Abstract

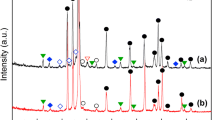

The microstructure, phase composition, and mechanical properties of Mg–9Er–6Y–xZn–0.6Zr (x = 1, 3, 5 wt%; nominal chemical composition) series alloys were investigated through optical microscopy, X-ray diffraction, scanning electron microscopy, energy-dispersive X-ray spectrometry, transmission electron microscopy, and tensile tests. Numerous granular Mg24(Er, Y, Zn)5 phases were distributed in a discontinuous network mainly along the grain boundaries in the alloy with 1 wt% Zn. With increasing Zn content, the Mg24(Er, Y, Zn)5 phases in the alloys gradually disappeared, the amount of block Mg12Zn(Y, Er) phases increased, and the block size became larger. In addition, a few lamellar phases grew parallel with one another from the grain boundaries to the grain interior in the alloys. The crystallographic structures of the Mg12Zn(Y, Er) and Mg24(Er, Y, Zn)5 phases were confirmed as 18R-type long-period stacking ordered structures and body-centered cubic structures, respectively. The Mg12Zn(Y, Er) phases with long-period stacking ordered structures increased the strength and toughness of the alloys more than the Mg24(Er, Y, Zn)5 phases with body-centered cubic structures.

Similar content being viewed by others

References

Boehlert CJ (2007) J Mater Sci 42:3675. doi:10.1007/s10853-006-1352-5

Liu K, Zhang J, Sun W, Qiu X, Huayi L, Dingxiang Tang LL, Rokhlin FM, Elkin JM (2009) J Mater Sci 44:74. doi:10.1007/s10853-008-3122-z

Ning ZL, Wang GJ, Cao FY, Sun JF, Du JF (2009) J Mater Sci 44:4264. doi:10.1007/s10853-009-3620-7

On˜orbe E, Garce′s G, Pe′rez P, Adeva P (2012) J Mater Sci 47:1085. doi:10.1007/s10853-011-5899-4

Singh A, Osawa Y, Somekawa H, Mukai T (2011) Scr Mater 64:661

Ayman E, Junko U, Katsuyoshi K (2011) Acta Mater 59:273

Li RG, Nie JF, Huang GJ, Xin YC, Liu Q (2011) Scr Mater 64:950

Kawamura Y, Hayashi K, Inoue A, Masumoto T (2001) Mater Trans JIM 42:1172

Abe E, Kawamura Y, Hayashi K, Inoue A (2002) Acta Mater 50:3845

Matsuda M, Ii S, Kawamura Y, Ikuhara Y, Nishida M (2005) Mater Sci Eng A 393:269

Kawamura Y, Yamasaki M (2007) Mater Trans 48:2986

Itoi T, Seimiya T, Kawamura Y, Hirohashi M (2004) Scr Mater 51:107

Yoshimoto S, Yamasaki M, Kawamura Y (2006) Mater Trans 47:959

Yamasaki M, Anan T, Yoshimoto S, Kawamura Y (2005) Scr Mater 53:799

Yang Z, Li JP, Guo YC, Liu T, Xia F, Zeng ZW, Liang MX (2007) Mater Sci Eng A 454–455:274

Homma T, Kunito N, Kamado S (2009) Scr Mater 61:644

LI J, Du W, Li S, Wang Z (2009) Rare Met 28:297

LI J, Du W, Li S, Wang Z (2009) Rare Met 28:261

Zhang J, Zhang X, Li W, Pan F, Guo Z (2010) Scr Mater 63:367

Zhang J, Li W, Zhang B, Dou Y (2011) Mater Sci Eng A 528:4740

Gao Y, Wang Q, Jinhai Gu, Zhao Y, Tong Y, Yin D (2009) J Alloys Compd 477:374

Liu K, Zhang J, Guihua S, Dingxiang T, Rokhlin LL, Elkin FM, Meng J (2009) J Alloys Compd 481:811

Saccone A, Delfino S, Maccio D, Ferro R (1992) Metall Mater Trans A 23:1005

Klyamkin SN, Kandalova NV, Verbetskii VN, Semenenko KN (1991) Russ J Inorg Chem 36:122

Okamoto H (2000) Desk handbook: phase diagrams for binary alloys. ASM International, Newbury

Luo ZP, Zhang SQ (2000) J Mater Sci Lett 19:813

Hagihara K, Yokotani N, Umakoshi Y (2010) Intermetallics 18:267

Shao XH, Yang ZQ, Ma XL (2010) Acta Mater 58:4760

Zhang S, Yuan GY, Lu C, Ding WJ (2011) J Alloys Compd 509:3515

Hagihara K, Kinoshita A, Sugino Y, Yamasaki M, Kawamura Y, Yasuda HY, Umakoshi Y (2010) Acta Mater 58:6282

Chino Y, Mabuchi M, Hagiwara S, Iwasaki H, Yamamoto A, Tsubakino H (2004) Scr Mater 51:711

Acknowledgements

The authors are grateful for the financial support from the Program for New Century Excellent Talents in University (Grant No. NCET-11-0554) and the National Key Technology R&D Program (Project No. 2011BAE22B04).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Song, P., Zhou, X. et al. A study of the microstructure, phase composition, and mechanical properties of extruded Mg–9Er–6Y–xZn–0.6Zr magnesium alloys. J Mater Sci 47, 6716–6723 (2012). https://doi.org/10.1007/s10853-012-6614-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6614-9