Abstract

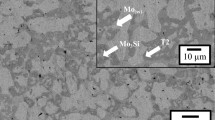

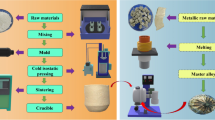

Interactions between Ni-44Ti-5Al-2Nb-Mo (at.%) alloy and oxide ceramics during the directional solidification (DS) process were studied. The experiments were performed using novel Y2O3-coated Al2O3 (Y2O3/Al2O3) crucibles and conventional Al2O3 crucibles with a withdrawal rate of 1 × 10−4 m s−1 at 1550, 1650, and 1750 °C, respectively. The results indicated that the Al2O3 reacted with the NiTi-Al alloy strongly, leading to the formation of the TiO and (Ti,Al)4Ni2O inclusions. The extent of the reaction increased with increasing heating temperature at a constant withdrawal rate. The oxygen increase in directionally solidified ingot using the Al2O3 crucible was up to 1.366 wt% at 1750 °C. With the same DS parameters using the Y2O3/Al2O3 crucible, no chemical reaction occurred between the Y2O3 and the alloy, suggesting that the Y2O3 layer exhibited an effective barrier capability to avoid the reaction between the Al2O3 and NiTi-Al alloy. Although the alloy ingot obtained at 1750 °C contained a small amount of Y2O3 particles, its maximum oxygen increase was only 0.046 wt%.

Similar content being viewed by others

References

Xu HB, Meng LJ, Xu J, Li Y, Zhao XQ (2007) Intermetallics 15:778

Jung J, Ghosh G, Olson GB (2003) Acta Mater 51:6341

Sang YR (2010) Master Thesis, Beihang University

Jiang WH, Sun XF, Guan HR, Hu ZQ (2001) J Mater Sci 36:859. doi:10.1023/A:1004830629974

Bei H, Pharr GM, George EP (2004) J Mater Sci 39:3975. doi:10.1023/B:JMSC.0000031479.32138.84

Zhao XB, Liu L, Yu ZH, Zhang WG, Zhang J, Fu HZ (2010) J Mater Sci 45:6101. doi:10.1007/s10853-010-4696-9

Tang JJ, Xue X (2009) J Mater Sci 44:745. doi:10.1007/s10853-008-3157-1

Tawancy HM, Abbas NM, Al-mana AI, Rhys-jones TN (1994) J Mater Sci 39:2445. doi:10.1007/BF00363439

Johnson DR, Chihara K, Inui H, Yamaguchi M (1998) Acta Mater 46:6529

Kim MC, Oh MH, Lee JH, Inui H, Yamaguchi M, Wee DM (1997) Mater Sci Eng A 239–240:570

Lapin J, Ondru′sˇ L, Nazmy M (2002) Intermetallics 10:1019

Wu MB, Guo XP, Wu XJ (2007) Rare Met Cem Car 35:9

Yang S, Liu WJ, Jia J (2001) J Mater Sci 36:5351. doi:10.1023/A:1012467817033

Gomes F, Puga H, Barbosa J, Ribeiro CS (2011) J Mater Sci 46:4922. doi:10.1007/s10853-011-5405-z

Lapin J, Gabalcova Z, Pelachova T (2011) Intermetallics 19:396

Hecht U, Witusiewicz V, Drevermann A, Zollinger J (2008) Intermetallics 16:969

Froes FH, Suryanarayana C, Eliezer D (1992) J Mater Sci 27:5113. doi:10.1007/BF02403806

Jia Q, Cui YY, Yang R (2006) J Mater Sci 41:3045. doi:10.1007/s10853-006-6785-3

Kuang JP, Harding RA, Campbell J (2001) Int J Cast Metals Res 13:277

Tang XX, Zhang HR, Gao M, Zhang H (2009) Chin Patent 200910079975.7

Zhang HR, Gao M, Tang XX, Zhang H (2010) Acta Metall Sin 46:890

Barin I (1997) Thermochemical data of pure substances, 3rd edn. Wiley-VCH, Germany

Tressler RE, Moore TL, Crane RL (1973) J Mater Sci 8:151. doi:10.1007/BF00550662

Sung SY, Kim YJ (2006) Intermetallics 14:1163

Hiroyuki T, Takeshita HT, Tetsu K, Nobuhiko T, Nobuhiro K (2002) J Alloys Compd 330–332:517

Nevitt MV (1960) Trans Metall Soc 218:327

Frenzel J, George EP, Dlouhy A, Somsen Ch, Wagner MF-X, Eggeler G (2010) Acta Mater 58:3444

Barbosa J, Ribeiro CS, Monteiro AC (2007) Intermetallics 15:945

Cui RJ, Gao M, Zhang H, Gong SK (2010) J Mater Process Technol 9:1190

Gao M, Cui RJ, Ma LM, Zhang HR, Tang XX, Zhang H (2011) J Mater Process Technol 211:2004

Wu Y, Hwang SK (2002) Acta Mater 50:1479

Helferich RL, Zanis CA (1973) Technical Repot, AD-754092, USA

Saari H, Beddoes J, Seo DY, Zhao L (2005) Intermetallics 13:937

Tetsui T, Kobayashi T, Kishimoto A, Harada H (2012) Intermetallics 20:16

Acknowledgements

The authors would like to thank Mr. L.M. Ma of Beihang University for his valuable help and the Journal’s editors and reviewers for their useful comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H.R., Tang, X.X., Zhou, L. et al. Interactions between Ni-44Ti-5Al-2Nb-Mo alloy and oxide ceramics during directional solidification process. J Mater Sci 47, 6451–6458 (2012). https://doi.org/10.1007/s10853-012-6577-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6577-x