Abstract

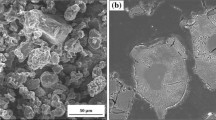

In the present study, we focus on the characterization of the necking mechanisms during the early stages of pressure-less spark plasma sintering (PL-SPS) compared to conventional sintering (CS) of two different types of powdered materials (Cu and α-Al2O3). SEM observations of the evolution of particle morphology and necks from the as-received powders to sintered ones show the nature of the neck between particles which were either in contact or not. For alumina, no particular necking process (melt or viscous bridge) was observed regardless of the sintering conditions (PL-SPS and CS), even for a very high heating rate 455 °C/min. For copper, this neck morphology is unequivocally not typical of conventional ones, thus, suggesting mass transport by an ejection mechanism. This particular morphology was seen occasionally. In comparison, the conventionally sintered Cu particles presented a smoother surface, with conventional curved necks suggesting the contribution of surface diffusion mechanisms. Based on partial pressure calculations, a direct thermal effect might not explain the observed non-conventional neck for copper. On the other hand, local field enhancement effect and local favourable thermal breakdown voltage conditions are described and discussed in order to support the experimental results.

Similar content being viewed by others

References

Zhang ZH, Wang FC, Wang L, Li S-K (2008) Mater Sci Eng A 476:201

Shen Z, Johnsson M, Zhao Z, Nygren M (2002) J Am Ceram Soc 85:1921

Riello P, Bucella S, Zamengo L, Anselmi-Tamburini U, Francini R, Pietrantoni S, Munir ZA (2006) J Eur Ceram Soc 26:3301

Gu YW, Loh NH, Khor KA, Tor SB, Cheang P (2002) Biomaterials 23:37

Omori M (2000) Mater Sci Eng A 287:183

Grasso S, Sakka Y, Maizza G (2009) Sci Technol Adv Mater 10:053001

Mondalek P, Silva L, Durand L, Belleta M (2010) AIP Conf Proc 1252:697

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, Van der Biest O (2005) Acta Mater 53:4379

Groza JR, Zavaliangos A (2000) Mater Sci Eng A 287:171

Carney CM, Mah TI (2008) J Am Ceram Soc 91:3448

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) J Mater Sci 41:763. doi:10.1007/s10853-006-6555-2

Chaim RJ (2006) J Mater Sci 41:7862. doi:10.1007/s10853-006-0605-7

Olevsky E, Froyen L (2009) J Am Ceram Soc 92:S122

Hulbert DM, Anders A, Dudina D, Andersson J, Jiang D, Unuvar C, Anselmi-Tamburini U, Lavernia EJ, Mukherjee AK (2008) J Appl Phys 104:033305

Langer J, Hoffmann MJ, Guillon O (2009) Acta Mater 57:5454

Kun W, Zhengyi F, Weimin W, Yucheng W, Jinyong Z, Qingjie Z (2007) J Mater Sci 42:302. doi:10.1007/s10853-006-1013-8

Zhaohui Z, Fuchi W, Lin W, Shukui L, Osamu S (2008) Mater Lett 62:3987

Song X, Liu X, Zhang J (2006) J Am Ceram Soc 89:494

Demirskyi D, Borodianska H, Agrawal D, Ragulya A, Sakka Y, Vasylkiv O (2012) J Alloys Compd 523:1

Chaim R (2007) Mater Sci Eng A 443:25

Aman Y, Garnier V, Djurado E (2011) J Am Ceram Soc 94:2825

Gephart S, Singh J, Kulkarni A (2011) J Mater Sci 46:3659. doi:10.1007/s10853-011-5283-4

Kang S-JL (2005) Sintering, 1st edn. Elsevier, Oxford

Frei JM, Anselmi-Tamburini U, Munir ZA (2007) J Appl Phys 101:114914

Raouafi F, Barreteau C, Desjonquères MC, Spanjaard D (2002) Surf Sci 505:183

Kumeda K, Nakamura Y, Takata A, Ishizaki K (1999) J Ceram Soc Jpn 107:187

Stanciu L, Quach D, Faconti C, Groza JR, Raether F (2007) J Am Ceram Soc 90:2716

Alcock CB, Itkin VP, Horrigan MK (1984) Can Metall Q 23:309

Geiger F, Busse CA, Loehrke RI (1987) Int J Thermophys 8:425

Brewer L, Searcy AW (1951) J Am Chem Soc 73:5308

Lou VKL, Mitchell TE, Heuer AH (1985) J Am Ceram Soc 68:49

Levi G, Kaplan WD (2002) Acta Mater 50:75

Ho Oh S, Chisholm MF, Kauffmann Y, Kaplan WD, Luo W, Rühle M, Scheu C (2010) Science 330:489

Lekner J (2010) J Electrostatics 68:299

Paschen F (1889) Ann Phys 273:69

Dhariwal RS, Torres JM, Desmulliez MPY (2000) IEE Proc 147:261

Slade PG, Taylor ED (2002) IEEE Trans Compon Packag Technol 25:390

Tirumala R, Go DB (2010) Appl Phys Lett 97:151502

Radmilović-Radjenović M, Radjenović B (2008) Plasma Sources Sci Technol 17:024005

Go DB, Pohlman DA (2010) J Appl Phys 107:103303

Richardson OW (1901) Proc Camb Phil Soc 11:286

Brandes EA, Brook GB (eds) (1992) Smithells metals reference book, 7th edn. Butterworth-Heinemann Ltd., Bodmin

Timko H, Djurabekova F, Nordlund K, Costelle L, Matyash K, Schneider R, Toerklep A, Arnau-Izquierdo G, Descoeudres A, Calatroni S, Taborelli M, Wuensch W (2010) Phys Rev B 81:184109

Cordier A, Kleitz M, Steil MC (2012) J Eur Ceram Soc doi:10.1016/j.jeurceramsoc.2011.12.022

Demirskyi D, Borodianska H, Grasso S, Sakka Y, Vasylkiv O (2011) Scripta Mat 65:683

Holland TB, Thron AM, Bonifacio CS, Mukherjee AK, van Benthem K (2010) Appl Phys Lett 96:243106

Toyofuku N, Kuramoto T, Imai T, Ohyanagi M, Munir ZA (2012) J Mater Sci 47:2201. doi:10.1007/s10853-011-6026-2

Acknowledgements

The authors gratefully acknowledge the support received from ‘Région Rhône Alpes—MACODEV’ for this study (M. Yann Aman thesis), Pr. G. Fantozzi and G. Bonnefont from the SPS consortium at INSA Lyon.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aman, Y., Garnier, V. & Djurado, E. Pressure-less spark plasma sintering effect on non-conventional necking process during the initial stage of sintering of copper and alumina. J Mater Sci 47, 5766–5773 (2012). https://doi.org/10.1007/s10853-012-6469-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6469-0