Abstract

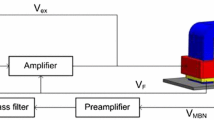

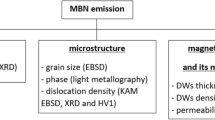

This study examined the Barkhausen noise (BN) response of carburising case-hardened steel with varying tempering stages. The test material was loaded in bending and in alternating loading. The aim of the study was to obtain relevant multiparameter BN data from different loading conditions and to investigate the effect of applied stress on the BN response. The test bar series was made from case-hardened steel. Different tempering parameters were used to vary the surface hardness and the surface residual stresses of the studied series of test bars. In the bending tests, the samples were subjected to incrementally applied loading in the purely elastic deformation region. In addition, uniaxial stepwise loading with tensile and compressive stress was applied to selected samples simultaneously with the BN measurements. The BN measurements were performed under different loading conditions along with X-ray diffraction strain measurements in bending. The results revealed linear behaviour between the reciprocal root mean square value and the stress values obtained with strain gages and X-ray diffraction for the tempered samples.

Similar content being viewed by others

References

Internet: http://www.msm.cam.ac.uk/phasetrans/2004/Tempered.Martensite/ tempered.martensite.html, 14.2.2012

Porter DA, Easterling KE (1992) Phase transformations in metals and alloys, 2nd edn. Nelson Thornes, Cheltenham

Honeycombe R, Bhadeshia HKDH (1995) Steels, microstructures and properties, 2nd edn edn. Edward Arnold, London

Totten GE (ed) (1997) Steel heat treatment: metallurgy and technologies. Deklor, New York

Moorthy V, Vaidyanathan S, Jayakumar T, Raj B (1997) J Magn Magn Mater 171:179

Shaw BA, Evans JT, Blaow M (2005) Proceedings of 5th international conference on Barkhausen noise and micromagnetic testing, Petten, The Netherlands, 2–3 June, 2005, p 133

Ahn ST, Kim DS, Nam WJ (2005) J Mater Process Technol 160:54

Moorthy V, Vaidyanathan S, Jayakumar T, Raj B (1998) Philos Mag A 77(6):1499

Jiles DC (1991) Introduction to magnetism and magnetic materials. Chapman and Hall, New York

Lindgren M, Lepistö T (2001) NDT E Int 34(5):337

Blaow M, Evans JT, Shaw BA (2007) J Mater Sci 42(12):4364. doi:10.1007/s10853-006-0631-5

Hyde TR, Evans JT, Shaw BA (2000) Mater Eval 58(8):985

Anglada-Rivera J, Padovese LR, Capó-Sánchez J (2001) J Magn Magn Mater 231:299

Stewart DM, Stevens KJ, Kaiser AB (2004) Curr Appl Phys 4:308

Cullity BD (1972) Introduction to magnetic materials. Addison-Wesley Publishing Company, Reading

Krause TW, Pattantyus A, Atherton DL (1995) IEEE Trans Magn 31(6):3376

Stefanita CG, Atherton DL, Clapham L (2000) Acta Mater 48(13):3545

Kleber X, Vincent A (2004) NDT E Int 37:439

Stefanita CG, Atherton DL, Clapham L (2000) J Mater Sci 35:2675. doi:10.1023/A:1004741606713

Blaow M, Evans JT, Shaw BA (2005) Acta Mater 53:279

Blaow M, Evans JT, Shaw BA (2004) Mat Sci Eng A 386:74

Moorthy V, Shaw BA, Hopkins P (2006) J Magn Magn Mater 299(2):363

Santa-aho S, Vippola M, Lepistö T, Lindgren M (2009) Insight 51(4):212

Mierczak L, Jiles DC, Fantoni G (2011) IEEE Trans Magn 47(2):459

Santa-aho S, Vippola M, Sorsa A, Latokartano J, Lindgren M, Leiviskä K, Lepistö T (2012) J Mater Process Technol 212(2):408

Sorsa A, Leiviskä K, Santa-aho S, Lepistö T (2012) NDT E Int 46:100

Sorsa A, Leiviskä K, Santa-aho S, Vippola M, Lepistö T (2010) Insight 52(6):293

European Committee for Standardization, SFS-EN 15305:2008 (2008) Non-destructive testing—Test method for residual stress analysis by X-ray diffraction, Brussels

Hauk V (1997) Structural and residual stress analysis by nondestructive methods. Elsevier, Amsterdam

Hoffmann K (1989) An introduction to measurements using strain gages. Hottinger Baldwin Messtechnik GmbH, Darmstadt

Cullity BD (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley Publishing Company Inc, Reading

Garikepati P, Chang TT, Jiles DC (1988) IEEE Trans Magn 24(6):2922

Allison HD, Hendricks RW (1997) Fifth international conference on residual stresses, Linköping, Sweden, 16–17 June 1997, p 640

Acknowledgements

The support of TEKES for the NOVEBARK research project is gratefully acknowledged. The authors would also like to thank the personnel of Stresstech group, Moventas Wind, Takoma Gears and Katsa Oy for their technical support during the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santa-aho, S., Vippola, M., Saarinen, T. et al. Barkhausen noise characterisation during elastic bending and tensile-compression loading of case-hardened and tempered samples. J Mater Sci 47, 6420–6428 (2012). https://doi.org/10.1007/s10853-012-6571-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6571-3