey RV (2009) Biomass Bioenergy 33:337

Adolfsson A, Nystrom C et al (1996) Int J Pharm 132:95

Maarschalk KV, Zuurman K, Vromans H et al (1996) Int J Pharm 140:185

Goh SM, Alten S, van Dalen G, Farr RS (2008) J Mater Sci 43:7171. doi:10.1007/s10853-008-3018-y

Larsson SH, Thyrel M, Geladi P et al (2008) Bioresour Technol 99:7176

Husain Z, Zainac Z, Abdullah Z (2002) Biomass Bioenergy 22:505

Razuan R, Finney KN, Chen Q et al (2011) Fuel Process Technol 92:609

Finney KN, Sharifi VN, Swithenbank J (2009) Energy Fuels 23:3203

Greenspan L (1977) Chemistry 81:89

Fell JT, Newton JM (1970) J Pharm Sci 59:688

Sinka IC, Motazedian F, Cocks ACF et al (2009) Powder Technol 189:276

Luangkiattikhun P, Tangsathitkulchai C, Tangsathitkulchai M (2008) Bioresour Technol 99:986

Duckworth WH (1953) J Am Ceram Soc 36:68

Wu CY, Seville JPK (2009) Powder Technol 189:285

Etzler FM, Bramante T, Deanne R et al (2011) J Adhes Sci Technol 25:501

Maarschalk KV, Zuurman K, Vromans H et al (1997) Int J Pharm 151:27

Michrafy A, Michrafy M, Kadiri MS et al (2007) Int J Pharm 333:118

Patel S, Bansal AK (2011) Int J Pharm 403:109

Wu CY, Best SM, Bentham AC et al (2005) Eur J Pharm Sci 25:331

Steendam R, Lerk CF (1998) Int J Pharm 175:33

Nasrin AB, Ma AN, Choo YM et al (2008) Am J Appl Sci 5:179

Anuar MS, Briscoe BJ (2009) Powder Technol 195:96

Akande OF, Rubinstein MH, Rowe PH et al (1997) Int J Pharm 157:127

Baba M, Nagafuji N (1965) Annu Rep Shionogi Rex Lab 15:147

Wagner KG, Krumme M, Beckert TE et al (2000) Eur J Pharm Biopharm 50:285

Armstrong NA (1989) Int J Pharm 49:1

David ST, Augsburger LL (1977) J Pharm Sci 66:155

Rees JE, Rue PJ (1978) J Pharm Pharmacol 30:601

Li Y, Liu H (2000) Biomass Bioenergy 19:177

Sun CC (2008) Int J Pharm 346:93

Shi LM, Feng YS, Sun CC (2011) Int J Pharm 416:43

Hann RA, Black JM, Blomquist RF (1963) For Prod J XIII:169–174

Mollan MJ, Celik M (1995) Int J Pharm 114:23

Casal MD, Gil MV, Pevida C et al (2010) Energy 35:3066

Newton JM, Alderborn G, Nystrom C et al (1993) Int J Pharm 93:249

Dam JEGV, van den Oever MJA, Teunissen W et al (2004) Ind Crops Prod 19:207

Yasin SM, Qureshi TA (1990) Pakistan J For 40:53

Acknowledgements

This work is supported by Curtin Collaborative Research Scheme. The authors would like to thank Sarawak Shell Berhad for the use of their facilities in the Production Chemistry Laboratory and Geological Services Department, Bintulu Lumber Development Sdn. Bhd. for the supply of palm kernel shells; and Professor Alistair Inglis for proofreading this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, Z.Y., Chua, H.B. & Goh, S.M. Influence of process parameters on the strength of oil palm kernel shell pellets. J Mater Sci 48, 1448–1456 (2013). https://doi.org/10.1007/s10853-012-6897-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6897-x