Abstract

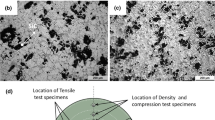

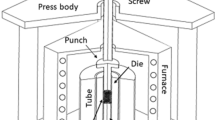

Aluminum matrix composites reinforced with SiC and graphite (Gr) particles are a unique class of advanced engineered materials that have been developed to use in tribological applications. The conventional techniques for producing these composites have some drawbacks. In this study, a new method, namely In situ Powder Metallurgy (IPM), is applied for the preparation of Al6061/SiC/Gr hybrid composites. In this method, the stir casting and the powder metallurgy synthesizing processes are combined into an integrated net shape forming process. 0–40 vol.% of SiC particles with an average size of 19 μm, along with 9 vol.% of uncoated Gr particles, were introduced to the molten 6061 aluminum alloy. Then, the slurries were stirred in a specified time–temperature regime resulting in mixtures of the SiC, Gr, and aluminum powder particles. The powder mixtures were cold pressed in six different pressures (between 250 and 750 MPa) and sintered. Finally, the produced composites were heat treated and their hardness and wear properties were investigated. Homogenous distribution of the SiC and Gr particles within the powder mixtures and the hybrid composites is clear from the SEM images. The results also show that the SiC particles decrease the compressibility of the hybrid powders and improve the hardness of composites. The best wear resistance is achieved in the hybrid composite containing 20 vol.% SiC particles.

Similar content being viewed by others

References

Basavarajappa S, Chandramohan G, Mukund K, Ashwin M, Prabu M (2006) J Mater Eng Perform 15:668

Ted Guo ML, Tsao CYA (2000) Compos Sci Technol 60:65

Roy D, Basu B, Mallick AB (2005) Intermetallics 13:733

Ramesh CS, Anwar-Khan AR, Ravikumar N, Savanprabhu P (2005) Wear 259:602

Lee KB, Kwon H (2002) Metall Mater Trans A 33A:455

O’Donnell G, Looney L (2001) Mater Sci Eng A 303:292

Yang G, Fan T, Zhang D (2004) J Mater Sci 39:3689. doi:10.1023/B:JMSC.0000030722.14054.e2

Ejiofor JU, Okorie BA, Reddy RG (1997) J Mater Eng Perform 6:326

Gui M, Kang SB (2001) Metall Mater Trans A 32A:2383

Suresha S, Sridhara BH (2010) Mater Des 31:4470

Leng J, Jiang L, Zhang Q, Wu G, Sun D, Zhou Q (2008) J Mater Sci 43:6495. doi:10.1007/s10853-008-2974-6

Leng J, Jiang L, Wu G, Tian S, Chen G (2009) Rare Met Mater Eng 38:1894

Ge D, Gu M (2001) Mater Lett 49:334

Urena A, Rams J, Campo M, Sanchez M (2009) Wear 266:1128

Tien YM, Wu PL, Huang WH, Kuo MF, Chu CA (2007) Powder Technol 173:140

Nor SSM, Rahman MM, Tarlochan F, Shahida B, Ariffin AK (2008) J Mater Process Technol 207:118

Jiang G, Daehn GS, Lannutti JJ, Fu Y, Wagoner RH (2001) Acta Mater 49:1471

Huang HS, Lin YC, Hwang KS (2002) Int J Refract Met Hard Mater 20:175

Ted Guo ML, Tsao CYA (2002) Mater Sci Eng A 333:134

Akhlaghi F, Pelaseyyed SA (2004) Mater Sci Eng A 385:258

Leng J, Wu G, Zhou Q, Dou Z, Huang X (2008) Scripta Mater 59:619

Smith LN, Midha PS, Graham AD (1998) J Mater Process Technol 79:94

Hafizpour HR, Sanjari M, Simchi A (2009) Mater Des 30:1518

Mahdavi S, Akhlaghi F (2009) In: Proceedings of the IIAC, Tehran, pp 106–112

Akhlaghi F, Mahdavi S (2009) In: Proceedings of the AMPT, Kuala Lumpur, pp 250–257

Akhlaghi F, Esfandiari H (2007) Mater Sci Technol 23:646

Akhlaghi F, Zare-Bidaki A (2009) Wear 266:37

Shim Y, Levine LE, Fields RJ (2005) Physica A 348:1

Sridhar I, Fleck NA (2000) Acta Mater 48:3341

Martin CL, Lame O, Bouvard D (2000) Mech Mater 32:405

Srivatsan TS, Al-Hajri M, Petraroli M, Hotton B, Lam PC (2002) Mater Sci Eng A 325:202

Hafizpour HR, Simchi A, Parvizi S (2010) Adv Powder Technol 21:273

Al-Qureshi HA, Soares MRF, Hotza D, Alves MC, Klein AN (2008) J Mater Process Technol 199:417

Poquillon D, Lemaitre J, Baco-Carles V, Tailhades Ph, Lacaze J (2002) Powder Technol 126:65

Martin M, Castro F (2003) J Mater Process Technol 143–144:814

Showaiter N, Youseffi M (2008) Mater Des 29:752

Ramesh CS, Noor Ahmed R, Mujeebu MA, Abdullah MZ (2009) Mater Des 30:1957

Unlu BS (2008) Mater Des 29:2002

Zhan Y, Zhang G (2003) J Mater Sci Lett 22:1087

Parvin N, Assadifard R, Safarzadeh P, Sheibani S, Marashi P (2008) Mater Sci Eng A 492:134

Seyed Reihani SM (2006) Mater Des 27:216

Salvo L, Suery M, Towle D, Friend CM (1996) Composites A 27A:1201

Jha AK, Prasad SV, Upadhyaya GS (1989) Tribol Int 22:321

Jha AK, Prasad SV (1989) Wear 133:163

Fuentes R, Rubio E, Gomez C, Herrera A, Castano VM (2003) Int Lubr Tribol 55:157

Liu YB, Lim SC, Ray S, Rohatgi PK (1992) Wear 159:201

Prasad SV, McConnell BD (1991) Wear 149:241

Archard JF (1953) J Appl Phys 24:981

Wang L, He Y, Zhou J, Duszczyk J (2010) Tribol Int 43:299

Teoh SH, Thampuran R, Seah WKH (1998) Wear 214:237

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahdavi, S., Akhlaghi, F. Effect of SiC content on the processing, compaction behavior, and properties of Al6061/SiC/Gr hybrid composites. J Mater Sci 46, 1502–1511 (2011). https://doi.org/10.1007/s10853-010-4954-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4954-x