Abstract

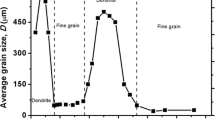

Considering non-equilibrium solidification and its influence on subsequent near-equilibrium solidification together, the description of recalescence behavior in bulk undercooled Cu70Ni30 alloy was adopted to predict the corresponding microstructure transition. The thermal plateau time for near-equilibrium solidification can be deduced directly with the calculation of non-equilibrium solid fraction formed in recalescence. On the basis of quantitative description for recalescence behavior, the non-equilibrium solid fraction, residual liquid fraction, dendrite broken-up time, and thermal plateau time can be determined as functions of initial undercooling. Then, a simple and accurate application of dendrite fragmentation model was performed as the grain refinement at both low- and high-undercooling originates from dendrite breakup. The predicted undercooling regions for the double grain refinement agree well with the experimental observation. Moreover, the change of grain morphology for the second grain refinement can be ascribed to the occurrence of recrystallization produced by the enhanced residual stress upon highly undercooled solidification.

Similar content being viewed by others

References

Christian JW (2002) The theory of transformation in metals and alloys, 3rd edn. Pergamon Press, Oxford

Kurz W, Fisher DJ (1998) Fundamentals of solidification, 4th edn. Trans Tech Publications Ltd, Switzerland

Baker JC, Cahn JW (1971) Solidification, 1st edn. ASM, Metals Park, OH

Walker JL (1959) The physical chemistry of process metallurgy. Wiley Interscience, New York, NY

Liu N, Liu F, Yang GC, Chen YZ, Chen D, Yang CL, Zhou YH (2007) Physica B 387:151

Chen YZ, Yang GC, Liu F, Liu N, Xie H, Zhou YH (2005) J Cryst Growth 282:490

Eckler K, Norman AF, Gätner F (1997) J Cryst Growth 173:528

Han XJ, Yang C, Wei B, Chen M, Guo ZY (2001) Mater Sci Eng A 307:35

Girtneri F, Norman AF, Greer AL, Zambon A, Ramous E, Eckler K, Herlach DM (1997) Acta Mater 45:51

Norman AF, Eckler K, Zambon A, Gärtner F, Moir SA, Ramous E, Herlach DM, Greer AL (1998) Acta Mater 46:3355

Maslov VV, Nosenko VK, Jurisch M (2002) J Mater Sci 37:4663. doi:10.1023/A:1020668904024

Willnecker R, Herlach DM, Feuerbacher B (1990) Appl Phys Lett 56:324

Dragnevski K, Cochrane RF, Mullis AM (2002) Phys Rev Lett 89:215502

Mullis AM, Cochrane RF (1997) J Appl Phys 82:3783

Mullis AM, Cochrane RF (1998) J Appl Phys 84:4905

Powell GLF (1968) Trans Met Soc AIME 242:2133

Li JF, Zhou YH, Yang GC (2000) Mater Sci Eng A 277:161

Karma A (1998) Int J Non-Equilib Process 11:201

Schwarz M, Karma A, Eckler K (1994) Phys Rev Lett 73:1380

Liu F, Yang GC (2006) Int Mater Rev 51:145

Yang W, Liu F, Wang HF, Chen Z, Yang GC, Zhou YH (2009) J Alloys Compd 470:L13

Yang W, Liu F, Liu H, Yang GC, Zhou YH (2009) J Cryst Growth 311:3225

Yang W, Liu F, Wang HF, Chen Z, Yang GC, Zhou YH (2010) J Alloys Compd 491:118

Piccone TJ, Wu Y, Shiohara Y, Flemings MC (1987) Metall Trans A 18:925

Galenko PK, Danilov DA (1999) J Cryst Growth 197:992

Wang TM, Xu JJ, Xiao TQ, Xie HL, Li J, Li TJ, Cao ZQ (2010) Phys Rev E 81:042601

Rosam J, Jimack PK, Mullis AM (2008) Acta Mater 56:4559

Ramirez JC, Beckermann C (2005) Acta Mater 53:1721

Sha W, Wu X, Keong KG (2010) Electroless copper and nickel-phosphorus plating: processing, characterisation and modelling, 1st edn. Woodhead Publishing Limited, Cambridge

Herlach DM, Eckler K, Karma A, Schwarz M (2001) Mater Sci Eng A 304–306:20

Acknowledgements

W. Yang is grateful to the financial support by the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201118) and Scientific Starting Foundation for Doctorate Research in Nanchang Hangkong University (EA201003234). The authors are also grateful to the Free Research Fund of State Key Lab. of Solidification Processing (09-QZ-2008; 24-TZ-2009), the 111 project (B08040), the Natural Science Foundation of China (Grant nos. 50771084; 51071127, 50901059), National Basic Research Program of China (973 Program) 2011CB610403, the HuoYingdong Yong Teacher Fund (111052), the Fundamental Research Fund of Northwestern Polytechnical University (2008JC01), Aeronautical Science Foundation of China (2008ZF56016), the Open Fund of Aeronautical Science and Technology Key Lab. of Aeronautical Materials Processing in Nanchang Hangkong University and the Project of Education Department of Jiangxi (GJJ08199).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, W., Liu, F., Xu, Z.F. et al. Use of recalescence behavior analysis for the prediction of grain refinement in undercooled Cu–Ni alloy. J Mater Sci 46, 3101–3107 (2011). https://doi.org/10.1007/s10853-010-5189-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5189-6